TOC

TOC

Photography by Shawn Brereton.

ROB MUNOZ

Wes Allison, Tommy Lee Byrd, Ron Ceridono, Grant Cox, Dominic Damato, Tavis Highlander, Jeff Huneycutt, Barry Kluczyk, Scotty Lachenauer, Jason Lubken, Steve Magnante, Ryan Manson, Jason Matthew, Josh Mishler, Evan Perkins, Richard Prince, Todd Ryden, Jason Scudellari, Jeff Smith, Tim Sutton, and Chuck Vranas – Writers and Photographers

AllChevyPerformance.com

ClassicTruckPerformance.com

ModernRodding.com

InTheGarageMedia.com

subscriptions@inthegaragemedia.com

Mark Dewey National Sales Manager

Patrick Walsh Sales Representative

Travis Weeks Sales Representative

ads@inthegaragemedia.com

inthegaragemedia.com “Online Store”

info@inthegaragemedia.com

Copyright (c) 2022 IN THE GARAGE MEDIA.

PRINTED IN U.S.A

FIRING UP

FIRING UP

BY NICK LICATA

BY NICK LICATAhe SEMA Show held at the Las Vegas Convention Center is always a great event, but the 2021 show was a little–no, a lot—more special than in years past. As this magazine company (In The Garage Media) is in its second year in business, we’ve been putting everything we’ve got into our three magazines: All Chevy Performance, Classic Truck Performance, and Modern Rodding. Unlike the previous company we all worked for, which had a fairly large staff to take care of everything from selling advertising to running social media, this little company lacks the luxury of extra human horsepower to do all those things, needless to say everyone here wears multiple hats. So, when In The Garage Media was named the 2021 Hot Rod Industry Alliance (HRIA) Business of the Year during the SEMA Show, we were totally surprised and absolutely honored. It felt good to be recognized for all the hard work our team puts in to produce three quality magazines each and every month.

Now, I typically attend the HRIA banquet for the free beer and quesadillas (this year they kinda looked like tacos) and to catch up with the industry folks I’ve known for years but typically only see once a year. It’s also a great way to meet up-and-coming car builders new to the scene and other young people getting started in the hot rod industry. Looking back, it now makes sense that this year we were seated more up front at the banquet, as us editorial types don’t typically hang out at the “big kids” table.

All kidding aside, this is a great honor that could not have happened without the dedicated staff–especially those who work behind the scenes doing much of the heavy lifting. They are the ones who make All Chevy Performance and our other two magazines look as good as they do and ensure proper grammar and punctuation is used throughout.

Parts Bin

Parts Bin

InTheGarageMedia.com

For more information, contact Lokar by calling (877) 469-7440 or visit lokar.com.

For more information, contact Master Power Brakes by calling (800) 472-4181 or visit mpbrakes.com.

For more information, contact Old Air Products by calling (817) 531-2665 or visit oldairproducts.com.

CHEVY CONCEPTS

CHEVY CONCEPTS

Text and Rendering by Tavis Highlander

Text and Rendering by Tavis Highlander

@TavisHighlander

@TavisHighlander Vehicle Build by: Milestone Paint & Body, Mt. Juliet, Tennessee

ilestone Paint & Body is celebrating 20 years in business and this ’56 Chevy will showcase that immense amount of accumulated skill in one project. Starting with a stout Art Morrison chassis, the ’56 will sport an LT4 backed by an 8L90E transmission. Wilwood brakes will stop the custom-coated Forgeline wheels with plenty of force. Other updates will include a Rick’s stainless fuel tank, Vintage Air, and Dakota Digital gauges. A custom interior by Speed & Design wrap up the build.

The big aesthetic changes on this project are all about stance, paint, and trim colors. Most trim elements on the body will be done up in a satin gold treatment, including the wheel centers and bumpers. A few elements will be gloss black to balance the intensity of the gold. Combine all of that with a gloss black body and the result should be pretty stunning.

FEATURE

FEATURE

Photography by the Author

ood things come to those who wait. This is true for those who try to build a car themselves. Everything seems to get in the way of completing the project, and the next thing you know 20 years have come and gone. It’s why so many people give up on the dream of building a hot rod.

