Upgrade Options

Tank Upgrade

Suspension

Upgrade

TOC

TOC

378 E. Orangethorpe Ave. Placentia, California 92870

#ClassicPerform

Wes Allison, “Rotten” Rodney Bauman, Shawn Brereton,

Tommy Lee Byrd, Ron Ceridono, Grant Cox, John Gilbert, Tavis Highlander, Jeff Huneycutt, Barry Kluczyk, Scotty Lachenauer, Jason Lubken, John Machaqueiro, Ryan Manson, Jason Matthew, Josh Mishler, Todd Ryden, Jason Scudellari, Jeff Smith, Tim Sutton, Wes Taylor, and Chuck Vranas – Writers and Photographers

Travis Weeks Advertising Sales Manager

Mark Dewey National Sales Manager

Patrick Walsh Sales Representative

ads@inthegaragemedia.com

AllChevyPerformance.com

ClassicTruckPerformance.com

ModernRodding.com

InTheGarageMedia.com

inthegaragemedia.com “Online Store”

For bulk back issues of 10 copies or more, contact store@inthegaragemedia.com

info@inthegaragemedia.com

Editorial contributions are welcomed but editors recommend that contributors query first. Contribution inquiries should first be emailed to info@inthegaragemedia.com. Do not mail via USPS as we assume no responsibility for loss or damage thereto. IN THE GARAGE MEDIA, INC. reserves the right to use material at its discretion, and we reserve the right to edit material to meet our requirements. Upon publication, payment will be made at our current rate, and that said, payment will cover author’s and contributor’s rights of the contribution. Contributors’ act of emailing contribution shall constitute and express warranty that material is original and no infringement on the rights of others.

Copyright (c) 2023 IN THE GARAGE MEDIA, INC.

PRINTED IN U.S.A.

firing up

firing up

BY NICK LICATA

BY NICK LICATA

ith the Jan. ’24 issue of All Chevy Performance magazine, we are excited about starting our third year in production. To all of us here at the In The Garage Media command center, it’s a huge milestone. At a time when print publications were struggling to survive, we decided to start a new one. That doesn’t sound very smart, but we were convinced that putting out a superior product to what was available would prove the naysayers wrong. We were right and All Chevy Performance’s reader base is growing each and every month.

As the saying goes, “Time flies when you are having fun.”

Who knew when we started this magazine endeavor three years ago we’d come as far as we have. Exactly how far is that? Glad you asked. When we began publishing All Chevy Performance the idea was to have the magazine available by subscription only. Since then, we grew at such a rapid pace, ACP can now be found in major book retailers like Barnes & Noble and Books-A-Million. But the game changer was when we got into Walmart stores. That was kind of a big deal. It was also a big deal when we took the magazine to a larger format starting with the Jan. ’22 issue. When it comes to magazines, there’s no denying that bigger is better.

