TECH

TECH

Photography by The Author

Photography by The Authorurchasing a used engine, be it from a friend, junkyard, or a swap meet, can be a practice in futility. Every small-block at the local high-performance swap meet has been bored and stroked, equipped with a hot cam, and originally resided in a Corvette. At least according to the seller. The truth, however, is usually much less impressive. In reality, that overbore was only applied to one cylinder, that hot cam has two flattened lobes, and the seller actually meant Chevette and not Corvette. The point is, buying a used engine is akin to buying something sight-unseen because though it might be sitting right there in front of you, what’s hiding inside usually can’t be inspected until after the deal is done. And that deal can sometimes burn.

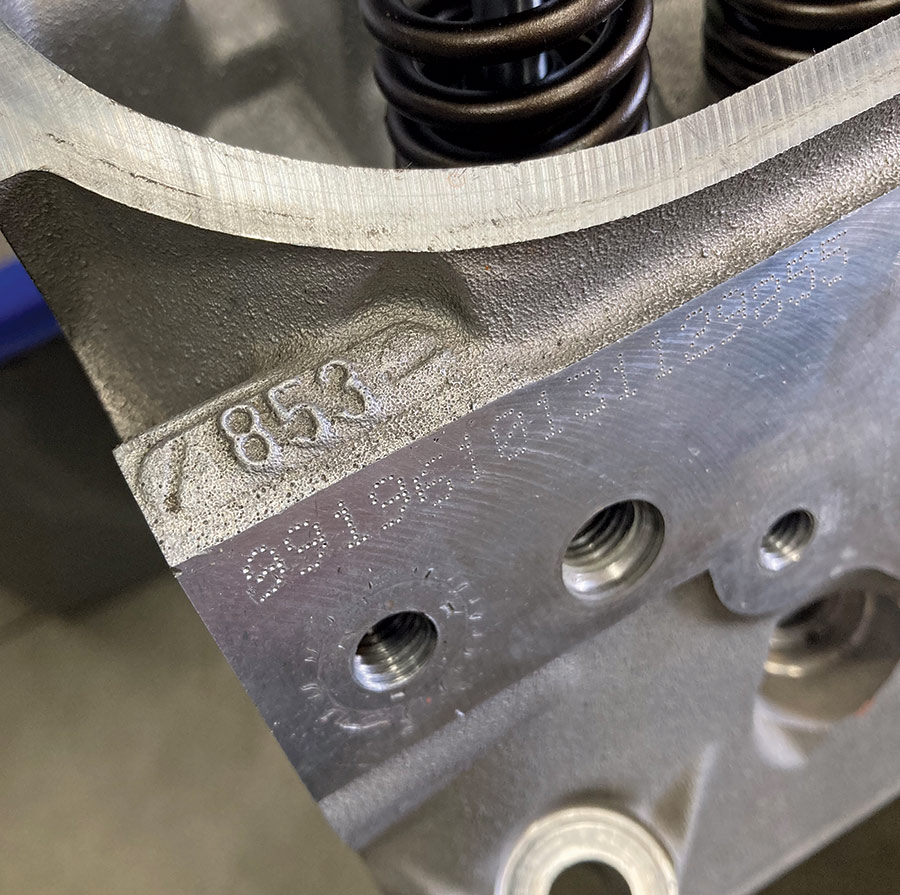

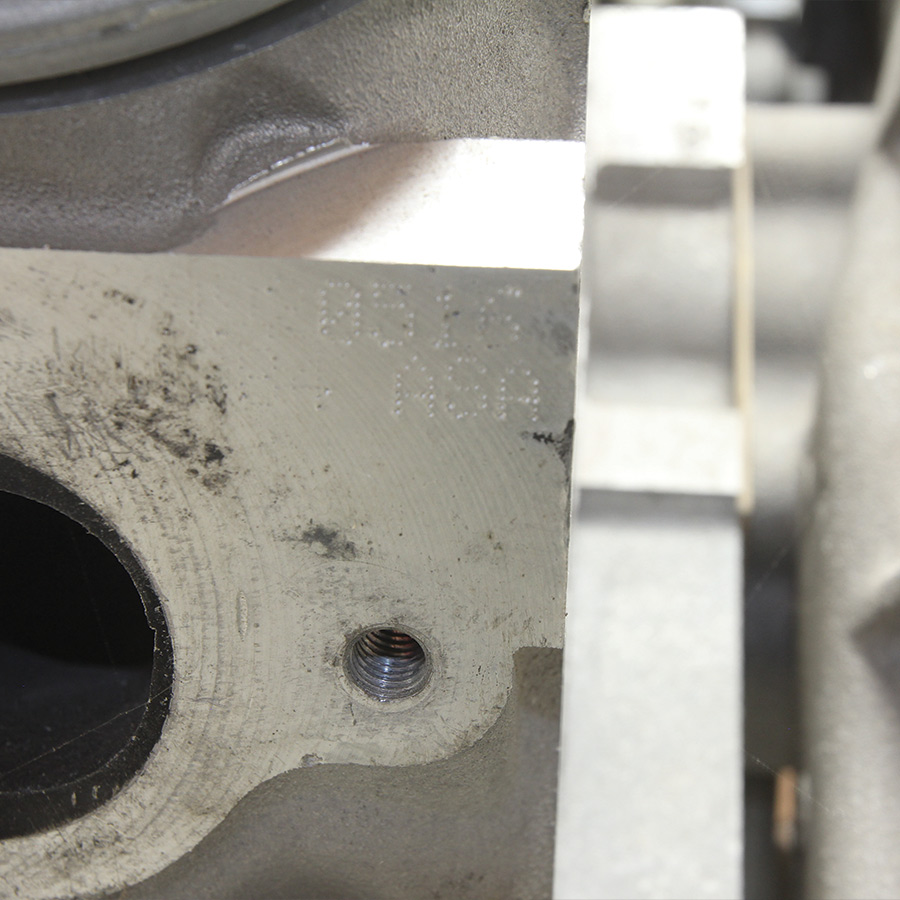

So, what can be done when it comes to buying a used engine? For starters, a heavy education in the make of engine one’s hunting for can help. Most blocks and heads can be identified by a variety of means, be it casting marks (think Camel hump heads) or casting numbers. A quick Interweb search will usually result in a fairly accurate identification that should help persuade, or dissuade, said purchase.

