FEATURE

FEATURE

BY Shawn Brereton

BY Shawn Brereton  Photography by The Author

Photography by The Authorife often throws challenges our way. How you adjust to compensate for it could mean the difference between success and failure. Since the early ’80s, Jay and Erin Doleshale, of Bonner Springs, Kansas, traveled state-to-state racing Outlaw Pro Street drag bikes. Jay was creeping up on the 6s at over 200 mph (with no wheelie bars) when they lost their entire operation to a shop fire in 2013—talk about challenges! Luckily, no one was hurt but there was nothing left. Instead of rebuilding the decades-old operation, they decided to switch to four wheels so they could both have fun.

Being a unibody car, CNA Performance started the back half from the firewall using round-tube chromoly. They kept it a stock-suspension-class car utilizing AFCO sliders on Smith Racecraft split monoleaf springs with adjustable mounting points in the front to alter ride height or pinion angle. Traction is controlled by Smith Racecraft Assassin traction bars and antiroll bar, dampened by AFCO double-adjustable shocks. The 3.25-geared rearend is a Ford 9-inch using a Strange Pro centersection, mini spool, and 35-spline axles.

CNA custom-built the chromoly 8.50-certified rollcage and front subframe outfitted with Speedway tubular A-arms, spindles, and rack-and-pinion steering to accommodate longer AFCO double-adjustable coilovers. Meanwhile, the braking system is an all-Wilwood affair with discs at all four corners. They sit behind Billet Specialties Comp 5 wheels mounted on 315/60R15 Mickey Thompson ET Street tires out back and 26×6 Sportsman S/R in the front.

