TOC

TOC

ROB MUNOZ

Wes Allison, Tommy Lee Byrd, Ron Ceridono, Grant Cox, Dominic Damato, Tavis Highlander, Jeff Huneycutt, Barry Kluczyk, Scotty Lachenauer, Jason Lubken, Steve Magnante, Ryan Manson, Jason Matthew, Josh Mishler, Evan Perkins, Richard Prince, Todd Ryden, Jason Scudelleri, Jeff Smith, Tim Sutton, and Chuck Vranas – Writers and Photographers

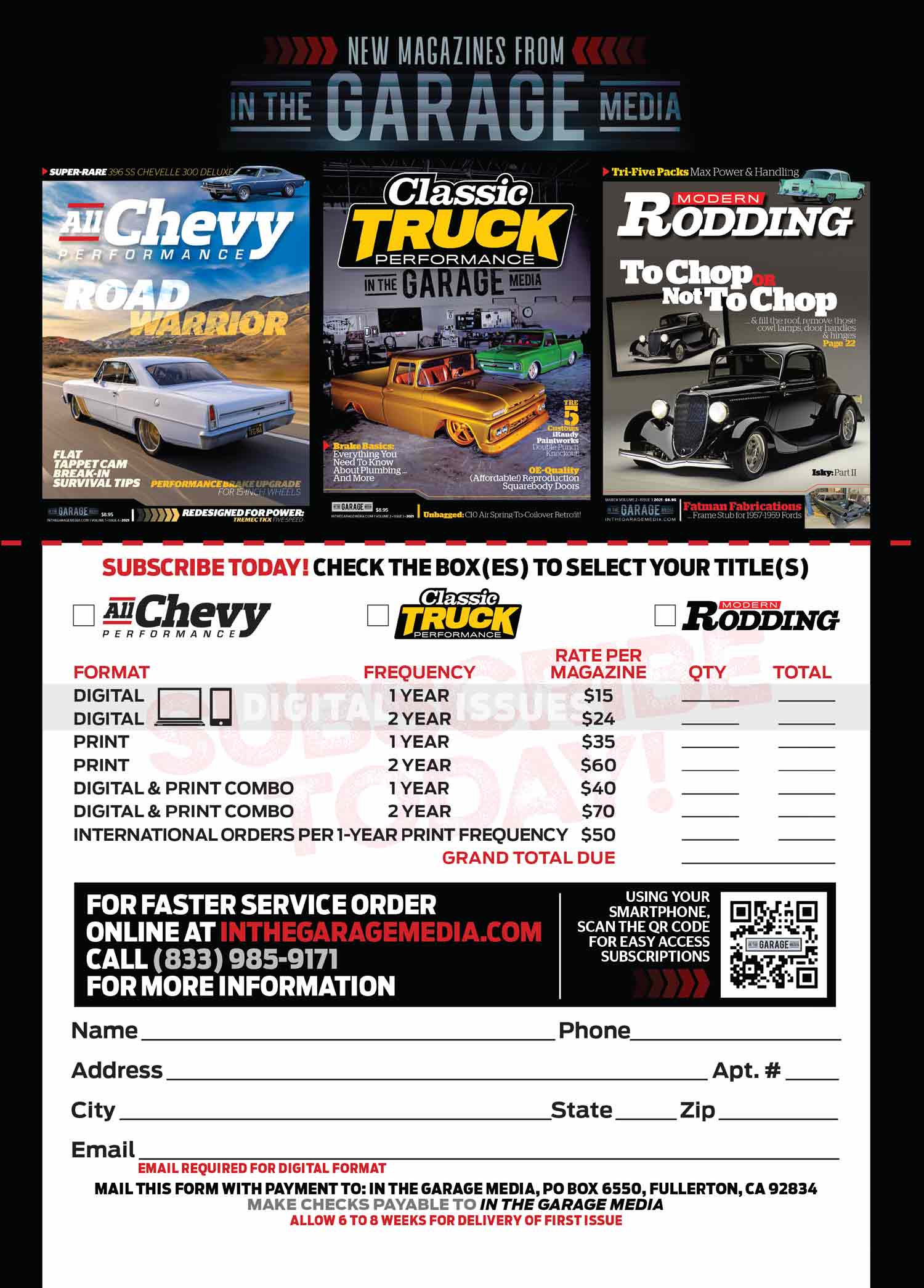

AllChevyPerformance.com

ClassicTruckPerformance.com

ModernRodding.com

InTheGarageMedia.com

subscriptions@inthegaragemedia.com

Mark Dewey National Sales Manager

Patrick Walsh Sales Representative

Travis Weeks Sales Representative

ads@inthegaragemedia.com

inthegaragemedia.com “Online Store”

info@inthegaragemedia.com

Copyright (c) 2021 IN THE GARAGE MEDIA.

PRINTED IN U.S.A

FIRING UP

FIRING UP

BY NICK LICATA

BY NICK LICATAor the past 10 or so years I’ve been hearing the phrase “print is dead.” Now, I’ve been in the magazine publishing biz for the past 20-or-so years and today I can tell you print is not dead–it’s not on a respirator or even its “last leg.” Yes, I’ve been editor of a couple magazines that have met a painful (to me, anyway) demise, but I, and many others involved, saw the killing of those magazines as premature. Most were staples of our industry and continued to show profit but still suffered the ultimate sacrifice due to the company moving in a different direction. Now, I’m not going to pretend print is as popular as it was back in the ’70s or anytime prior to the Internet age, but I firmly believe there is still an audience for print—those who prefer to hold a tangible magazine in their hands and flip actual pages, you know like in the “olden days.”

Although the Internet and social media are important platforms that combined with print contribute to the success of the magazine publishing industry, there are still many of us who aren’t quite ready to get our hot rod and muscle car fix exclusively in digital format.

When we here at In The Garage Media started this venture, the business plan was to offer digital-only versions of our magazines. But readers and advertisers spoke up–they wanted old-school print versions of our magazines. Thankfully we listened. From day one print outsold the digital by a long shot. And that trend continues today.

