Are Those Old Rollers Gathering

Dust or Gaining Worth?

TOC

TOC

ROB MUNOZ

Wes Allison, Tommy Lee Byrd, Ron Ceridono, Grant Cox, Dominic Damato, John Drummond, Joe Greeves, Tavis Highlander, Jeff Huneycutt, Barry Kluczyk, Scotty Lachenauer, Jaon Lubken, Steve Magnante, Ryan Manson, Jason Matthew, Josh Mishler, Evan Perkins, Richard Prince, Todd Ryden, Jeff Smith, Tim Sutton, and Chuck Vranas – Writers and Photographers

Mark Dewey – National Sales Manager

Janeen Kirby – Sales Representative

Patrick Walsh – Sales Representative

Travis Weeks – Sales Representative

AllChevyPerformance.com

ClassicTruckPerformance.com

ModernRodding.com

InTheGarageMedia.com

subscriptions@inthegaragemedia.com

ads@inthegaragemedia.com

info@inthegaragemedia.com

The All Chevy Performance trademark is a registered trademark of In The Garage Media.

1350 E. Chapman Ave. #6650, Fullerton, CA 92834-6550.

FIRING UP

FIRING UP

Go This Direction

Go This Direction

BY NICK LICATA

BY NICK LICATAeing editor of a monthly automotive publication, my work consists of a constant process of trying to put together an editorial package that resonates with as many readers as possible, so it’s important to check the most number of boxes when deciding what material to include in the magazine. For example, doing an article on the basic inner workings of an engine will generate interest with the newer and less-versed readership but probably won’t pique the meter of those well-versed engine gurus, whereas doing a technical piece on using thinner piston rings for horsepower gains just might. Just like a basic bolt-on suspension article will be useful to someone just getting into handling aspects of their project, it might seem somewhat elementary to someone wanting to learn about the relationship between rebound and compression on their double-adjustable coilover shocks. And that same person may also want to know how adding 100-pound per inch higher spring rate to the front suspension will affect the car’s turn-in characteristics.

Being in the editor’s seat of this here magazine requires the inclusion of a wide variety of articles that readers find interesting and, most importantly, can actually learn something from. So, there’s a good chance you’ll see technical articles in these pages in which you are totally familiar with, and I really hope the subjects we cover can be applied to your current or future project.

On the car feature side, I appreciate the amazing work that the extremely talented builders are able to put into a super high-end build, while at the same time, I love what some guys are capable of achieving in their home garage with a small budget, a few friends, and a lot of determination. So, covering these two extreme car building styles enables us to provide a balanced editorial package that appeals to as many Chevy enthusiasts as possible.

Parts Bin

Parts Bin BY Nick Licata

BY Nick Licata

diameter valvesprings, and positive stop valve seals bring the vaunted camel hump heads into the 21st century.

CHEVY CONCEPTS

CHEVY CONCEPTS Text and Rendering by Tavis Highlander

Text and Rendering by Tavis Highlanderrind Hard Garage (GHG), out of Stuart, Florida, is putting together a 1969 Chevelle that is subtle all the while being somewhat wild. Some main specs on the car include a Roadster Shop chassis, Wilwood six-piston brakes, a 525hp LS engine backed by a 6L80, and a Performance Design carbon intake manifold. All of those items give the car a great foundation for handling and performance.

Sheetmetal fab is one place where GHG shines, and that talent will be put to use on a multitude of exterior items. Front and rear bumpers will be tucked and fitted, a custom front lip will be shaped from scratch, and the hood will feature stock shapes that are raised to clear the custom intake. The engine bay will also receive heavy shaping with a custom firewall, inner fenders, and core support.

The interior will be stock-ish with cleaned-up and refreshed lines inspired by the OEM design. Avant Garde will tackle the fabwork.

Text and Rendering by Tavis Highlander

Text and Rendering by Tavis Highlanderrind Hard Garage (GHG), out of Stuart, Florida, is putting together a 1969 Chevelle that is subtle all the while being somewhat wild. Some main specs on the car include a Roadster Shop chassis, Wilwood six-piston brakes, a 525hp LS engine backed by a 6L80, and a Performance Design carbon intake manifold. All of those items give the car a great foundation for handling and performance.

Sheetmetal fab is one place where GHG shines, and that talent will be put to use on a multitude of exterior items. Front and rear bumpers will be tucked and fitted, a custom front lip will be shaped from scratch, and the hood will feature stock shapes that are raised to clear the custom intake. The engine bay will also receive heavy shaping with a custom firewall, inner fenders, and core support.

The interior will be stock-ish with cleaned-up and refreshed lines inspired by the OEM design. Avant Garde will tackle the fabwork.