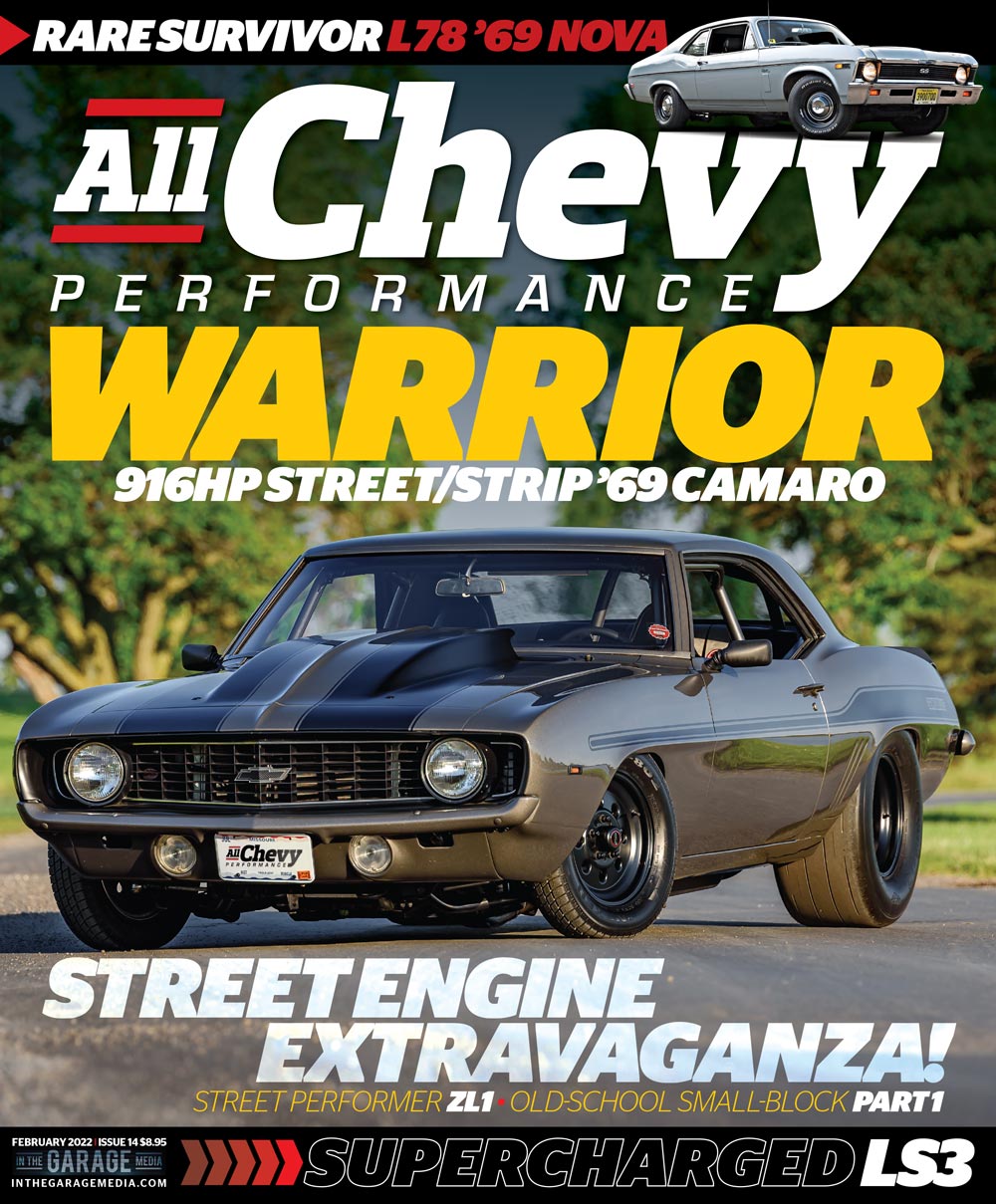

Brian Raymond, of Union, Missouri, is a lifelong car guy who played this game for more than 26 years with this ’69 Camaro. His father fixed and restored vehicles for side money. Though he died when Brian was just a high school freshman, he bequeathed his passion for the automotive hobby to a very willing and capable young lad.

Brian didn’t take the gift for granted and enrolled in auto shop classes. “It’s all I ever wanted to do,” he says. “I learned everything I could, so I could do it all myself instead of paying someone else to do it.” After graduation, he found a job at Wally Elder’s Custom Auto Works, acquiring the Camaro in 1995 for $1,400. But money was tight, so the car sat patiently waiting.

TECH

TECHPhotography by The Author

t’s been said that legends rarely live up to their hype, but the original, all-aluminum ZL1 big-block did just that.

Originally conceived as a lightweight racing engine for the Can-Am road racing series (Group 7), the original, solid-lifter 427ci ZL1 engine was never intended for production vehicles, but Chevrolet’s motorsports engineers never counted on an enterprising and forward-thinking Illinois dealer named Fred Gibb. He used Chevrolet’s COPO (Central Office Production Order) special-order system to produce the legendary Camaro ZL1.

Even though the engine made its mark earlier and continued to be used in racing into the ’70s, it was in those 69 ’69 Camaros—and a pair of Corvettes—that grew the myth of the ZL1. Over the years, Chevrolet stoked the embers, including a reissue of the aluminum cylinder block, which spawned a Ram Jet–topped ZL1 crate engine and an anniversary 427 crate engine.

FEATURE

FEATURE Photography by Wes Allison

Photography by Wes Allison

haun Dove never set out to buy a ’62 Bel Air. In fact, he didn’t even buy the one you see here. It was actually left at his shop by a customer who brought it in to get some finishing touches done after it made some rounds through a few shops a couple years prior. “The customer purchased the car of his dreams, but it needed work. By the time it got to us, the owner had gone through some life changes so the car was just hanging around our shop,” Shaun tells. “It’s been with me for about 10 years now, so the owner gave me the green light to do some upgrades and drive it as if it were mine. I know at some point he’ll come back for the car, but until then she is mine.”

