TECH

TECHInTheGarageMedia.com

Photography by The Author

Photography by The Author

Installing Holley Sniper Quadrajet Fuel injection on a ’72 Nova

ars were meant to be driven. David Whitmer’s ’72 Nova with the ultrarare Sky Roof option is no exception. Whitmer restored the car after high school by rebuilding all the mechanical bits, replacing multiple rotten panels, and lovingly blocking the body on which he sprayed the paint.

The Nova has garnered plenty of street miles since its restoration, now with Whitmer’s wife and young daughter in tow. With even more family outings planned, more road miles to be earned, and considerably more precious cargo, it was time to up the reliability, driveability, and fun factor of the car once again. That process entailed a switch to modern, electronic fuel injection.

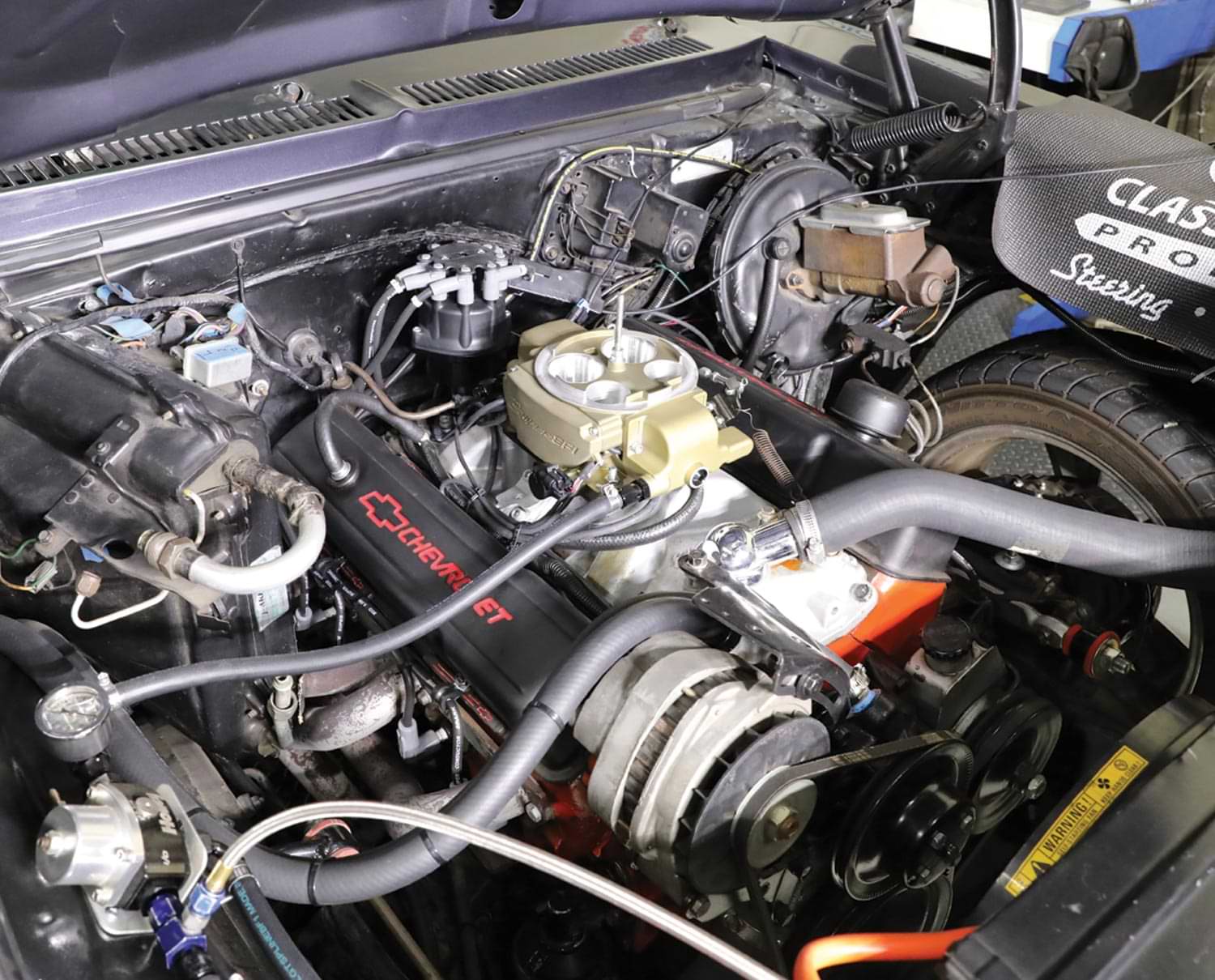

The Sniper uses a spread-bore throttle-blade arrangement just like the outgoing Quadrajet carburetor and bolts directly to the intake flange of the manifold. It accepts the standard Quadrajet throttle linkage and kickdown cable for the TH350 transmission, which simplifies installation significantly.

