TECH

TECH

Photography by ACP Staff

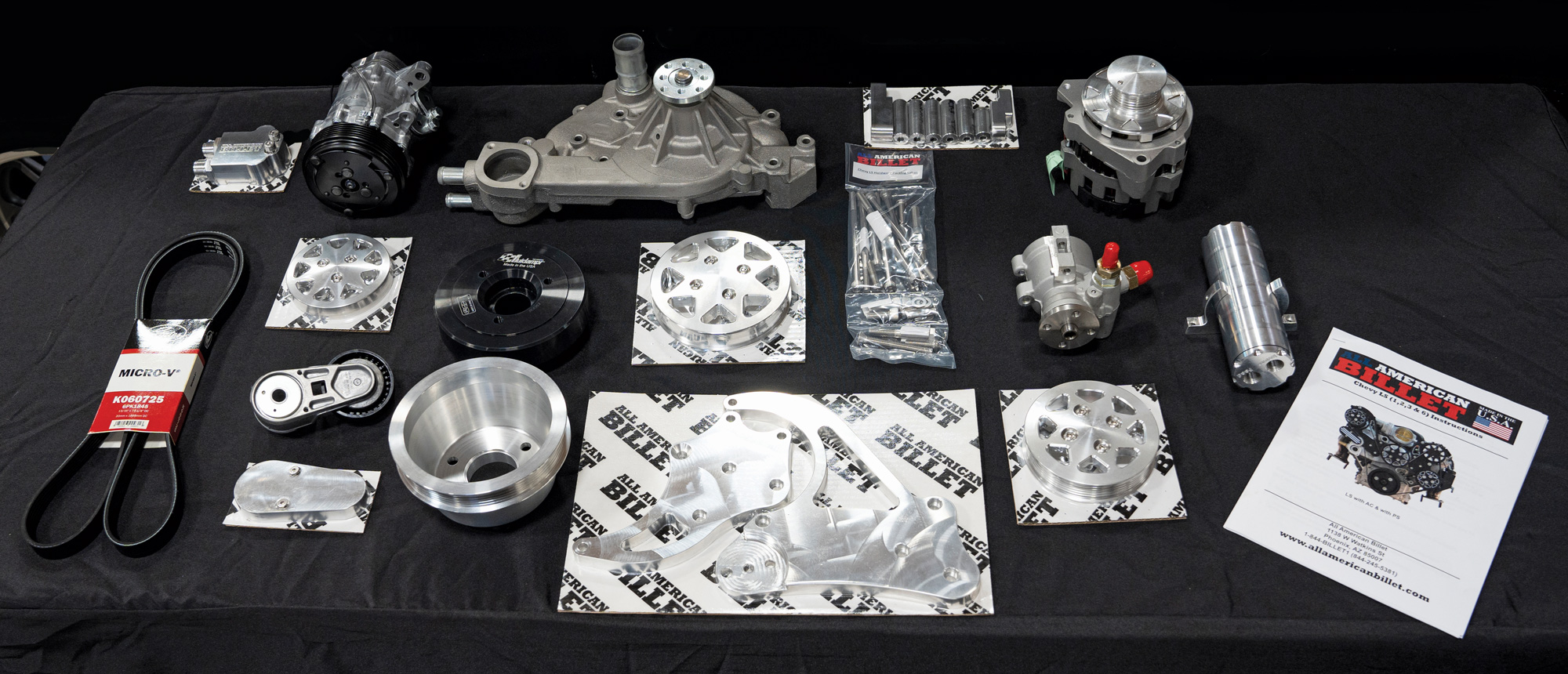

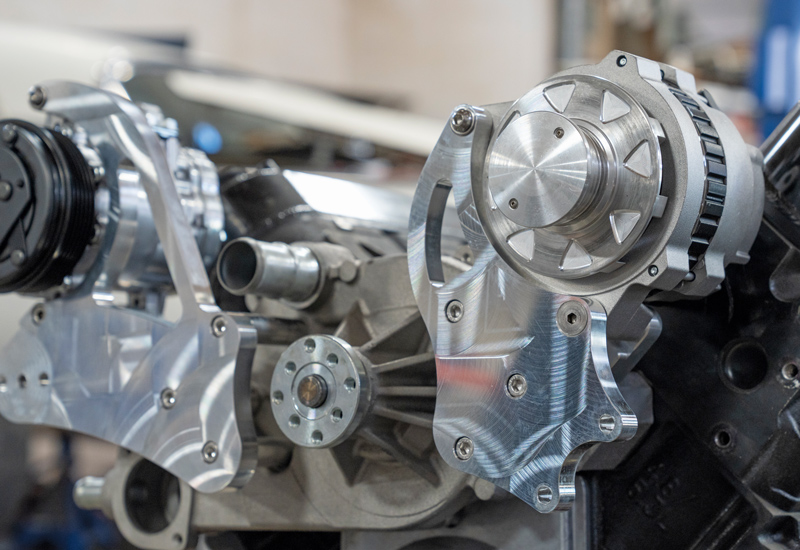

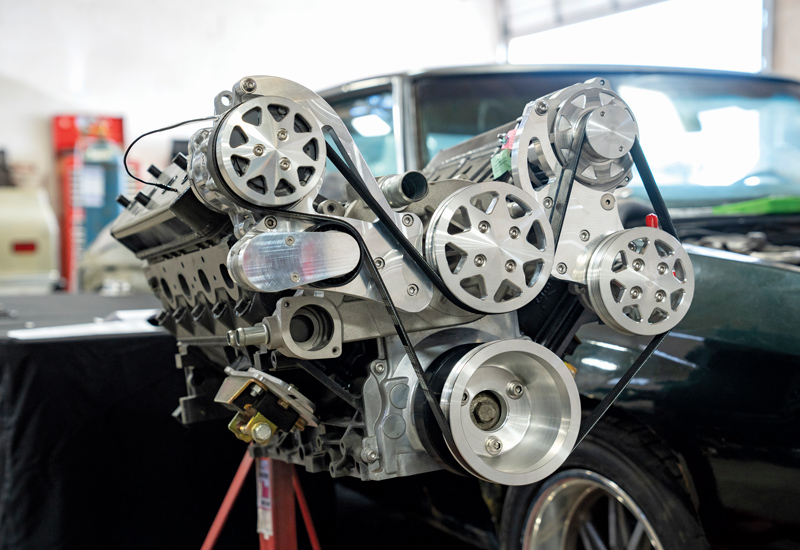

Photography by ACP Staffftermarket LS accessory drive systems are nothing new, but they play an important role in making our engines look better and perform better, especially when increased horsepower is part of the equation. No doubt we all want our engines to look as good as possible and the fine folks at All American Billet offer front drive system kits for a variety of engines, but for this article we’ll be focusing on their billet serpentine system for LS Gen III- and Gen IV-style engines. While All American Billet offers machined, black anodized, and Silverline Series, this particular system is the polished kit for those wanting to liven up the front end of their LS engine with a little pizazz.

While it looks 100 percent more attractive than the stock GM system, the six-rib Gates belt system offers the ability to handle that extra horsepower you’ve added without belt slippage that is common with high-performance engines.

As mentioned, All American Billet offers systems for Chevy small- and big-block as well as systems for Ford and Chrysler engines. With a variety of finishes, there’s sure to be something to fit the style you are after for your ride.