TECH

TECH

Photography by The Author

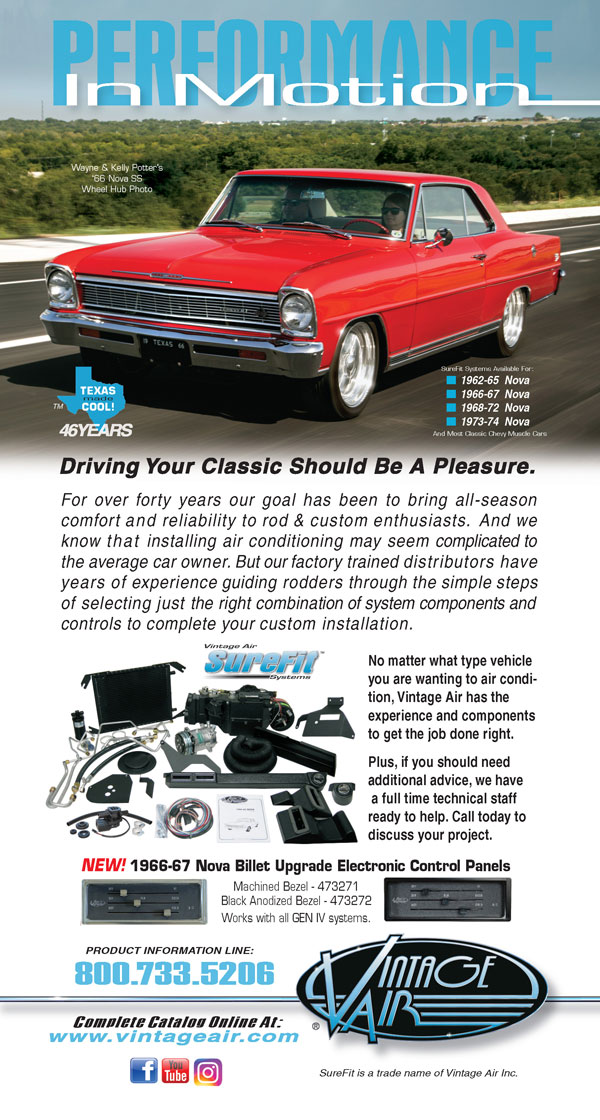

Photography by The Authorast month we introduced you to our ’66 Chevy II project, an all-original six-cylinder car that is being treated to a few modern creature comforts. We’re starting the upgrade process with a Vintage Air SureFit A/C system (PN 961166); you’ll see more of this car in future articles. In last month’s installment, we disassembled the cooling system, installed the condenser (and associated lines), installed the Steel-eez compressor bracket, and began prepwork inside the cockpit for the new A/C system.

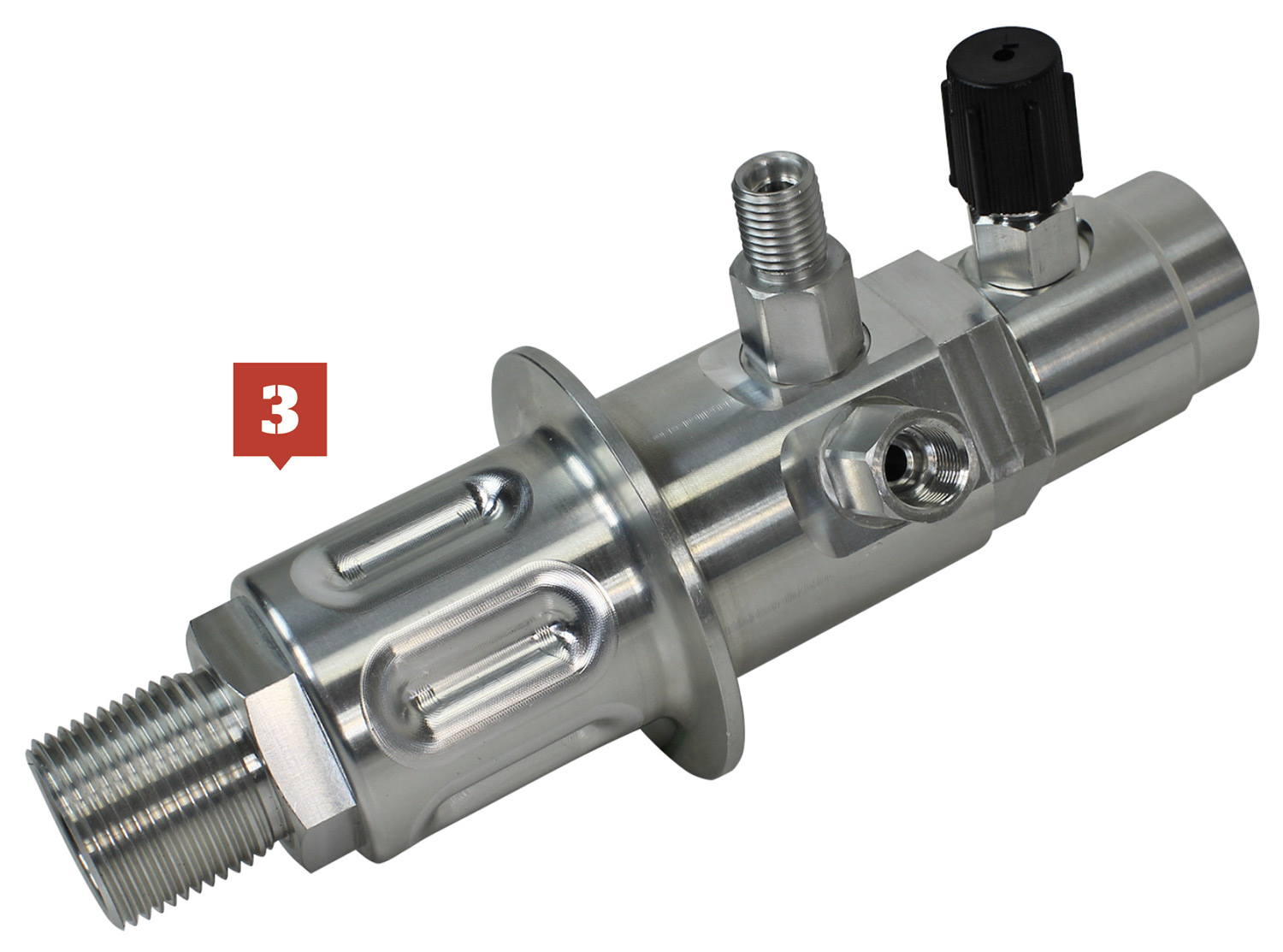

This time, we’re wrapping up the A/C conversion by assembling and installing the Vintage Air evaporator and then completing the system plumbing and wiring. We added Vintage Air’s new Control Panel (PN 473272), which fits in the factory location and makes it completely electronic, instead of having to convert the original sliders to work electronically. The plug-and-play setup simplified the installation greatly, as did the E-Z Clip hose system (PN 547002), which allowed us to build our own refrigerant hoses without the assistance of a hydraulic hose shop.