Feature

Feature

FEATURE OF THE MONTH SPONSORED BY OPTIMA BATTERIES

FEATURE OF THE MONTH SPONSORED BY OPTIMA BATTERIES

FEATURE OF THE MONTH SPONSORED BY OPTIMA BATTERIES

FEATURE OF THE MONTH SPONSORED BY OPTIMA BATTERIES Photos by Jason Matthew

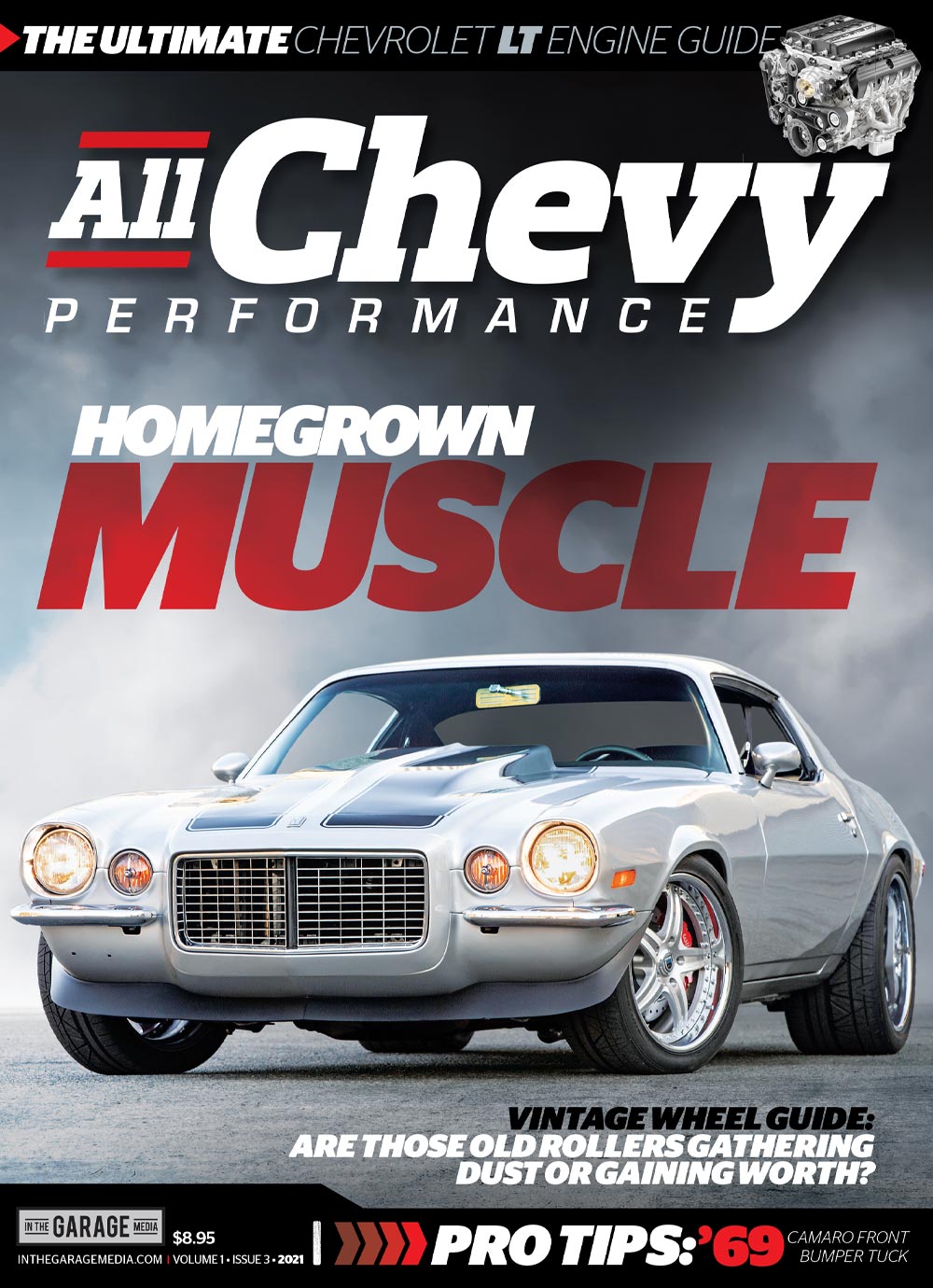

Photos by Jason Matthewany classic Chevy enthusiasts consider the 1969 Camaro the pinnacle of ’60s American muscle badassery. The body lines are sexy and timeless–the car looks fast even while sitting still and its willingness to accept aftermarket suspension systems and engine swaps make it that much more desirable. That’s all fine for most, but Rob Torres has always gravitated a little more toward the unique style of the 1970-1973 F-bodies. “A friend of mine, Franklin, had a 1969 Camaro, and he was the one who inspired me to buy this 1971,” Rob says.

As is the case with most projects, this one started with a good ol’ Internet search. “I was on a quest to find an early second-gen Camaro, and while cruising on craigslist.org I spotted this 1971,” Rob recalls. “The car was in Pennsylvania and after doing some research I found out it was originally from Arizona. The body was rust-free and in fair condition, so I offered the guy $7,000—$3,000 below his asking price.” The owner passed on that day’s offer, but Rob laid back—stayed cool—and thankfully the seller called the following day to accept Rob’s offer.