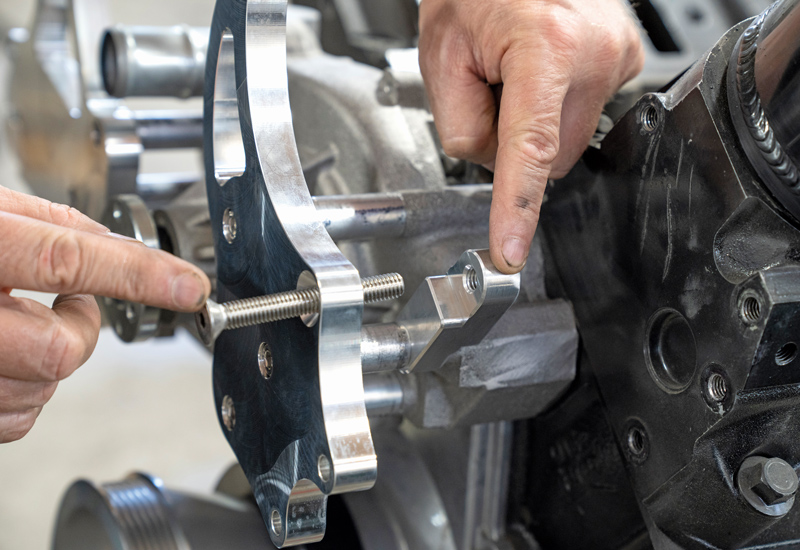

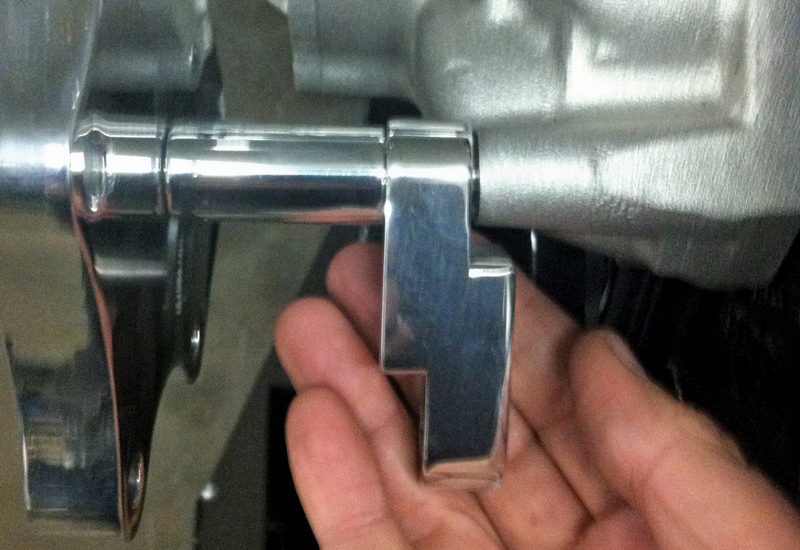

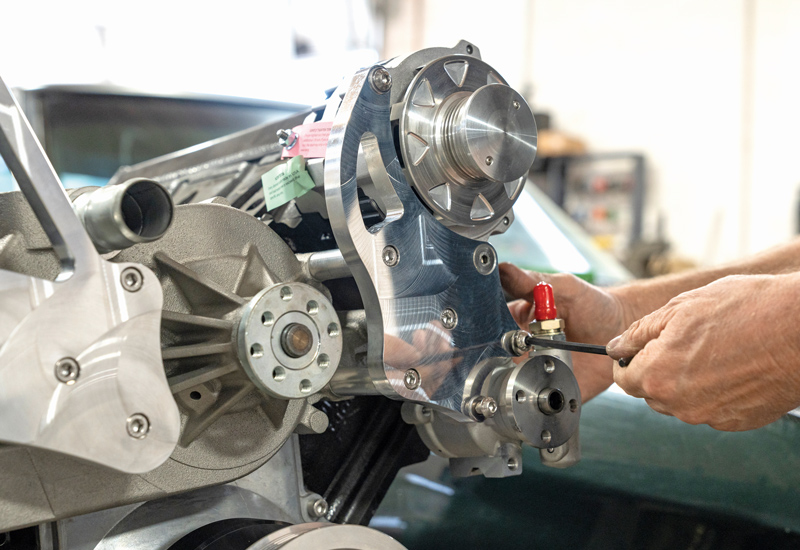

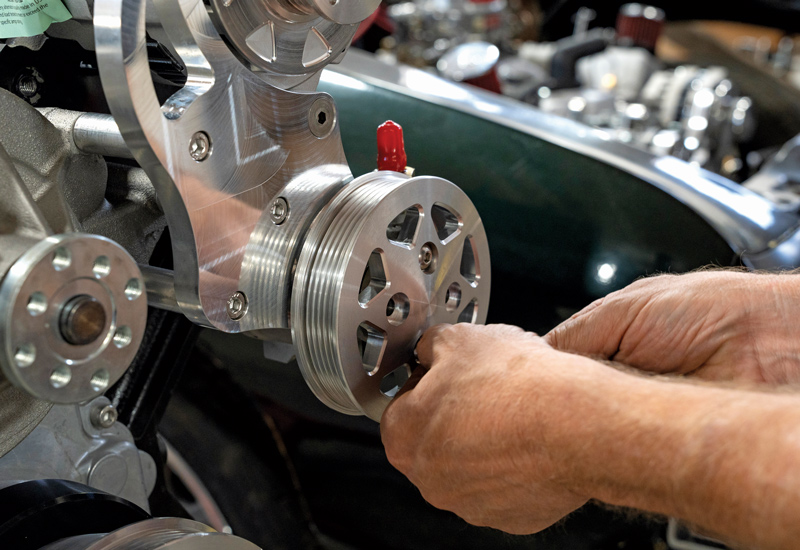

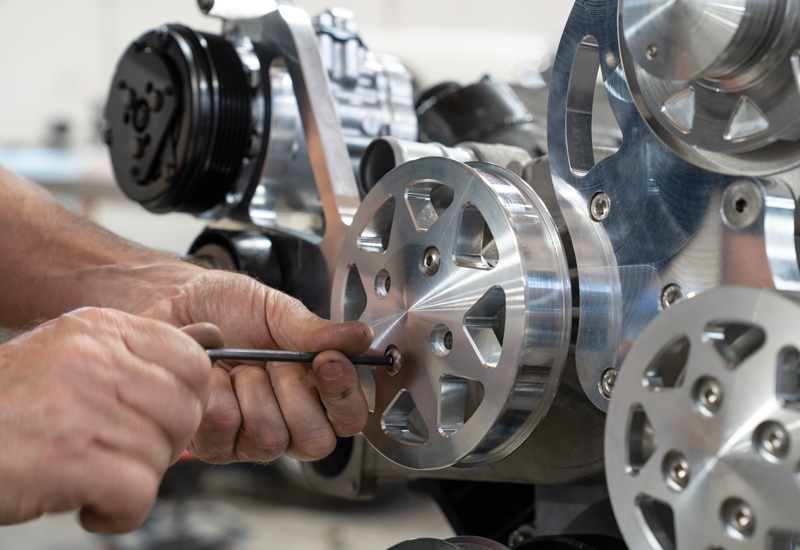

The All American Billet LS Serpentine Kit comes with all the necessary hardware and detailed instructions for a drama-free installation. All you need are some basic mechanical skills, a decent set of tools, a free afternoon, and good buddy to lend a hand when needed.

