TOC

TOCPhotography by Shawn Brereton

ROB MUNOZ

Wes Allison, Tommy Lee Byrd, Ron Ceridono, Grant Cox, Dominic Damato, Tavis Highlander, Jeff Huneycutt, Barry Kluczyk, Scotty Lachenauer, Jason Lubken, Steve Magnante, Ryan Manson, Jason Matthew, Josh Mishler, Evan Perkins, Richard Prince, Todd Ryden, Jason Scudellari, Jeff Smith, Tim Sutton, and Chuck Vranas – Writers and Photographers

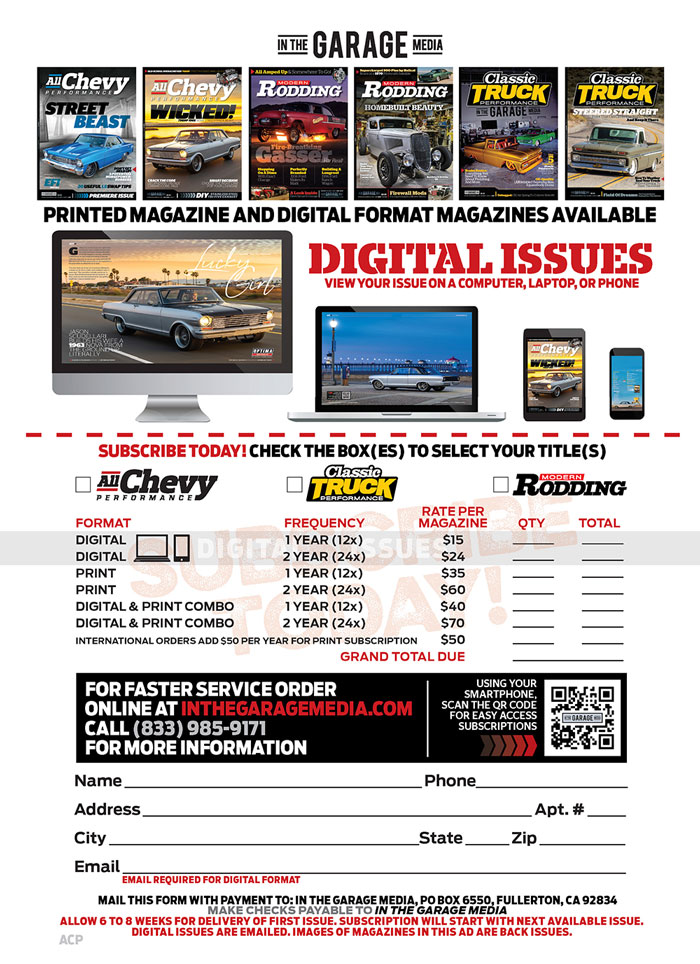

AllChevyPerformance.com

ClassicTruckPerformance.com

ModernRodding.com

InTheGarageMedia.com

subscriptions@inthegaragemedia.com

Mark Dewey National Sales Manager

Patrick Walsh Sales Representative

Travis Weeks Sales Representative

ads@inthegaragemedia.com

inthegaragemedia.com “Online Store”

info@inthegaragemedia.com

Copyright (c) 2021 IN THE GARAGE MEDIA.

