TECH

TECH Photography by The Author

Photography by The Author

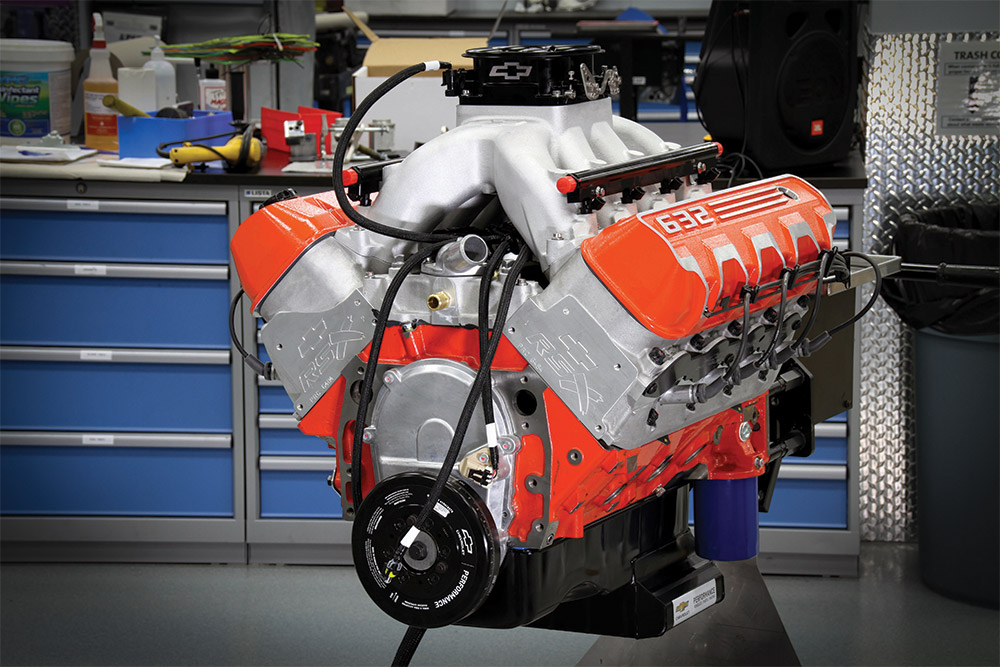

hevrolet Performance’s all-new ZZ632 crate engine is simply the biggest, baddest, and most powerful big-block ever from Chevrolet. It’s rated at a stunning 1,004 hp and 860 lb-ft of torque—with Pro Stock–inspired spread-port cylinder heads and other modern technologies that enable that incredible performance on 93-octane pump gas.