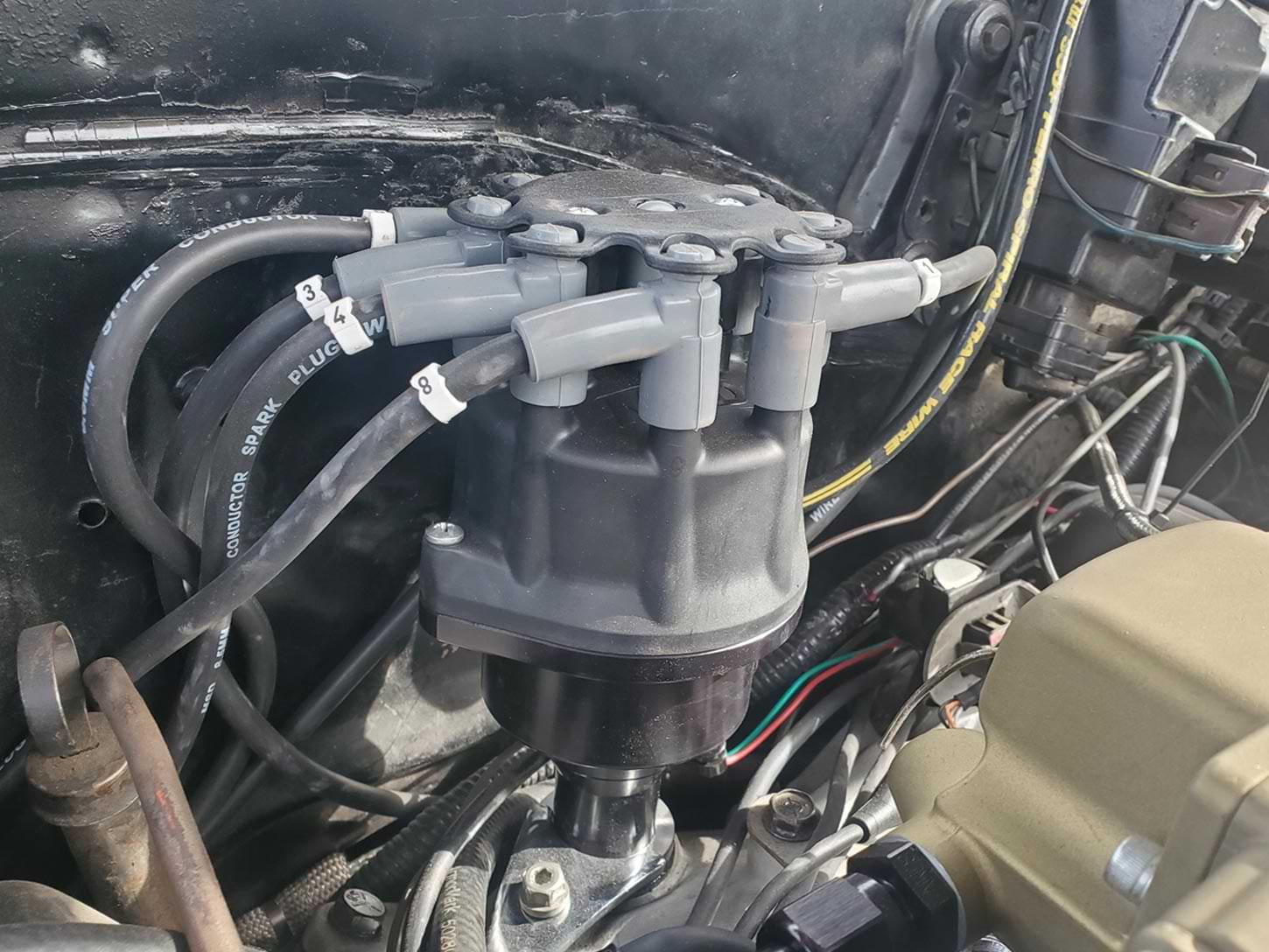

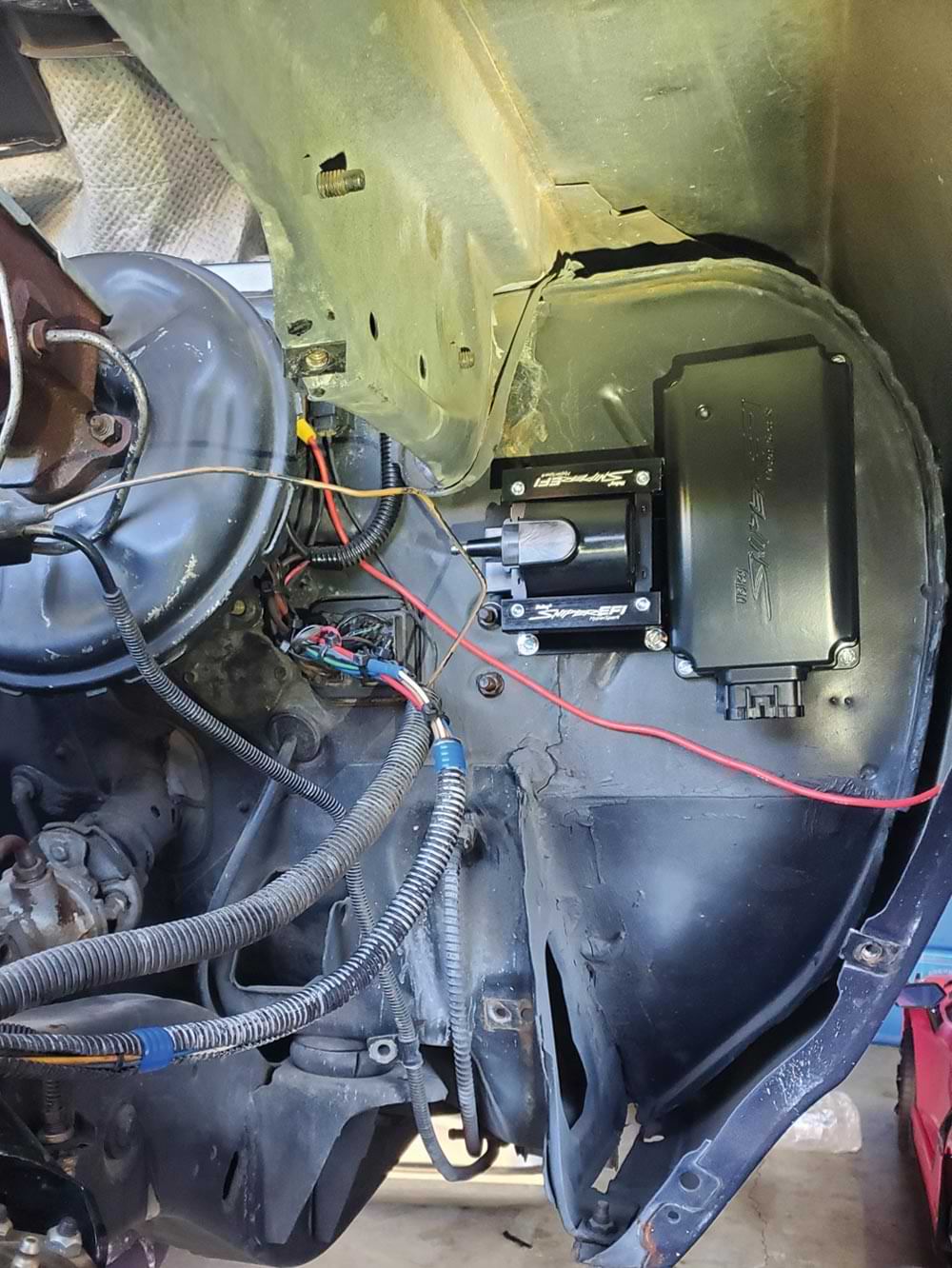

Wiring the Sniper was relatively straightforward as well, with the Sniper needing a 12V ignition source, positive and negative battery connections, an O2 sensor bung installed, and the coolant temperature sensor to be plumbed into the thermostat housing area of the intake manifold. The rpm input came by way of the Holley HyperSpark distributor and ignition box, which plugs directly into the Sniper harness.