PRINTED IN U.S.A

FIRING UP

FIRING UP

BY NICK LICATA

BY NICK LICATA

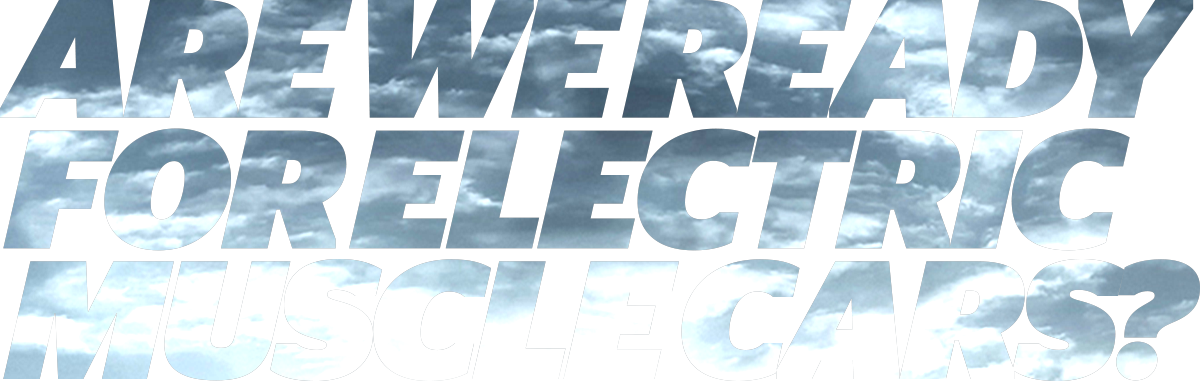

ecently, I was asked by a fellow automotive industry person—one who has been in the aftermarket suspension business for over 30 years—what I thought about electric-powered muscle cars and if I have heard anything lately regarding this new-ish technology; and if, in fact, there is any recent news on the subject. While asking the question his voice carried a nervous tone as if he wasn’t sure he really wanted to hear what I had to say. But what I did have to say wasn’t much more than “I don’t really know.” His voice became more at ease as my answer had likely been what he did want to hear. Being on the editorial side of the aftermarket industry, I sometimes catch wind regarding the latest muscle car trends, but must admit, it’s been quite a while since I’ve heard anything regarding GM’s e-crate motor, which by now we should be seeing more of. In fact, as of this writing, there is nothing new on the Chevrolet Performance website beyond eCOPO Camaro concept, which was announced at the 2018 SEMA Show and the E-10 truck from the 2019 SEMA Show. Earlier this year there was information released regarding the fact that GM had selected Lingenfelter Performance Engineering as the first aftermarket company to develop a certified e-crate Connect & Cruise installer program, but that was the last I heard anything on that front.

Parts bin

Parts bin By Nick Licata

By Nick Licata

CHEVY CONCEPTS

CHEVY CONCEPTS

Text and Rendering by Tavis Highlander

Text and Rendering by Tavis Highlander

aking a muscle car appear more modern is a delicate procedure. Change things too much and you end up with an abomination. If you don’t change enough you may have something too subtle for your liking. Murray Kustom Rods tasked me with riding that line with their 1970 Nova project. It had the great underpinnings already started with modern power and a Roadster Shop chassis. Tuning the overall look was going to be the trick.

We started by shaping a minimalist front bumper that still jives with the stock grille shell. Under that would be some 1969 Camaro-esque foglamps. A custom front spoiler finishes off the chin. Inside the grille is a custom hex-themed insert that is also mimicked on the rear taillight panel. The hood started as a desire to run a cowl induction unit, but that quickly morphed into a fabricated scoop that blends into the cowl. At the rear, a fabbed spoiler combines with an exhaust panel detail to give the area some interest. Front fender vents also help to break up the side profile a bit.

FEATURE

FEATURE

BY Shawn Brereton

BY Shawn Brereton  Photography by The Author

Photography by The Authorife often throws challenges our way. How you adjust to compensate for it could mean the difference between success and failure. Since the early ’80s, Jay and Erin Doleshale, of Bonner Springs, Kansas, traveled state-to-state racing Outlaw Pro Street drag bikes. Jay was creeping up on the 6s at over 200 mph (with no wheelie bars) when they lost their entire operation to a shop fire in 2013—talk about challenges! Luckily, no one was hurt but there was nothing left. Instead of rebuilding the decades-old operation, they decided to switch to four wheels so they could both have fun.