Tech

Tech

ard as it is to believe, the Gen V small-block—the “LT” family—has been in production for nearly a decade, after debuting in 2013 in the redesigned 2014 Silverado. Shortly after that came the LT1 versions in the C7 Corvette and Gen 6 Camaro.

The LT engine architecture has its roots in the LS family that established unprecedented performance benchmarks and reinvigorated hot rodding, with the same sort of fundamental shift that could be attributed to the original small-block. While there is a lineage from LS to LT, the two branches of the small-block tree are significantly varied.

There are essentially no interchangeable parts between the LS and LT families and all LT engines feature direct fuel injection. With the proliferation of LT engines increasing in production vehicles and as swap material for hot rods, trucks, and Pro Touring machines, it’s worth stepping back for a moment to survey the landscape to discuss the engines out there and where they fit in the LT hierarchy.

Feature

Feature Text and Photos by Scotty Lachenauer

Text and Photos by Scotty Lachenauer

ike Ingoglia had a good idea of what his son, Anthony, needed for his 16th birthday. You see, Dad had a long history with Chevy’s A-body, having owned several hot Chevelles since his youth. He figured the time had come for his progeny to experience the same exhilaration as he did back in the day, and Anthony couldn’t agree more with good ol’ pops. The youngster was ready to help build his own big-block–powered, backstreet bruiser to command the neighborhood streets.

Mike had recently become the proprietor of a spacious three-car garage, so now was the perfect time to hunt down a builder for his son. A steady search soon commenced and it didn’t take long before a needy 1972 Chevelle was spotted on the side of a local road with a For Sale sign stuffed in the passenger door window. This particular “ride in the raw” would become the basis for the Ingoglias’ Chevelle project.

Text and Photos by Scotty Lachenauer

Text and Photos by Scotty Lachenauer

ike Ingoglia had a good idea of what his son, Anthony, needed for his 16th birthday. You see, Dad had a long history with Chevy’s A-body, having owned several hot Chevelles since his youth. He figured the time had come for his progeny to experience the same exhilaration as he did back in the day, and Anthony couldn’t agree more with good ol’ pops. The youngster was ready to help build his own big-block–powered, backstreet bruiser to command the neighborhood streets.

Mike had recently become the proprietor of a spacious three-car garage, so now was the perfect time to hunt down a builder for his son. A steady search soon commenced and it didn’t take long before a needy 1972 Chevelle was spotted on the side of a local road with a For Sale sign stuffed in the passenger door window. This particular “ride in the raw” would become the basis for the Ingoglias’ Chevelle project.

Tech

Tech TEXT & PHOTOS BY Jason Lubken

TEXT & PHOTOS BY Jason Lubkenucking and flush mounting bumpers is a common modification at most pro-level fab shops. That’s not to say it’s unattainable on the average build. The aftermarket might be one option, but with the right guide you can’t beat the fit and finish of a DIY job.

We’re in Lincoln, Nebraska, catching up with the pros at No Coast Custom & Rod Shop. They let us take a peek at their custom 1969 Camaro project and shared a few tricks that would shed some light on any ambitious do-it-yourselfer. Lead fabricator Matt Gooder and owner Ben Vaneperen are always finding new ways to play with metal. They look for a clean aesthetic and love making subtle little tweaks. We dropped in just after they finished reworking the lower valance. You’ll notice those factory bumper mount windows have been filled. Here’s what they did.

A little side note: Before diving in, make sure the fenders, doors, and hood are in their final resting position. As with any fabrication work, build the foundation first and finish building out from there. The must-have tools: a welder, tape measure, your favorite hammer, and a metal saw blade of choice.

Feature

Feature

TEXT AND PHOTOS BY Richard Prince

TEXT AND PHOTOS BY Richard Princeark Anthony grew up in a family full of auto mechanics, so cars were an important part of his life from the beginning. He credits a neighbor, however, with his obsessive devotion to 1969 Camaros in particular. “I was in the driveway, working on my mini-bike, as usual, when a guy from around the block went past my house doing a wicked burnout with his 1969 Camaro race car. I was just a kid, but from that moment I was hooked!”

Back in 2009 a friend who knows about Mark’s love for 1969 Camaros turned him onto our feature car. “The original owner put it into a barn with only 27,000 miles on the clock,” Mark recalls, “and it sat there for more than 30 years. Unfortunately, it was directly beneath a hole in the roof, so it got very rusty, but it was a completely original RS still titled to the first owner, so I thought it was worth saving.”