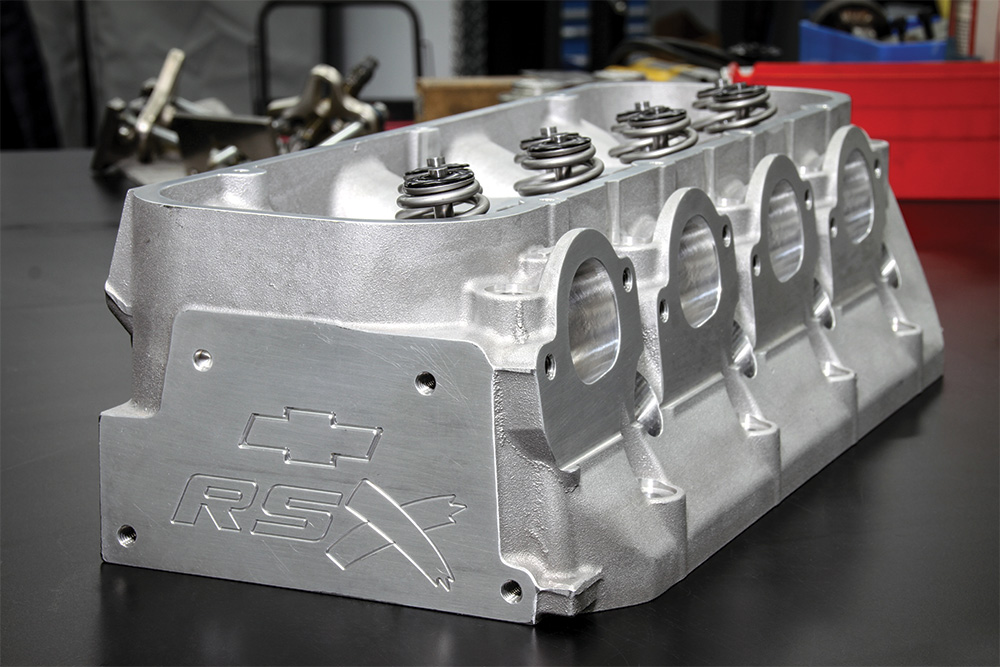

In fact, the ZZ632 is designed for dual-purpose performance. Electronic fuel injection, advanced ignition technology, and a carefully developed hydraulic roller camshaft profile contribute to a unique balance of great driveability on the boulevard, while the all-new RSX spread-port cylinder heads—named for Chevrolet Performance engineer Ron Sperry, who helped develop Chevrolet racing engines—support amazing high-rpm capability on the dragstrip.

“We challenged ourselves to take big-block street performance to the next level and 1,000 hp on pump gas was it,” Alin Dragoiu, Chevrolet’s design release engineer for the engine, says. “The ZZ632 has dual capabilities, but it was first and foremost designed as a street engine, so we had to balance maximum power with idle quality and other such considerations.”