Parts Bin

Parts Bin BY Nick Licata

BY Nick Licata

CHEVY CONCEPTS

CHEVY CONCEPTS

Text and Rendering by Tavis Highlander

Text and Rendering by Tavis Highlander

Text and Rendering by Tavis Highlander

Text and Rendering by Tavis Highlanderhe crew at Painthouse are no strangers to building high-end custom cars. They find their way into the finals of SEMA’s Battle of the Builders and take home big awards wherever they go. This latest project is being given the same treatment as many of their other builds, so you’ll probably be seeing it at the biggest events once it’s complete.

Providing a foundation for this build is an Art Morrison chassis. Between those rails there’s a ZL1 Camaro engine along with an eight-speed transmission. With this combo, the project has been dubbed the ZL Camino.

Custom design touches are numerous but subtle on this build. Era-correct hubcap wheels have been designed and will be machined in 18- and 19-inch sizes to clear a modern brake package. The front grille is totally done over, and the surrounding sheetmetal has been massaged to tighten the look. On top of the hood will be GM factory-inspired hood vents machined to fit.

FEATURE

FEATURE

Photography BY The Author

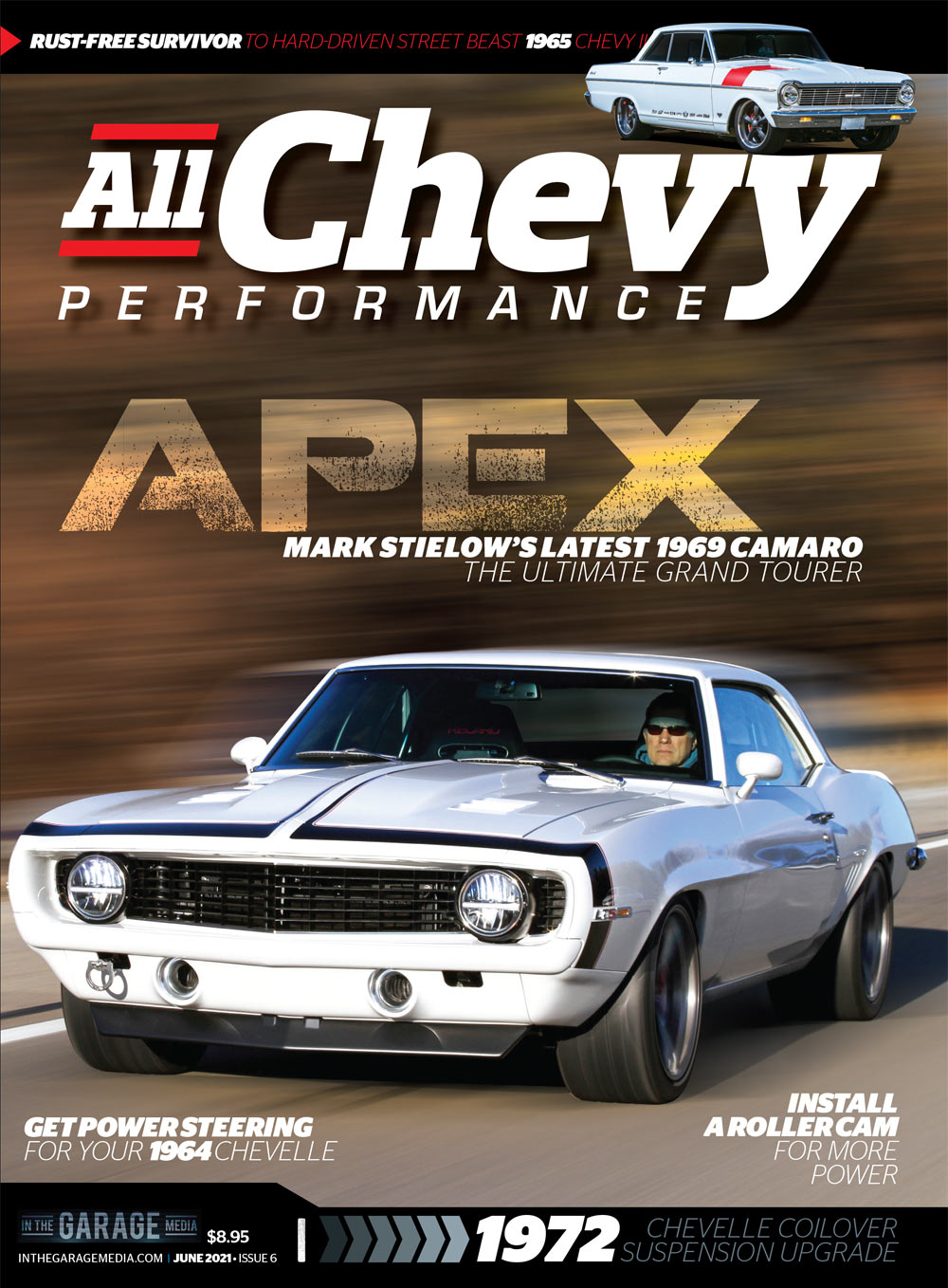

Photography BY The Authorogether, the Van Nuys and Norwood assembly plants pushed more than 243,000 1969 Camaros out of their collective doors. Mark Stielow hasn’t quite yet turned all of them into Pro Touring powerhouses, but with his latest build—dubbed Apex—he’s getting closer.

In reality, the white, LT5-supercharged 1969 is “only” his 17th first-gen Camaro. Even still, he must be using up what’s left of the nation’s strategic reserve of 1969 models. This one started as an original, rust-free California black-plate car and its build consumed much of his stockpile of long-cultivated takeoff parts.

TECH

TECH Photography by Nick Licata

Photography by Nick Licatane of the most innovative developments on the automotive aftermarket suspension scene was the introduction of coilover shock absorbers. Among the first to offer billet aluminum coilovers for street performance and drag racing was Aldan American. Forty years later they’re still producing quality products that are made entirely in the U.S.