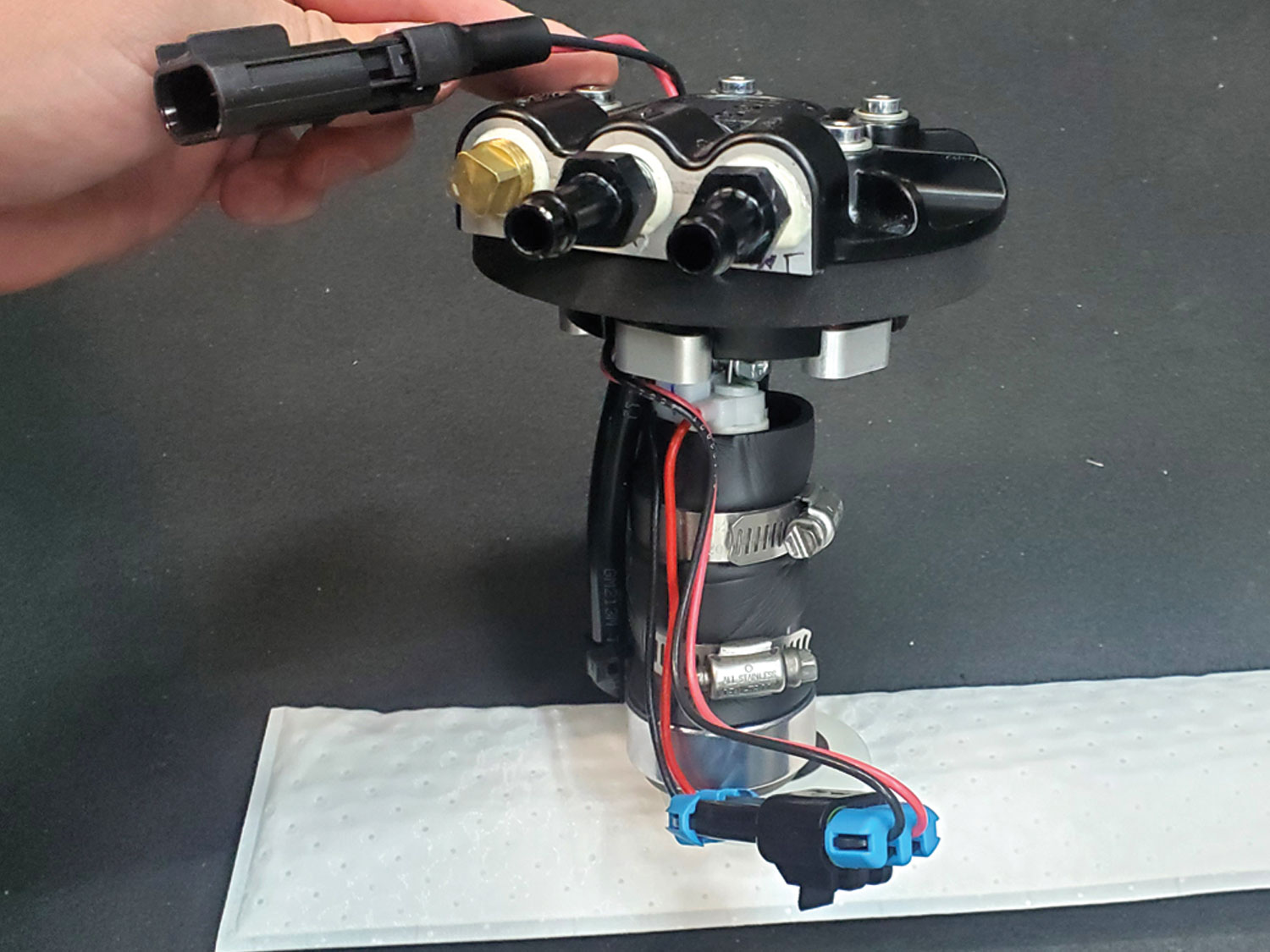

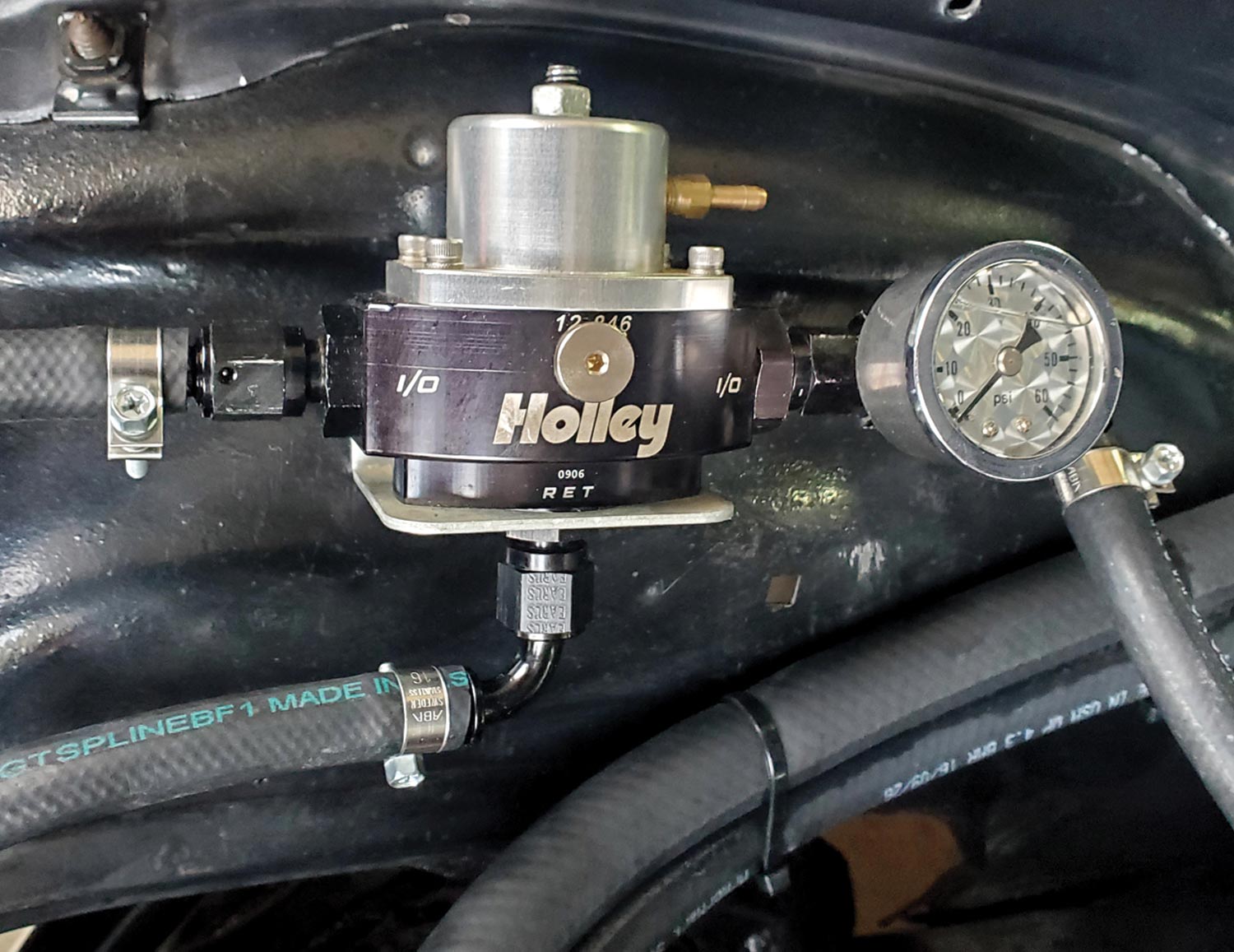

To suit Whitmer’s Nova, a Holley die-cast fuel module was sourced. This was installed in a factory-replacement style tank, though Holley does offer retrofit EFI tanks that have the pump already inside. A 3-inch holesaw was used to cut through the tank’s corrugated surface and the pump dropped in place. Swing-out cams and a thick, neoprene gasket did the job of sealing up the new pump. On top of the module are ports for pressure, return, and a vent, making plumbing the new lines very simple.