PARTS BIN

PARTS BIN

1. GB3C

CHEVY CONCEPTS

CHEVY CONCEPTS

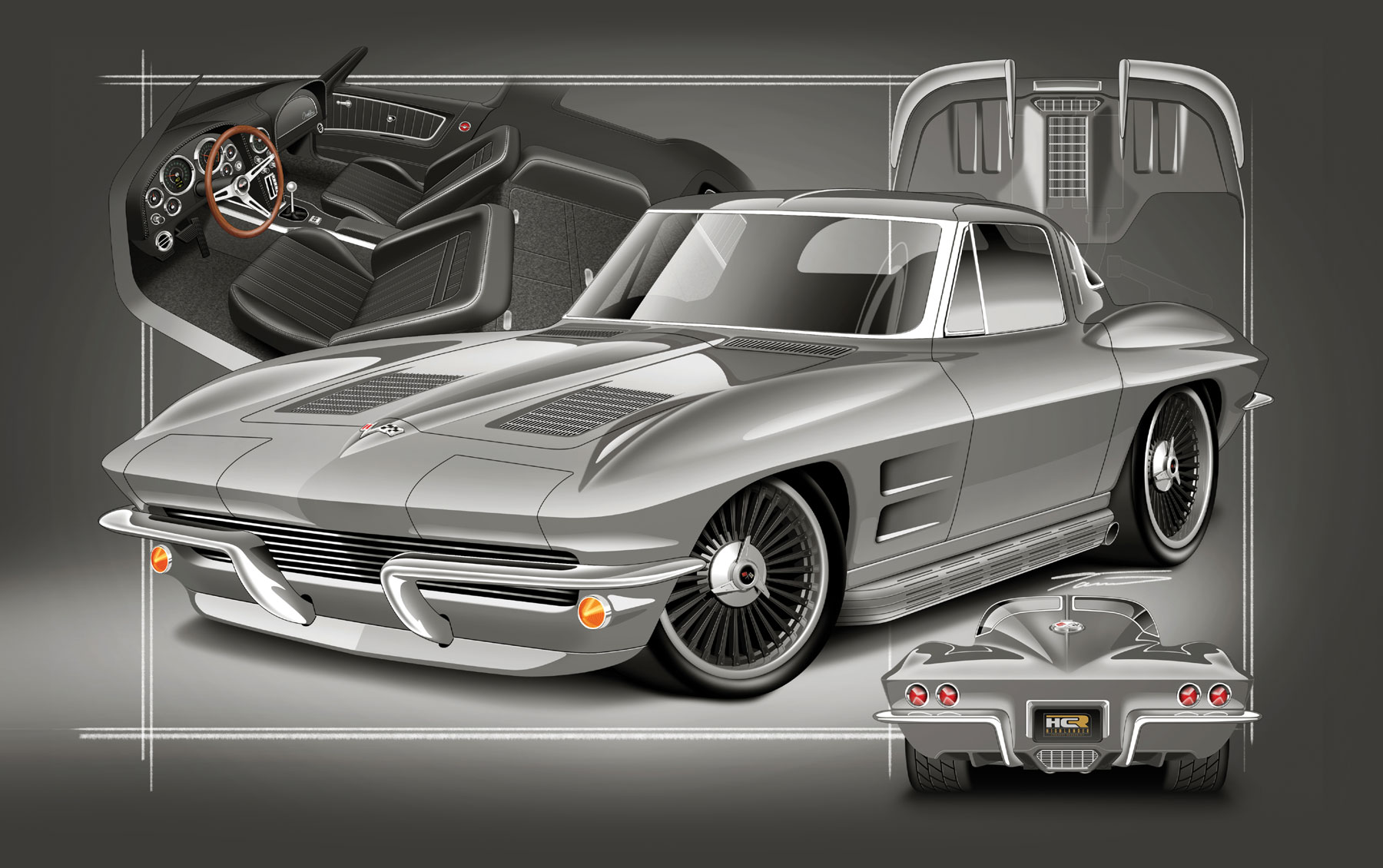

Text & Rendering by Tavis Highlander

Text & Rendering by Tavis Highlanderhere’s a lot going on with this Vette, and at first glance you wouldn’t even know it. The front valance under the grille has been extended down to match the rocker height. Underneath that is a small front lip that matches the bottom of the side pipes. The rear of the car features a very intense diffuser/pan that terminates with a center exit exhaust. Small detail adjustments were made to the factory turbine-style wheels to make them a bit more unique.

Inside the cockpit everything appears fairly stock, but it’s a fully built interior. The door panels mimic what GM had going on, just with more detail and depth. Bolstering has been added to the seats and custom inserts keep them looking vintage. In the rear is a storage system under the floor that is accessed via custom doors.

Feature

Feature

Photography by John Jackson

Photography by John Jacksonrowing up on an island completely void of anything muscle car–related makes the story of how this ’67 Chevelle came about somewhat of a longshot and one worth telling. Owner John Spanos grew up on a small Greek island where there was an abundance of motorcycles but no muscle cars to speak of. “Where I grew up, everyone rode motorcycles, so I was naturally drawn to them,” John explains. “With half my childhood being spent there, I suppose that makes me a late bloomer when it comes to the muscle car scene.”