Tech

Tech

TEXT & PHOTOS BY Chuck Vranas

TEXT & PHOTOS BY Chuck Vranasegardless what model of Chevrolet performance vehicle you drive, the main link to transferring its power resides in the back half of your ride. Once the goods move through your driveshaft, it’s all up to the rearend, suspension, and brakes to make the magic happen. The last thing you need is a weak link when you’re ready to hit the go pedal on the street or track. If you’re driving an original car or one restored to factory specs, its fine to rely on the setup that was engineered for the driveline combination as the car rolled off the production line. However, if you’re planning to up the ante in the horsepower department with more cubic inches, a supercharger, or even turbos, it’s best to map out a plan to handle the increase as it moves out back. It’s a formula that’s served hot rodders for decades where the front-to-rear performance balance needs to be rock solid.

TEXT & PHOTOS BY Chuck Vranas

TEXT & PHOTOS BY Chuck Vranasegardless what model of Chevrolet performance vehicle you drive, the main link to transferring its power resides in the back half of your ride. Once the goods move through your driveshaft, it’s all up to the rearend, suspension, and brakes to make the magic happen. The last thing you need is a weak link when you’re ready to hit the go pedal on the street or track. If you’re driving an original car or one restored to factory specs, its fine to rely on the setup that was engineered for the driveline combination as the car rolled off the production line. However, if you’re planning to up the ante in the horsepower department with more cubic inches, a supercharger, or even turbos, it’s best to map out a plan to handle the increase as it moves out back. It’s a formula that’s served hot rodders for decades where the front-to-rear performance balance needs to be rock solid.

Feature

Feature TEXT AND PHOTOS BY Chuck Vranas

TEXT AND PHOTOS BY Chuck Vranasaking on the full build of a performance car can guarantee you a ticket to an epic journey. It all starts with sourcing the bones and follows by filling in the chapters as you move toward completion. The wicked 1964 Chevelle Malibu laid out across these pages, owned by Chris Castro of North Reading, Massachusetts, started off as a restoration with a driveline upgrade that eventually altered its path.

Tech

Tech

TEXT & PHOTOS BY Tommy Lee Byrd

TEXT & PHOTOS BY Tommy Lee Byrdne of the easiest and earliest methods of automotive personalization comes in the form of tires and wheels. Aftermarket rolling stock originally offered a combination of upgraded strength, convenience, and appearance. The custom wheel industry kicked off in the racing world, but by the late ’60s, aftermarket wheels were commonly used as an upgrade for regular street cars. You could buy them through many mail-order companies, such as JC Whitney, or you could even buy them through major retailers, such as Sears, JCPenney, and more. As aftermarket wheels became more affordable, everything from Corvairs to Corvettes had many options for custom fitments. Dozens of brands gave customers a wide range of styles, finishes, and sizes to fit their needs.

We could write a book about the history of the aftermarket wheel and the major players in the industry, but the purpose of this article is to educate you on the various types of wheels that you may stumble across at a swap meet. While you may be fortunate enough to find some cool Halibrand wheels, or magnesium American’s at a swap meet, you’ll likely be met with a gigantic price tag. These wheels are like gold to old-school drag racers and hot rodders. You may also find that front runners (wheels that measure 3 to 5 inches in width) bring more than the more common 6-, 7- and 8-inch-wide sizes. It’s easy to get a little too excited by the high prices on eBay or at swap meets, so control your spending habits and do your homework before you unload a bunch of cash on a set of wheels.

There are lots of important factors to remember when searching a swap meet for vintage wheels. The obvious things, like size and bolt pattern, can be checked with a pocket-sized tape measure, so don’t leave home without one. Always check the condition of the wheel thoroughly, but understand that you’re taking a gamble when buying vintage wheels. There could be hidden damage, such as bends or cracks in the material. You’re dealing with fatigued metals that could be upwards of 60 years old, so be prepared for potential heartache if your wheels end up as garage decoration. On the bright side, the perfect set of legit vintage wheels can take your old-school muscle car to the next level. Let’s dig into the fun of scrounging around at a swap meet, and take a look at some great vintage wheels that may be awesome additions to your project car or parts collection.

ftermarket racing wheels can be traced all the way back to the 1900s, but things really got serious in the ’40s and ’50s. Originally, all-steel racing wheels took the place of wooden-spoke wheels to provide better strength and handling. Then, racers wanted strength without the extreme weight. Magnesium was the material of choice for lightweight racing wheels, dating back as early as 1946 when Ted Halibrand debuted his special 18-inch racing wheels designed for Indy racing.

Halibrand Engineering Company built wheels primarily for Indy racing throughout the rest of the ’40s and into the ’50s. Racers began using the Indy-style wheels for other types of machines, including salt flat racing and drag racing. As drag racing got more serious in the late ’50s, purpose-built magnesium wheels hit the market. The biggest difference in an IndyCar wheel and a drag racing wheel was how it attached to the car: IndyCar wheels attached using six pins and a knock-off hub assembly, while most drag racing wheels attached using conventional 5-lug bolt patterns. It was also somewhat common to see 6- or even 8-lug magnesium wheels for drag cars to match the heavy-duty truck axles that were used in the early days.

