TECH

TECH

Photography by The Author

Photography by The Authoruel pumps used to be simple. They bolted to the side of your engine, were 100 percent mechanical in nature, and usually had enough capacity built in to handle some basic engine upgrades. Plus, they were cheap, simple, and easy to replace. As the induction systems that power our rides have evolved, so have the fuel systems required to power them. With modern EFI, choosing the right fuel pump is more critical than ever to longevity and power.

Also, fuel pumps are typically able to flow a greater volume of fuel at lower pressures. A pump might flow one volume at 43 psi and a lesser volume at 60 psi. Knowing what pressure your fuel injection will operate at is key to evaluating if a particular fuel pump will deliver sufficient flow.

If your engine was run on an engine dyno before being installed in a car, knowing the BSFC (brake specific fuel consumption) is the best way to accurately size your fuel pump. The math problem works out like this:

Peak Horsepower x BSFC = Max Fuel Required (typically measured in lb/hr)

Pumps are typically rated in gallons per hour (gph) so some additional conversion will be needed, i.e., dividing by the specific weight of the fuel you’re using, about 6 pounds for gasoline and about 6.59 pounds for ethanol and methanol to get to gallons per hour. If you’re shopping for pumps rated in the metric equivalent of liters per hour, which many pump manufacturers now use, you’ll need to convert gallons per hour to liters per hour. It’s important to make sure the units of measure are equal for accurate comparison.

The most important consideration for your new fuel pump will be how it’s mounted. In the early days of fuel injection, it was common to mount the pump along the framerail, where it could be easily reached. While this was great for maintenance purposes, manufacturers soon realized that this made for a pump that was both loud in operation and prone to overheating and vapor lock. To combat those issues, fuel pumps started to be installed inside the fuel tank. The volume of fuel in the tank helped to quiet the pump’s operation and act as a coolant to help regulate the pump’s operating temperature. The result was a quieter, longer-lasting pump.