After we buttoned up the install, we calibrated the new control panel. First, we turned the ignition switch to the “ON” position, then positioned the sliders to “HI,” “DEF,” and “HOT” settings. Then, we connect the white jumper wire to the gray program wire and wait approximately 5 seconds for the blower speed to change. Finally, we slide the controls to “OFF,” “DASH,” and “COLD” and disconnect the jumper wire. The blower speed should change again, indicating completion of the calibration.

FEATURE

FEATURE

Photography by Kevin DiOssi

Photography by Kevin DiOssi

ou ever go to a car show just to look around and appreciate the cars with no intention to buy? We do all the time, same goes for Ed Nash … usually. He and his wife, Terry, go to these events because they like vintage muscle cars and to promote their business, Chassis Crafters in Daytona Beach, Florida. “We were at a local car show when Terry spotted a cool Chevy pickup, and while giving it a look she struck up a conversation with the owner, Jeromie Fehrenbach, from Sterling Customs Hot Rod Shop. She told Fehrenbach that they brought a customer’s ’71 Camaro to display in their booth,” Ed relays. “[Fehrenbach] mentioned he had ’72 Camaro project for sale at his shop in Blue Ridge, Georgia, that a customer had started then backed out.” Coincidentally, Blue Ridge is where Ed and Terry spend a good amount of time vacationing.

TECH

TECH

Photography by The Author

Photography by The Author

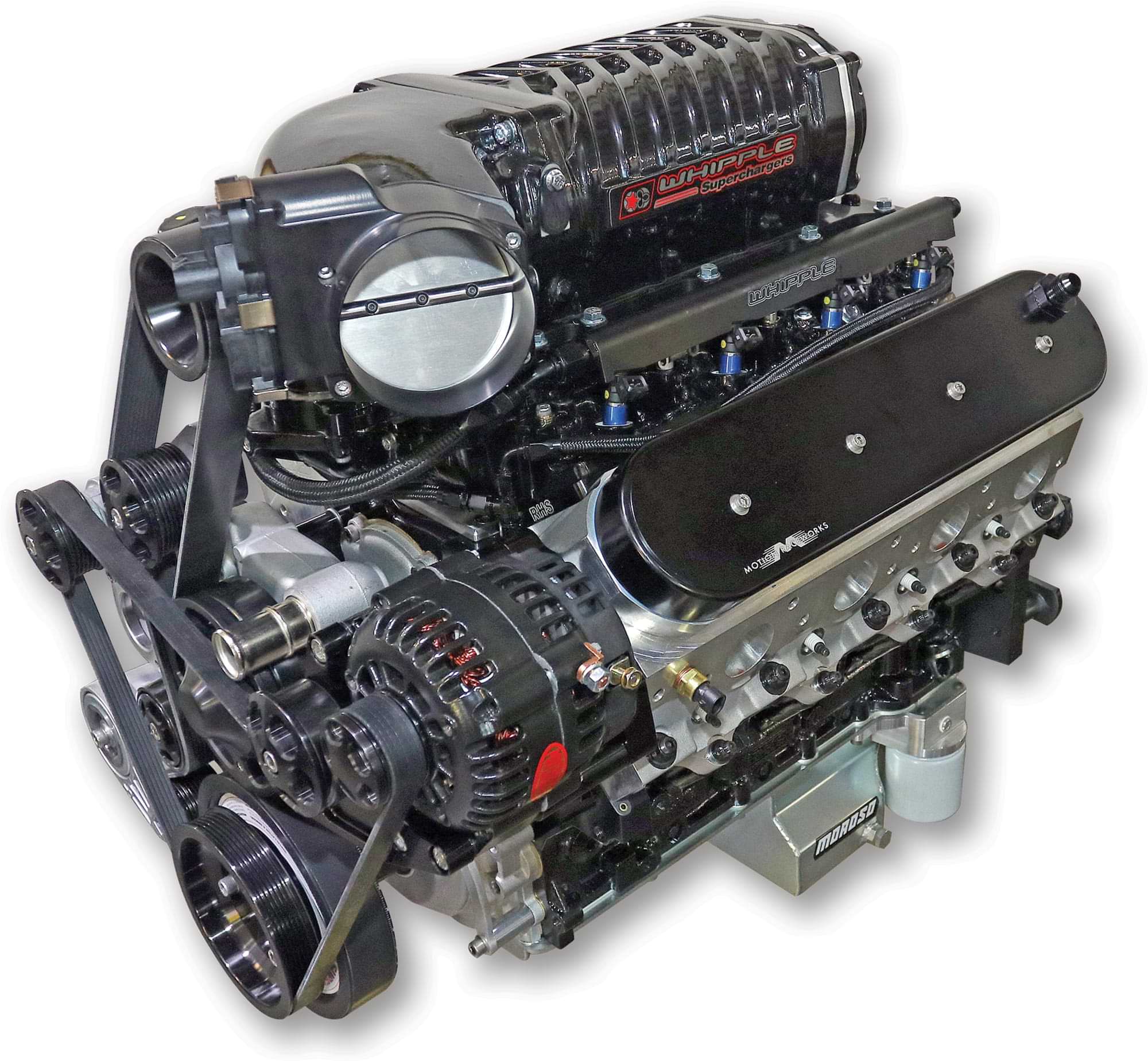

hipple superchargers have been a popular option when it comes to making horsepower for years because their screw-blower designs are proven to make great power in a compact package. A twin-screw supercharger has an advantage over the roots supercharger because its design allows it to move air more efficiently.