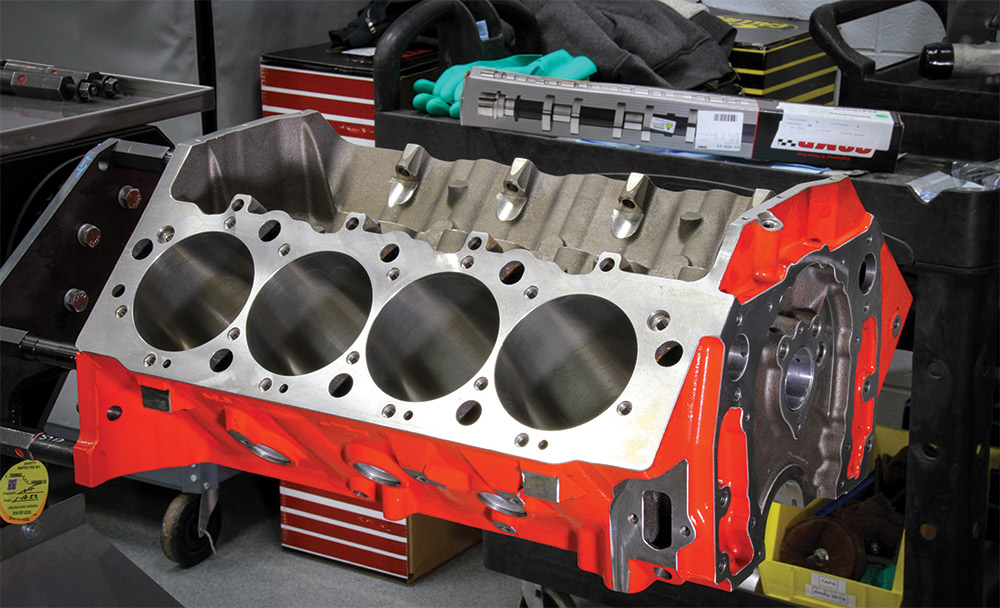

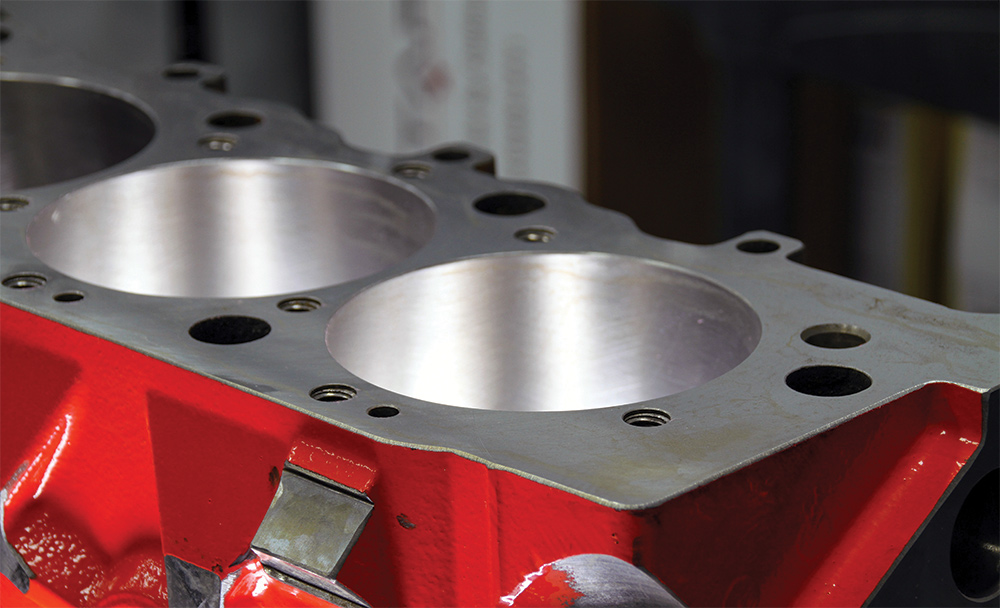

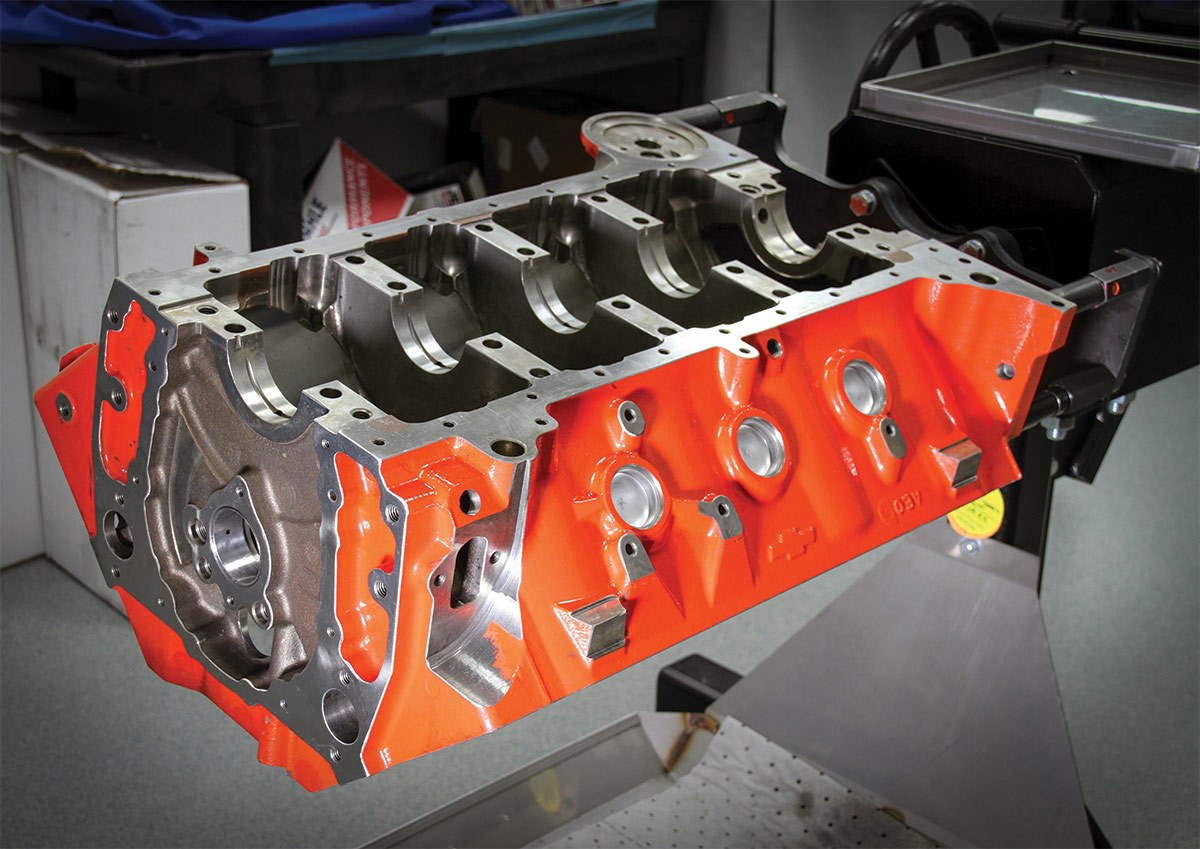

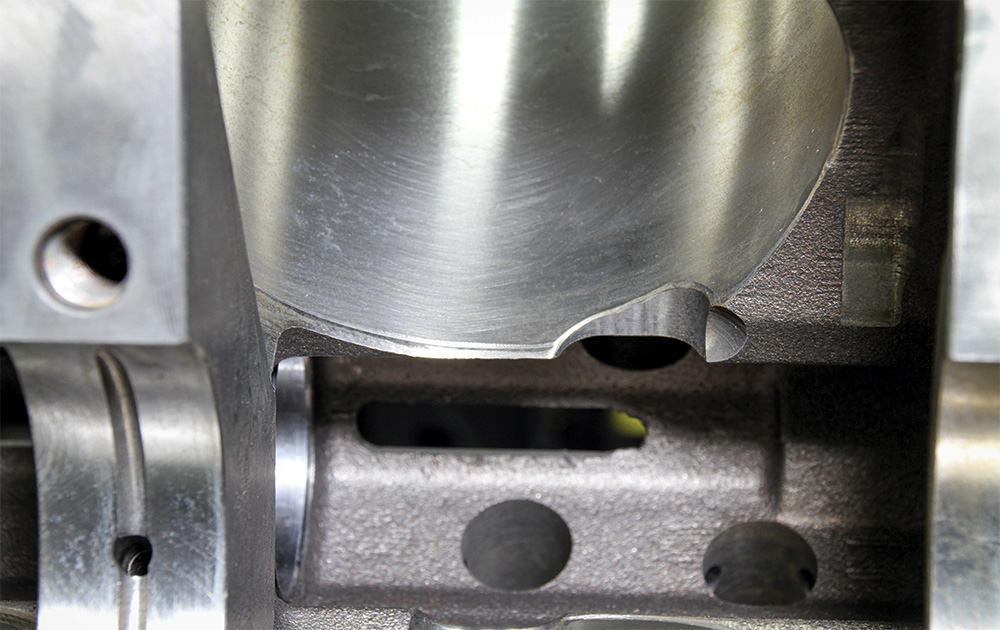