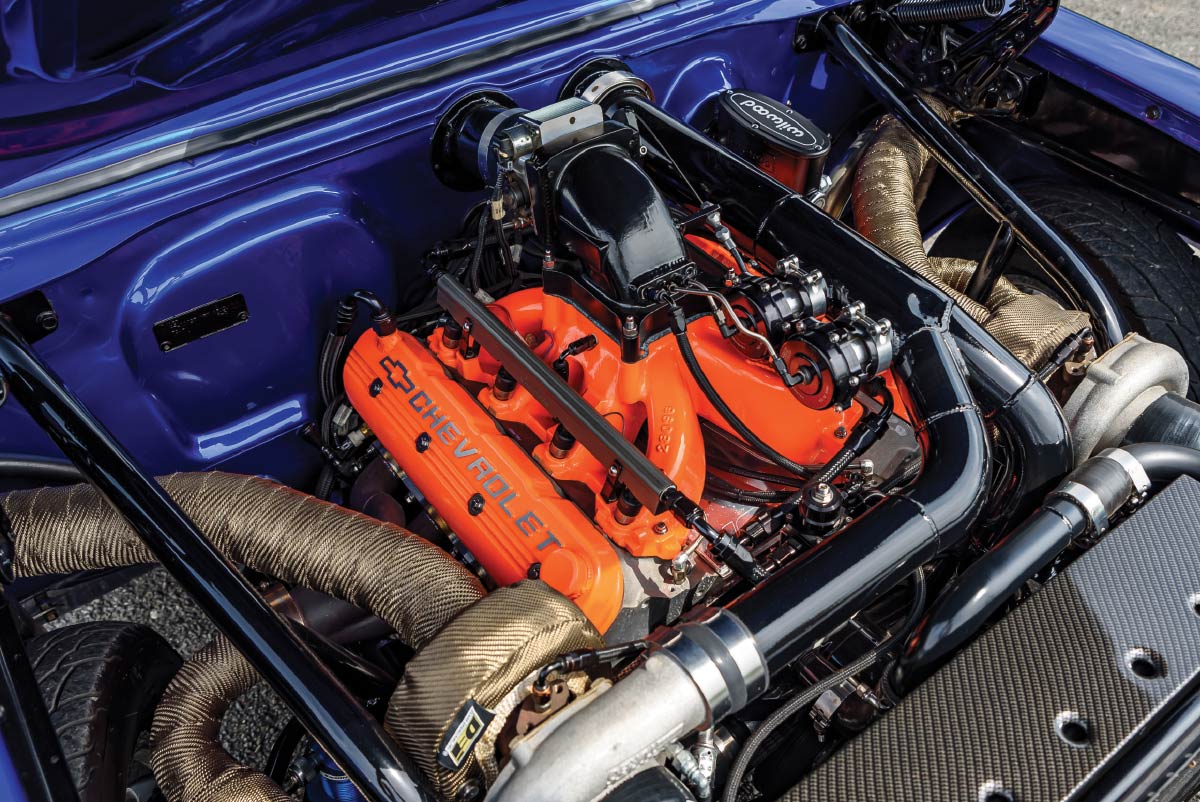

To run Drag Week these days the engine has to be very versatile. It must be civil enough to make the drive between races, yet outrageous enough to turn low e.t.’s. This car achieves it by using a Holley Dominator kit, a flex-fuel sensor, dual fuel tanks, twin turbos, and lots of cooling systems. CNA built two fuel tanks, one 12-gallon to run pump gas and one 5-gallon for race gas with two Aeromotive pumps per tank.

Air ingested through two 62/66 Precision turbos makes its way through piping inside the car to a liquid-to-air intercooler above the rearend plumbed to a heat exchanger with an electric fan and an ice tank that can be filled for quarter-mile passes. The cooled air travels back through the cabin into an Edelbrock Super Victor intake manifold where it meets fuel and spark supplied by the Holley Dominator kit. The mixture leaves in a hurry through the turbos and custom-fabbed exhaust piping by CNA. An aluminum radiator and Meziere water pump keep it all cool.

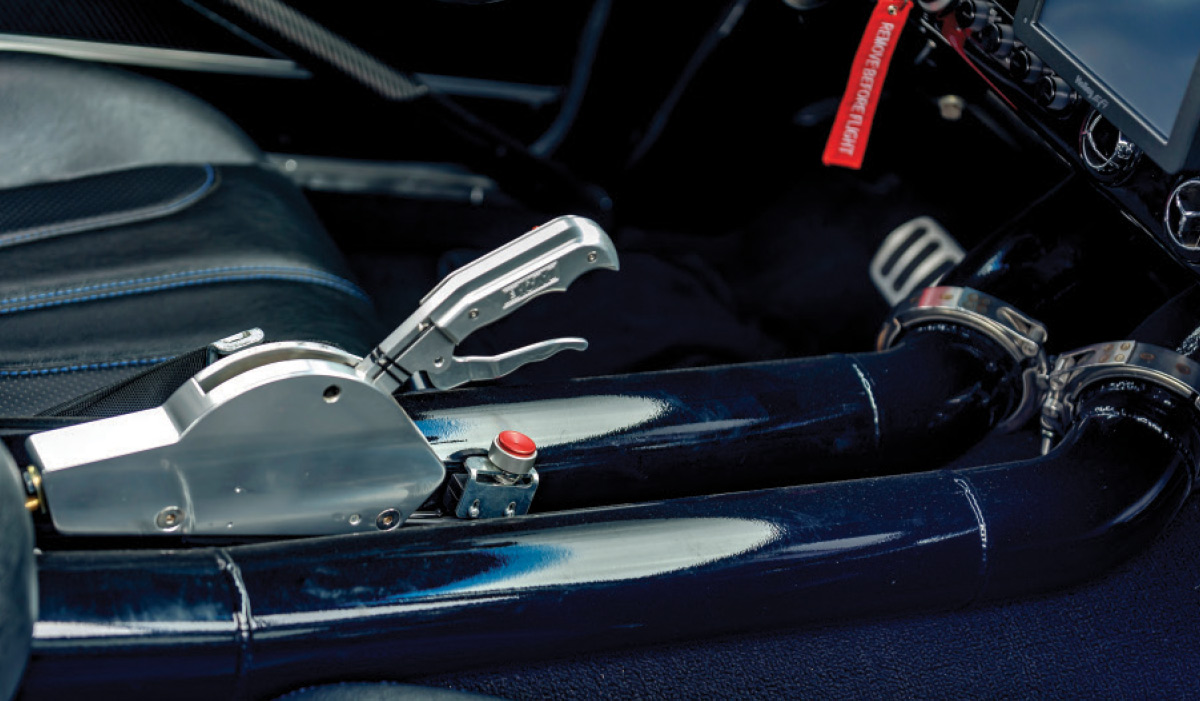

An Ultimate Converter Concepts 3,600-stall converter transfers power to a B&M-shifted Turbo 400 assembled by Edgar Transmission in Bonner Springs. A 4-inch aluminum driveshaft built by PSP connects it to the rear. Altogether, the setup is good for 1,200 hp at 7,000 rpm on race gas but it also gets 19 mpg on pump fuel!