TECH

TECH

Photography by The Author

Photography by The Authorritics have been calling for the death of the internal combustion engine for decades now. And, as you very well know, so far they have been sorely disappointed.

That’s because smart engineers and innovators have been continually finding ways to make gasoline engines more efficient until we have the marvels of modern engineering that hot rodders are enjoying today. One of the latest innovations that has made a really big difference is direct injection. Like a diesel, direct-injection engines squirt the gasoline directly into the combustion chamber instead of into the intake port above the valve like on previous-generation port fuel-injected engines.

The biggest benefit of direct injection is you can squirt the fuel into the combustion chamber whenever you want and not have to time the injector to when the intake valve is open. This means you can inject the fuel into the combustion chamber at the last possible moment before igniting the mixture with the spark plugs. This not only improves fuel burn for fewer pollutants going out the exhaust, but it also unlocks horsepower thanks to the higher compression ratios that are now possible with pump gas since the late injection of fuel reduces the chances of detonation.

FEATURE

FEATURE

Photography BY Wes Allison

Photography BY Wes Allisonn the early ’30s, Bell Auto—located, you guessed it, in Bell, California—was a hot rodder’s hangout, the place to be and be seen at the time. Owner George Wight started out with a wrecking yard, but his interest in performance parts along with his talent in refurbishing them turned his focus into what became the first and most important speed shop in the country. We could go on about what made Wight so successful and how he bought and improved the Valve-in-Head for Model A Fords, as it’s a very cool story, but we’re here to dig into Rick Van Unen’s impressive ’57 Chevy Bel Air.

So why even bring up George Wight and Bell Auto? Well, that’s the place Rick worked as a teenager back in 1963 and, as he puts it, “that’s where I got my hot rod education. Working alongside Wally Parks’ brother, Kenny, and Jot Horne–the designer of the iconic Cragar S/S wheel—was an amazing experience,” Rick says. “I looked up to those guys and here I was working with them and learning everything I could about hot rodding and the ins and outs of running a speed shop.”

After leaving Bell Auto, Rick served in the Marine Corps, came back, and went to work for a small four-wheel-drive company called Dick Cepek. Over the years, Rick worked his way up the ladder and became president of the company. He left there for an entrepreneurial career, and once he’d had enough of the workforce grind, he called it a day and simply retired. And that’s when Rick really got busy. Through the years, he’s owned numerous rides of various makes and models, and today he spends much of his time driving his hot rods on a number of cross-country tours. In past issues of All Chevy Performance, we have featured two of Rick’s cars: an LT4-powered ’64 Chevelle wagon and a ’73 Camaro powered by a supercharged L99 engine, both of which do very little sitting as he makes sure each one gets plenty of road time.

TECH

TECH

Photography by The Author

Photography by The Authorot rodders and racers of all sorts have long understood the advantages to coilover suspension: the spring rate can be easily changed, the shock absorbers are available with fixed, single- and double-adjustable damping characteristics, and ride height can be quickly altered. While coilovers are often found on a variety of vehicles, it was always considered too difficult to retrofit vehicles that came equipped with coil springs from the factory. That all changed with the availability of what can best be described as hybrid coilover kits, like those available from Aldan American.

Aldan has been a leading manufacturer of suspension components for well over 40 years. All their shocks and coilover kits are manufactured in the U.S. from lightweight, high-strength 6061-T6 billet aluminum, which makes them incredibly strong and light weight. All use low-friction Viton seals and O-rings, the shock’s shafts are heat-treated, chromed, and finish ground before final assembly to reduce seal friction. All shocks are fully serviceable and rebuildable and come with Aldan’s 100 percent satisfaction guarantee. Now, along with shock absorbers and conventional coilovers, Aldan’s product line includes retrofit coilover kits for a long list of IFS-equipped cars.