While Ted Halibrand’s company led the way in magnesium wheel offerings, a fellow by the name of Romeo Palamides came onto the scene during the ’50s. He built a pair of magnesium rear wheels for his personal dragster, which graced the cover of Hot Rod magazine in 1956. The enormous amount of feedback he received about his custom rear wheels sparked a new business, which would later be named American Racing Equipment. A few years into his endeavor, Palamides’ wheel offerings consisted of a four-window rear wheel (known as a Standard) and a 12-spoke spindle-mount front wheel. A stroke of genius came around 1960 when American Racing Equipment debuted its Torq-Thrust wheel, a design that would become an industry icon.

Originally produced exclusively in magnesium, the Torq-Thrust wheel eventually transitioned in the aluminum construction and instantly became an affordable custom option for muscle cars and hot rods. This would send a ripple throughout the wheel industry, as many high-performance wheels made the switch from magnesium to aluminum construction. Magnesium had inherent issues with corrosion, as even highly polished wheels would quickly turn back to the original gray finish. Aluminum wheels, even if left completely raw, would keep a good shine, which appealed to hot rodders and muscle car owners. By this point, the term “mag wheel” had already stuck, so even though many aftermarket wheels are constructed with aluminum, steel, or the combination of the two metals, they’re still referred to as “mag wheels.”

Cragar was another big player in the aftermarket wheel industry. The Super Sport (S/S) wheel took the world by storm in 1964, with a timeless five-spoke design with a combination of a steel hoop and a cast centersection. Cragar S/S wheels were affordable and plentiful, and they ended up on countless drag cars, street machines, and even daily drivers. While they provided little in the way of performance gains, the Cragar S/S holds a special place in the custom wheel timeline, and you can still buy them to this day.

Tech

Tech PHOTOS BY Gary Kollofski, Dale Pelvit, AND THE AUTHOR

PHOTOS BY Gary Kollofski, Dale Pelvit, AND THE AUTHOR ave you ever played the cylinders game with your car buddies? It counts and includes all functioning cylinders residing in your garage. One word of caution. Don’t play this game with Gary Kollofski if his 1957 Chevy is in the vicinity.

Kollofski is a fan of big cubic inches. But his predilections do not fall within the normal confines of stroker big-block Chevys or even tall-deck monsters that Pro Mod and tractor pullers have made famous. Kollofski has always followed a different alchemist’s path. If his name sounds familiar and you were reading car magazines in 1977 you might remember his bad-to-the-bone black 1955 Chevy that graced the pages of Hot Rod magazine. Many consider that car as among the progenitors of the Pro Street movement. Others remain simply awed by its sinister appearance that, had it survived, would still draw crowds today.

So, after building another 1955 Chevy a few years ago using an obscure Italian marine V-12, Kollofski and coconspirator/fabricator Dale Pelvit tumbled upon a plan that fully intended to raise the high-water mark for outrageousness. The dictionary positions that word as somewhere between startlingly bad and very unusual. Kollofski and Pelvit call it the W24.

Bowtie Boneyard

Bowtie Boneyard

TEXT & PHOTOS BY Steve Magnante

TEXT & PHOTOS BY Steve Magnanten this month’s installment of Bowtie Boneyard we’re at Bernardston Auto Wrecking in Bernardston, Massachusetts (413/648-9300), checking out a couple of relics from the past. As always, we cranked up our powers of observation and discovered an uncommon manual transmission–equipped Camaro and the skeleton of a Chevy legend.

