TECH

TECHBy Taylor Kempkes  Photography by The Author

Photography by The Author

here is no engine platform more ubiquitous in the hot-rodding community than the small-block Chevy. Of that engine family, the Gen I holds on as the longest running and most popular—sorry to break it to you, LS. With small-block Chevy production starting for the ’55 model year, the basic technology of this engine is, admittedly, old. But the magic of the small-block lies in its overwhelming aftermarket support. Sixty-eight years later, companies are still finding ways to make better products to support these engines.

All that said, we were nearing the end of our 383 stroker build (you can read part one and two in previous issues of All Chevy Performance) when we realized our small-block wouldn’t be complete without accessories. Cleaning up and reusing the factory brackets is always an option. Well, we say always, but in our case the stamped-steel bracketry hanging the alternator and power steering pump in our ’69 Nova were pretty bent out of whack, leading to poor pulley alignment. Then, just to give us more reason to switch things up, our power steering pump conveniently decided to throw in the towel a few weeks ago.

We needed something better. We needed something to integrate more modern components in a simpler manner that would result in far superior reliability. Turns out our friends at Eddie Motorsports had the answer.

Actually, they had a few answers, ranging from an updated V-belt setup to a truly modern serpentine system. With just about every configuration of power steering or no power steering, with or without an A/C compressor, full chrome or flat black, we felt like a kid in a video game store.