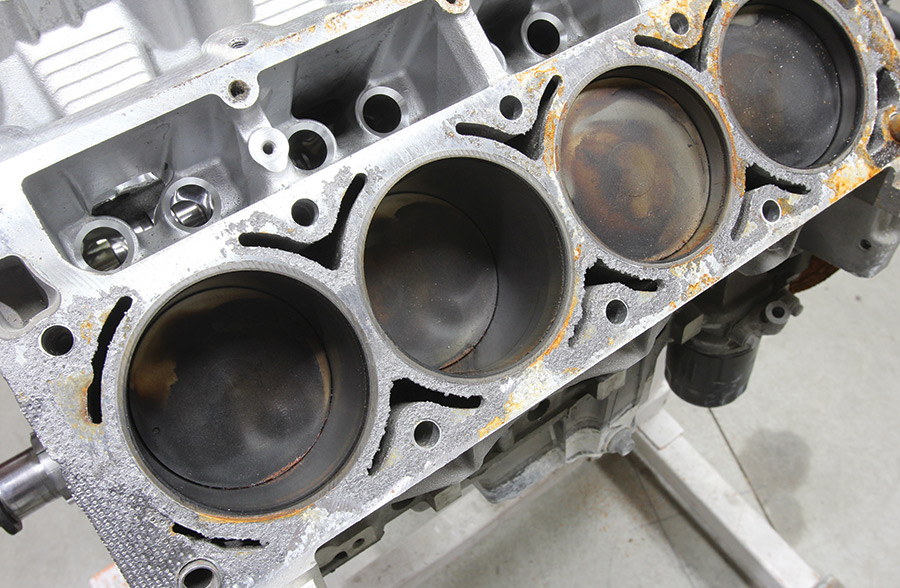

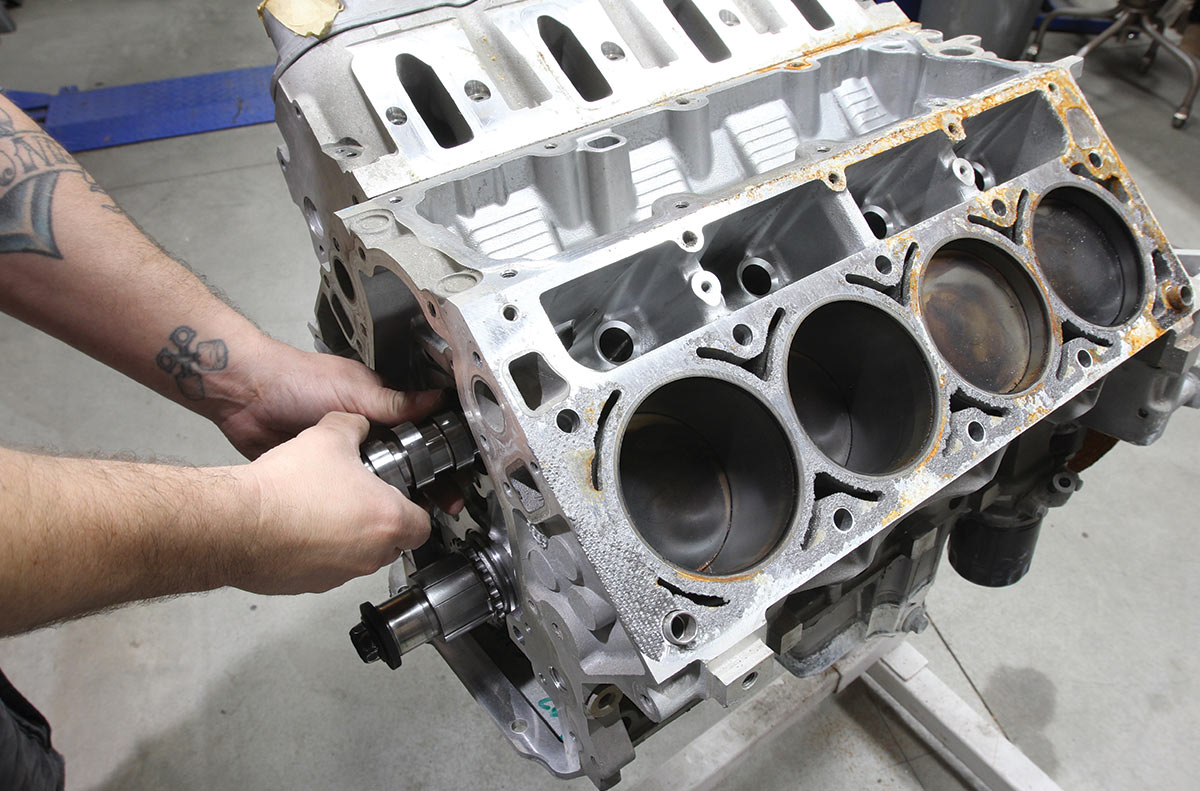

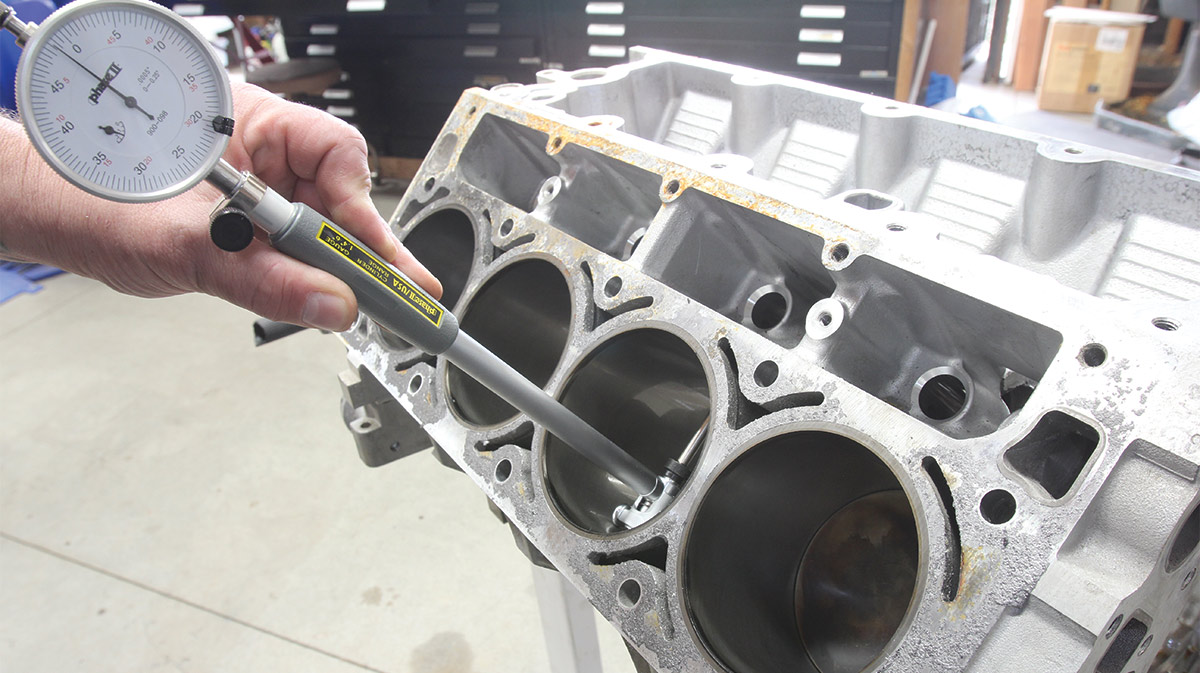

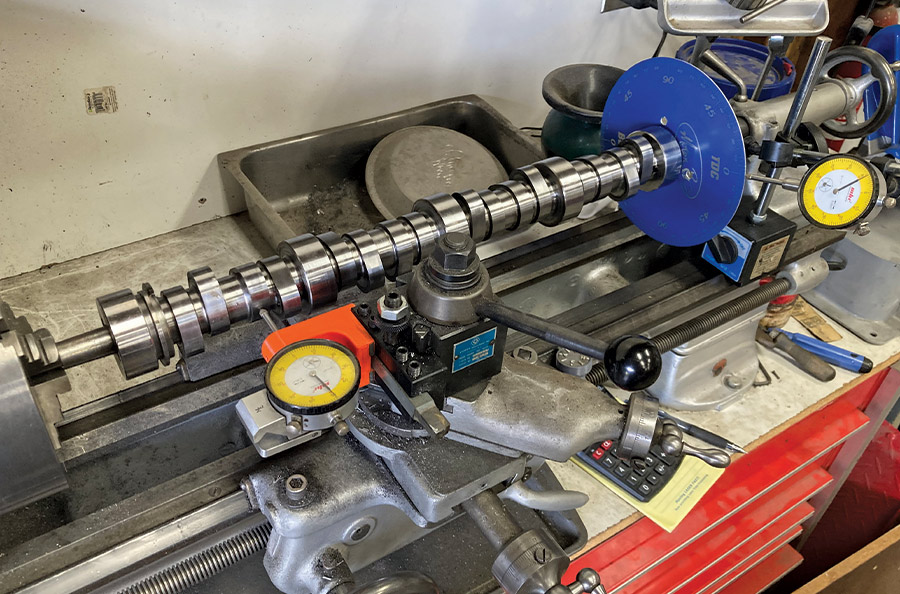

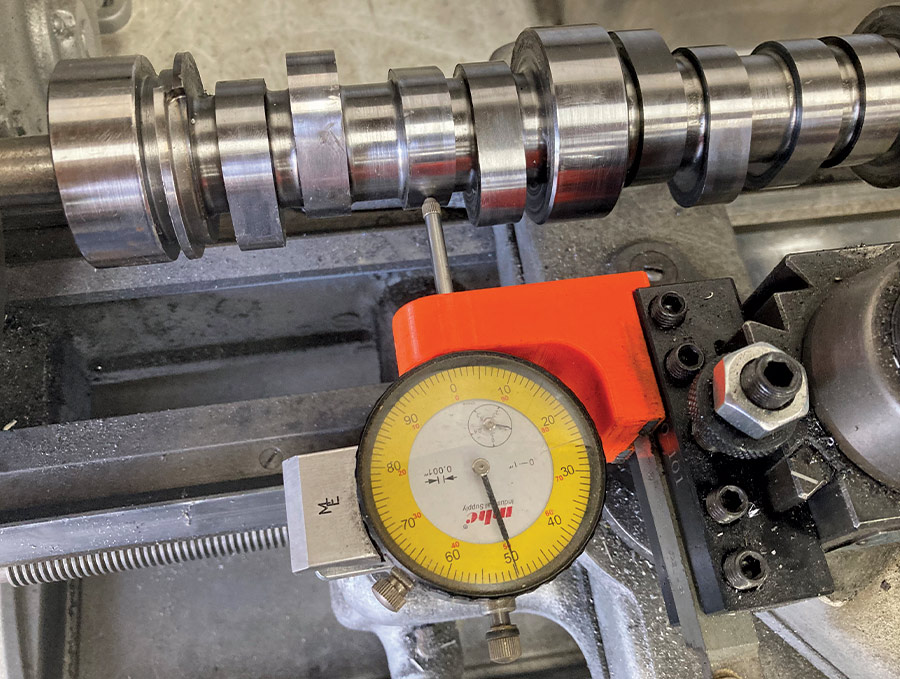

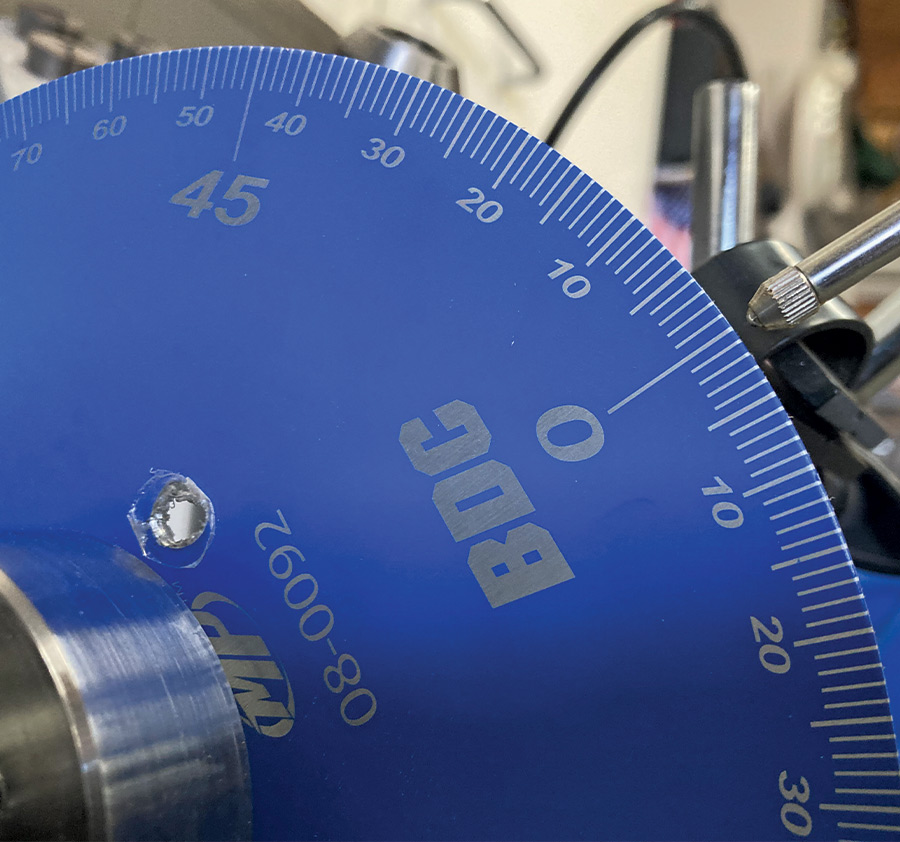

A recent discussion with our buddy Zane Cullen of Cotati Speed Shop brought up this topic spurred by the realization that the mock-up LS engine that they’ve been using in the shop for the last decade-and-a-half might actually hold some performance pedigree. After some quick sleuthing, it was determined that the early LS might have lived its younger days under the hood of a stock car. And by stock car, we mean Stock Car. Back around the turn of the century, American Speed Association (ASA) in conjunction with GM decided to regulate the engines used in the racing series and it just so happened that the guys at The General had the perfect ace in the hole in the form of their LS1 V-8. Spec’d and sealed upon delivery, every car used the same engine with the same tune to create a more perfect form of fairness.