The old-school roots supercharger uses the spinning lobes to move air along either side of the case and into the intake plenum. The air exits the supercharger at atmospheric pressure, so boost has to be built up inside the intake plenum.

Meanwhile, a twin-screw supercharger moves air in a cavity created between the screws. As the screws rotate, the cavity moves from the opening in the supercharger case directly to the exit. Meanwhile, the shape of the lobes on the screws also means the cavity gets smaller as the air moves closer to the exit, compressing it. That means the air is already under pressure as soon as it enters the engine.

FEATURE

FEATURE

Photography BY The Author

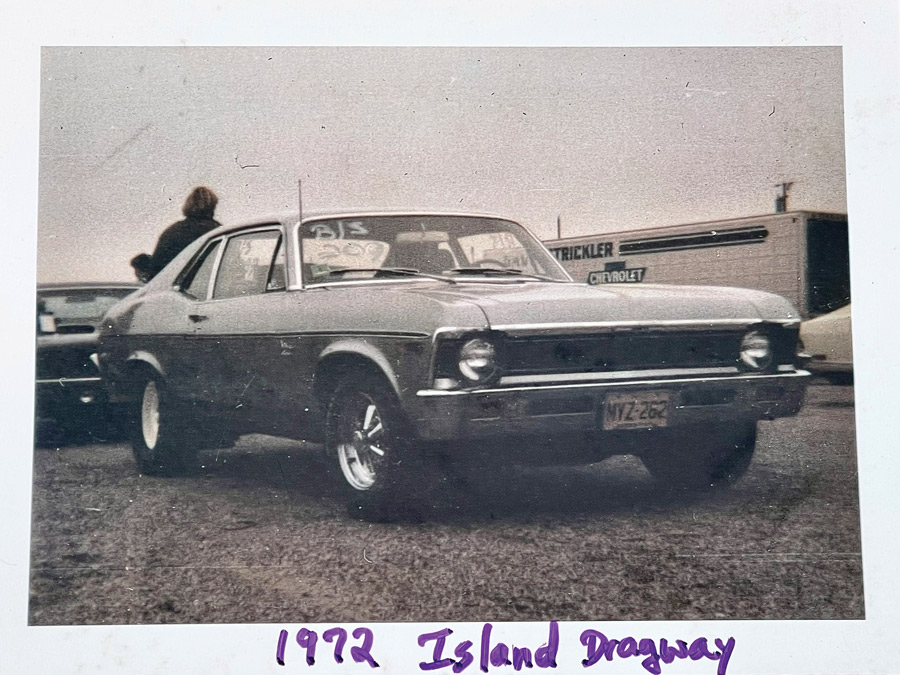

Photography BY The Authoreil Zimbaldi wasn’t looking for any golden fruit when he spotted an Azure Aqua Chevy II sitting under an apple tree in upstate New York. What he was really looking for was a vehicle to take on the streets of the “Big Apple.” Born with an appetite for speed, the young hot rodder was in need of an appropriate ride to build as his new street fighter. This basic box Nova piqued his interest from the first day he laid eyes on it.

“I remember seeing it when I was a grade schooler riding the bus back in the early ’70s. I kept an eye on it for over a year. One day I asked the owners about the car,” Neil says. They were interested in selling and wanted $75, which believe it or not was kind of crazy for a basic used car back then. I could have gotten a beater for $25 at the junkyard.”

Unfortunately, the young gun was still a few dollars shy of pulling off the deal, so he begged his mom for the extra $50 needed to buy the car. “My mom was a tough Italian woman who never spoiled me,” Neil states. “She soon relented but never let me forget that cash gift for the next 35 years.” The next day Neil and his buddy, John, picked up the Chevy and drove it home for 2 miles … with no brakes. “With ground-down drums, I just missed running into the garage door trying to get it to stop,” Neil laughingly reveals.

TECH

TECHBottom-End Assembly

Photography by The Author

Photography by The Authore all deserve the best bang for our buck, and that goes for anything we spend our hard-earned cash on. When it came time to decide on an engine for my own project, I asked myself the same questions you would. Why build a mild-performance engine myself if I can go aftermarket (even with a warranty) and save a ton of time? My knee-jerk reaction was to opt for the aftermarket crate options. But, as with anything, the power of peer pressure can easily justify temptation. And … I’m glad I gave in!

FEATURE

FEATURE

Photography BY The Author

Photography BY The Authormagine being an up-and-coming muscle car enthusiast who is continually exposed to a steady stream of top-of-the-line GM muscle rides rolling in and out of his next-door neighbor’s driveway on a daily basis; the owner using their services for a year, only to trade in the cars for the next year’s hottest new model. Well, if you were Dennis Linkroum of Bridgewater, New Jersey, you knew the pain of seeing these goodies paraded in front of your yearning eyes and dealing with the anguish from constant pining for a dream ride of your very own.

But there is a happy ending to this torrid tale of “muscle car lust” for our friend Dennis, as the young gun decided one day to take fate into his own hands and make his hot rodding dreams become a reality. Though some of the memories are a little hazy (hey, it was over 50 years ago), the proof of that experience is sitting in his garage back home in Jersey, which has been under his ownership for the past five decades.

TECH

TECH Photography by Jason Scudellari

Photography by Jason Scudellarihen the first Chevy II rolled off the assembly line in 1962, few people, including those at General Motors who designed and built it, would have guessed that 60 years later these cars would still be sought after.