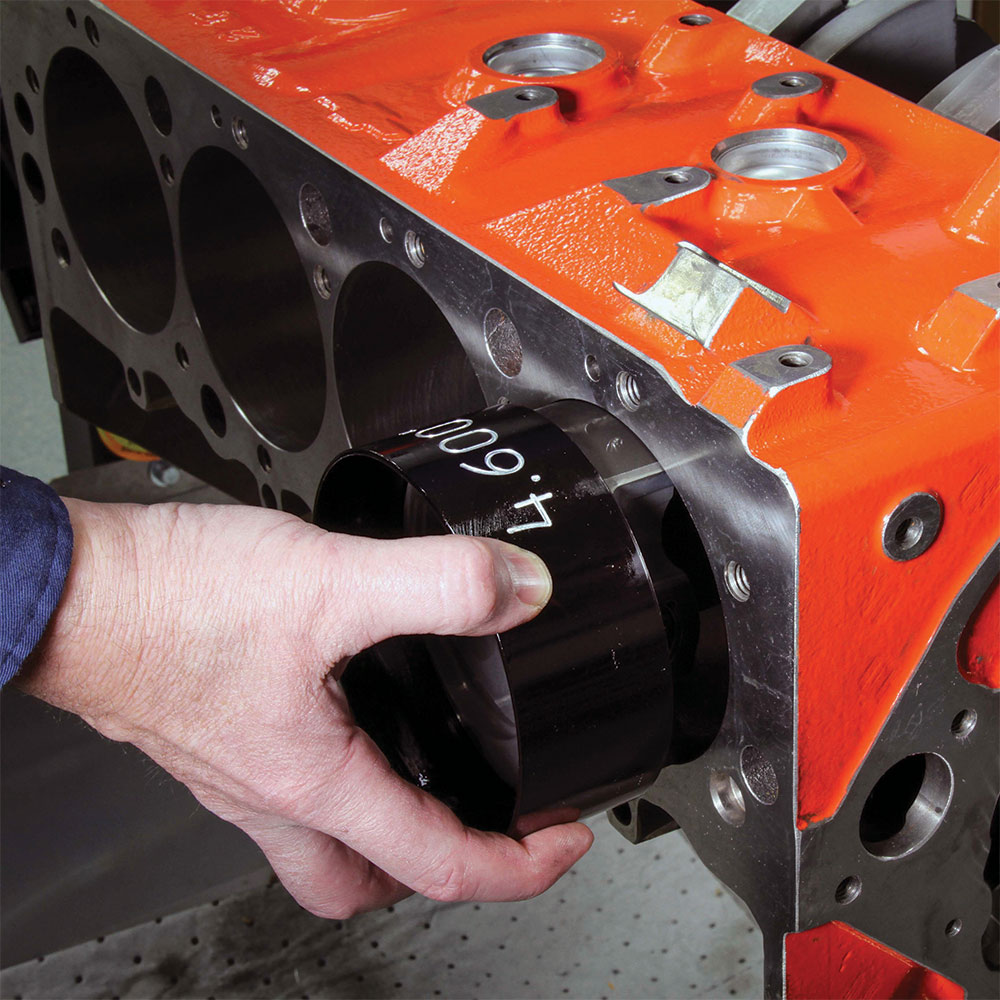

- A Sportsman tall-deck cylinder block with huge 4.600-inch bores

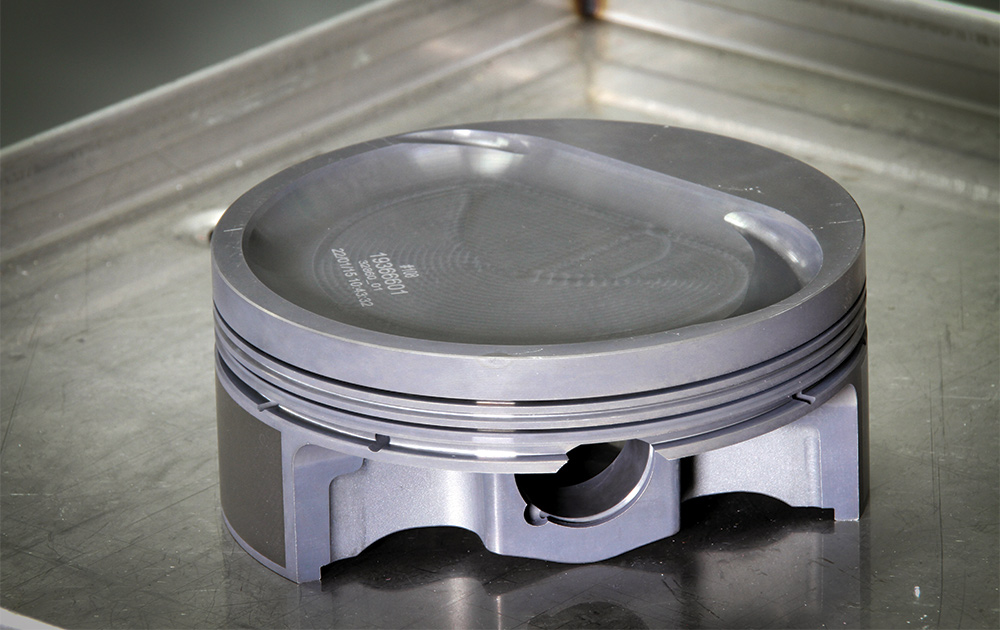