Now it was time to put it all back together. Luckily, Jay found a wiring expert in Kevin Umshive who came to his shop to work his complicated magic. Umshive designed the wiring so almost everything runs off the glovebox-mounted Holley ECU—fans, water pump, fuel pumps, and so on—he even fabbed the horn to double as a bump box when the transbrake button is pushed. It’s crowded under the dash, but somehow, they found room for a Vintage Air system.

After five years in the making and finished in 2018, Jay and Erin are busy enjoying the fruit of all the labor, picking up a Goodguys Builder’s Choice award in Texas, a FAST award at NSRA Springfield, Best of Show at Street Car Takeover, and now a Best Engineered award where we found them at the Du Quoin Street Machine Nationals. But, now it’s time to see what it’ll do. Rocky Mountain Drag Week 2.0 in September is next on the list of achievements. With the owners’ racing pedigree, we’re sure it’ll turn heads for more than just its good looks.

Good luck, Doleshales!

Vehicle: 1967 Chevy II

Type: Chevrolet LM7

Displacement: 327 ci

Compression Ratio: 10:1

Bore: 3.810 inches

Stroke: 3.622 inches

Cylinder Heads: Chevrolet 799 hand-ported by Don Burlington

Rotating Assembly: GM crankshaft, Eagle H-beam connecting rods, and Diamond forged pistons with Hellfire rings; all ARP bolts or studs in the entire engine

Valvetrain: Stock GM with trunion upgrade, stainless intake, Inconel exhaust valves

Camshaft: Comp Cams hydraulic roller (0.600/0.605-inch lift, 227/231deg. duration at 0.050, 115-deg lobe separation angle)

Induction: Twin Precision 62/66 turbos, Holley Dominator ECU, 160-pound Holley injectors, Custom liquid-to-air intercooler with a heat exchanger for the water to go back through before going back into the water tank; Motion Raceworks CO2 wastegate kit (to control a boost curve programmed into the Holley Dominator)

Assembly: Liberty Machine and Hot Rod

Exhaust: Custom stainless headers, hot side, and stainless fender exhaust by CNA Performance

Ancillaries: Dual fuel system; two fuel tanks, one for pump gas or E85 second tank holds 5 gallons of race gas; each tank has two electric pumps controlled by a Holley Dominator; the car has two valves that control which tank the fuel is returned to; Motion Raceworks Flex fuel sensor; the Holley Dominator controls, electric water pump, electric cooling fan on radiator, fuel, timing, boost control, water pump for water-to-air intercooler, fan on heat exchanger for water coming from intercooler, transmission cooler fan, and four fuel pumps (two in pump gas tank and two in race fuel tank)

Output: 1,100 to 1,200 rwhp on Ignite Red 114/19 mpg on pump gas

Transmission: GM Turbo 400, Ultra bell housing, transbrake, Ultimate Converter Concepts 3600 converter; B&M shifter, PSP 4-inch driveshaft

Front Suspension: Custom built by CNA Performance with AFCO double-adjustable coilovers, Speedway tubular A-arms, and Speedway rack-and-pinion steering

Rear Suspension: Tube chassis from the firewall back, AFCO double-adjustable shocks, Smith Racecraft leaf springs, AFCO leaf spring sliders, Smith Racecraft Assassin traction bars, Smith Racecraft antiroll bar, leaf springs have adjustable mounting points to adjust ride height or pinion angle

Brakes: Four-wheel Wilwood disc brakes, Parachute

Wheels: Billet Specialties Comp 5 front 15×3.5, rear 15×12 double beadlock

Tires: Mickey Thompson Sportsman S/R front, 315/60R15 ET Street R rear

Upholstery: Black loop carpet, carbon-fiber wheeltubs, interior, door, and trunk panels

Seats: Hyundai Tiburon seats covered with Ultraleather, Stroud five-point harnesses

Steering: Speedway tilt steering column

Shifter: B&M Shifter on a custom mount

Dash: Stock instrument cluster with working fuel gauge, Holley 7-inch dash, MSD shift light

HVAC: Vintage Air

Rollcage: Full custom chromoly cage and chassis built by CNA Performance with NHRA 8.50 certification

Bodywork and Paint: Ken Ussery Custom Paint and Body

Paint: Ultra Sonic Blue 2.0/black

Hood: Steel with 2-inch cowl

Grille: Stock

Bumpers: Fiberglass front, GM rear; folding license plate with parachute mount behind plate