TECH

TECH Photography by The Author

Photography by The Author

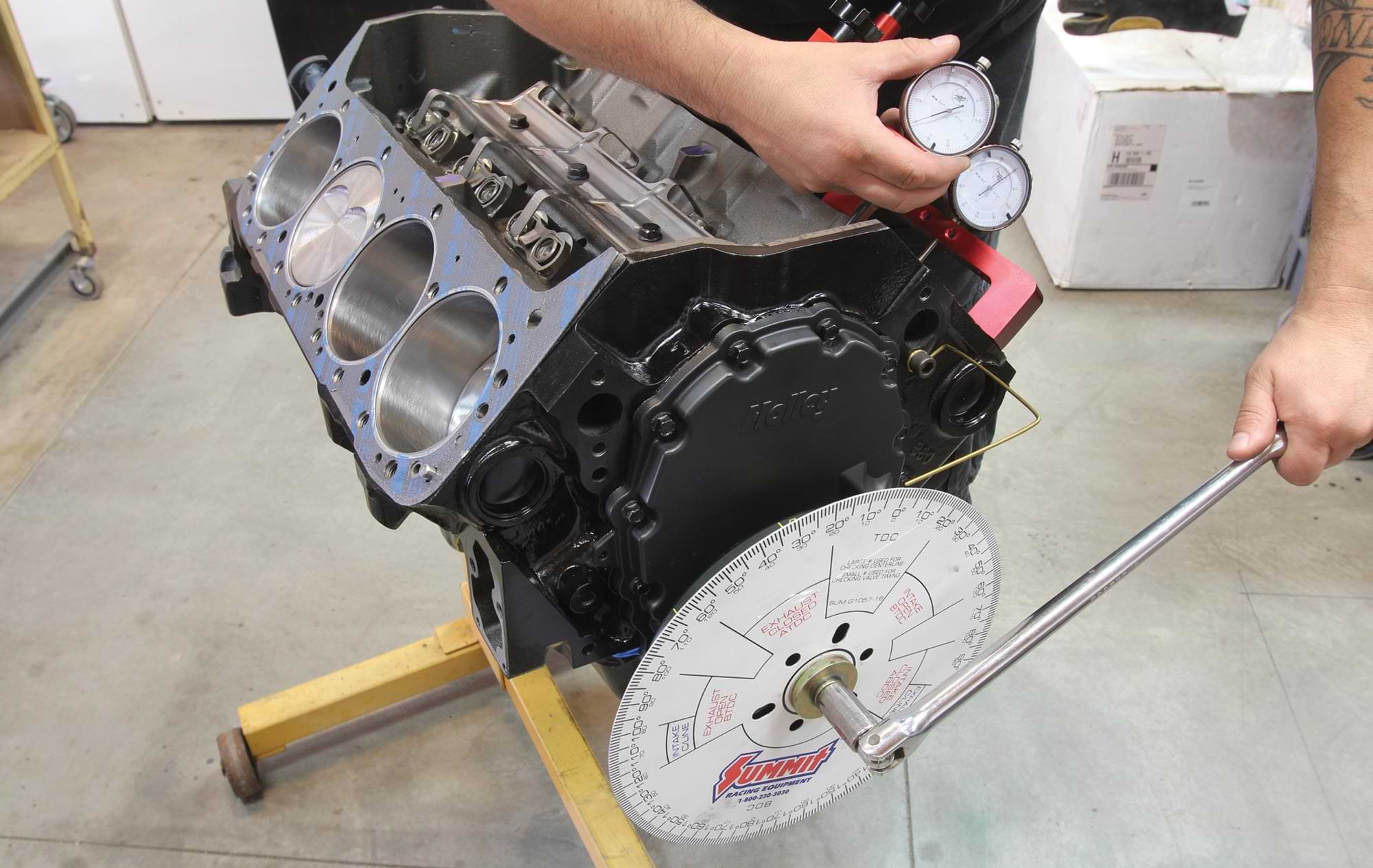

Degreeing a Camshaft and Deciphering Static Compression Ratio

hen it comes to installing a camshaft the operation is pretty straightforward: lube the lobes, slide it in the block, and install the timing chain set. But for those gearheads who might want to adjust the timing of the cam for a little more low-end grunt or to move the powerband up a few hundred rpm, there’s more to the simple stab-and-go approach. And even if you find yourselves, like us, not chasing that little bit of extra power but like the idea of double-checking that everything is as advertised, there lies more to a camshaft install than one might realize. This extra step is commonly known as “degreeing” the camshaft.

In layman’s terms, degreeing a camshaft is the simple operation of checking that the installed camshaft functions happen as specified on the cam card. Each and every camshaft is ground to achieve a certain event at a certain moment, so it’s important to ensure that those events happen when they’re supposed to after the camshaft and timing chain set are installed. This easy operation ensures that not only has the camshaft been manufactured according to the cam card’s specs, but also ensures that the engine builder didn’t make a mistake—a mistake that could possibly take out expensive components if installed incorrectly. By comparing the results from degreeing the camshaft with the cam card, we can verify that the valves will open and close when they’re supposed to and the lift and duration is as advertised.

FEATURE

FEATURE

Photography by Randy Pugh

Photography by Randy Pughhen it comes to building a classic hot rod you can pay a shop to do it all and have it done fairly quickly, or as in Mike Friend’s case with the build of his 1968 Camaro, you can take the ol’ “start ’n’ stop” route, which, unfortunately, adds a few more years to the build. It’s not ideal, and it wasn’t Mike’s initial plan, but that’s how it went down.

“I bought the car off an eBay auction about nine years ago from a guy in Detroit who claimed he was the second owner who purchased it from a guy in Bakersfield who claimed to be the original owner,” Mike states. “The shell was in good shape with little-to-no rust, although it needed a tail panel, doorskin, hood, and fender. Oh, and the engine, seats, and console were stolen when the shop doing the restoration got broken into.