What makes these coilover conversion kits work are the unique coil springs that fit into the car’s original upper spring pockets in the chassis on one end, with small-diameter “pig tails” that fit onto the shock’s threaded adjusters on the other. Like conventional coilover springs, these conversion springs are available in a wide variety of spring rates to provide the ride and handling qualities to fit your specific application. One of Aldan’s coilover kits that caught our attention was PN 300134 that fits ’58-70 fullsize Chevrolets and ’63-82 Corvettes—just what we needed for our split-window Vette project.

Feature

FeatureBY Scotty Lachenauer  Photography by THE AUTHOR

Photography by THE AUTHOR

e’ve all seen it; the lifelines of similarly bred muscle cars can vary greatly. It all depended on what the purchaser had in mind when he laid his hard-earned money down on his future dream ride. Did you buy that big-block bruiser for a life on the street, dominating your local enthusiasts at every streetlight standoff? Or was it purchased to be a standalone racer to do its dirty work a quarter-mile at a time?

TECH

TECH

Photography by The Author and Courtesy of the Manufacturers

Photography by The Author and Courtesy of the Manufacturerst’s not like you woke up one morning and told yourself “I’m going to become an engine builder.” That’s rarely how it starts. It more often begins when you find yourself buying a torque wrench, a dial caliper, or maybe a universal piston ring compressor. Pretty soon, there’s a growing collection of gear in your tool cabinet, but to do the job correctly, you know you need to get serious, and that demands better tools.

We thought it would be worth the effort to assemble a collection of the popular LS engine building tools that any self-respecting master of the micrometer should have in his or her possession. This is not a complete set of ideas but rather a collection of the tools that experience shows are necessary for this next-generation small-block Chevy.

The initial part of our list covers the basics that everyone needs to accomplish the barest of engine assembly tasks. A few of the more specialized items can be considered universal items like ring grinders and cam degree components, while the majority will aim specifically at the LS engine family.

Feature

Feature

The “Tiger II” Chevelle Funny Car Lives Again!

Photography by THE AUTHOR

Photography by THE AUTHORf you’ve ever wondered where the term “Funny Car” came from, it may become apparent with one glance at this wildly altered Chevelle drag car. The odd proportions were the result of moving the rear axle forward to achieve better weight transfer, but the reality is that these funky-looking creations didn’t last long before the one-piece fiberglass flip-top bodies became the norm. The name Funny Car stuck, even though the floppers of the late ’60s had much better proportions. But for a brief time in 1965 and 1966 the cars were wild, and they literally got wilder with every week that passed. This meticulously restored drag car is one of the founding fathers of Funny Cars, as it is the world’s first tube chassis, center steer, full-bodied drag car. This car’s restoration and careful attention to detail allows us to hit the pause button on the rapidly evolving world of A/FX match racing and Funny Cars, pinpointing a three-month window when the “Tiger II” Chevelle ran in this configuration.

TECH

TECH

1. Our ’77 Nova daily driver gets some much-needed attention with a new tank and sending unit from Classic Industries.

Fill’er Up!

Installing a New Gas Tank in a Crusty Nova

By TOMMY LEE BYRD  Photography by The Author

Photography by The Author

f you’ve ever daily driven an old car, then you know about the perpetual repair and maintenance process. The more you drive it, the more issues you’ll uncover, but there comes a point where things settle down and you can just turn the key and go. Our example is a ’77 Chevy Nova, which you’ve seen before on the pages of All Chevy Performance in other tech articles. We addressed the brakes in previous installments and now we’re moving onto the fuel system. The car runs and drives great, but one look under the rear was enough to tell us the fuel system needed some attention.

The rust and crust had accumulated to a great degree, but our initial hope was that the inside of the tank was clean. That hope went away when the car’s fuel gauge suddenly started reading incorrectly due to an issue with the sending unit. After running out of gas on two occasions when the gauge read a quarter tank, we decided it was time to make a call to Classic Industries and get some new parts on the way. A new gas tank (PN FT2007A) would ensure a fresh supply of gas would make its way into our malaise era small-block. We added new straps (PN FT1103B), an anti-squeak rubber set (PN UK915) and a new sending unit (PN 25000309). Four feet of 3/8-inch rubber hose from the local parts store gave us enough material to replace all rubber in the fuel system, and we also picked up a new Wix fuel filter and gas cap while we were there.

