FEATURE

FEATURE

Photography by the Author

ood things come to those who wait. This is true for those who try to build a car themselves. Everything seems to get in the way of completing the project, and the next thing you know 20 years have come and gone. It’s why so many people give up on the dream of building a hot rod.

Brian Raymond, of Union, Missouri, is a lifelong car guy who played this game for more than 26 years with this ’69 Camaro. His father fixed and restored vehicles for side money. Though he died when Brian was just a high school freshman, he bequeathed his passion for the automotive hobby to a very willing and capable young lad.

Brian didn’t take the gift for granted and enrolled in auto shop classes. “It’s all I ever wanted to do,” he says. “I learned everything I could, so I could do it all myself instead of paying someone else to do it.” After graduation, he found a job at Wally Elder’s Custom Auto Works, acquiring the Camaro in 1995 for $1,400. But money was tight, so the car sat patiently waiting.

Brian’s vision for the car was a high-horsepower street car that would feel at home on the track Saturday night or the ice cream shop on Sunday. He notched the frame to fit the 315 radials and strengthened it with extra crossbracing. He modified a Jerry Bickel 10-point cage with double framerail–style center bars running to a dash bar and lower door bars welded behind the rockers. He added half of a Funny Car ’cage and made the upper door bars and harness bar removable for easier access to the back seat.