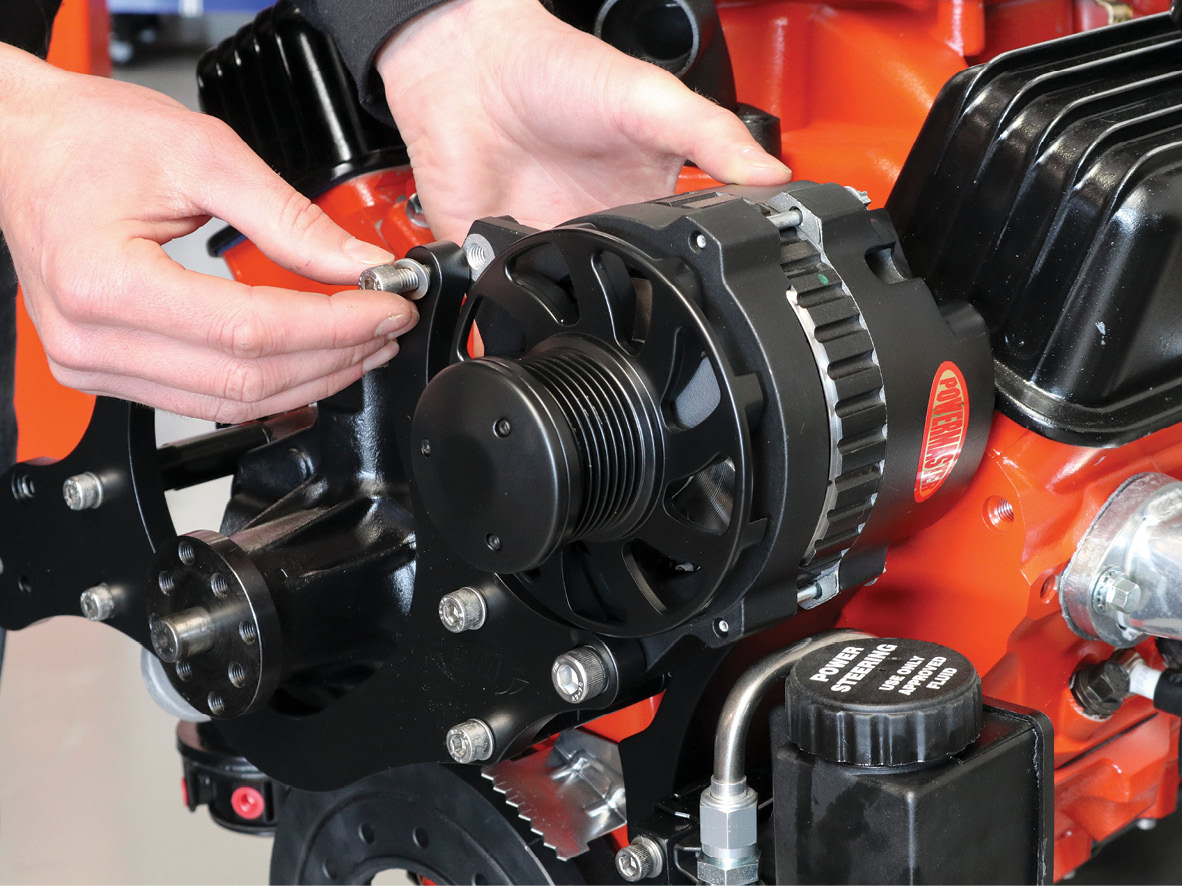

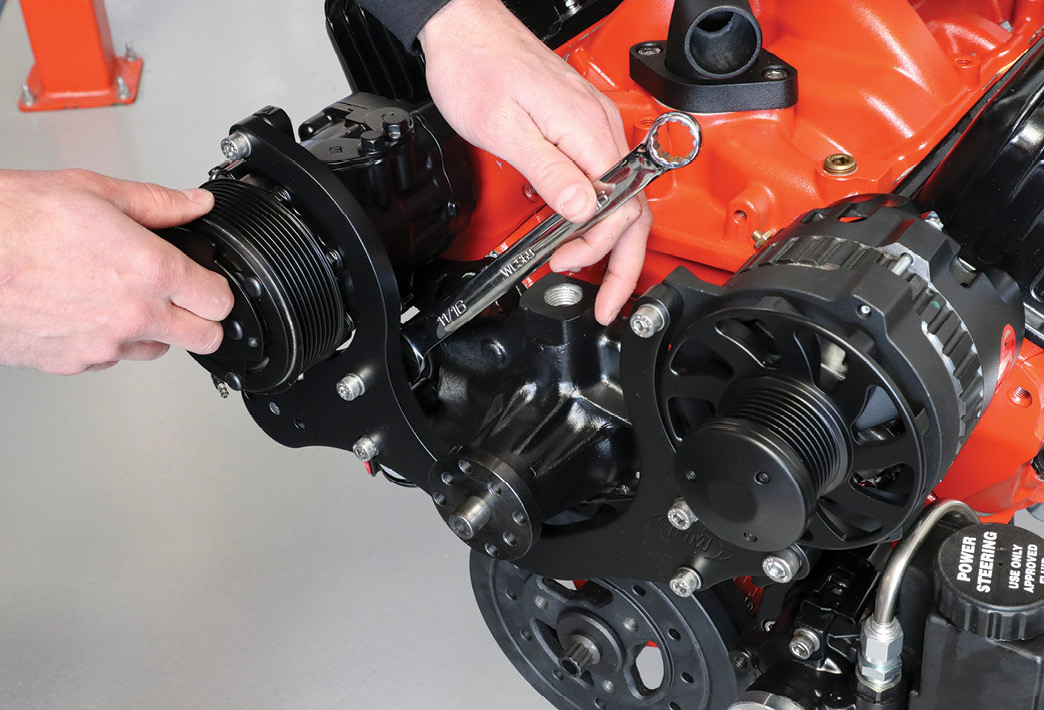

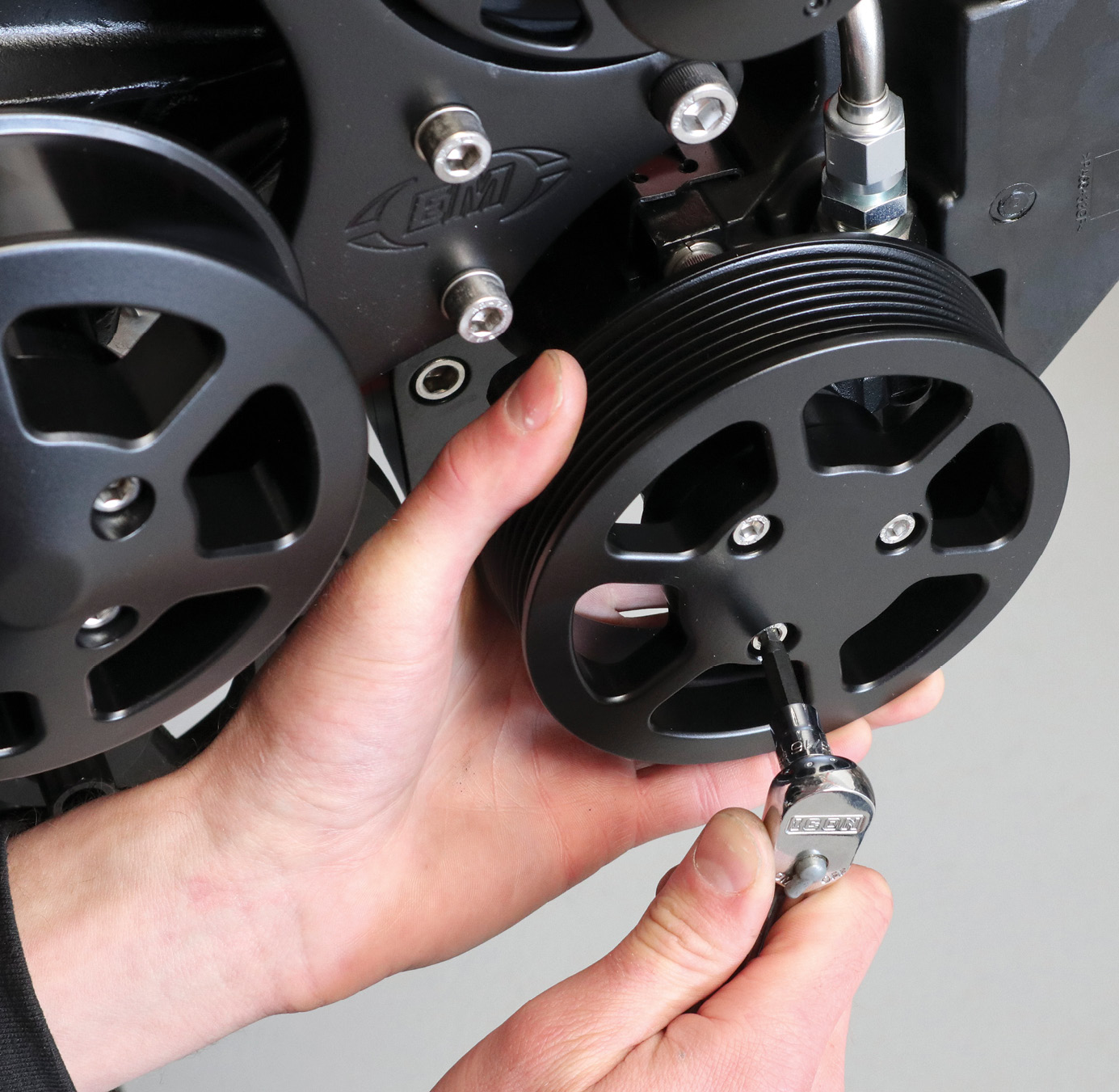

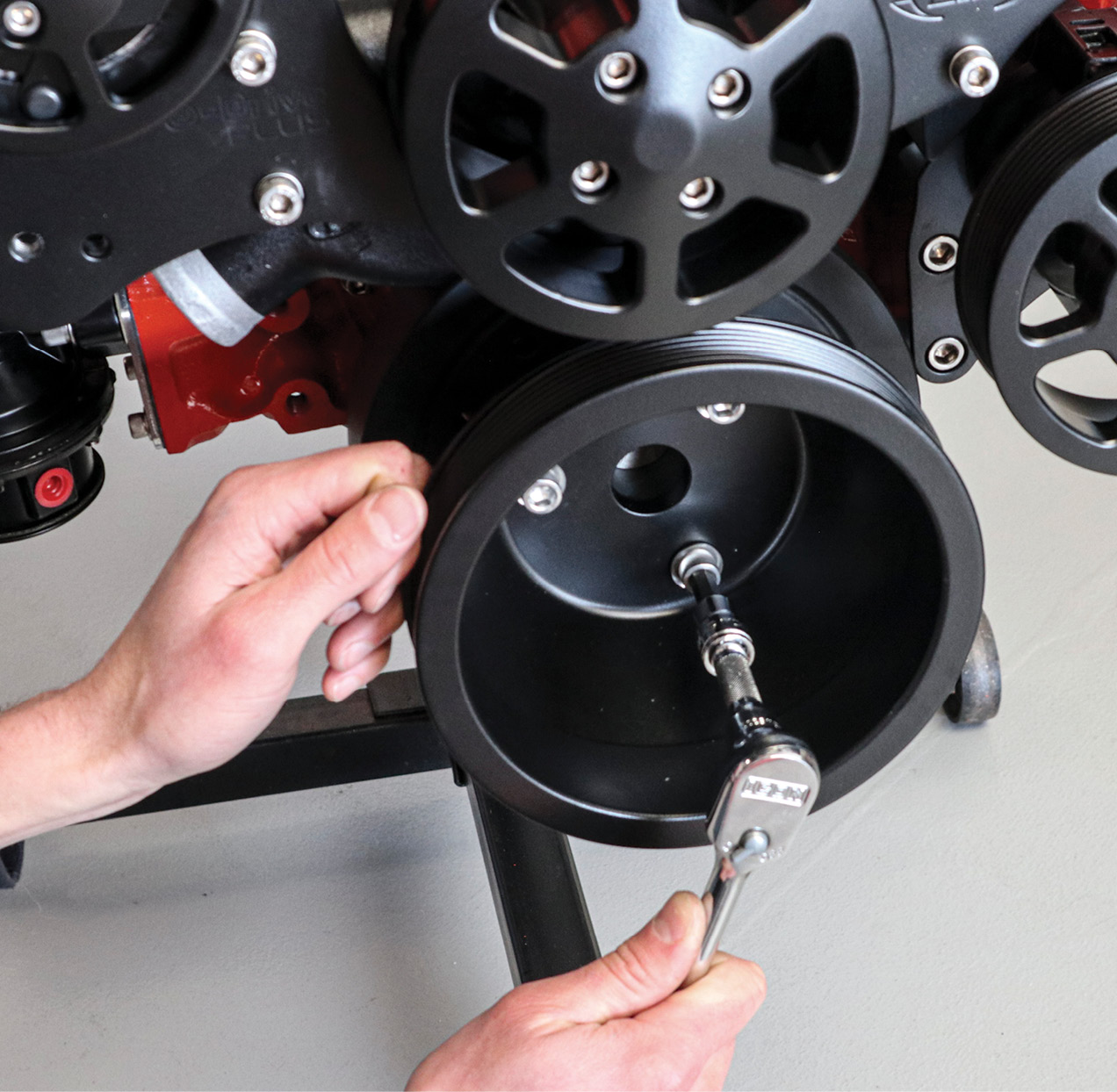

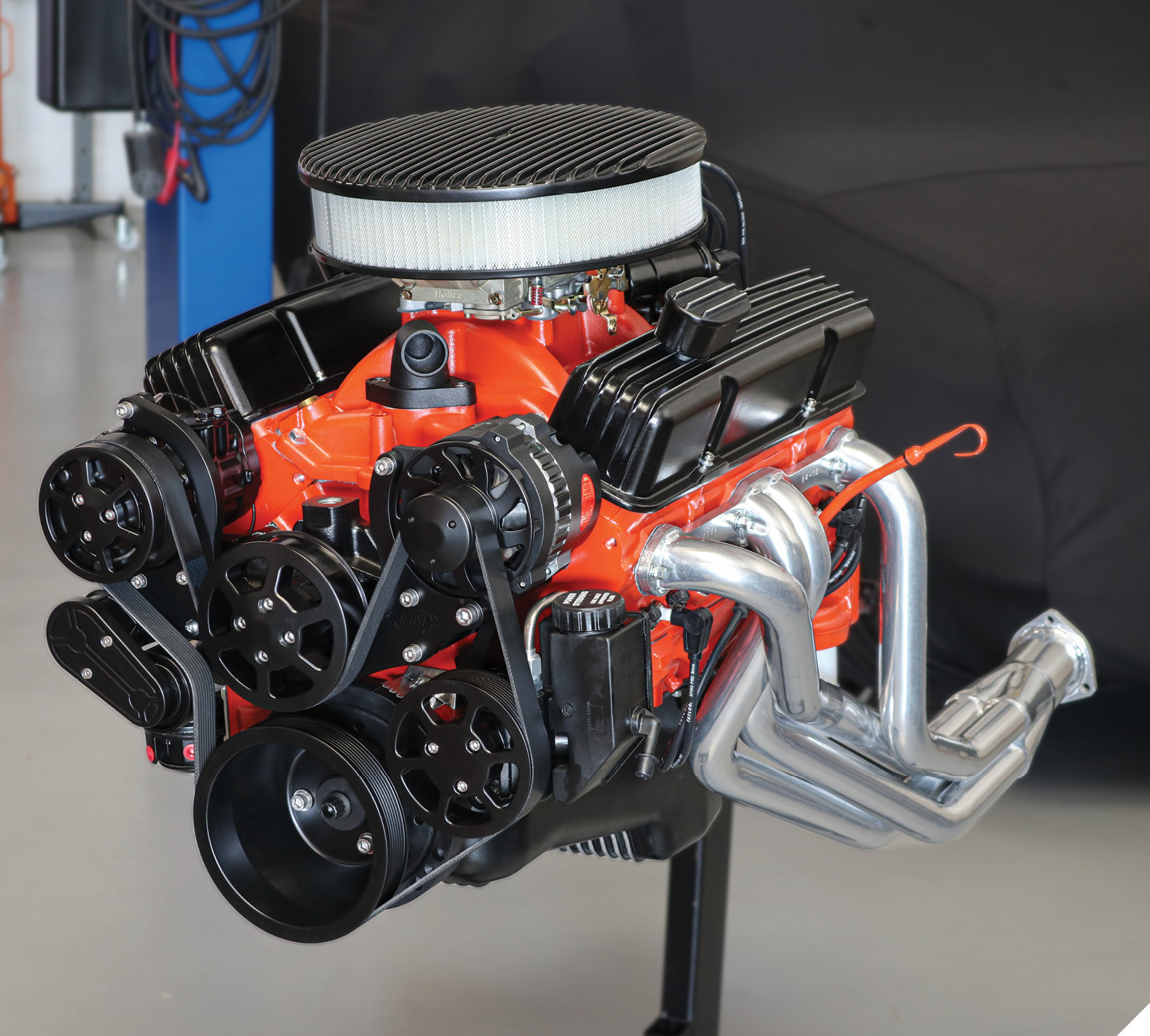

We decided to max out on modernity and go with a serpentine system. Using a single belt gives the setup a more organized and coherent look while also being functionally simple. The compact design should fit nicely in the engine bay of our Nova without having an alternator or compressor hanging unnecessarily high above the block. Another great feature of Eddie Motorsports’ serpentine system is the belt tensioner. There’s no more guessing how tight to make your drivebelt—let alone needing to set the tension on multiple belts—and it’s easy to install or remove, too. The tensioner is also a common GM part that you can pick up at a local auto parts store if it ever needs replacing. Then, deciding between the six- and eight-rib options, we opted for the latter. Eddie Motorsports claims the wider belt can handle 33 percent more torque, which is especially helpful for vehicles with wider front tires that like to hit the autocross course every now and then.