We had a couple of options for the type of sending unit: a single line and a dual line, which is used for a return-style system. The return-style system was a relatively new concept in the ’70s and still utilized a mechanical fuel pump. Since we replaced the original fuel pump with a standard single-line mechanical pump for an older application, we went with the single-line sending unit. The dual-line sending unit would be a great drop-in option if you wanted to upgrade to EFI.

Feature

FeatureInTheGarageMedia.com

BY Scotty Lachenauer  Photography by THE AUTHOR

Photography by THE AUTHOR

grew up loving the second-gen Camaro body style. To me they always looked fast while standing still; knowing that, my dad picked up this ’79 Camaro for me when I was 15. I didn’t even have my driving permit, but it was a smart move to grab it while it was available. We both knew we could build it into a dependable street/strip car,” Nick Trial of Babylon, New York, says.

The young gun felt like the luckiest kid in the world when his dad, John, had the wherewithal to purchase this ’79 Berlinetta for his very own. “The Camaro was a clean, original ride, with a spotless interior and a 350 underhood. It had sat for over 25 years, but my dad saw the potential. I remember the day he brought it home. I waited up till 3 a.m. to see it. Even with two bent pushrods I got the chance to drive it around the block,” Nick states.

EVENT

EVENT

By barry kluczyk  Photography by The Author

Photography by The Author

wen Simpson raised more than a few eyebrows on a cool September morning when his ’70 Yenko Deuce cut the beams in 11.88 seconds at Mid Michigan Motorplex—a track more than 200 miles away from his home in rural Ontario, Canada—during the Pure Stock Muscle Car Drag Race.

It was not only the quickest pass for a Chevy at the race—and second-quickest overall, behind only a Hemi Mopar—it was the quickest-ever pass for a small-block-powered car in Pure Stock Drag’s history and the highlight for a competitor who’s been coming to the race since his high school days more than 15 years ago. It’s a legacy that builds on his father “COPO Pete” Simpson, who’d been a fixture at the event since its very beginning until his death about a decade ago.

“It’s a family tradition,” Owen says. “My dad was competing here from the very start of the race and it’s just something we do.”