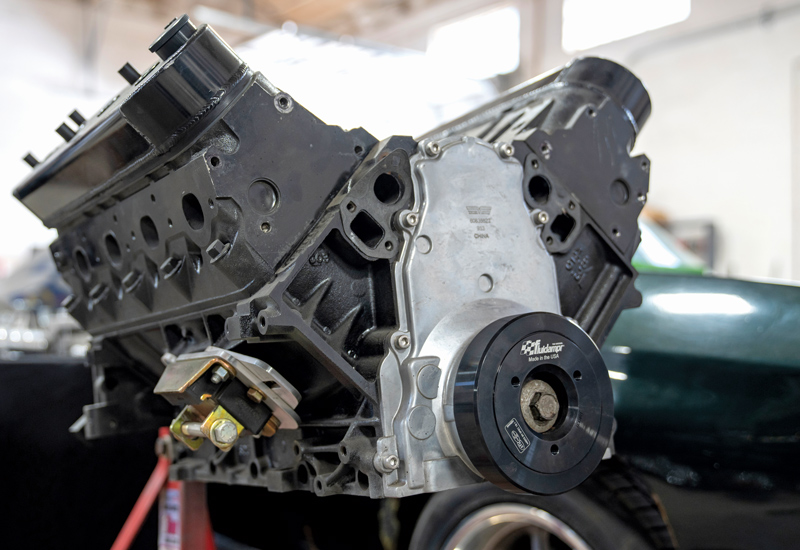

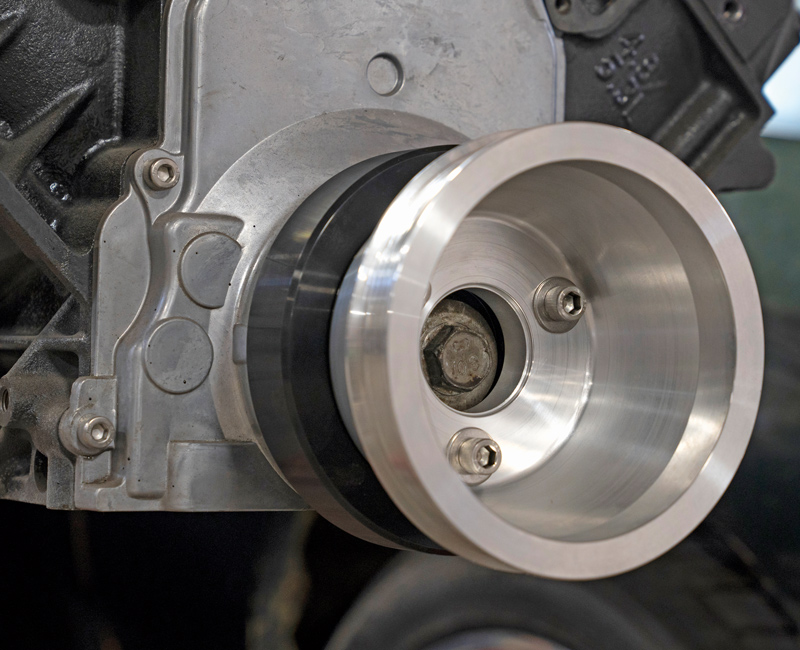

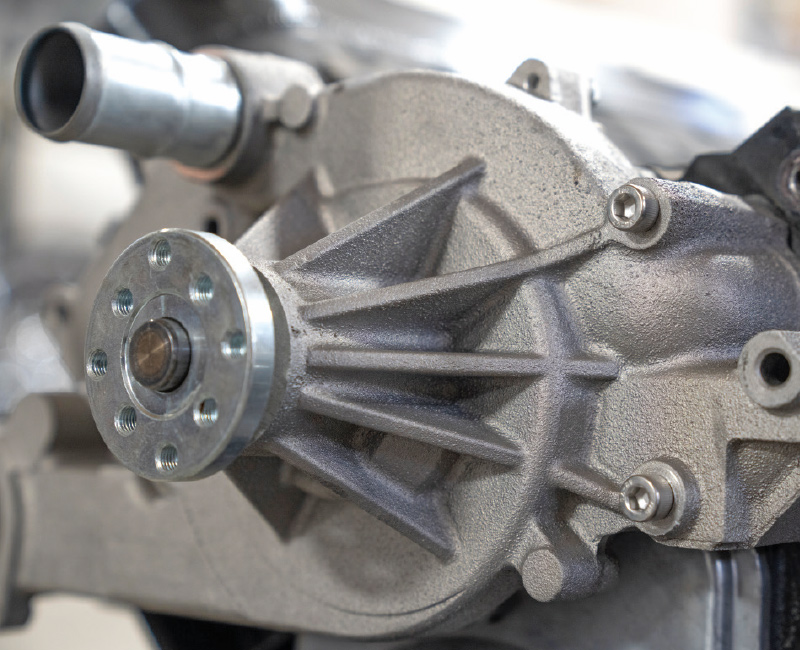

For visual clarity, we’ll be performing the install with our LS on an engine stand, but this can be done with your engine bolted in your engine bay, too. Follow along as we illustrate how to bump up the looks and performance of your LS engine in just a few hours. Remember to follow the included highly detailed instructions to make sure your installation goes exactly as planned.

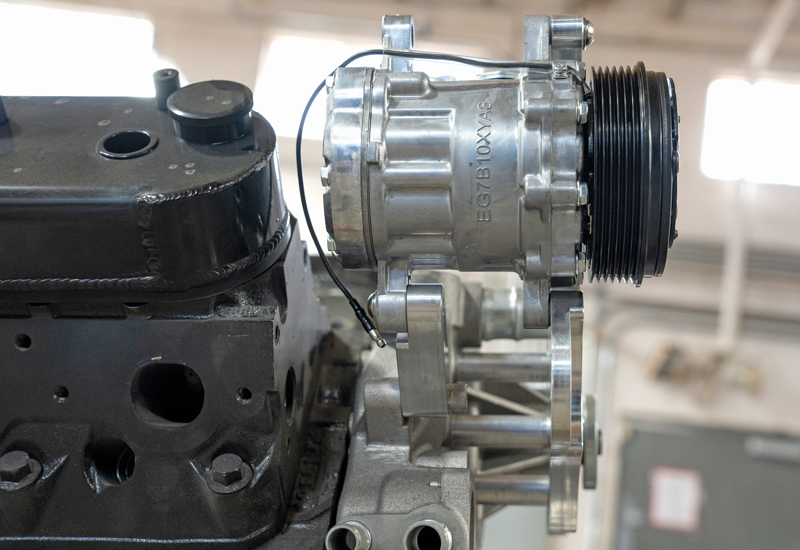

16. Next, bolt on the alternator and All American Billet pulley and fan attachment. After that, it’s time to tighten the main bracket/water pump, alternator, and A/C bolt what were only finger tightened earlier. Tighten to spec per the instructions.