Advertiser

- Aldan American75

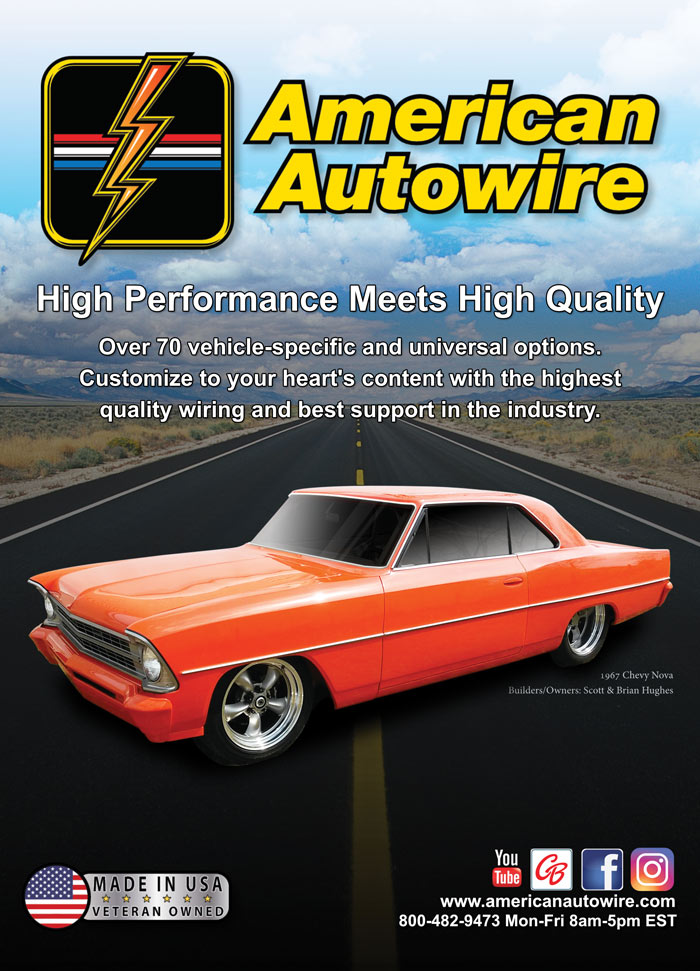

- American Autowire61

- American Legend Wheels81

- Art Morrison Enterprises37

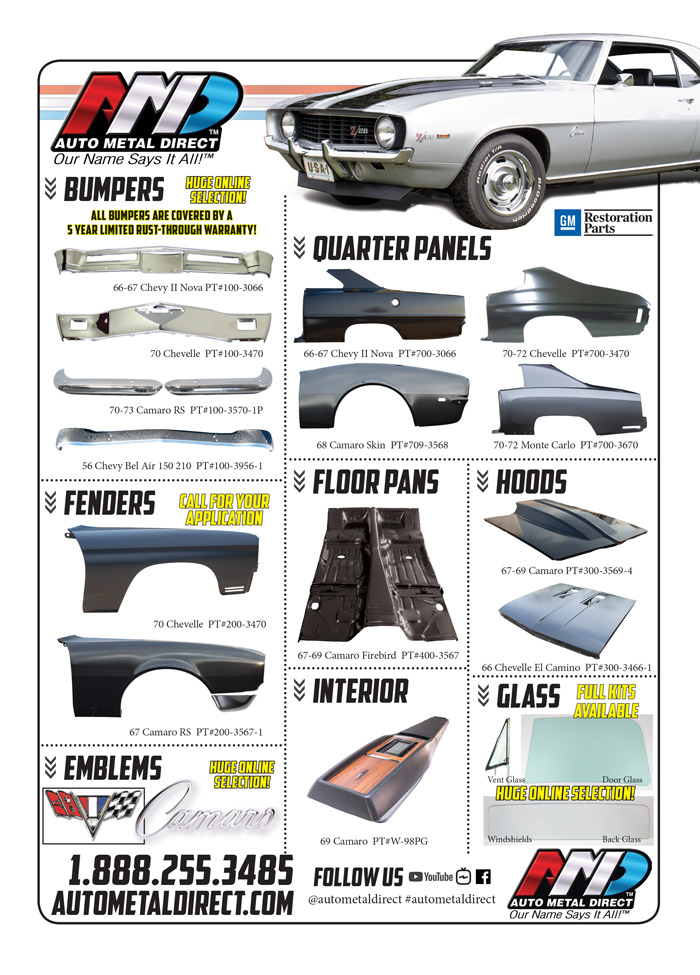

- Auto Metal Direct59

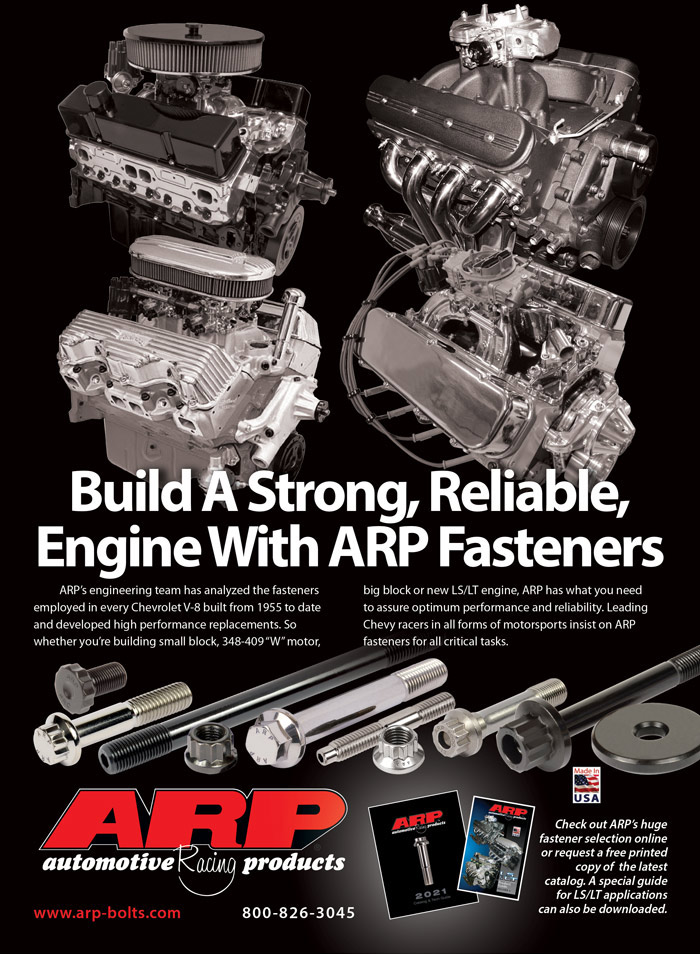

- Automotive Racing Products39

- AutoZone29

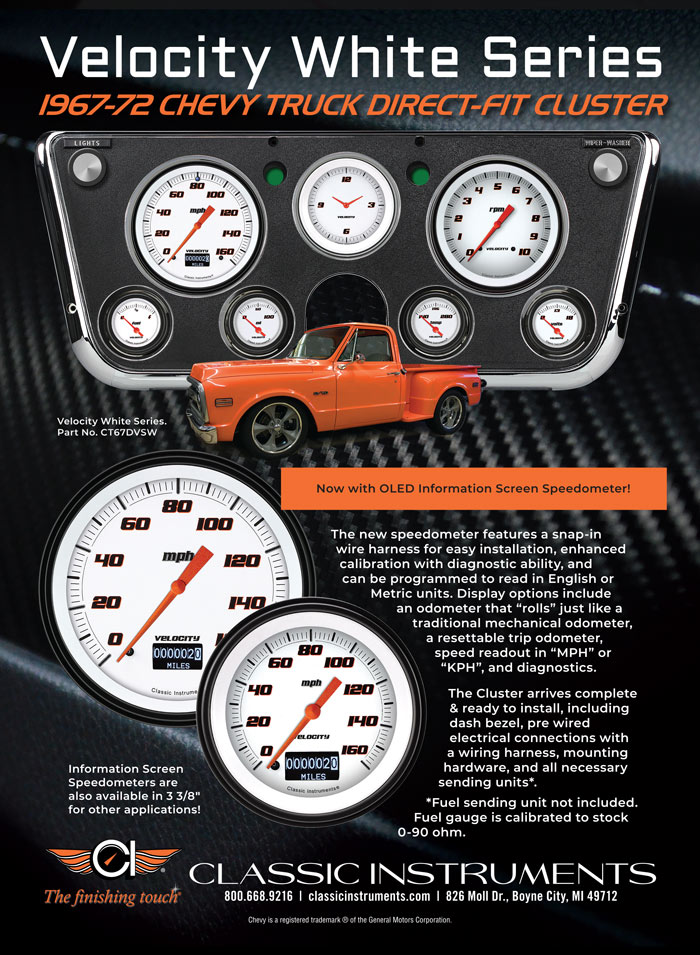

- Classic Instruments9