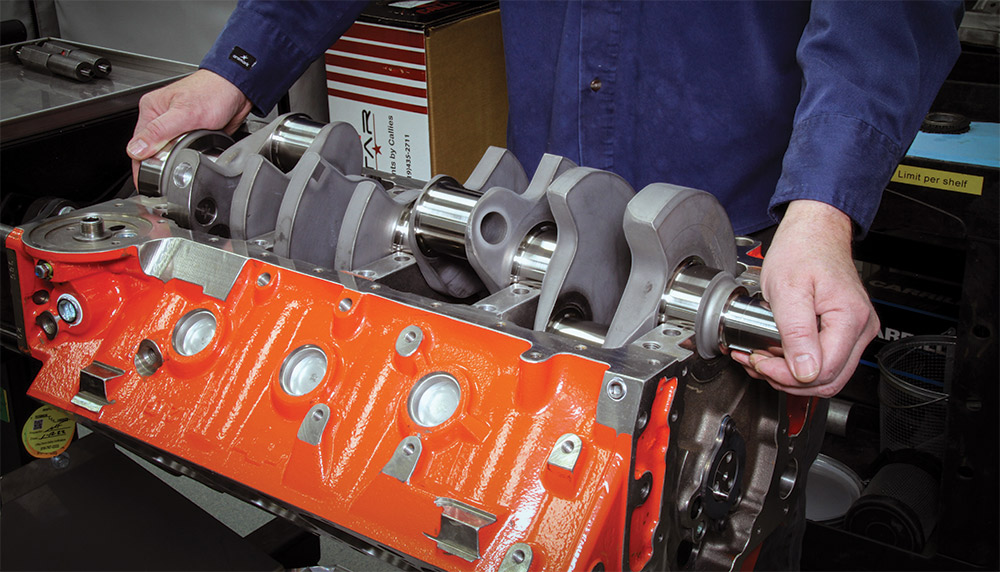

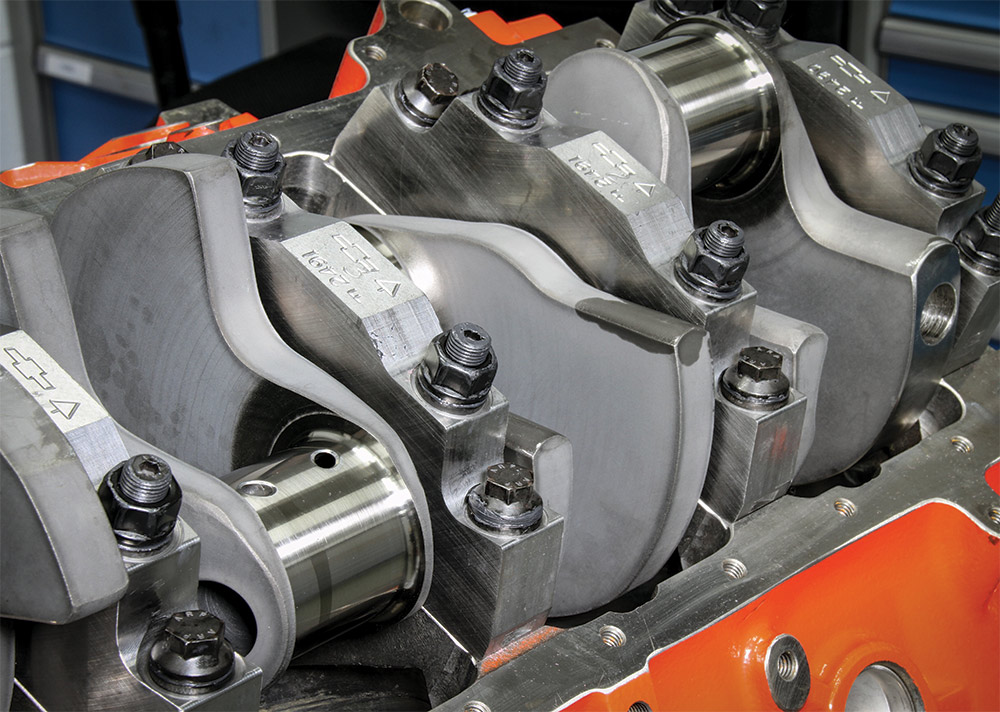

- An all-forged rotating assembly, including a 4340-forged crankshaft with a long 4.750-inch stroke

- A 12:1 compression ratio

- Electronic port fuel injection with a throttle body mounted on a high-rise intake manifold