The obvious advantage to coilovers is that wrapping the springs around the shock absorber makes an extremely compact suspension system, and there are other advantages as well. Tuning the suspension by altering the spring rate is simply a matter of swapping the replaceable coil springs. As coilover springs they are available in a wide range of spring rates, finding the right one for any application is easy, quick, and affordable. In addition, altering ride height is just a matter of turning the threaded adjuster on the shock absorber body.

While coilovers have commonly been found on sports cars, hot rods, and other cars with custom chassis for a long time, converting larger vehicles with essentially stock suspension to coilovers was difficult and expensive. However, now there is an easy-to-install, affordable method to incorporate all the advantages of coilover suspension in a variety of GM products, including 1964-1972 A-body cars (the example we’re showing here is a 1972 Chevelle but the installation procedure for the others is basically the same).

FEATURE

FEATURE Photography BY Wes Allison

Photography BY Wes Allison

alifornia Car—two words put together that add value to just about any classic car, especially those seeking out a solid foundation for a ’60s muscle car build. That was exactly the case with Jon Henson’s 1965 Chevy II Nova. He was no stranger to the car as he had been helping his friend, Shannon Gaither, wrench on it for about 11 years. “I actually went with [Gaither] to look at the car and talked him into buying it, as it was in amazing condition,” Jon says. “It is a native California car with no rust, original paint, original trim, and sheetmetal, the windows sealed tightly, and the doors closed with a distinct ‘thud’—the perfect blank slate.”

After years of the duo putting in work and the car nearing the finish line, Gaither had to move onto another project for SEMA. That’s when Jon expressed interest in buying the car. Gaither didn’t want to sell it, but knew if he sold the car to Jon it would still be “in the family.”

TECH

TECH Photography by The Author

Photography by The Authort wasn’t long ago that a trick roller camshaft in a small-block Chevy was high-end, drag race tech that looked good in glossy magazine pages but was yet out of reach for the average hot rodder. Boy, how times have changed. These previously exotic grinds have trickled from “can’t get it” to “can’t afford it,” all the way down to “Yeah, my Silverado came with that.” And whether we’re talking classic big- or small-block or late-model LS/LT, roller camshafts are here to stay. Today, they’re a practical, readily-available upgrade to any big- or small-block engine.

Photography by The Author

Photography by The Authort wasn’t long ago that a trick roller camshaft in a small-block Chevy was high-end, drag race tech that looked good in glossy magazine pages but was yet out of reach for the average hot rodder. Boy, how times have changed. These previously exotic grinds have trickled from “can’t get it” to “can’t afford it,” all the way down to “Yeah, my Silverado came with that.” And whether we’re talking classic big- or small-block or late-model LS/LT, roller camshafts are here to stay. Today, they’re a practical, readily-available upgrade to any big- or small-block engine.

When applied to camshafts, the word roller corresponds to the interface between the cam lobe and lifter. In older engine architectures, the lifter was of a flat tappet style (see last month’s issue), where the crown of the lifter rode directly on the cam lobe with no roller bearing assistance. The lifter had a slight taper to it and touched the lobe only on its outermost edge, which caused the lifter to spin in its bore during engine operation.

FEATURE

FEATUREs a kid, Steve Aguilar harkens back to the days when young hot rodders in his neighborhood were wrenching on Tri-Five Chevys, old Pontiacs, and ’60s-era Chevys. His best friend had a 1966 Chevelle loaded with a 396, and that was all it took to get him hooked.

With a long history of being into muscle cars, in 2012 he got a hankerin’ to seek out a 1967 GTO as a project to take him back to the good old days when he stumbled across a really nice 1971 Z28 Camaro. “The car was in a Porsche shop in Costa Mesa, California. It was in great shape and well documented,” Steve says. After driving the car a few times, the lack of power and handling capabilities left Steve wanting more.

Photography by Wes Allison

Photography by Wes AllisonAmerican Muscle

took a GT

approach with

his 1971 Camaro

FEATURE

FEATURE Photography by Wes Allison

Photography by Wes Allisontook a GT

approach with

his 1971 Camaro

s a kid, Steve Aguilar harkens back to the days when young hot rodders in his neighborhood were wrenching on Tri-Five Chevys, old Pontiacs, and ’60s-era Chevys. His best friend had a 1966 Chevelle loaded with a 396, and that was all it took to get him hooked.

With a long history of being into muscle cars, in 2012 he got a hankerin’ to seek out a 1967 GTO as a project to take him back to the good old days when he stumbled across a really nice 1971 Z28 Camaro. “The car was in a Porsche shop in Costa Mesa, California. It was in great shape and well documented,” Steve says. After driving the car a few times, the lack of power and handling capabilities left Steve wanting more.

TECH

TECH

Photography by Jason Scudellari

Photography by Jason Scudellarihen it comes to safely securing the human cargo in a pre-’70s Chevy, it’s rare to find an option that improves upon the basic lap belt. Vehicle designs of the time were more based on styling than safety, so when it comes to upgrading the restraint system in a vintage Chevy, one’s often faced with some daunting decisions. Such was the case when Jason Scudellari was bolting together a 1963 Chevy Nova for his wife, Randi. The lack of B-pillars in the hardtop meant even something as simple as mounting a traditional three-point shoulder restraint was out of the question. One of the motivations behind the build was to take it to track days and autocross events, pushing the supercharged LS engine through its rev range and around the course. That said, Jason decided that the safety of its precious cargo would be paramount, and a pair of lap belts just wouldn’t do.

While perusing his interior options with TMI Products, Jason spotted their Pro-Chicane Series bucket seats. Knowing that the provided bolster support would be perfect to keep the occupants planted, it was the shoulder harness cutouts that got the wheels turning. A separate conversation with Craig Morrison at Art Morrison Enterprises and Jason had the solution to his safety problem. Jason mentioned his idea for a simple harness bar, mounted to the floor behind the front seats to act as the upper mounting point for a four-point harness system from G-Force Racing Gear. Morrison recommended taking things a step further by incorporating the harness bar with a full rollbar that will span the entire height and width of the interior of the car, providing further safety for the occupants. To support the rollbar, a pair of removable door bars would be incorporated, as would a pair of rear support tubes, connecting the top of the rollbar with the rear floor of the Nova’s body. It should be noted that while this setup definitely adds a degree or two of safety to the vehicle, building a full rollcage that met the specs of any sanctioning body was not the intention.