The Chevy II came about because Chevrolet needed to fill a void in their product line. In 1960 Ford introduced the Falcon as a small, affordable option to a fullsize car. General Motors’ pre-shrunk auto option that year was the Corvair. But despite the fact the motoring press praised Chevy’s bold new offering (the Corvair was Motor Trend magazine’s 1960 Car of the Year), the buying public wasn’t as enthusiastic. By the time Ralph Nader expressed his disdain for the air-cooled, rear-engine Corvair, Chevrolet desperately needed a “Falcon fighter”—and the first series Chevy II (1962-1967) was it.

Advertiser

- Aces Fuel Injection87

- American Autowire51

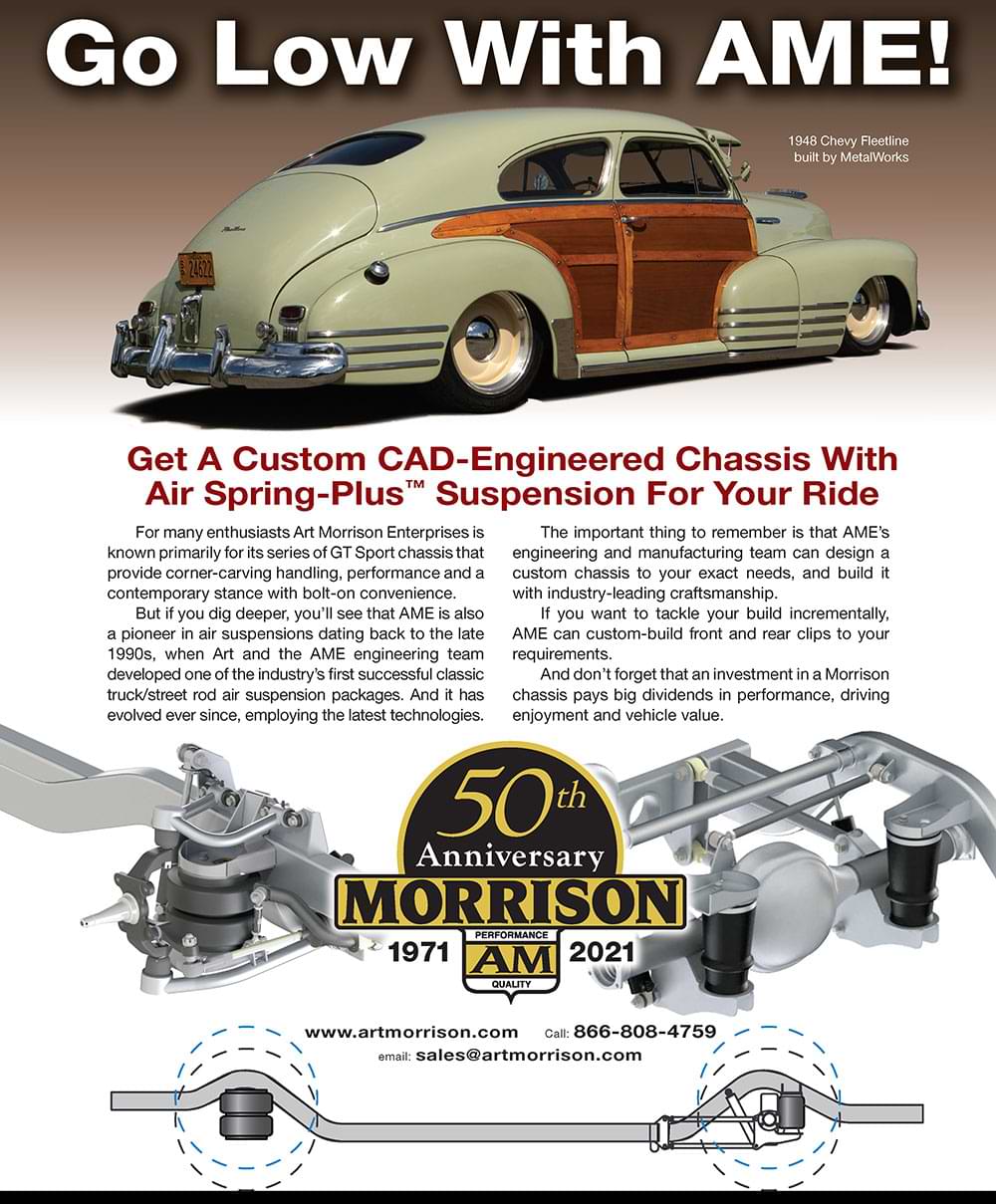

- Art Morrison Enterprises31

- Auto Metal Direct29

- Automotive Racing Products9

- Borgeson Universal Co.3