The system is a plug-and-play into the Sniper EFI harness, and the ability to create a load-based timing map will allow the car to gain additional fuel economy at cruise, start better cold, and even help to stabilize idle speed through quick adjustments by the computer. The ignition timing can also be changed digitally. Once the initial timing is synced and verified, there’s no longer a need to break out the timing light for future changes to ignition advance. A fresh set of MSD wires with HEI-style ends and eight new spark plugs rounded out the ignition upgrades.

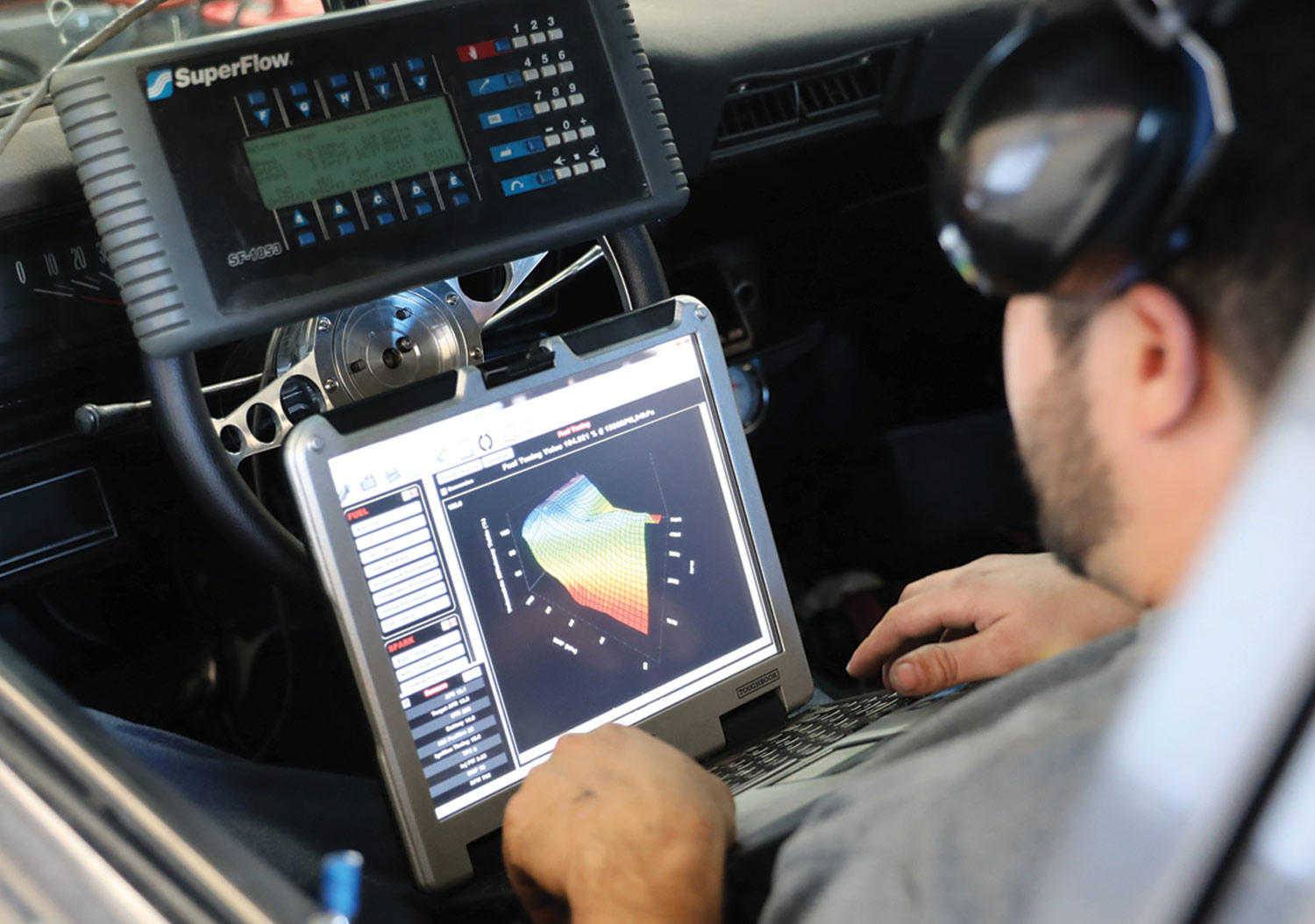

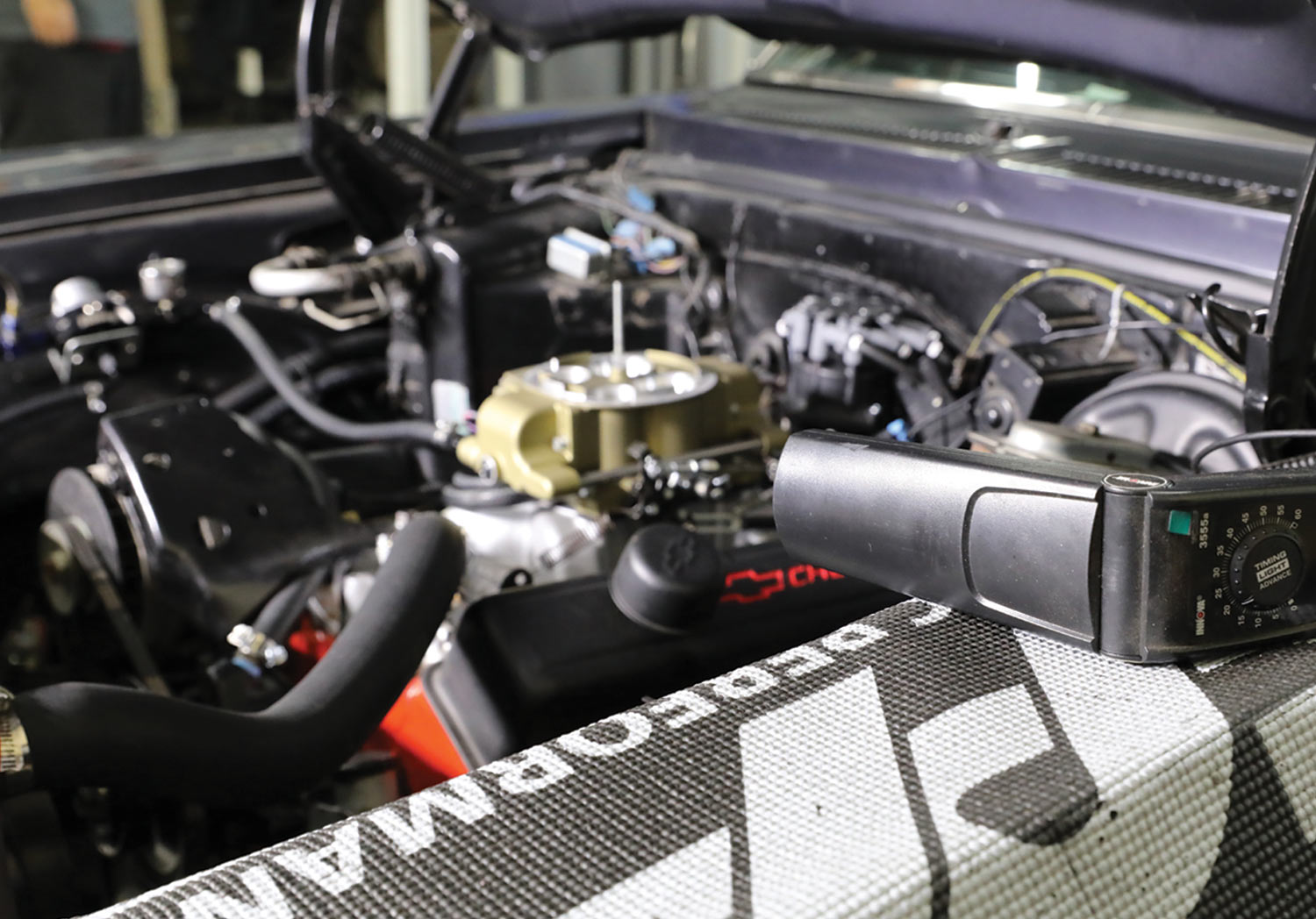

13. Before any power pulls were performed, Westech used a timing light to verify the ignition timing at the crank matched what the Sniper was seeing in the software.