FEATURE

FEATURETOUCH

Photography by Mike Chase

Photography by Mike Chasen 1974 ABBA and The Beach Boys ruled the airwaves, a 55-mph speed limit was imposed nationwide in order to save gas, and a portable television could be had for around $264. Strangely enough, today you can buy a 50-inch 4K Smart TV for about the same price. While those shenanigans were happening, Rich Williams was in high school using his auto shop class as a means to paint and perform engine swaps on his 1964 Mustang. There’s no telling if Rich’s auto shop teacher allowed music during class, but there’s a good chance The Beach Boys would have been part of Rich’s soundtrack while wrenching on cars.

TECH

TECH

Photography by The Author

Photography by The Authororsepower and comfort don’t exactly go hand-in-hand. In order to make more horsepower, you sometimes have to sacrifice comfort, and to be more comfortable, you may have to sacrifice a little horsepower. In our younger days, those comfort sacrifices included stripping all of the seemingly unnecessary accessories off the front of the engine—it just seemed like the right thing to do. The air conditioning and power steering system often went to the scrap pile in an effort to save weight and take some drag off the engine. But there’s a time in every car guy’s life that he needs a little more comfort.

That’s the point we’ve reached with this 1964 Chevelle. It’s a cool cruiser with a mostly original 283ci small-block, but we’ve been fighting the original manual steering system for years. When simple tasks like backing out of the garage and navigating a tight parking spot at the local burger joint become a chore, you know it’s time to make a change. We’re finally doing something about it with a Power Steering Conversion Kit from Classic Performance Products (CPP).

The kit (PN CPP6467PSK) is a direct bolt-on system that includes a new 500 Series steering box, steering coupler, power steering pump, and hoses. In order to adapt the kit to our original 283ci engine, we ordered the 6468PSBK-SB bracket kit, as our engine does not have accessory holes in the heads. The guys at CPP helped us determine which pulleys we’d need to make it work. A CP38809 power steering pump pulley and a CP38812 add-on crankshaft pulley did the trick. We were also advised to pick up a power steering filter, so we grabbed a PSFF-K to make sure the new box would have a long service life.

Feature

Feature

Photography by The Author

Photography by The Authorreating a good father-son relationship requires more than passing a football in the backyard. It takes a lot of time and a lot of patience to form this sort of bond. Randall Matheson found the perfect way to spend quality time with his son, Dave, and the end result is this flawless 1968 Camaro RS/SS. Randall is a longtime Camaro lover and owned his first one, which happened to be a 1968 RS/SS, at the age of 16. He sold the car in the mid ’80s when he got married and his new bride promised that one day they’d have another one. As it turns out, she was right and the 1968 Camaro on these pages was bought after 20 years of marriage.