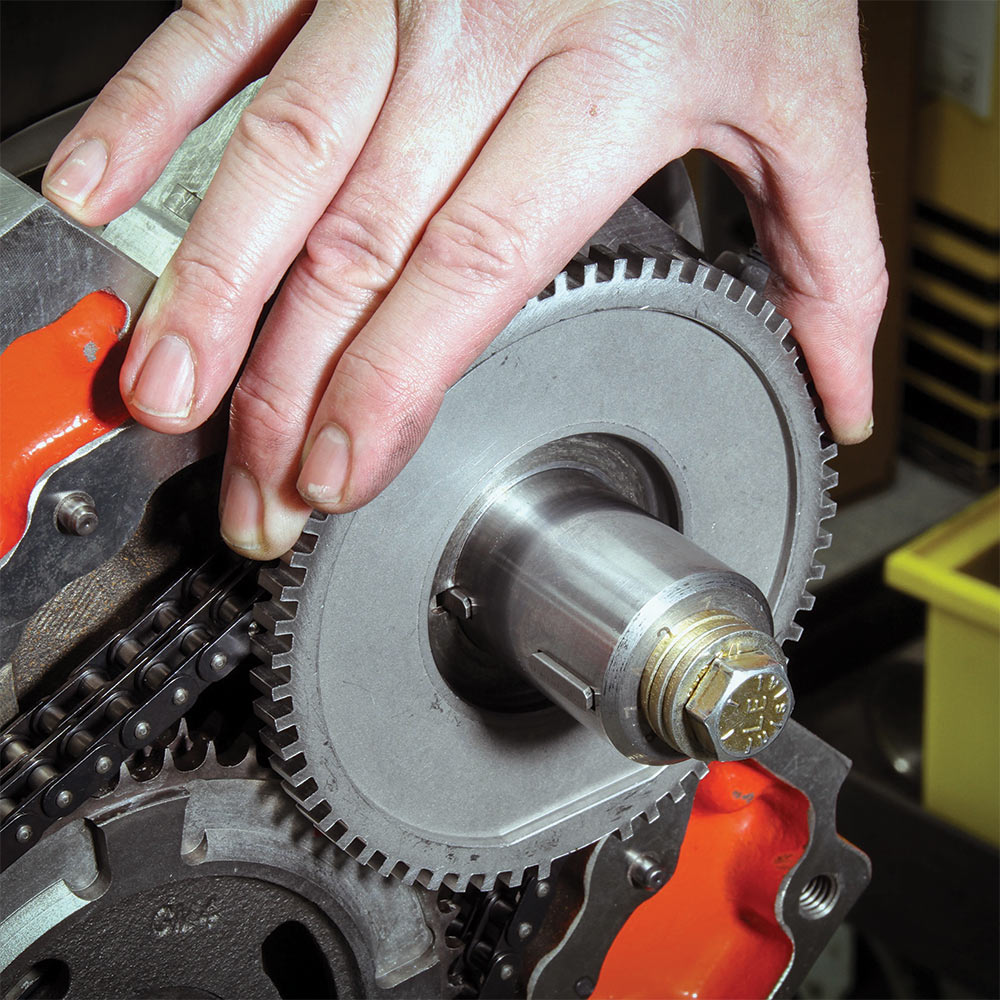

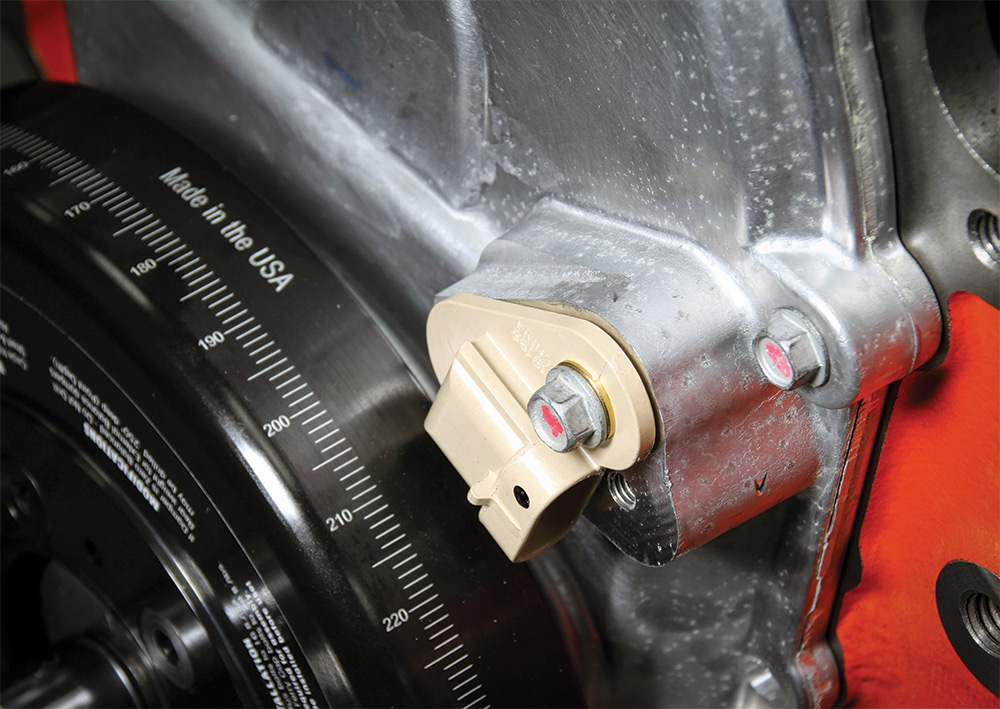

- A precise 58X crank-trigger ignition system with individual coil-near-plug ignition coils and those huge-flowing RSX cylinder heads

- A Holley-supplied control system

“We couldn’t get away with such high compression without them,” Dragoiu says. “They enable the balance we’re able to strike between low-speed streetability and the high-rpm performance of a racing engine.”