TECH

TECH

Photography by The Author

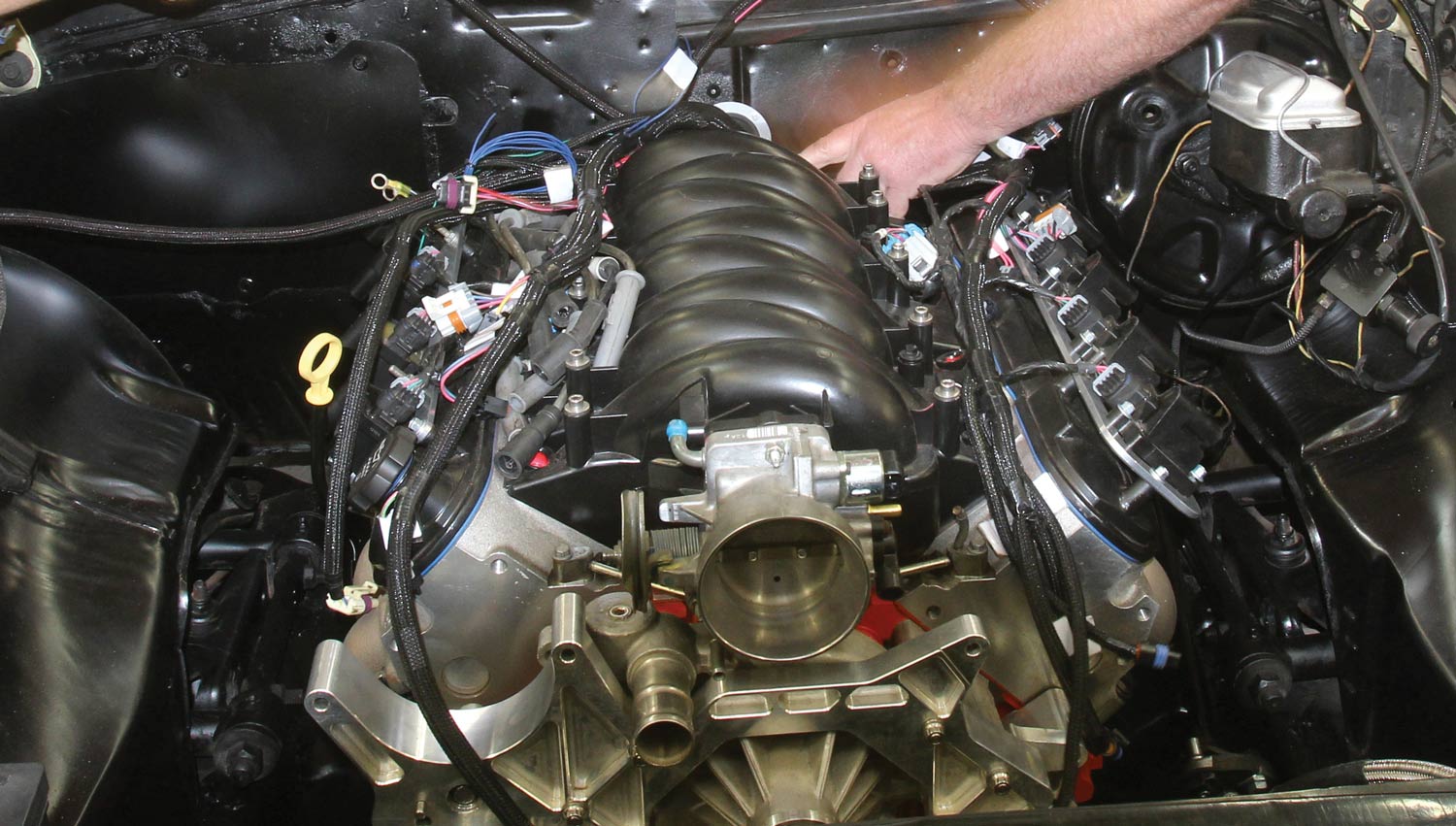

Photography by The Authorn LS swap into a Chevelle is not breaking news. In fact, it’s a nearly commonplace occurrence. Most media stories reveal just the main points and never the little details and information that make the swap a success. There are plenty of nuances to these swaps and after struggling through our fair share of these, we thought we’d share the little nuggets as well. For example, if you don’t choose the right oil pan, ground clearance will suffer, the pan will hit the crossmember or the steering linkage at full lock.

Our test mule is a somewhat out-of-the ordinary 1967 Custom 300 sedan that Eric Rosendahl purchased with a small-block 383 and a TREMEC five-speed. While he loved the car with its Hotchkis suspension, 17-inch wheels, four-wheel discs, and great paint, he envisioned a modern driveline with a much more tractable 5.7L LS and a 4L60E controlled with a factory ECU. The swap demanded quite a bit of time to execute correctly as the project ran into typical old car issues that added to the build time.

FEATURE

FEATURE

PHOTOGRAPHY BY Dominick Damato

PHOTOGRAPHY BY Dominick Damato

TECH

TECH

Photography by The Author

Photography by The Authorf you are familiar with NASCAR Cup engines, then you are likely aware that they have used their solid-gold R&D budgets to develop dry-sump oiling systems that use a multi-stage pump to do more than just move motor oil around. The engines are actually sealed tight, and the external oil pump also scavenges air along with oil to effectively pull a vacuum inside the crankcase.

Obviously they are doing that because it helps create horsepower. But the Cup system also comes with a lot of complexity and maintenance, and for hobby-level racers dry-sump oiling systems aren’t usually legal. The good news, however, is there is an option for those of us with cubic zirconia budgets that can get us close to the same result.

FEATURE

FEATURE

Photography by The Author

Photography by The Authorhe saying goes, “One man’s junk is another man’s treasure.” For ex-Sprint Car racer Shawn Rhyne of Marion, Arkansas, it took a little bit of time and trading to make the other man’s “junk” 1970 Camaro RS into a treasure, but he finally got there. The story is proof that persistence pays off.

Shawn was deep into Sprint Car racing—like over-his-head deep. He was pretty successful punching above his weight, racing on a shoestring budget around the South. However, it all changed in 2011. After spending his winnings refreshing the chassis in the offseason, he was taken out by another competitor in the first race, stuffing the car under a guardrail. With a family on the way and no money left in the bank after fixing the car, he made the tough decision to hang up his racing gloves.