TECH

TECH

Photography by The Author

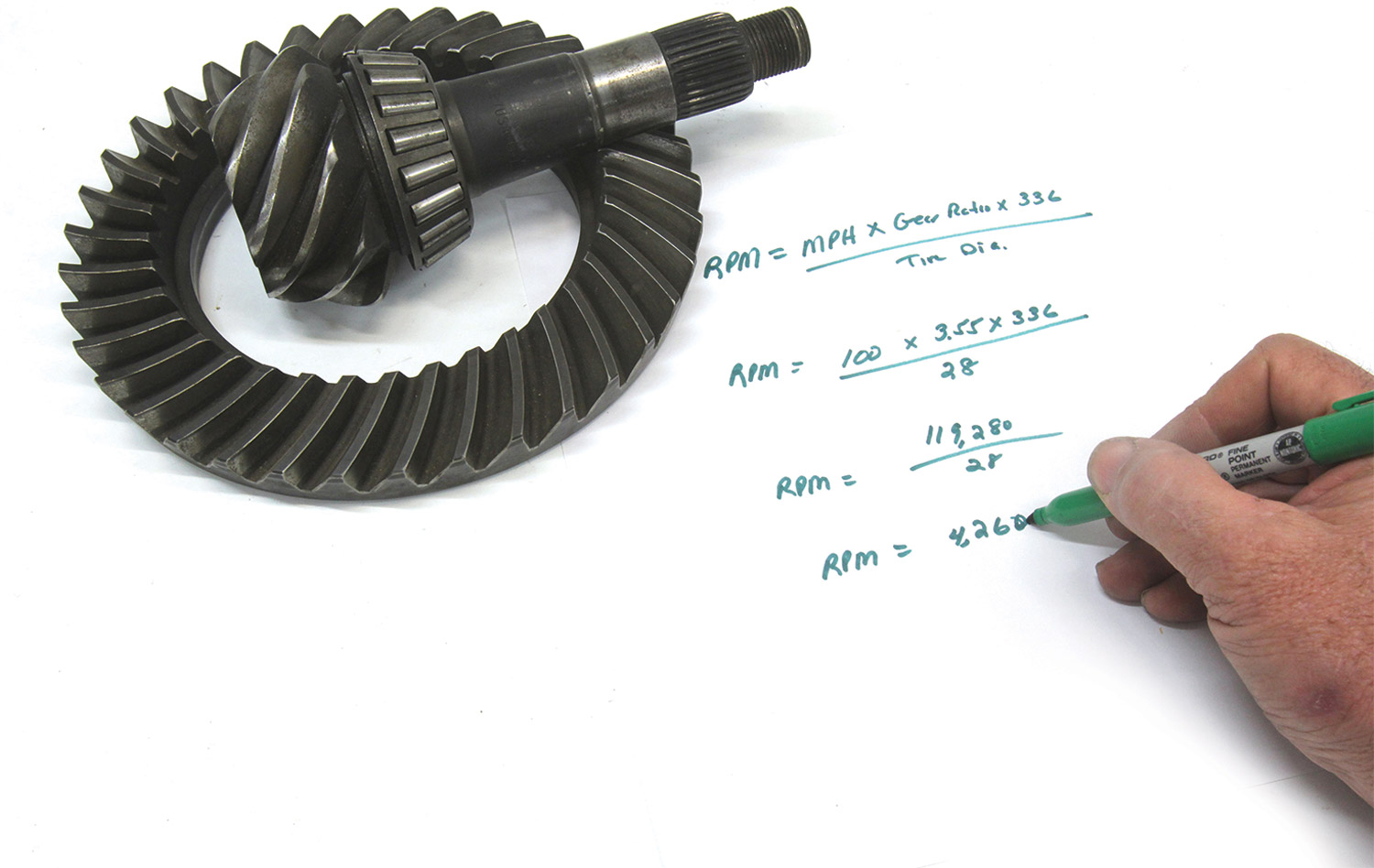

Photography by The Authorear ratio is one of the easiest ways to improve acceleration if your goal is a quicker car in the quarter-mile. Or, a gear ratio change can be used to establish a desired engine speed for a better highway cruiser. Or, you may be looking at what effect a rear tire diameter has on highway cruise rpm. These are common questions that come up when bench racing or planning your next project. While it’s common knowledge that a 4.10:1 rear gear ratio is better for the dragstrip than a 3.08:1 rear gear, the questions relate to how to accurately determine the exact result these changes might have on other aspects of building a street car.

If all we wanted to do was build a car for the dragstrip that accelerated as quickly as possible, figuring out that ratio would not be difficult. In fact, toward the end of this story, we’ll show you one way to approach that question. But for street-driven cars, the issue of gear ratio often involves compromise. A 4.10:1 rear gear is great for the dragstrip, but it comes at the unacceptable price of excessive engine rpm for highway cruising. This story will offer some simple math equations you can use that will offer insight into the effect of gear ratio and tire diameter. We’ll also illustrate how an overdrive ratio in the transmission will improve highway cruise rpm.

Let’s start with a simple example. Let’s say we are building a C10 Chevy pickup for the street. The truck will be powered by a mild LS 5.3L LS engine and backed with a TH350 automatic transmission. Let’s say that you may decide to tow with this truck so it needs a decent rear gear. Let’s put in a 3.55:1 rear gear with a 27-inch-tall rear tire. The question then is how to predict the engine cruise rpm at 70 mph.