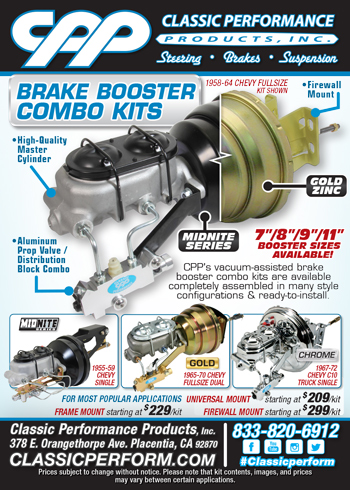

- Classic Performance Products4-5, 85, 92

- Dakota Digital91

- Danchuk USA11

- Dart Machinery85

- Eddie Motorsports71

- FiTech EFI73

- Flaming River31

- Gandrud Chevrolet85

- Golden Star Classic Auto Parts7

- Granatelli Motor Sports, Inc.83

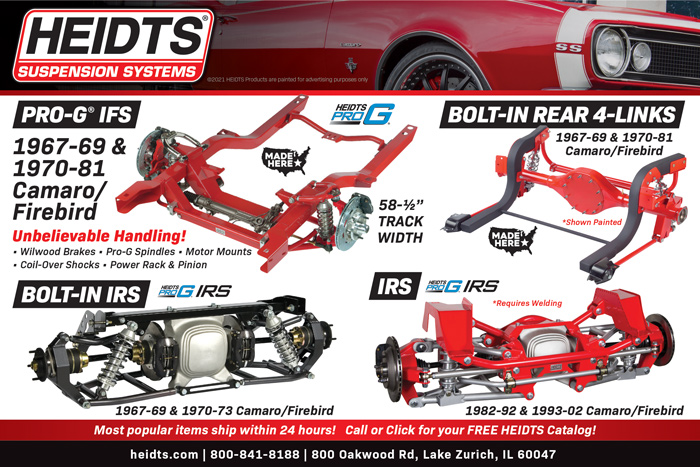

- Heidts Suspension Systems75

- Lokar2