Shawn grew up helping his dad, Mike, build hot rods and hoped to quench his thirst for speed on the street instead of dirt. Having trouble selling the Sprint Car, he traded it for a clean Harley-Davidson motorcycle, figuring it would be easier to sell. Shawn listed it for sale or trade on RacingJunk.com and was immediately contacted by Bryan Bruce of Georgia, who offered to trade his 1970 Camaro.

TECH

TECH Photography by The Author

Photography by The Authoror most performance fans, the 2020 Corvette is just about perfect. With tons of horsepower cranking out from the mid-engine 6.2L LT2 powerplant, big sticky tires at the four corners, and an interior right out of a SpaceX rocket, there’s no reason to change a thing, right?

As if that weren’t enough, J.R. applied some further power-adder madness, the kind of crazy “what if” thinking that has powered many of his high-powered creations around speedways like the Indianapolis Motor Speedway. Yep, J.R. decided to “poke the bear” and pulled out a Nitrous Express nitrous kit, forcing that highly explosive gas into the virgin engine’s cylinders just to see what it would do. But that’s just J.R. Granateltli, we were to learn.

TECH

TECH

Photography by The Author

Photography by The Authorodern technology has certainly crept into our world of hot rodding and performance. There are plenty of electronically controlled devices, from ignitions to gauges, transmissions, and, of course, fuel injection systems. In many cases, these make great updates to our Chevys, but sometimes keeping things simple is a welcome change.

One of the great debates over the last decade is that of going with modern EFI or sticking with the old technology of a carburetor. It seems that all the talk is about throttle bodies and port fuel injection these days, but we recently saw the updates Edelbrock made to their line of AVS series carburetors and we can tell you that the R&D on their tried-and-true carbs continues right alongside their EFI program.

They recently released the next generation of their carbs as the AVS 2 series, which has received a number of upgrades while keeping it affordable and easy to tune. In fact, they started with all-new tooling for the carb, which is cast and assembled in Sanford, North Carolina. You’ll quickly notice the details and crisp appearance of the fresh housing right away.

EVENT

EVENT

Photography BY The Author

Photography BY The Authorhere’s nothing better than the sound of a hopped-up Chevy mill, especially if it’s running a set of dual quads, a blower, or turbochargers. The sheer adrenalin rush of feeling the ground shake under your feet as your heart races lets you know all is well in the performance automotive world. With everything that’s passed in the last year it was a refreshing break to get back on the road and head off to a huge national event to hang out with like-minded car owners who were more than ready for a long-awaited horsepower fix. We topped off the tank and set our sights on New York to experience the 21st Annual NAPA Auto Parts Syracuse Nationals.

EVENTS

EVENTS

Photography BY The Author

Photography BY The Author

here’s nothing better than the sound of a hopped-up Chevy mill, especially if it’s running a set of dual quads, a blower, or turbochargers. The sheer adrenalin rush of feeling the ground shake under your feet as your heart races lets you know all is well in the performance automotive world. With everything that’s passed in the last year it was a refreshing break to get back on the road and head off to a huge national event to hang out with like-minded car owners who were more than ready for a long-awaited horsepower fix. We topped off the tank and set our sights on New York to experience the 21st Annual NAPA Auto Parts Syracuse Nationals.