- Bowler Performance Transmissions85

- Classic Industries27

- Classic Instruments52

- Classic Performance Products4-5, 85, 92

- Concept One Pulley Systems85

- Dakota Digital91

- Danchuk11

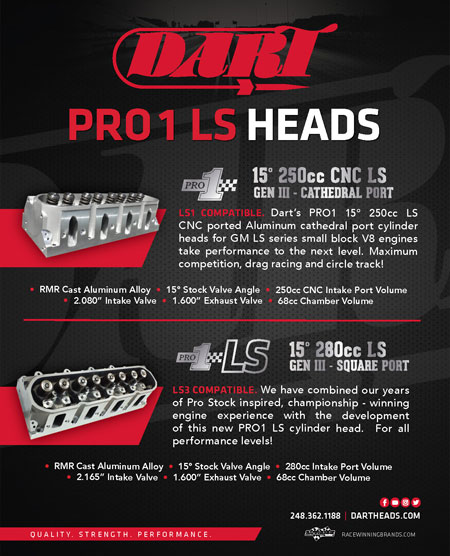

- Dart Machinery83

- FiTech EFI79

- Golden Star Classic Auto Parts7

- Heidts Suspension Systems73

- Holley Performance Products53

- HushMat87

- John’s Industries83

- Lokar2

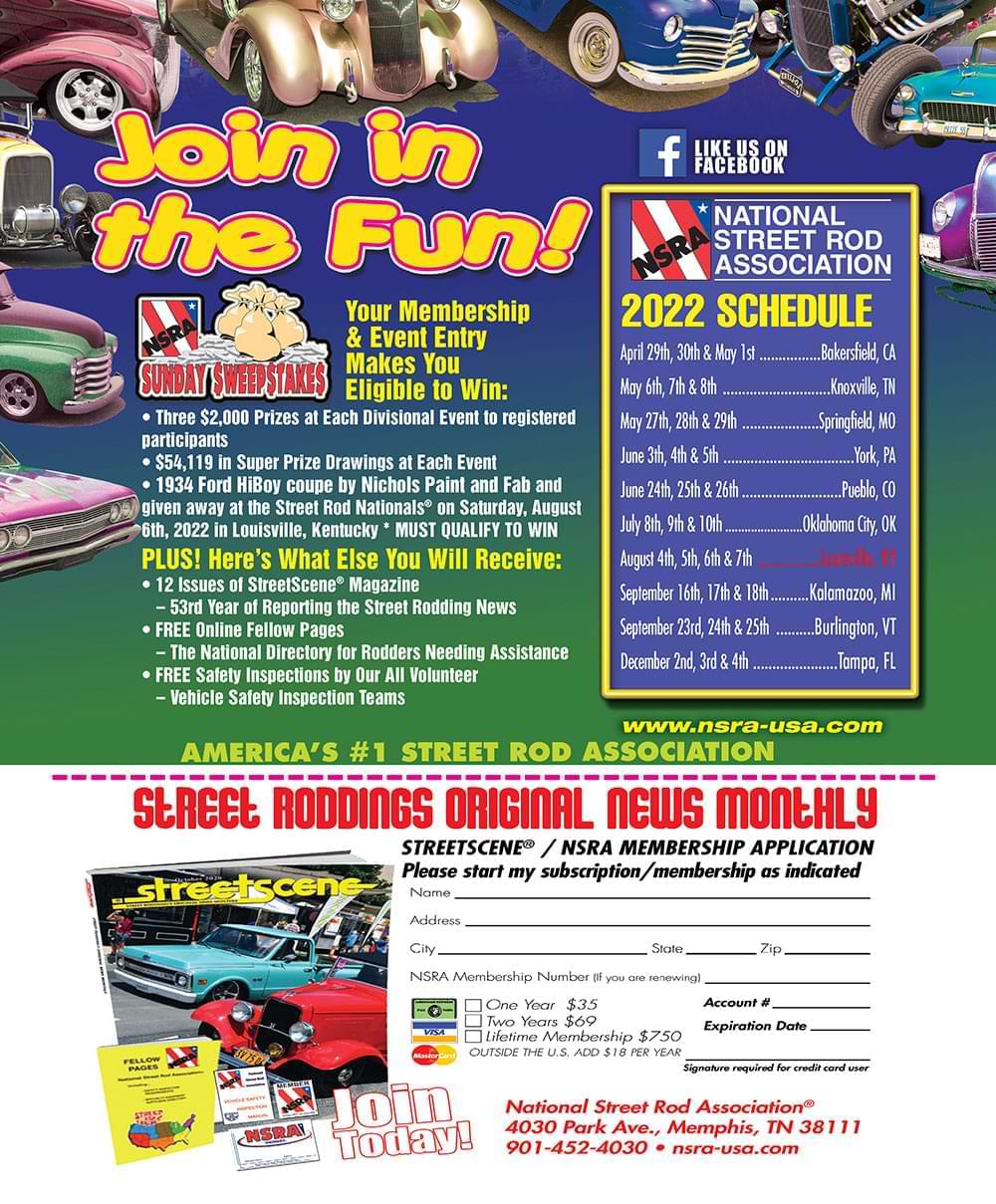

- National Street Rod Association59

- Original Parts Group13

- Powermaster Performance67

- Roadster Shop57

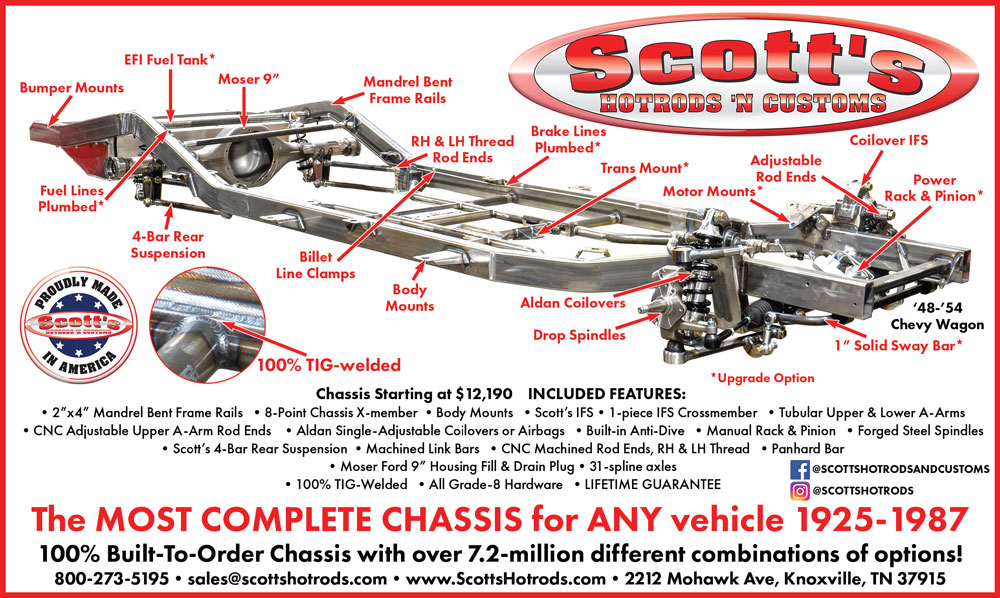

- Scott’s Hotrods67

- Speedway Motors45

- That’s Great News87

- Thermo-Tec Automotive83

- Tuff Stuff Performance Accessories79

- Vintage Air6

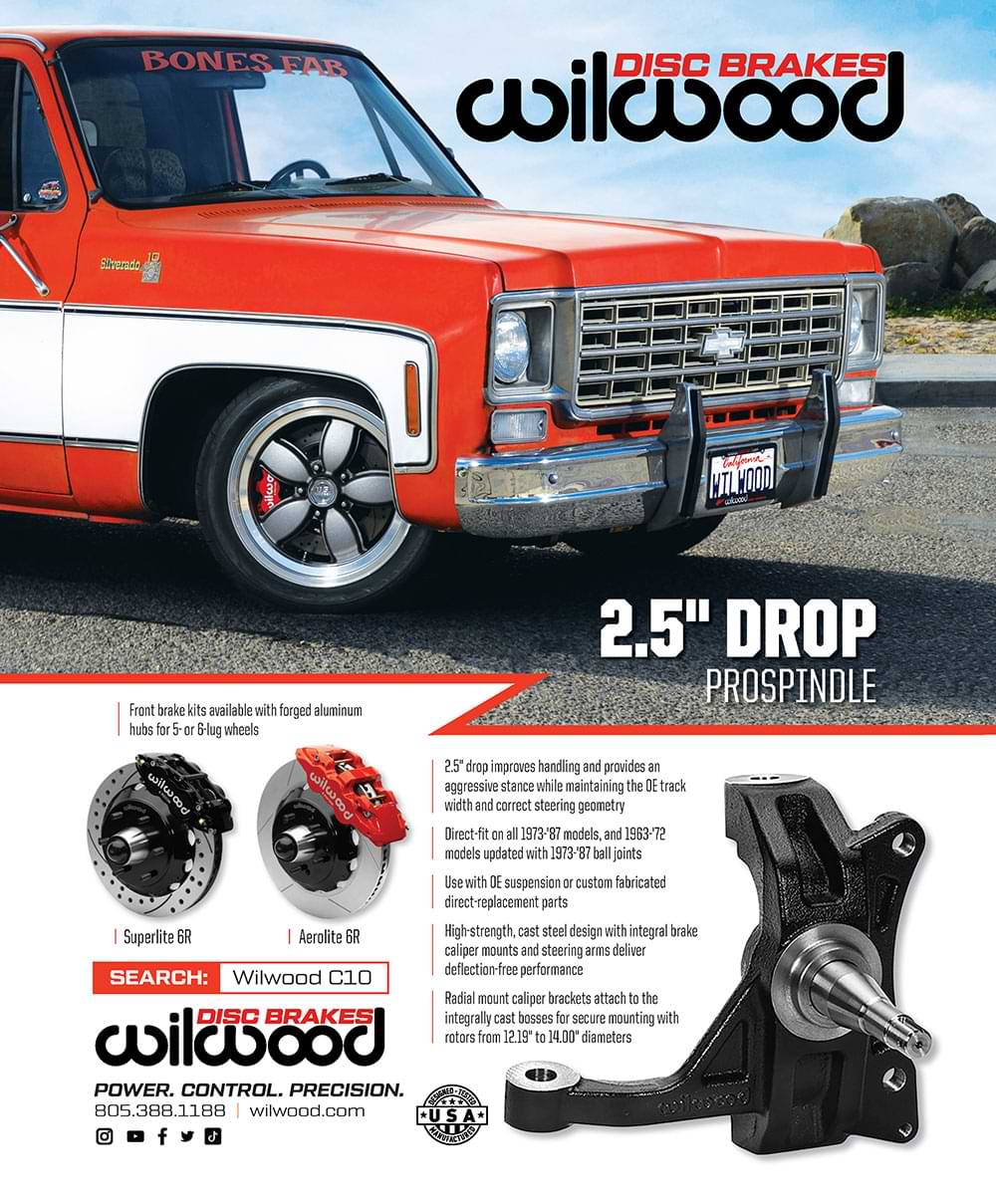

- Wilwood Engineering43

- Year One83

BOWTIE BONEYARD

BOWTIE BONEYARD

Photography by The Author

Photography by The Authoroes anyone remember the ’80s? This writer sure does. It was a time of awakening. A time of rebirth. The dreaded “Smog ’70s” were a thing of the past. Chevrolet launched two blinding stars into the automotive firmament: the C4 Corvette in 1984 and the Third-Generation Camaro in 1982.

Though the brutal big-blocks of the Supercar ’60s never returned, a new emphasis on braking and handling crutched the fact that horsepower levels above the 200 mark were an extreme rarity.

As good as the ’82 Camaro was (and is), the real fun began in 1987 with the availability of the then-massive Corvette L98 350 as an alternative to the 305. Sold as RPO B2L, for an extra $1,045 top-tier IROC-Z buyers had 225 hp and a yummy 330 lb-ft of torque under foot.