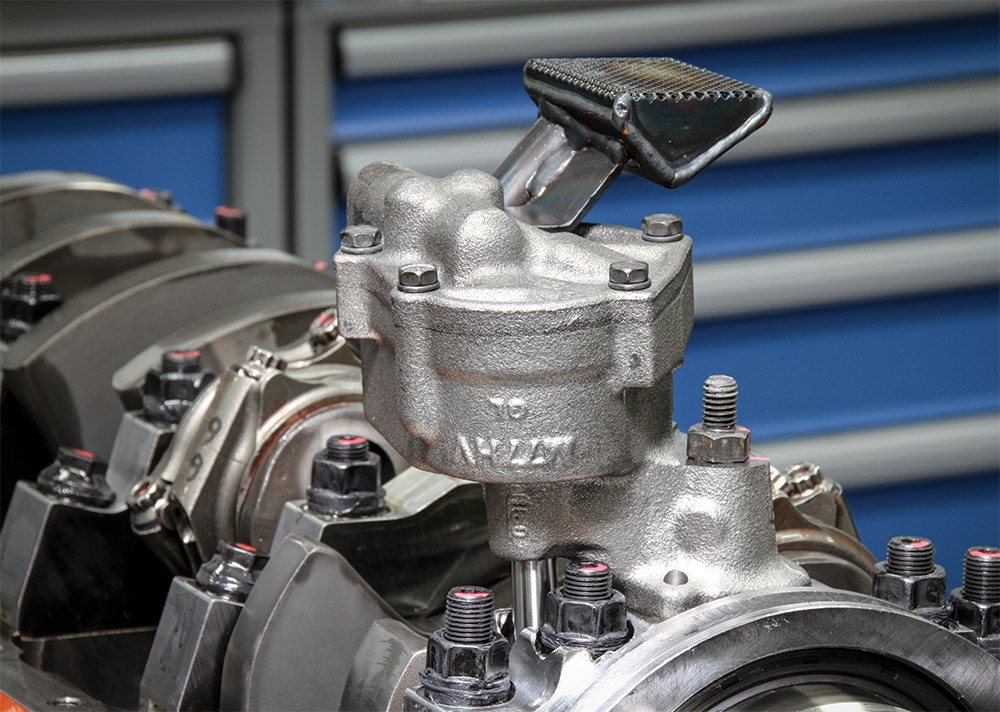

It’s worth noting here, too, that when it comes to the ZZ632’s assembly, Chevrolet treats it very much like a racing engine. In fact, it’s built by the same technicians as other racing engines, such as the COPO program, the Corvette Racing program, and more, with hand assembly from start to finish by a single builder—a process that doesn’t happen with other production-based crate engines.

“This is a very unique crate engine for Chevrolet Performance, with performance capability unlike anything else in the portfolio,” Dragoiu says. “So, we take extra care to ensure every last detail on the assembly, from file-fitting the rings to checking every last bearing clearance.”

We recently got a glimpse of the hand-assembly process when Chevrolet Performance allowed us to follow the build of the very first production ZZ632. There’s much going on in this distinctive and groundbreaking big-block street engine, so we’re splitting our story into two parts.

This first installment follows the short-block assembly, and our follow-up article will delve into the Pro Stock–derived cylinder heads, fuel and ignition systems, and more—including allaying concerns regarding whether the combined height of the tall-deck block, tall heads, and gorgeous cast-aluminum valve covers will pose a brake booster interference problem in your vehicle.

Spoiler alert: Vacuum is not this engine’s strong suit, so you’ll probably want to investigate hydroboost systems.

We’ll also discuss the engine’s dyno performance, so you’ll want to stay tuned. For now, follow along as we build up the all-forged short-block.