Advertiser

- ACES Fuel Injection87

- American Autowire7

- American Legend Wheels71

- Art Morrison Enterprises39

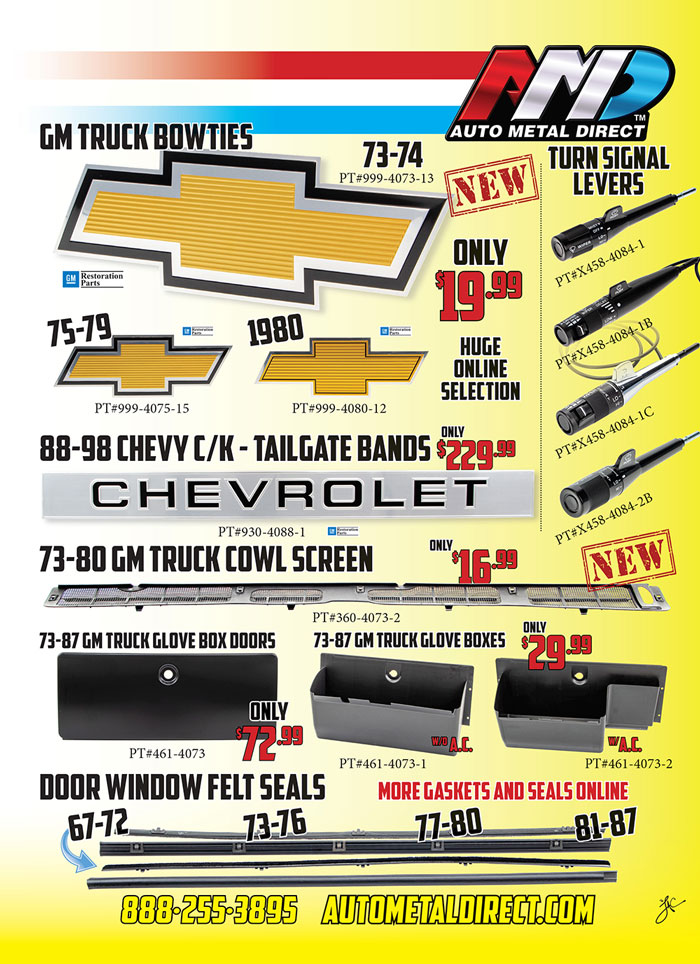

- Auto Metal Direct27

- Borgeson Universal Co.41

- Bowler Performance Transmissions77

- Classic Industries29

- Classic Instruments9

- Classic Performance Products4-5, 81, 92

- Concept One Pulley Systems87

- Dakota Digital91

- Danchuk USA11

- FiTech EFI65

- Gandrud Chevrolet87

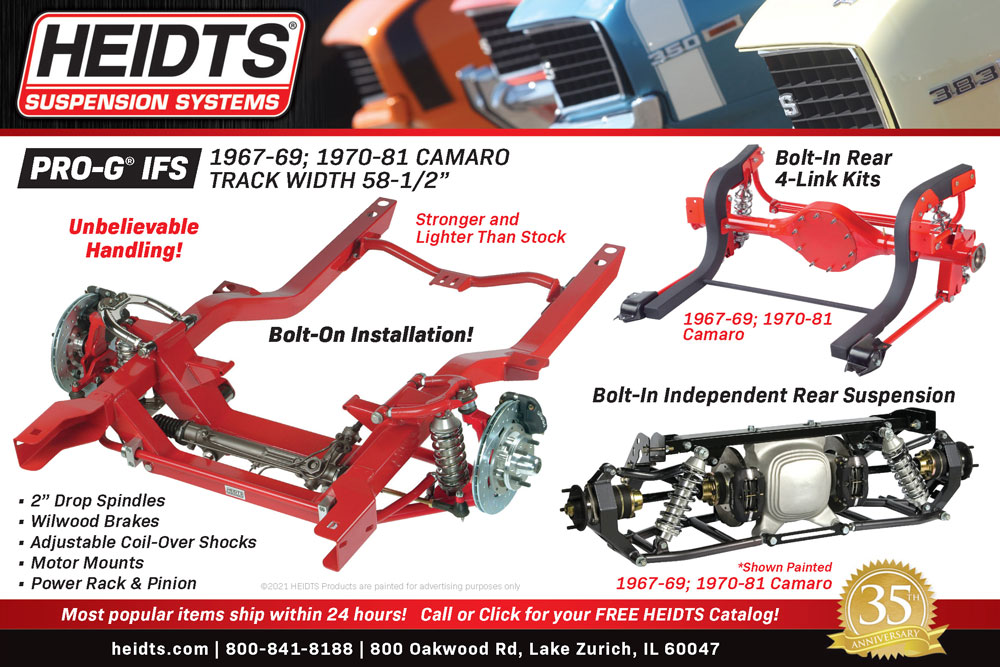

- Heidts Suspension Systems65

- HushMat81

- John’s Industries77

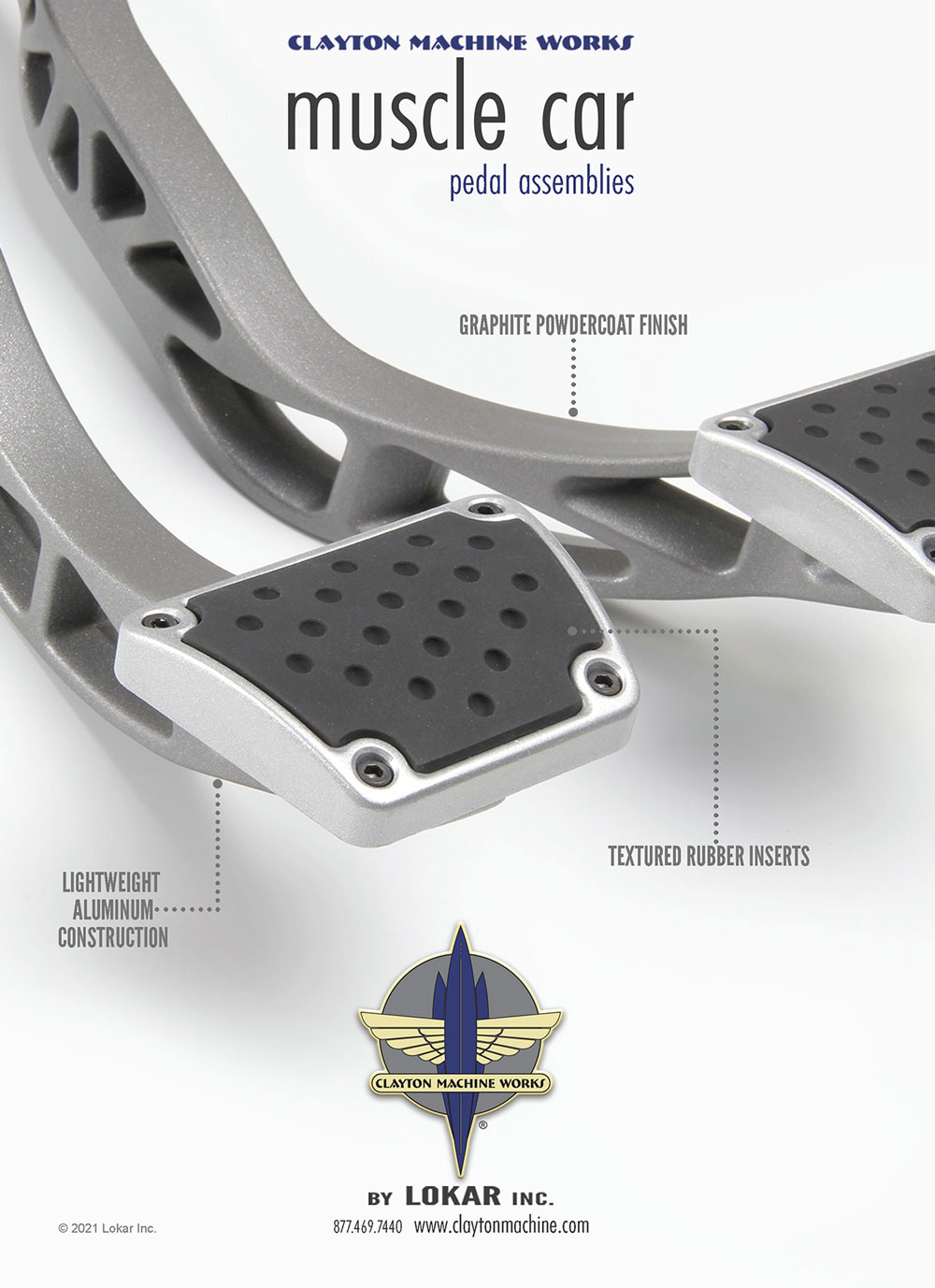

- Lokar2

- National Street Rod Association63