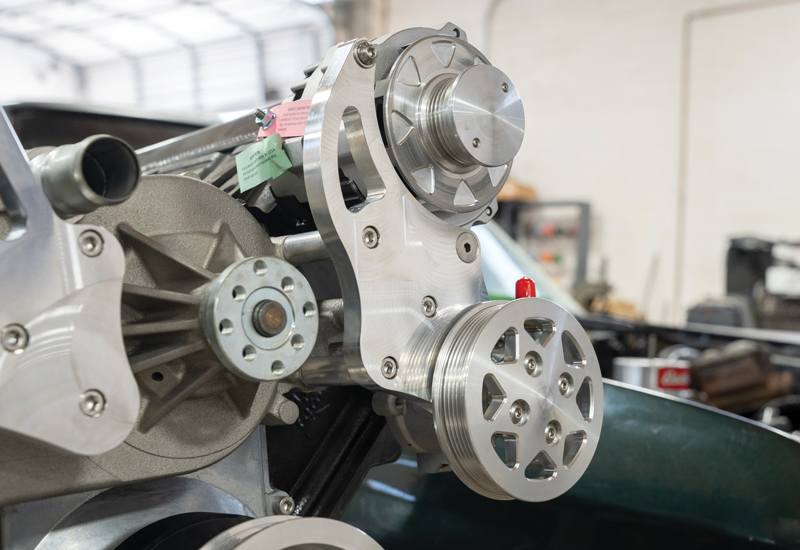

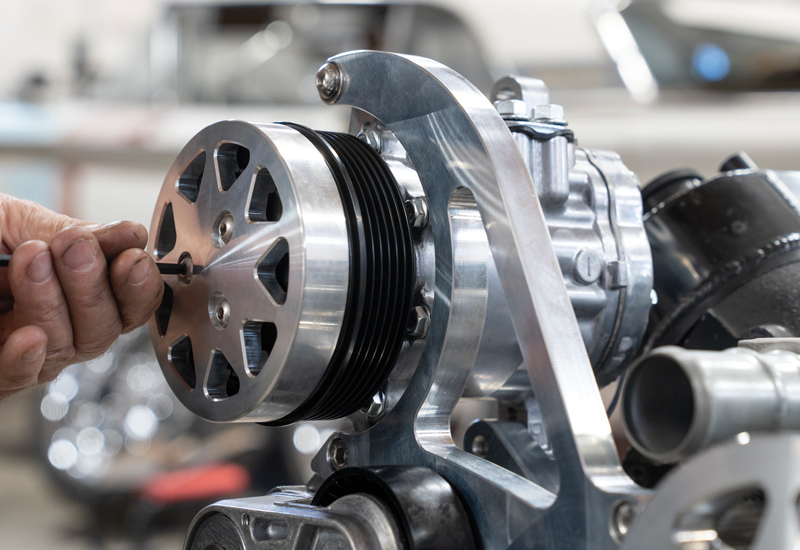

18. Using the supplied hex head bolts and a small amount of blue Loctite, the tensioner goes on next.

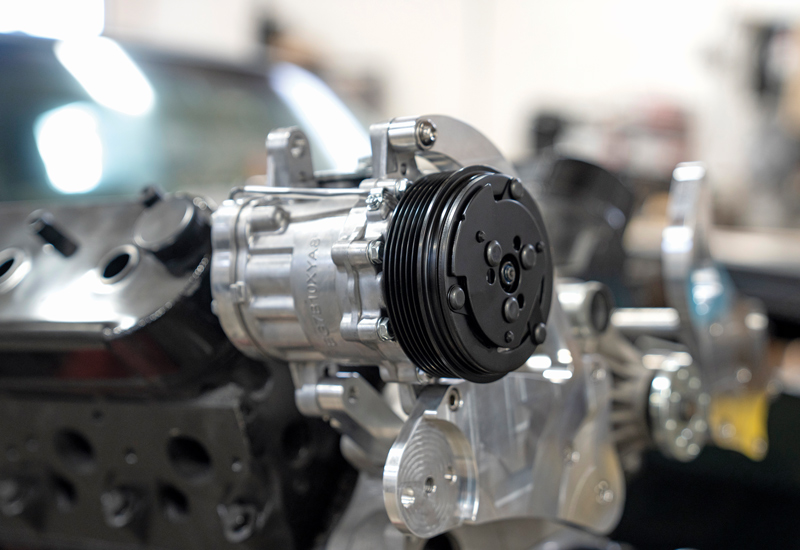

20. It’s starting to look pretty sweet.

22. … and the billet A/C pump pulley cover.

24. Finish that up by installing the billet tensioner cover.

SOURCE

SOURCE