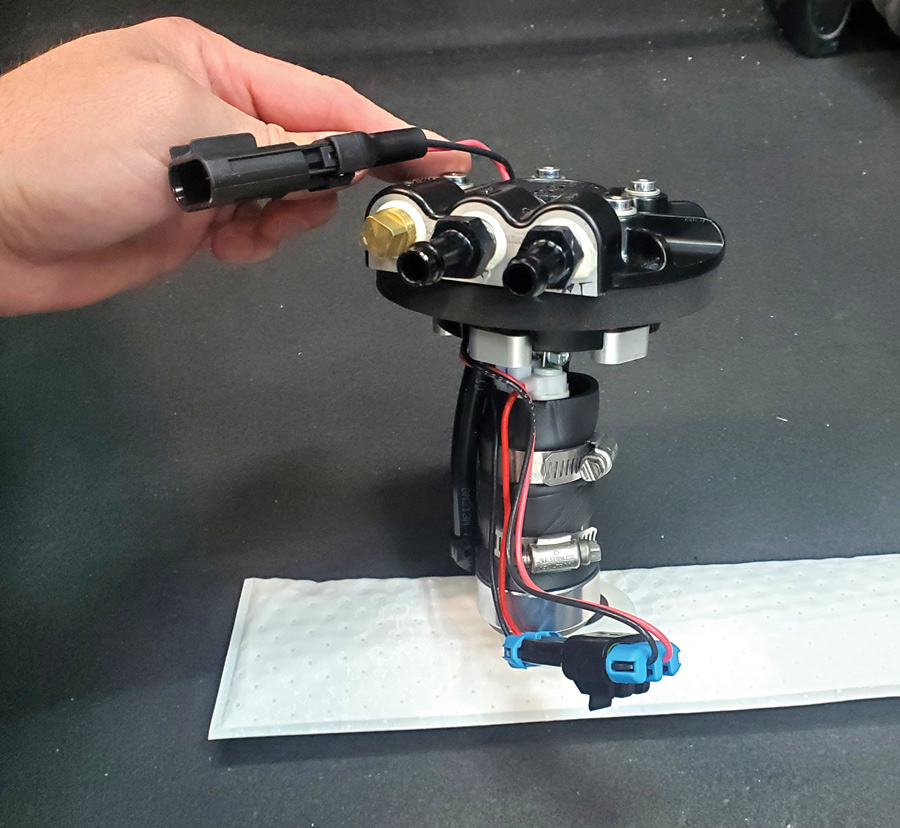

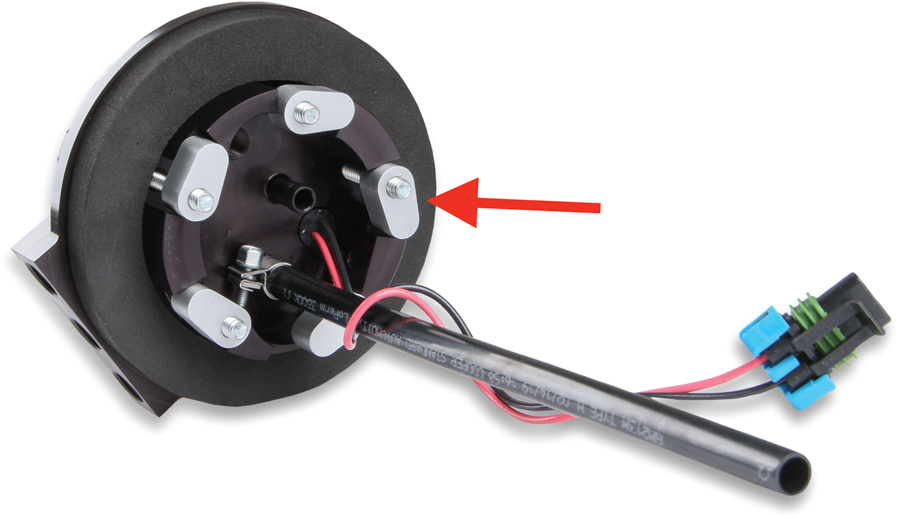

Holley’s In-tank Muscle Car Diecast EFI Modules are the hot ticket for just about any fuel tank between 7 and 12 inches deep. They are offered in return-style and return-less configurations and install simply by drilling a hole in the top of the tank. Once the hole is drilled, the module drops into place and small cams swing out while the pump is tightened down. These cams grab the sheetmetal of the tank and pull it flush while sandwiching a thick gasket.

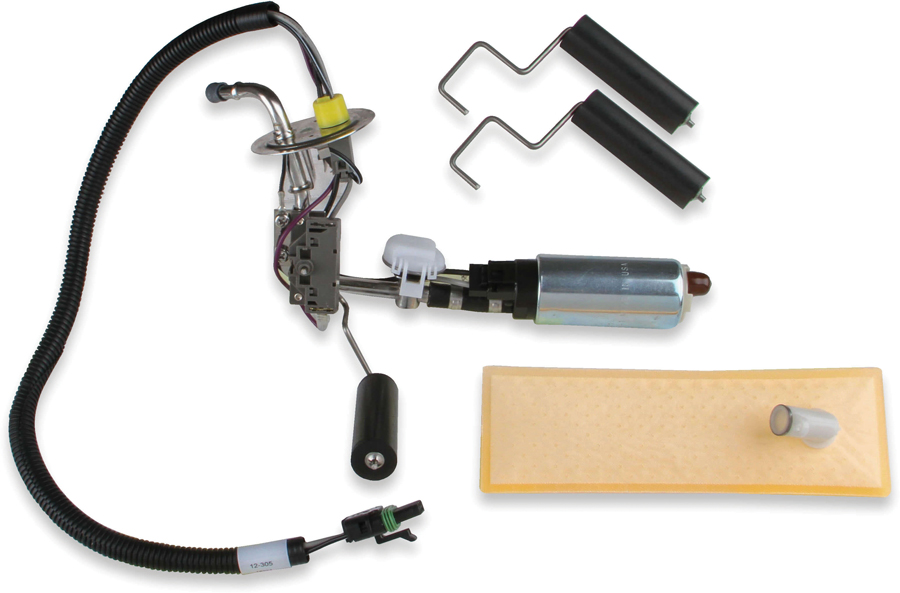

Pumps such as the Holley Dominator in-line series are available in twin and single configurations and are compatible with nearly all fuel types. They are a staple in the racing world and can even be mounted in-tank if a custom tank/cell is being fabricated. The dual pump variants (such as PN 12-1800) are designed to run off one pump, but a pressure switch or other switching means can be used to turn on the second pump. This is especially useful for boosted or nitrous-assisted cars and helps to keep fuel temperatures lower when power demands are low.