Advertiser

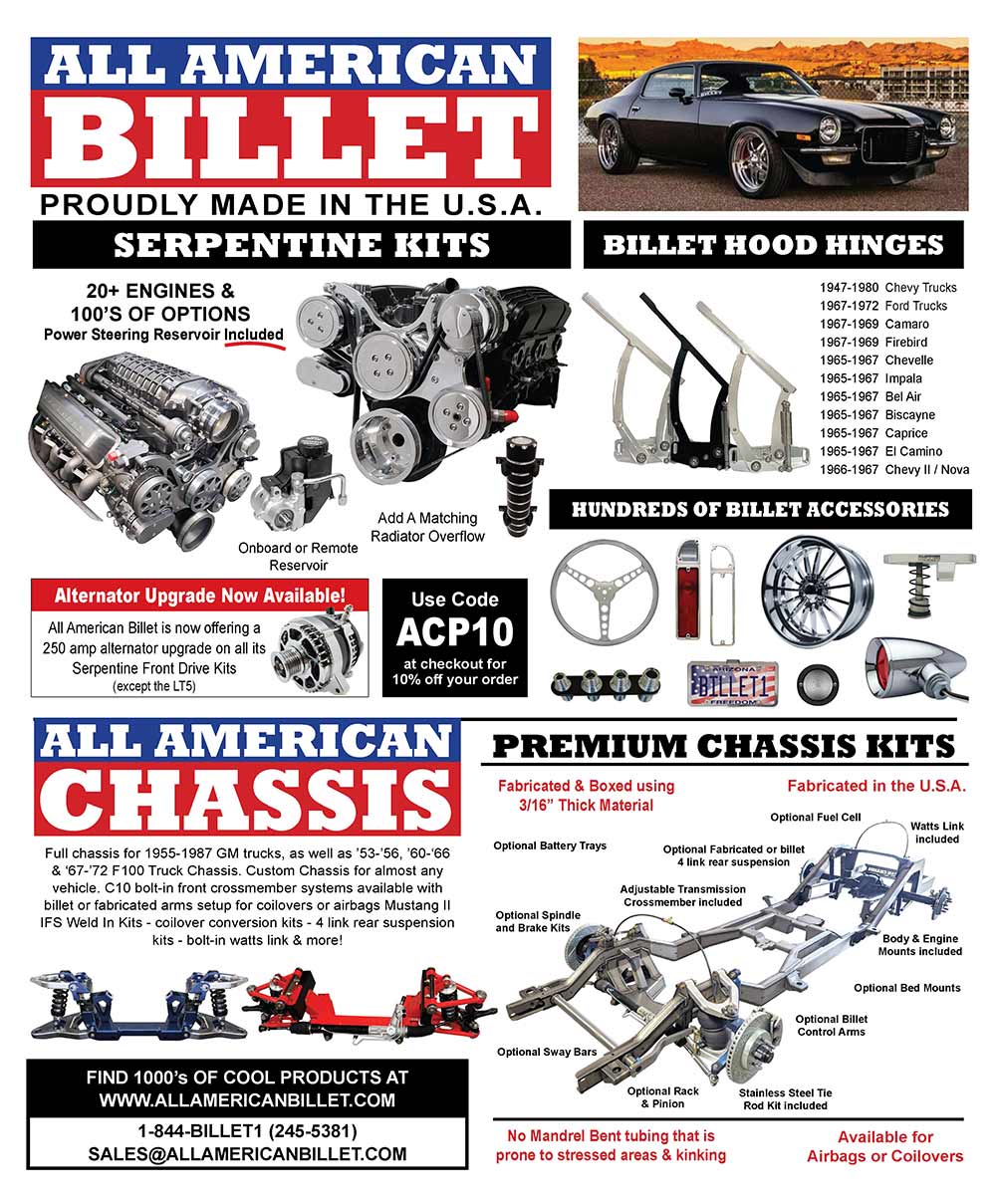

- All American Billet23

- American Autowire27

- AMSOIL9

- Art Morrison Enterprises35

- Auto Metal Direct7

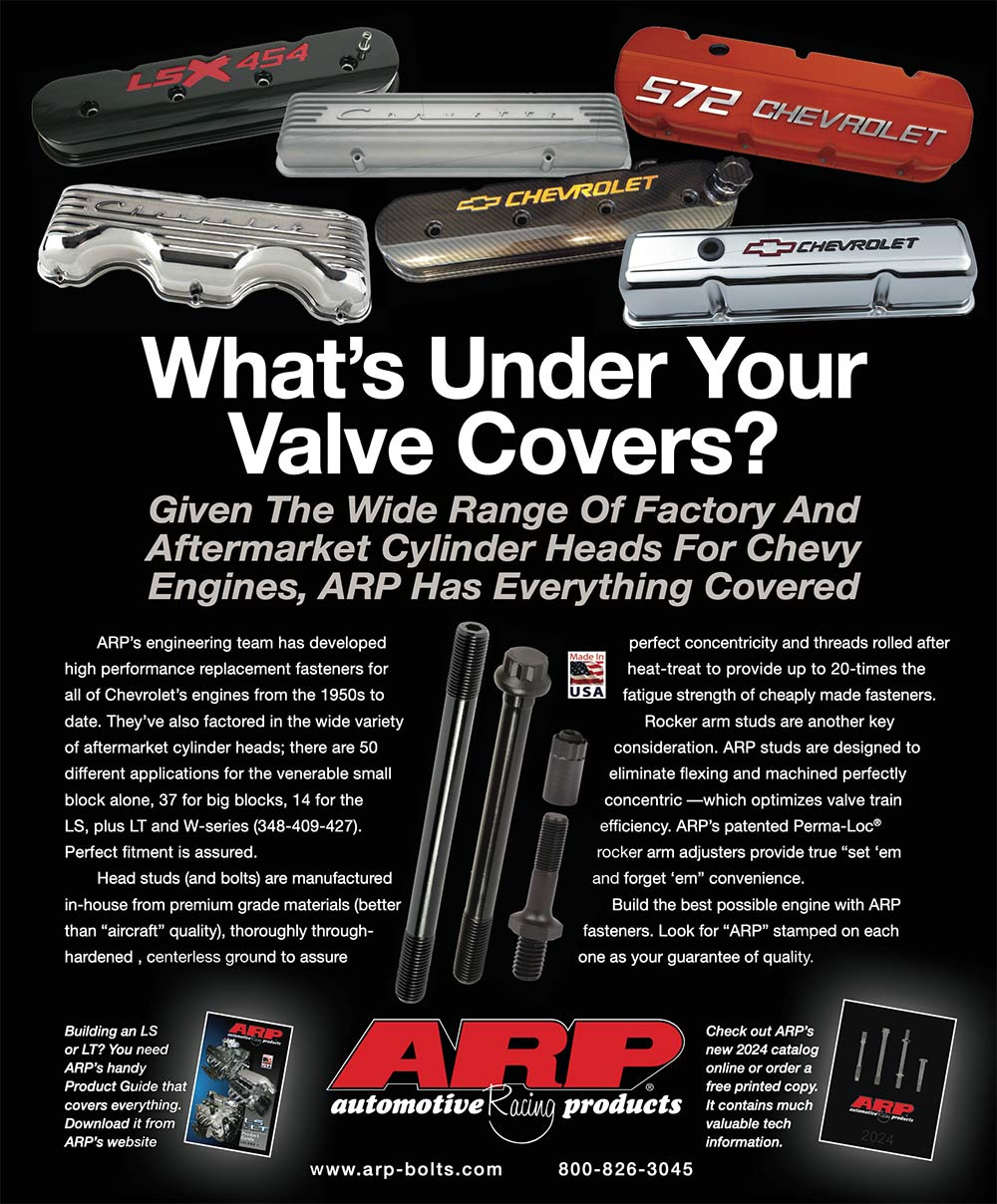

- Automotive Racing Products11

- Borgeson Universal Co.29

- Classic Industries61

- Classic Performance Products4-5, 87, 92