Vehicle: ’69 Chevrolet Camaro

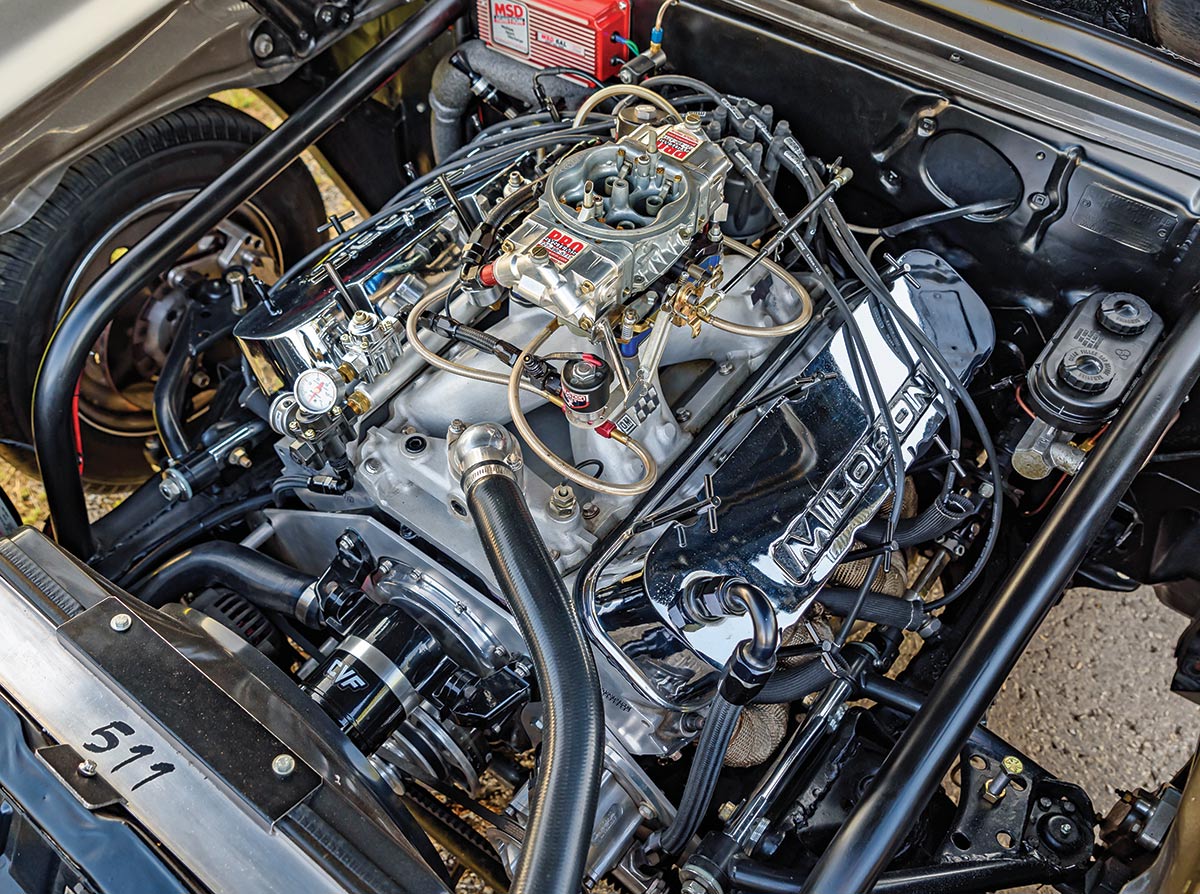

Type: ’69 Chevy 10.2-inch tall-deck dump truck

Displacement: 511 ci

Compression Ratio: 10.5:1

Bore: 4.312 inches

Stroke: 4.375 inches

Cylinder Heads: Chevrolet Performance “572” ported

Rotating Assembly: Ohio Crankshaft 4340, Molnar Rods, RaceTech Pistons, King Race Bearings, Total Seal Rings

Valvetrain: Stock 2.25/1.88 springs spec’d by Chris Straub, 572 rockers

Camshaft: Custom Straub Technologies hydraulic roller (0.731/0.714-inch lift, 272/274 deg. duration at 0.050)

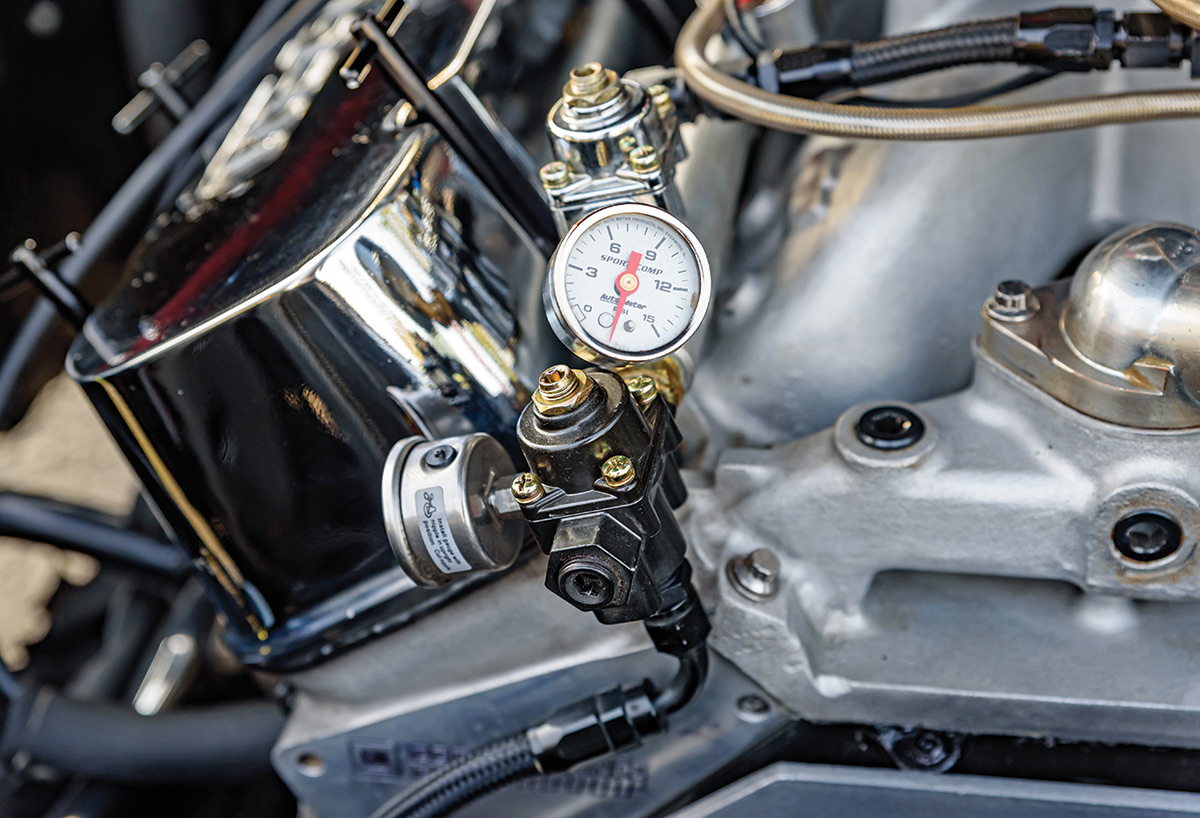

Induction: Chevrolet Performance 572/620 4150 manifold with Steve Johnson Induction Solutions 4150 Sledgehammer nitrous plate, Pro Systems 1,000-cfm 4150 carb