- Original Parts Group81

- Performance Online25

- Powermaster Performance73

- Roadster Shop13

- Scott’s Hotrods73

- SEMA53

- Speedway Motors57

- Steele Rubber Products55

- Tuff Stuff Performance Accessories71

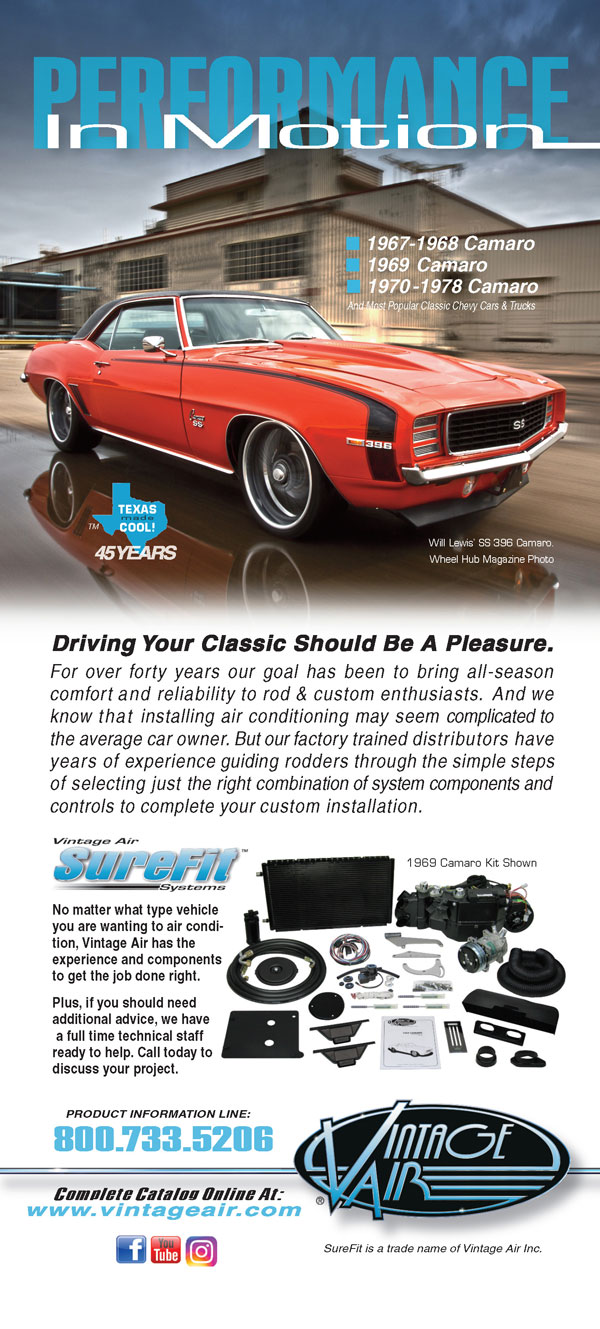

- Vintage Air6

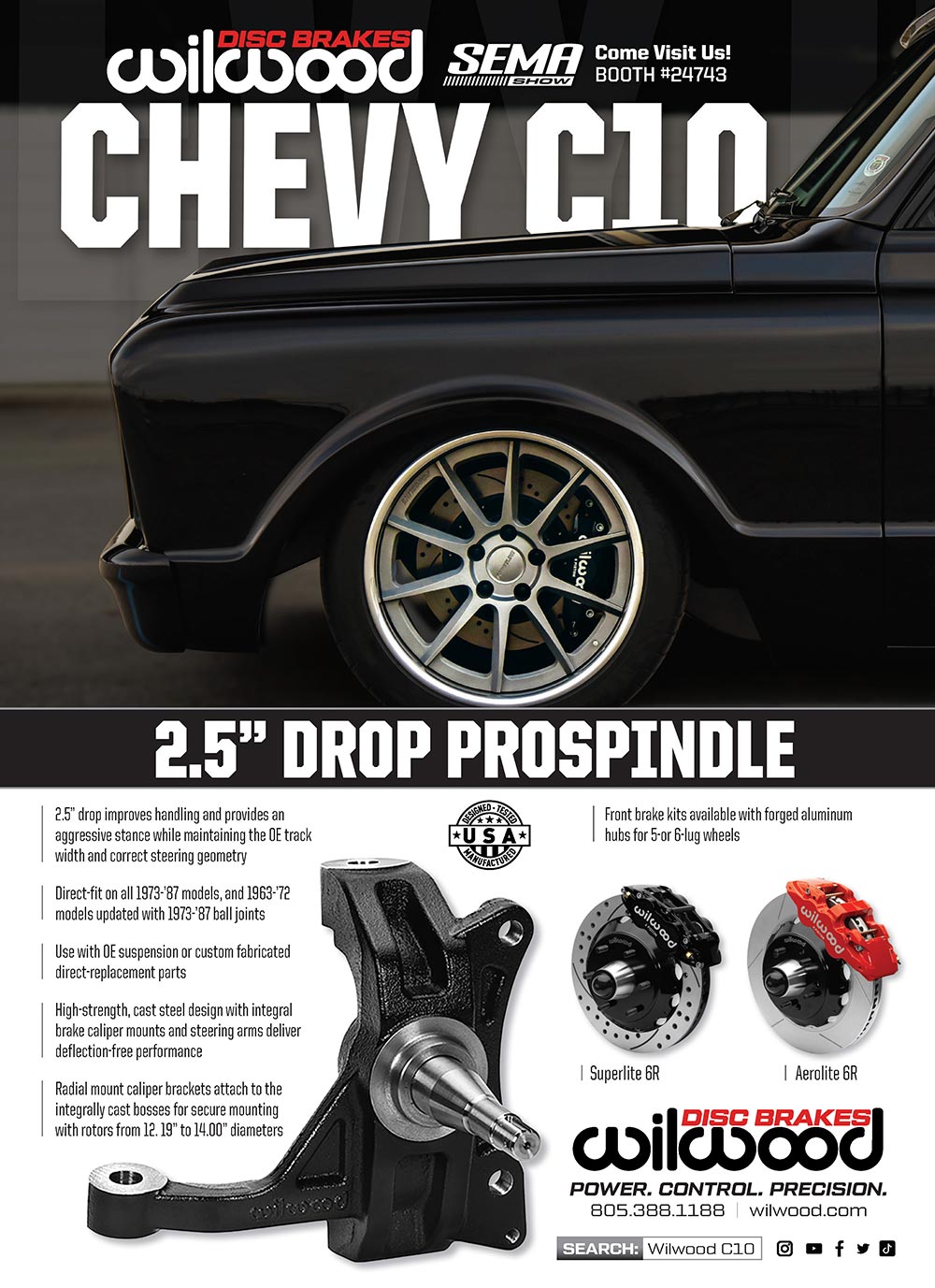

- Wilwood Engineering43

- Year One81

BOWTIE BONEYARD

BOWTIE BONEYARD

Photography by The Author

Photography by The Authorhe COVID-19 national lockdown of 2020 gave many of us a case of cabin fever–the feeling of being imprisoned in our otherwise-comfortable and happy homes. By staying out of circulation, we did our part to help squash the bug. But on occasion it was necessary to venture out into the world–preferably to sparsely populated locations where the risk of transmission was minimal. Such was the case one June afternoon in 2020 when we visited the quiet farming town of Charlemont, Massachusetts, and Clark’s Chevy Ranch.

Over a year has passed since these photos were taken, so enjoy this review of interesting Chevy relics that face their own special pandemic: rust. It’s true that rust never sleeps, but with the same spirit of human enterprise that so quickly conjured a COVID-19 remedy, any one of these vintage Bowties could be rescued.