- Custom Autosound83

- Dakota Digital91

- Eddie Motorsports59

- FiTech EFI83

- Flaming River Industries43

- Forgeline Motorsports45

- Granatelli Motor Sports, Inc.81

- Heidts Suspension Systems81

- Hemmings67

- Lokar2

- National Street Rod Association69

- Original Parts Group37

- Powermaster Performance85

- Rod Shows73

- Schwartz Performance89

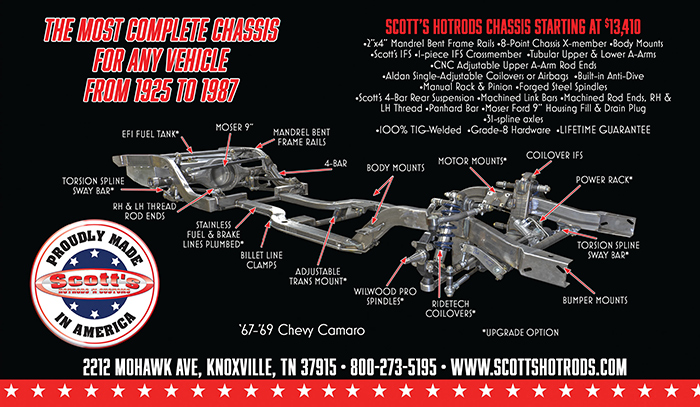

- Scott’s Hotrods87

- Speedway Motors75

- Steele Rubber Products57

- Summit Racing Equipment13

- That’s Great News89

- Thermo-Tec Automotive89

- Vintage Air6

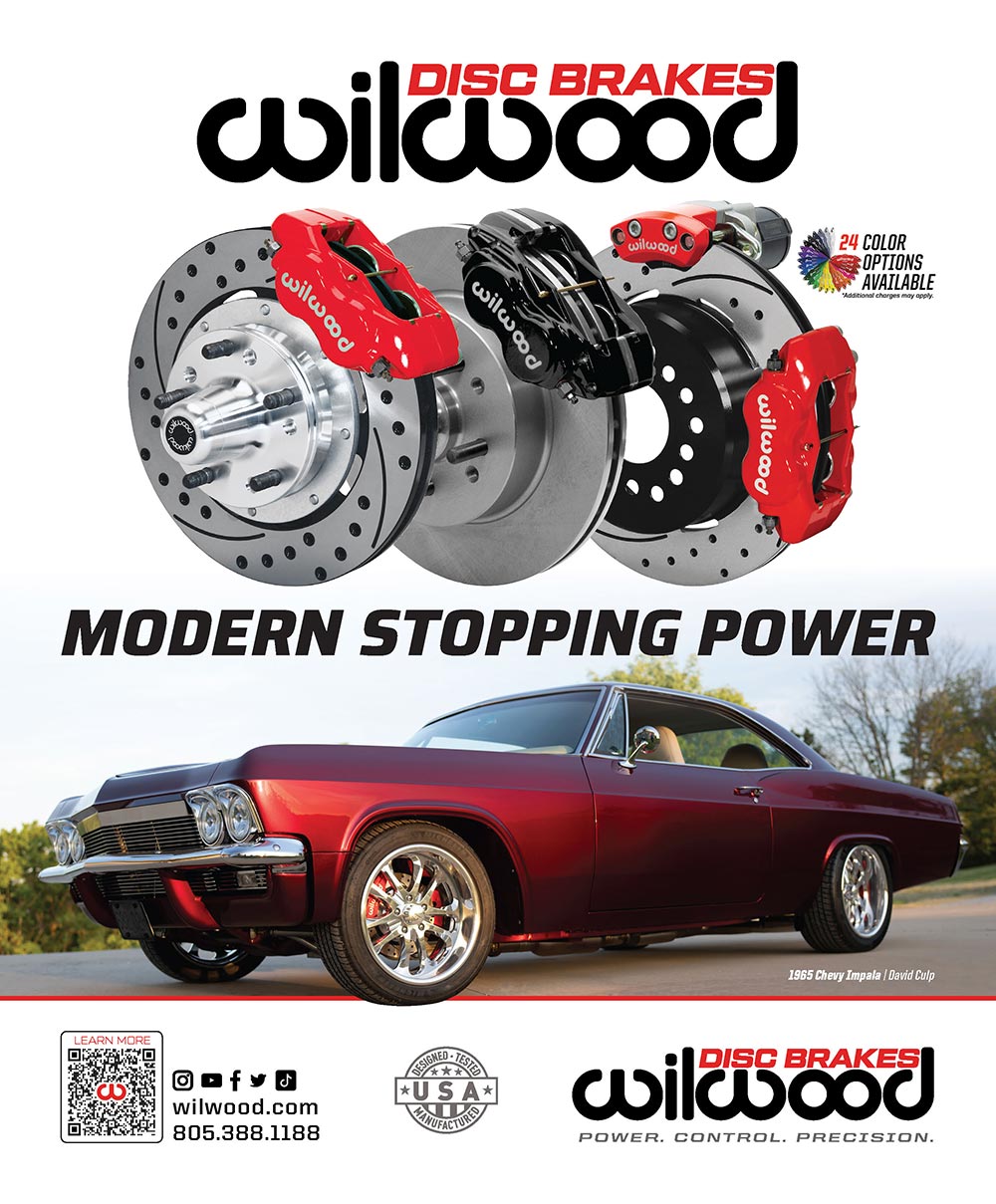

- Wilwood Engineering41

- Year One87