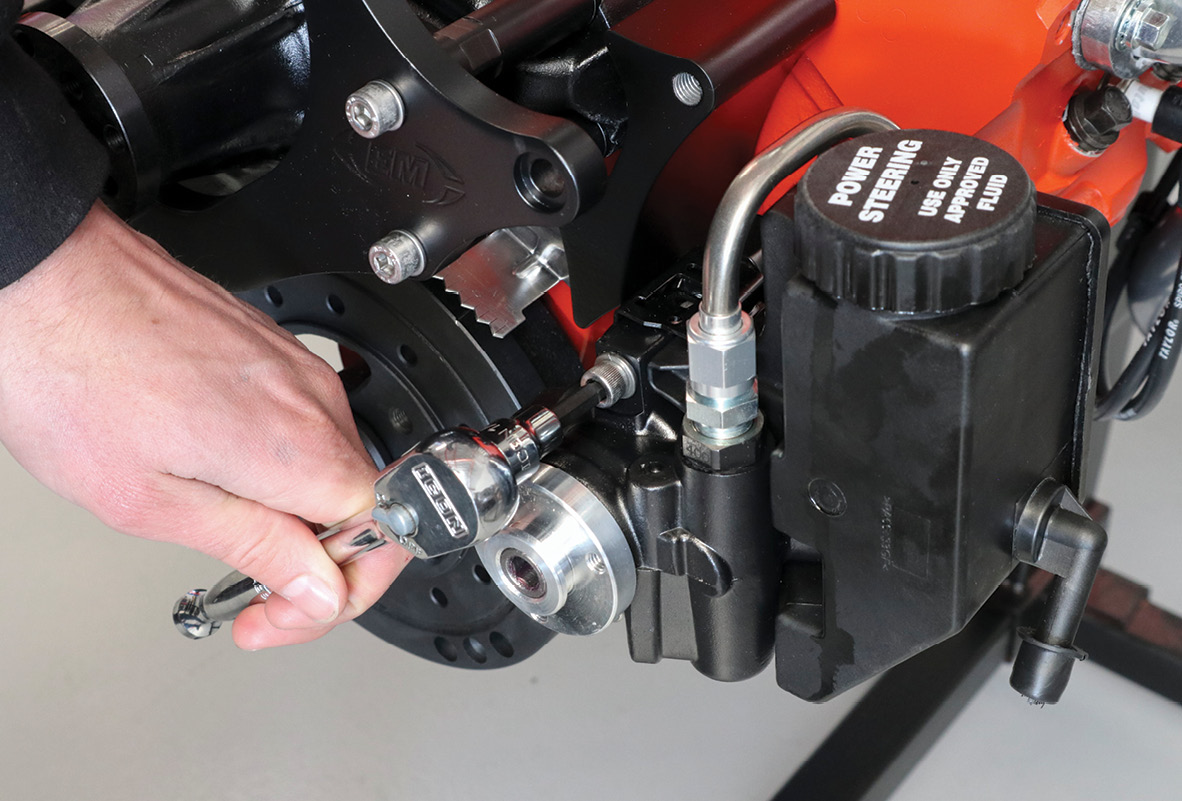

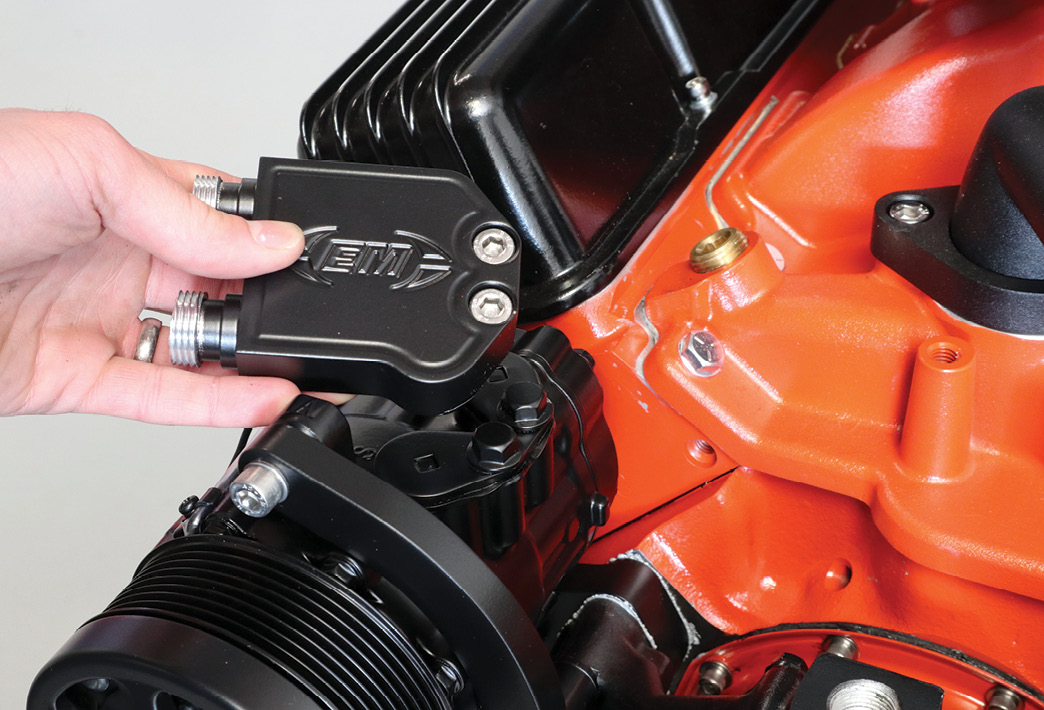

For accessories, we definitely needed a power steering pump; having a GM Type II pump is a plus in terms of reliability and compactness. We were happy with the standard plastic reservoir, although a billet aluminum version was also available. The alternator that comes with the kit is a 170-amp, single-wire unit from Powermaster. This will give us way more output than we need for our current, mostly stock electrical system but gives plenty of overhead for future upgrades.

Finally, we hemmed and hawed for a bit over getting the A/C compressor. On one hand, our Nova is a Southern California cruiser and we’re unlikely to put in the effort to install a complete climate-control system anytime soon. On the other hand, it’s a small additional investment to at least give us the option in the future. If you looked at the feature image of this article you probably already spotted our decision.

The next fun choice we got to make was the finish (or color) of our serpentine system. Eddie Motorsports offers a plethora of finishes, ranging from raw to polished to black anodized and more. Already having played a bold move by painting our entire aluminum-headed engine Chevy Red-Orange, we felt the need to offset all that color. Eddie Motorsports’ Raven Series was just what we were looking for. More specifically, we decided to go with their Matte Black Fusioncoat.