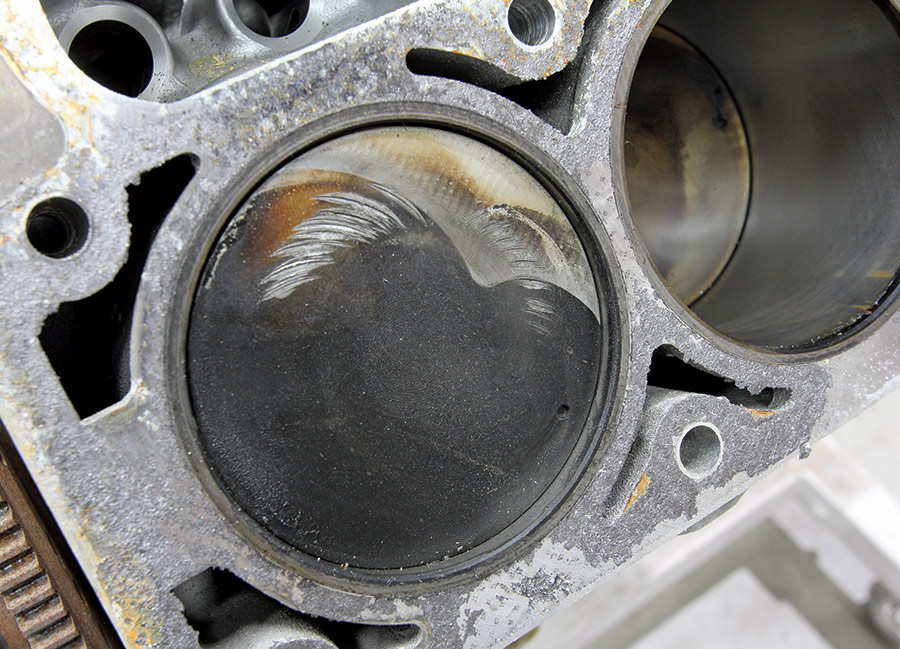

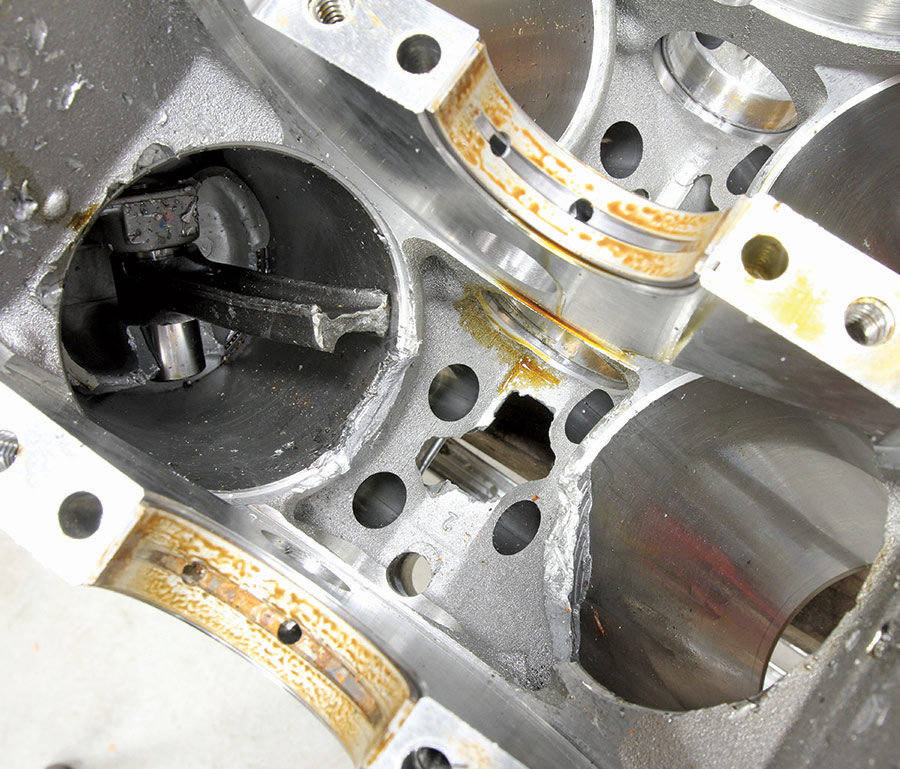

Now, all that sounds well and good, but could Cullen’s LS really be a Sierra Hotel racing engine or is it more likely to be a detuned version of the production engine, which, as it turns out, really did originate from the Corvette? He was determined to find out and dropped the powerplant off at the Clampdown Competition headquarters where it was to be opened up and inspected. What we found surprised us all, to say the least, and should serve as a lesson to all potential engine buyers that you never know what you’re gonna get!

SOURCES

SOURCES(800) 230-3030