Assembly: Chris Caulkins (St. Clair, MO)

Exhaust: Hooker Super Comp 2⅛-inch primaries to 3.5-inch collectors, 3-inch single-chamber Flowmaster mufflers

Ancillaries: MSD 6 ignition, Griffin radiator, CVF water pump, Flex-A-Lite Black Magic X-treme electric fan, Aerospace Components vacuum pump

NA Output: 733.7 hp at 6,300 rpm, 661.4 lb-ft at 5,200 rpm

Nitrous Output: 916.3 hp at 6,300 rpm, 871.1 lb-ft at 5,000 rpm

Transmission: Powerglide

Torque Converter: Old Fairbanks Gold series, 3,400 stall

Rear Axle: Ford 9-inch with Quick Performance aluminum through-bolt center, 3.70:1 ratio, 33-spline Moser axles

Front Suspension: Auto City Classic factory-style tubular A-arms; QA1 GS401 single-adjustable dampers

Rear Suspension: 32-inch Chassis Engineering ladder bars and diagonal link, Tim McAmis antiroll bar, Strange double-adjustable coilovers

Brakes: Speedway disc on rear, Aerospace Components four-piston disc on front; 11.75 vented rotors; Strange master cylinder

Wheels: Weld Drag Lites: 15×4 front, 15×10 rear

Tires: Nexen (front) 165/80R15; Mickey Thompson ET Street R (rear) 315/65R15

Upholstery: Black loop carpet

Seats: Jaz Racing front, stock rear

Steering: Stock column with quick-release adaptor and Grant carbon-fiber wrapped wheel

Shifter: B&M Pro Ratchet

Dash: Stock with molded ABS dash insert

Instrumentation: Auto Meter

HVAC: Stock AstroVentilation

Rollcage: Custom-modified 4130/mild steel 10-point Jerry Bickel Race Cars Funny Car

Bodywork & Paint: Owner and Wally Elder of Custom Auto Works (Dittmer, MO)

Paint: Kirker Paint, medium charcoal gray metallic/Hot Rod Black satin stripes

Hood/Fenders/Trunk/Bumpers: Glasstek Fiberglass

Spoiler: Custom-made with drilled air slots

The front end uses factory-style tubular A-arms, 2-inch drop spindles, a pinto manual rack, and QA1 single-adjustable coilovers. Aerospace Components four-piston brakes connect to a Strange master cylinder. Weld Drag Lites sit on all four corners: 165/80R15 Nexen tires on the front and 315/65R15 (3.5-inch backspace) with Mickey Thompson ET Street R tires on the rear.

Remembering a short-block combination from the old PAW catalogs, Brian chose a ’69 10.2-inch, tall-deck dump truck engine displacing 511 ci. Chris Caulkins of St. Clair, Missouri, did the machining and assembly using all the best internals. The combo looks mean just sitting in the engine bay with a Pro Systems 1,000-cfm carb, Sledgehammer nitrous plate, and Chevrolet Performance manifold and 572 heads topped with some late-’80s Milodon valve covers.

Despite not being a “car girl” before she met Brian, Jenn played instrumental parts in some critical aspects of the build. After changing his mind “50 times in 20 years,” Brian settled on Candy Tangerine Orange for the color. Jenn asked him one question: “Do you want it to look pretty at the car show from across the field, or do you want it to look BADASS driving down the road?” Just like that, it changed to Medium Charcoal Gray Metallic from Kirker Paint expertly laid down by Wally Elder at Custom Auto Works.

The Hot Rod Black Satin stripes were Brian’s creation. He figured he’d never own a Yenko or a true Z/28, so why not just combine them. Brian was looking for a name to put where “Yenko” would usually go but was having trouble coming up with a name. Again, Jenn saved the day when the word “obnoxious” popped out of her mouth after her maiden voyage—and the ’69 had a new moniker!

“When I got it, I was just a kid,” Brian says. “I never thought I would be married, pushing 50 with kids, before I drove it. Jenn saw the car on our second date, and she got her first ride after 16 years of marriage.” However, Brian is ecstatic about the way “OBNOXIOUS” turned out and is happy he got to make memories with his own son. Isn’t that what hot rodding is all about?