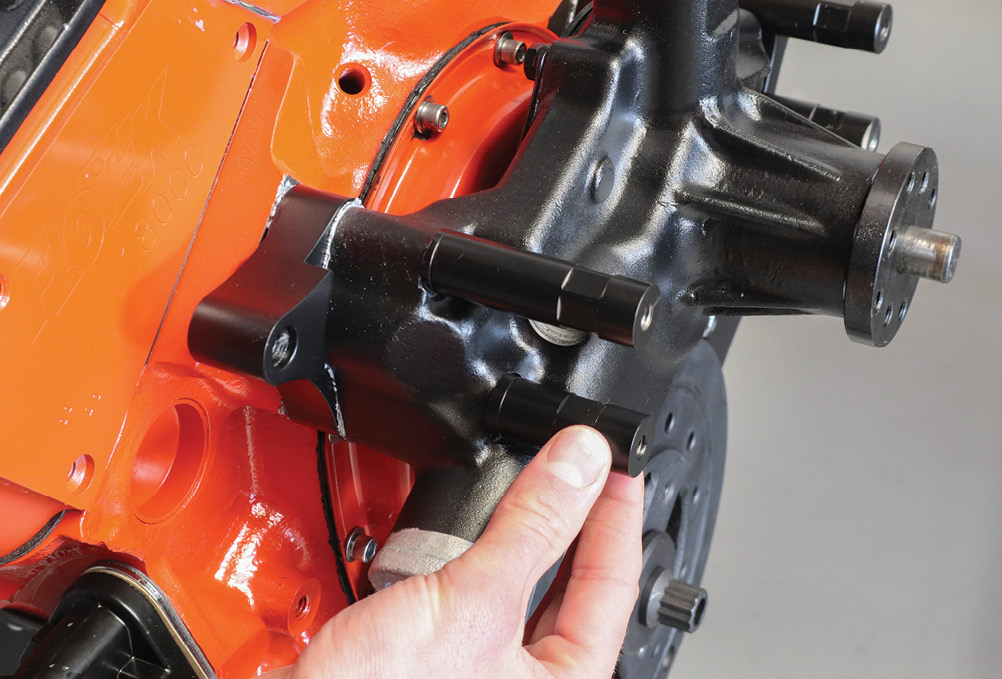

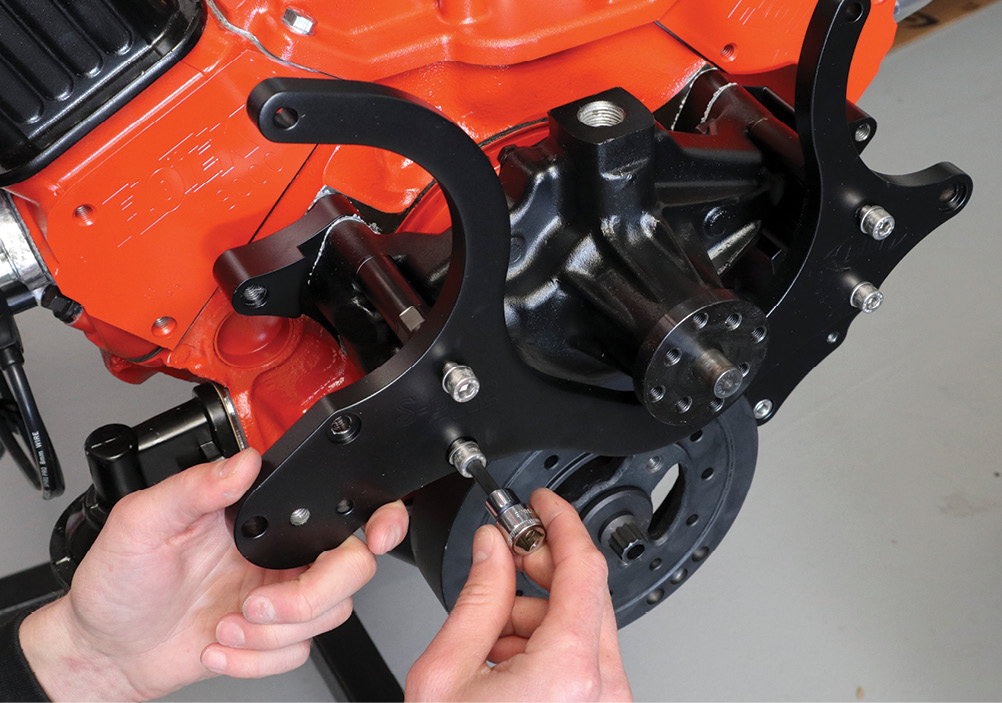

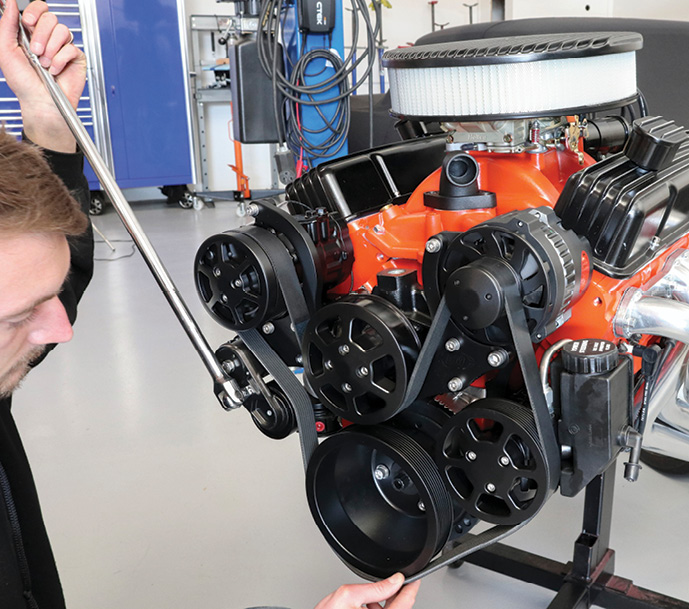

The installation process was refreshingly simple, no specialty tools needed, and it only took a leisurely couple of hours on a Saturday morning to complete.

16. The final accessory to hang was the A/C compressor, which has two M8x25mm capscrews for the main bracket and then a ½-inch shoulder bolt securing it to the compressor bracket.

19. Make sure not to install the A/C compressor manifold until you are fully ready to install your A/C lines and charge the system.

SOURCE

SOURCE