Advertiser

- ACES Fuel Injection81

- American Autowire49

- American Legend Wheels75

- Art Morrison Enterprises51

- Auto Metal Direct69

- Borgeson Universal Co.55

- Bowler Performance Transmissions81

- Classic Industries41

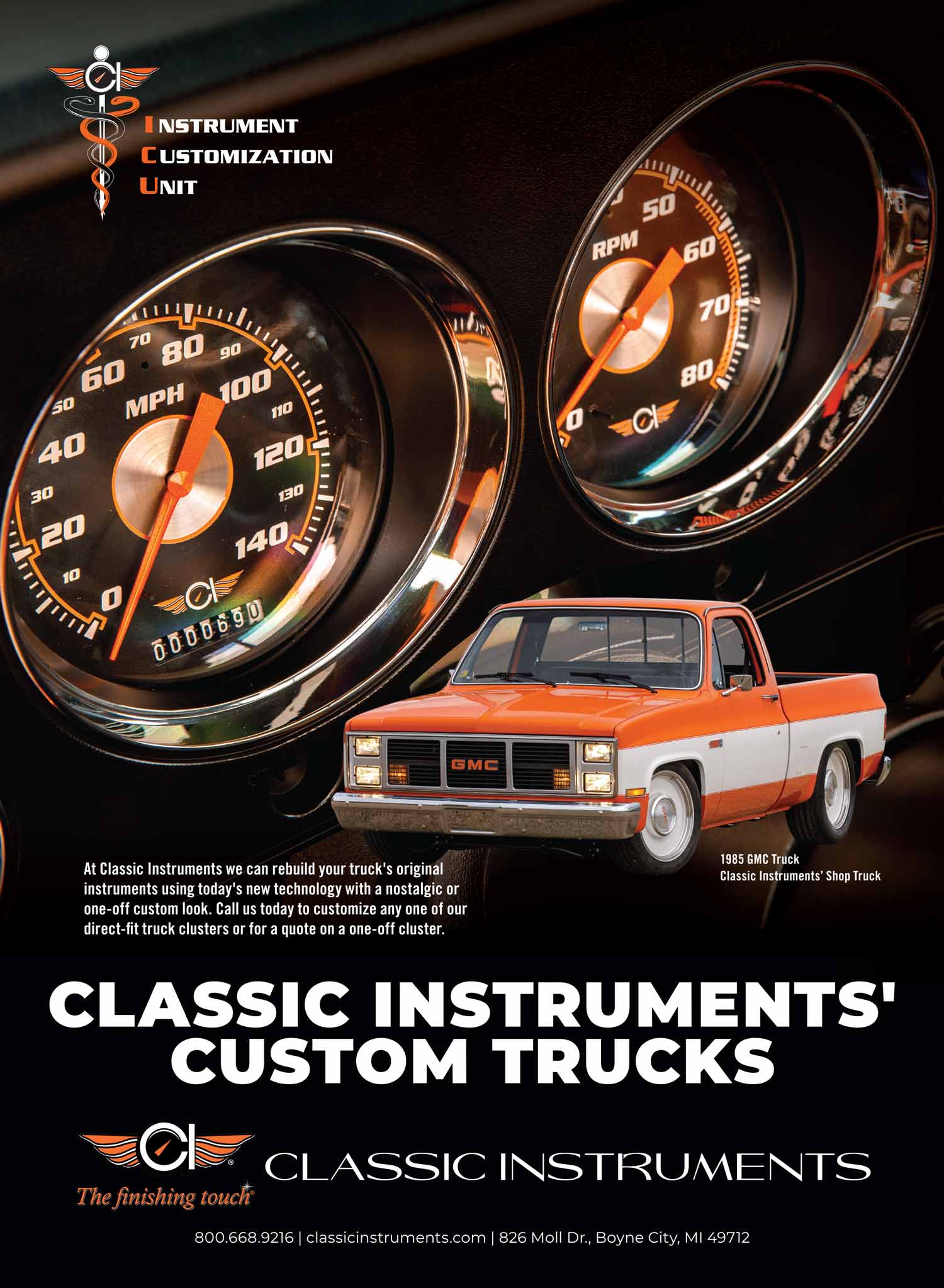

- Classic Instruments9

- Classic Performance Products4-5, 87, 92

- Dakota Digital91

- Danchuk USA11

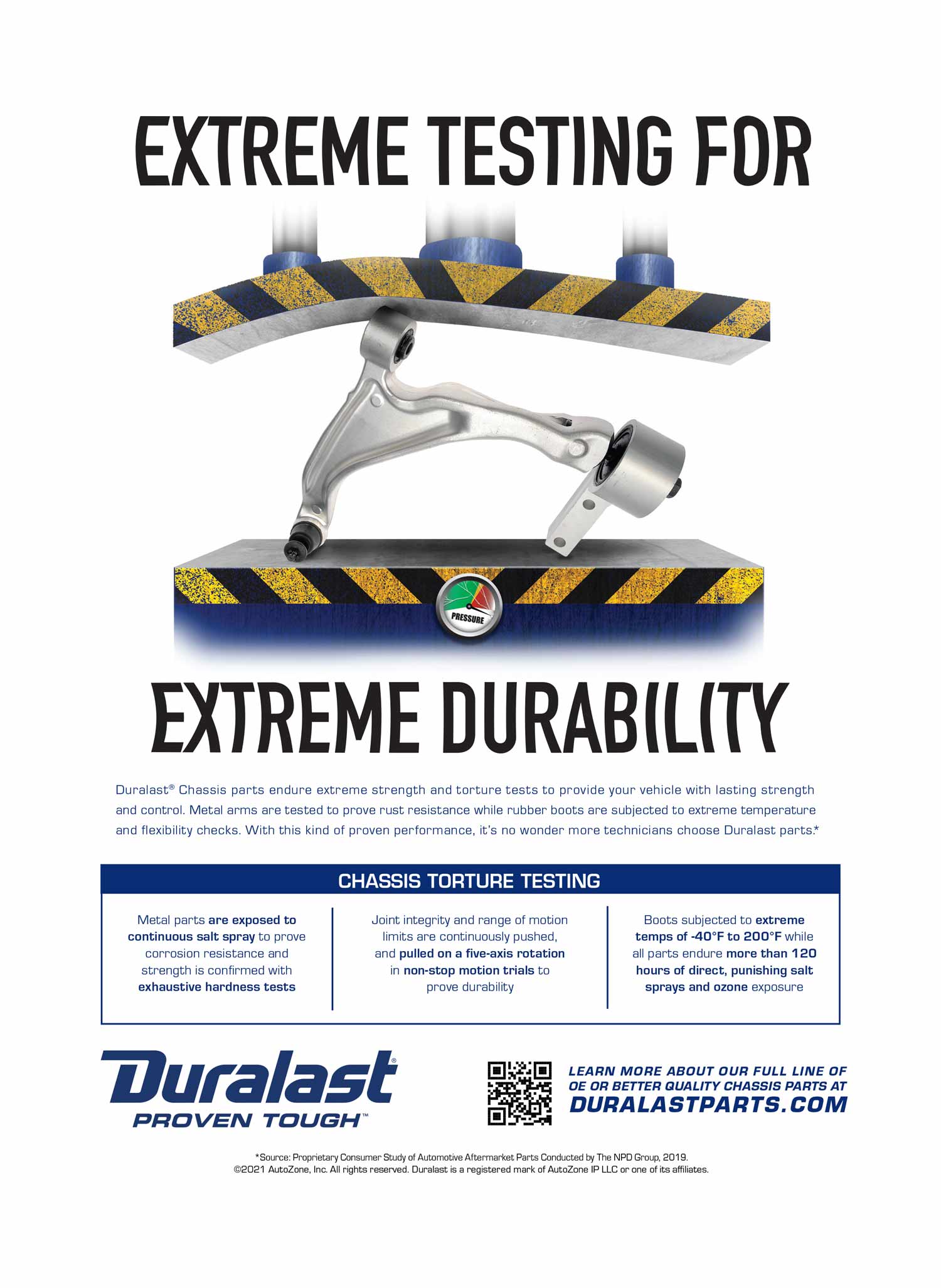

- Duralast23

- FiTech EFI73

- Gandrud Chevrolet81

- Heidts Suspension Systems73

- HushMat87

- John’s Industries85

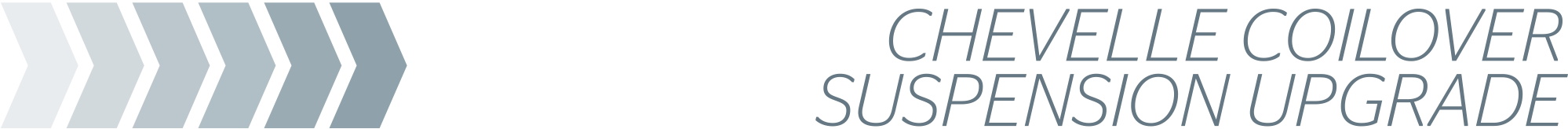

- Lokar2

- National Street Rod Association57

- New Port Engineering81

- Original Parts Group85

- Performance Online37

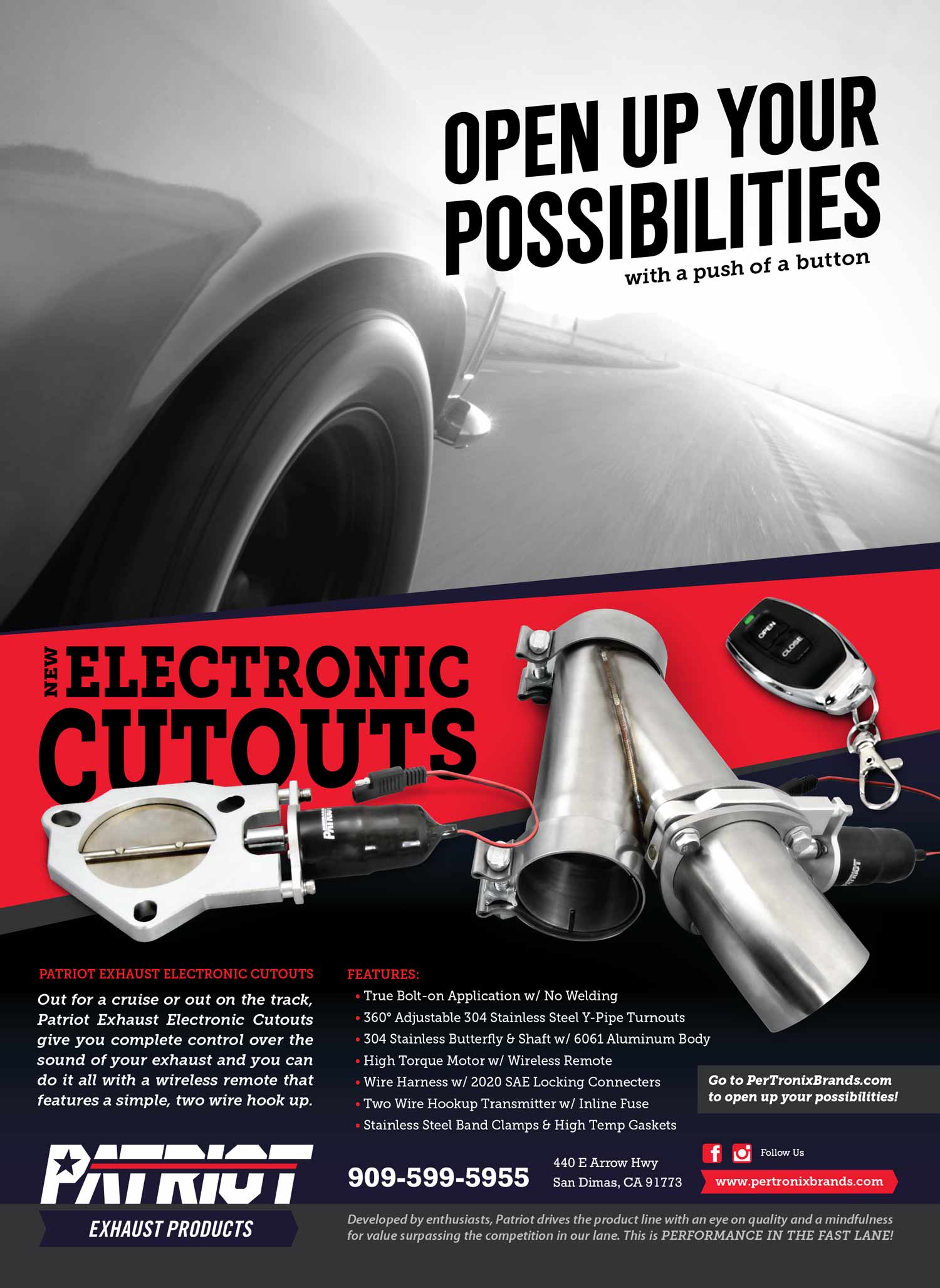

- PerTronix29

- Roadster Shop13

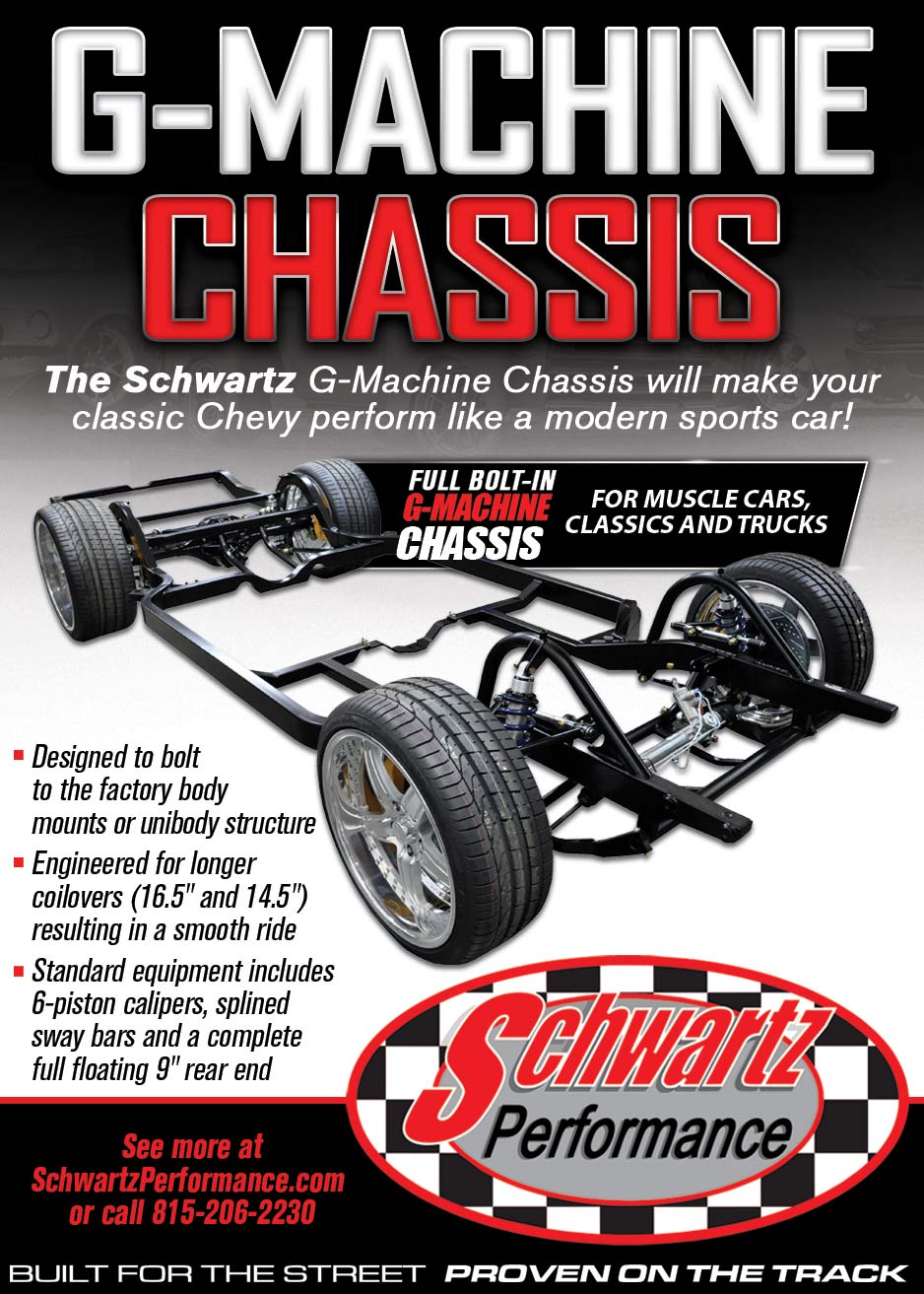

- Schwartz Performance85

- Scott’s Hotrods79

- Speedway Motors59

- That’s Great News87

- The American Tri-Five Association43

- Tuff Stuff Performance Accesssories75

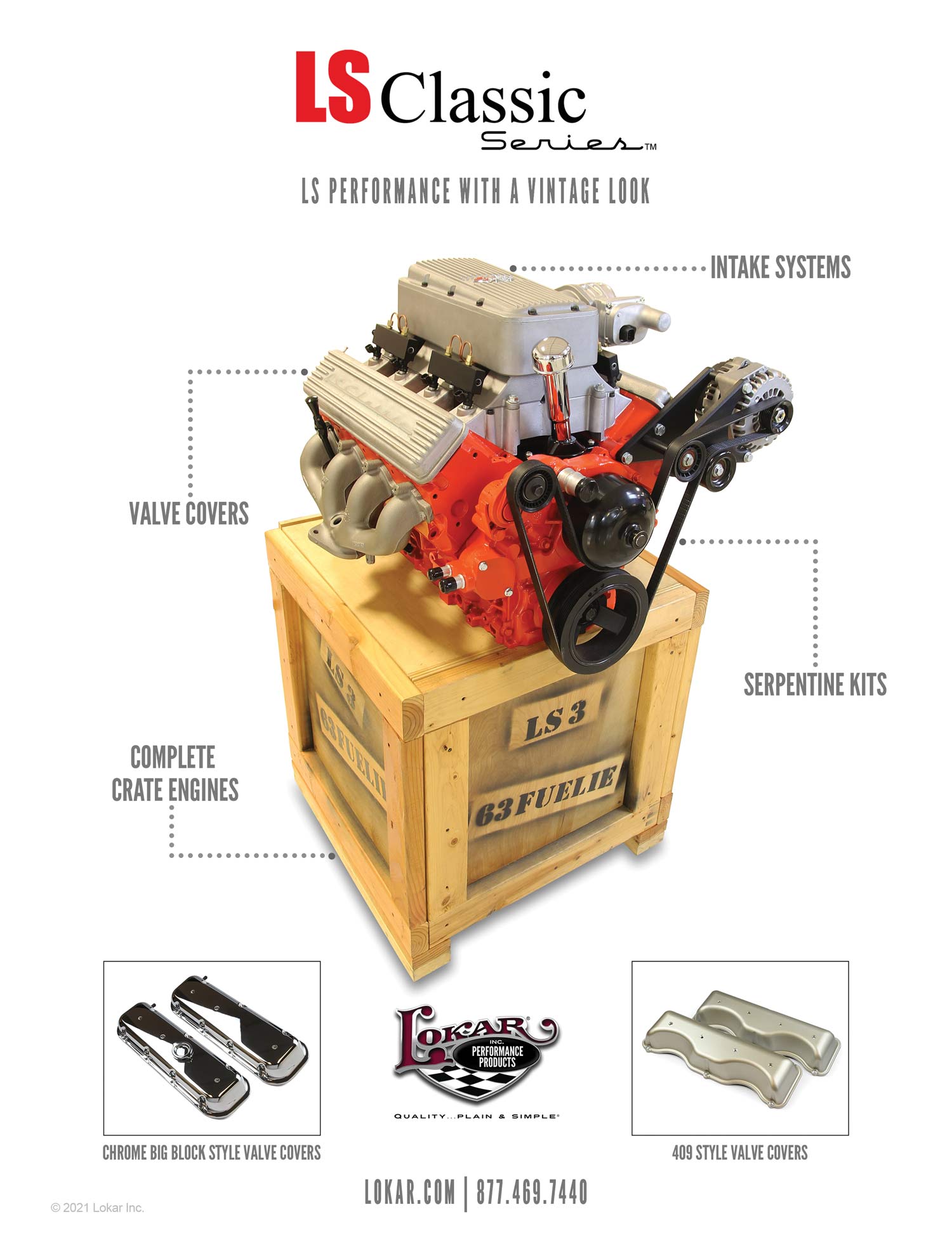

- Vintage Air6

- Wilwood Engineering7

- Year One85

BOWTIE BONEYARD

BOWTIE BONEYARD Photography BY THE AUTHOR

Photography BY THE AUTHORver since the late, great Bill “Grumpy” Jenkins shocked his NHRA Pro Stock competitors with a home-brewed V-8 Vega in 1972, horsepower junkies have appreciated the Vega’s blend of mini-Camaro styling, low mass, and open-up-and-say-V-8 engine bay dimensions. In this installment of Bowtie Boneyard we’re in Santa Teresa, New Mexico, at Joe Duran’s Bow Tie Pro-Formance where we stumbled onto a very unassuming 1973 Vega station wagon with a special surprise. Let’s dig in!