- New Port Engineering89

- Performance Online45

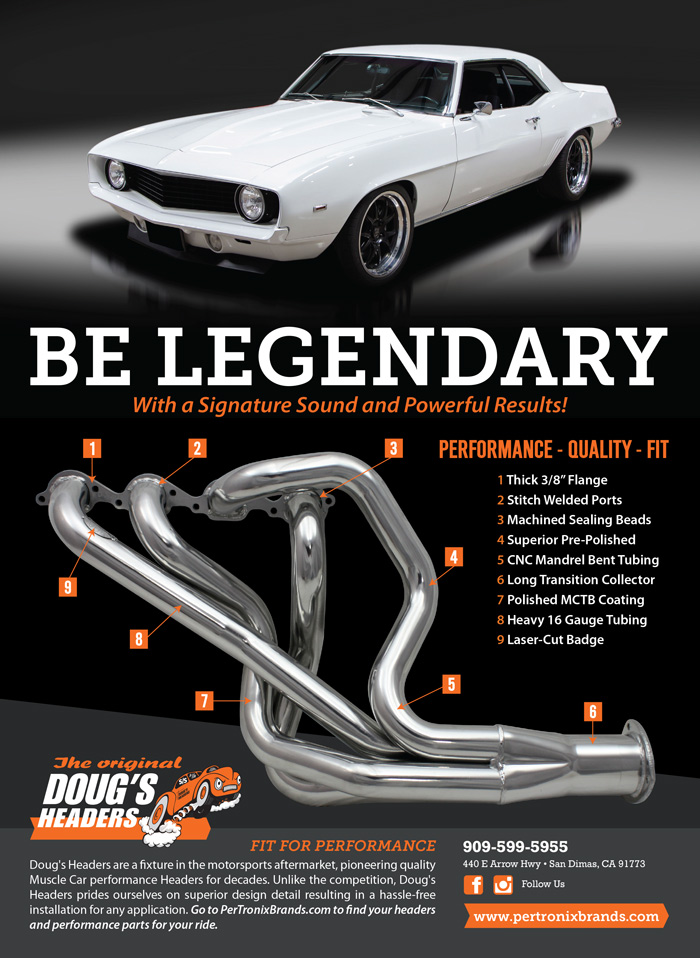

- PerTronix43

- Roadster Shop67

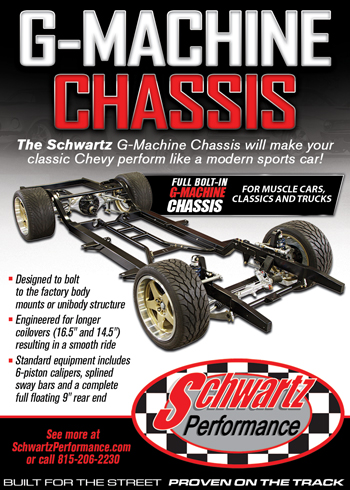

- Schwartz Performance89

- Scott’s Hotrods83

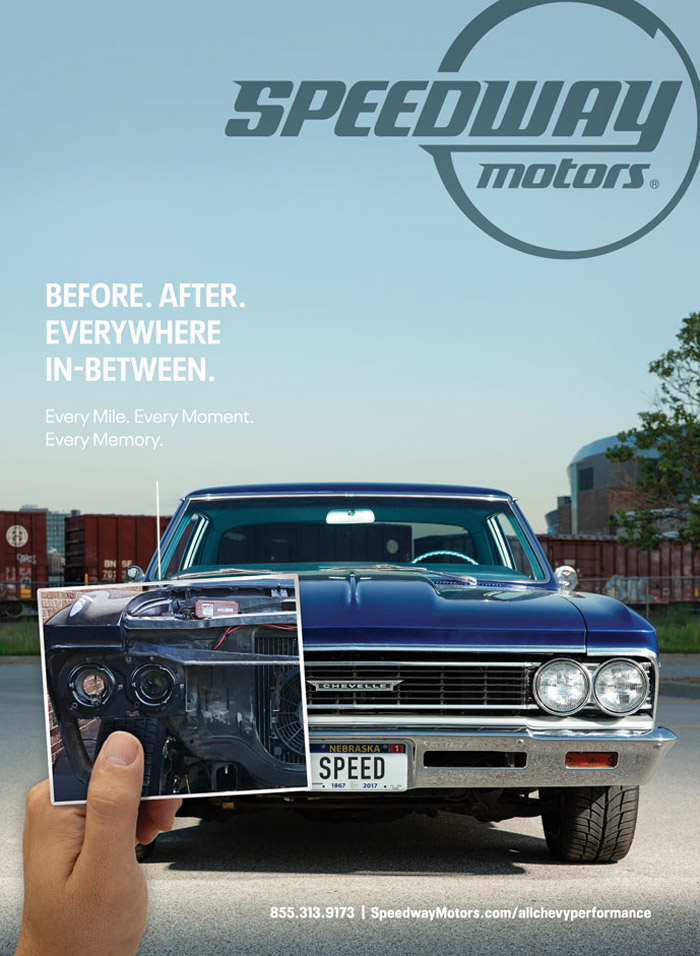

- Speedway Motors13

- Strange Engineering81

- Vintage Air6

- Wilwood Engineering47

- Year One85

Instagram:

Instagram: