LT Engine Swap Fuel System

LS3 Accessory Drive System

TOC

TOC

Photo by Wes Allison

378 E. Orangethorpe Ave. Placentia, California 92870

#ClassicPerform

Wes Allison, “Rotten” Rodney Bauman, Shawn Brereton, Tommy Lee Byrd, Ron Ceridono, Grant Cox, John Gilbert, Tavis Highlander, Jeff Huneycutt, Barry Kluczyk, Scotty Lachenauer, Jason Lubken, Ryan Manson, Jason Matthew, Josh Mishler, Evan Perkins, Richard Prince, Todd Ryden, Jason Scudellari, Jeff Smith, Tim Sutton, and Chuck Vranas – Writers and Photographers

Travis Weeks Advertising Sales Manager

Mark Dewey National Sales Manager

Patrick Walsh Sales Representative

John Viscardo Sales Representative

ads@inthegaragemedia.com

AllChevyPerformance.com

ClassicTruckPerformance.com

ModernRodding.com

InTheGarageMedia.com

inthegaragemedia.com “Online Store”

For bulk back issues of 10 copies or more, contact store@inthegaragemedia.com

info@inthegaragemedia.com

Copyright (c) 2022 IN THE GARAGE MEDIA.

PRINTED IN U.S.A.

FIRING UP

FIRING UP

BY NICK LICATA

BY NICK LICATA

s we head into the heart of the holiday season and get ready for the upcoming new year, hopefully you’ve spent time with family and friends, or are looking forward to doing so. It’s also a good time to reflect on how much improved this year was over the last. A disastrous 2020 and 2021 really made me appreciate 2022 and being able to get back out to some shows to check out the latest muscle car builds while also appreciating a few that have been around for some time. While out and about I noticed a few fresh builds showing some diversity and old-school personality taking a road less traveled—more like a road not driven on since the ’70s. As I was taking a lengthy walk around the NSRA Nationals (just kidding, I was riding in a golf cart) this past August, I noticed a little less LS and a few more small- and big-block builds under the hoods of classics, paying homage to the past.

I’m not saying modern engines or the Pro Touring scene are dwindling by any means, as that style is cruising along just as strong as ever. Owners of these rides pretty much dominate most local get-togethers as they still enjoy getting behind the wheel of a vintage car that behaves like a late-model hot rod.

Parts Bin

Parts Bin

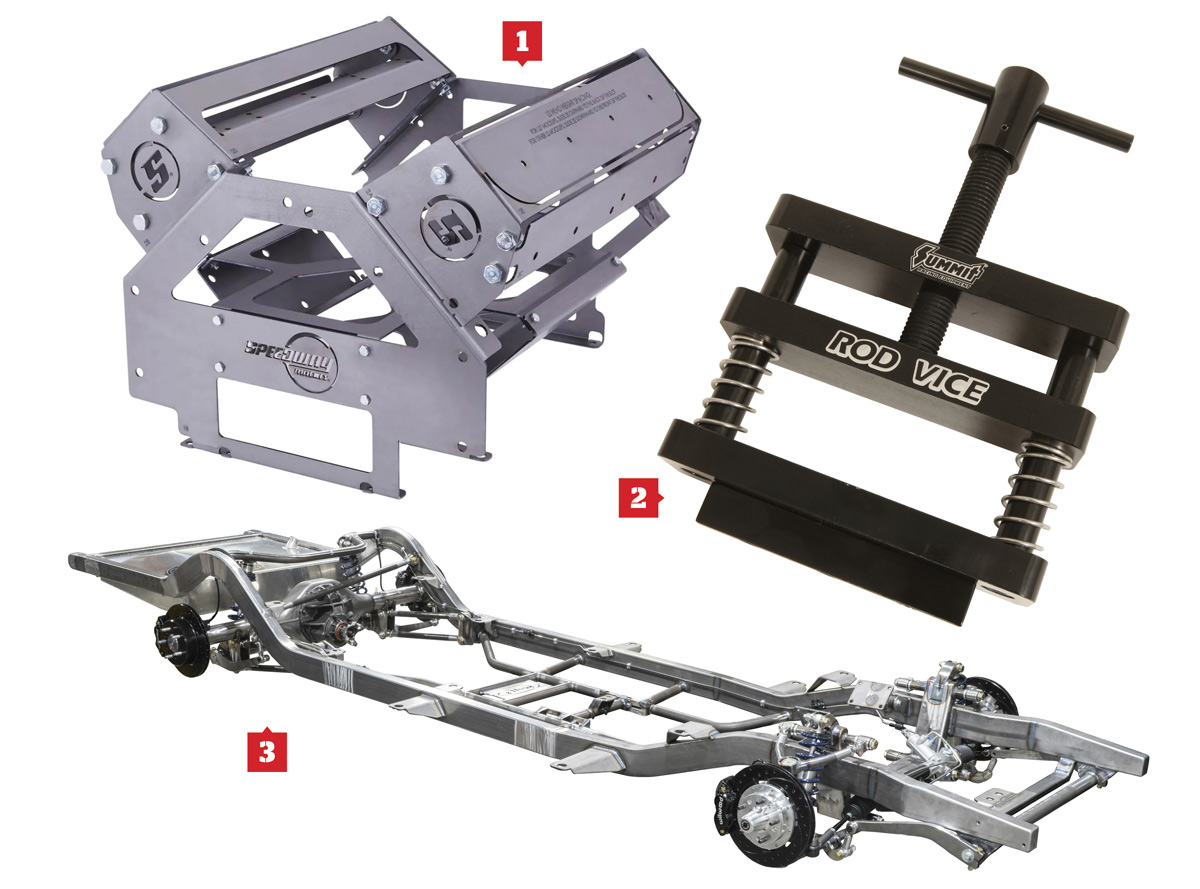

1. Mock Block

For more information, contact Speedway Motors by calling (855) 313-9173 or visit speedwaymotors.com/allchevyperformance.

The Summit Racing Connecting Rod Vise is designed to hold steel and aluminum connecting rods to make removing and installing rod bolts, beam polishing, or beam machining easier. The aluminum vise has the ability to hold several connecting rods at a time and can be mounted in your bench vise or permanently mounted to your workbench.

For more information, contact Summit Racing by calling (800) 230-3030 or visit summitracing.com.

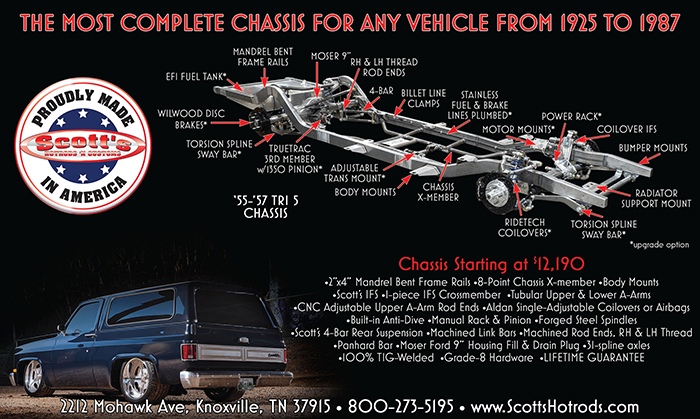

If you are planning on building an all-out Pro Touring street machine or you just want a solid, comfortable cruiser, Scott’s Hotrods ’N Customs has you covered. Their chassis includes complete mandrel-bent 2×4-inch framerails, eight-point chassis crossmember, Scott’s independent front suspension, Scott’s True Parallel 4-Bar Rear Suspension with Panhard bar, and Moser 9-inch housing. Upgrade options include shocks, brakes, fuel tank, power rack-and-pinion, and more. Custom tailor a brand-new chassis to fit your dream hot rod.

For more information, contact Scott’s Hotrods by calling (800) 273-5195 or visit scottshotrods.com.

CHEVY CONCEPTS

CHEVY CONCEPTS

Text and Rendering by Tavis Highlander

Text and Rendering by Tavis Highlander

wner Terry Davlin and I worked together to determine the visual battle plan for his ’66 C2 project. His intent was to maintain as much of the stock look as possible while taking every step to upgrade the performance of the vehicle to his liking. That foundation of performance would center around a Roadster Shop chassis equipped with big Baer brakes. Power is coming from an LME-built aluminum 427ci LSR putting out 685 hp at 7,200 rpm.

With all that performance handled, the attention was then put on how to make the car look the part. The interior would remain stock-looking but quite modified. Sculpted bolsters hold you in place while a reworked dash houses modern A/C vents and controls for comfort.

On the outside, the wheels demanded some big choices. Several options were drawn up, including variations on the stock wheel covers. Forgeline RS6s always look great on C2 Vettes, so that combination has been presented as well.

@TavisHighlander

@TavisHighlander ![]() TavisHighlander.com

TavisHighlander.com

Vehicle Builder: GAP Racing

Vehicle Owner: Terry Davlin

Feature

Feature

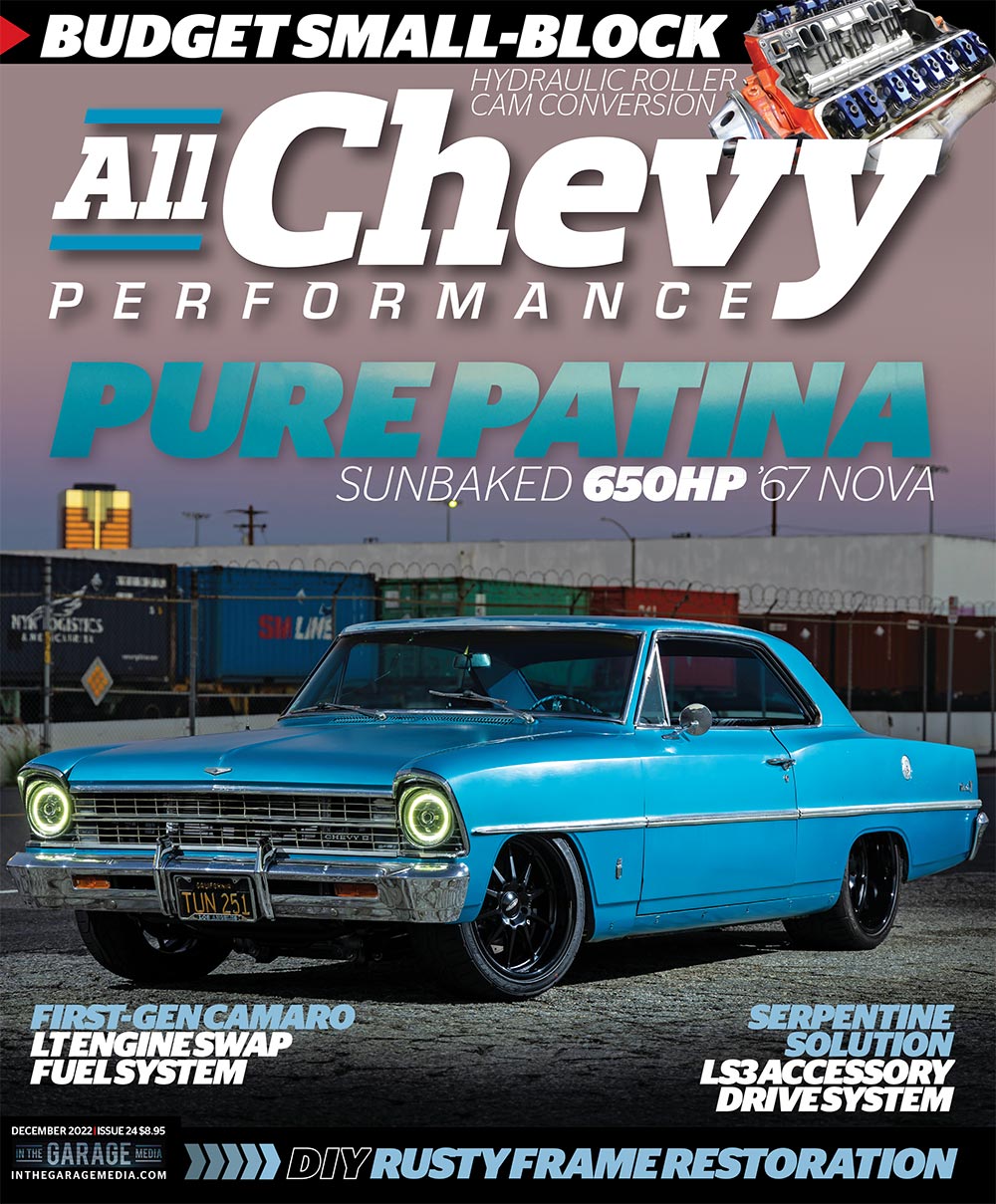

Photography by Wes Allison

Photography by Wes AllisonA surface calcification of implements, usually indicating great age. That’s one definition found on dictionary.com, although when it comes to vintage cars we’d likely include the word “cool” to said definition. It would make that interpretation a more accurate description regarding the finish on Mike Everett’s ’67 Chevy Nova.

TECH

TECHInTheGarageMedia.com

Concept One’s LS Victory Series Pulley System is the Answer to an Accessory Drive Dilemma

BY Ryan Manson  Photography by The Author

Photography by The Author

hen it comes to upgrading the drivetrain on a vintage Chevy, it doesn’t come much easier than using a crate engine from Chevrolet Performance, especially when it comes to their Connect & Cruise systems. Complete from pan to throttle body, these offerings come equipped with a factory-tuned ECU that makes for a literal plug-and-play situation, with a few caveats. Being car guys at heart, when it came time to dress their LS crate engines they knew that fitment would be an issue, depending on accessory location and installation configuration. Put simply, some vehicles have more room than others, especially when it comes to the lower-mounted accessories, namely the power steering and A/C compressor. Additionally, not every installation would require all three accessories, with some opting for a simple alternator mount or an alternator/power steering combo, and so on. That said, it was decided to ship their LS crate engine offerings sans accessory drive, leaving the decision up to the end user. That’s good news for a company like Concept One Pulley Systems that specializes in providing turnkey accessory drive kits for crate engines, new builds, and junkyard resurrections alike.

Feature

Feature

Photography by Wes Allison

Photography by Wes Allison-bodies are becoming quite popular within the muscle car world–and compared to a ’60s-era muscle car they are relatively affordable. But if you have a hankerin’ to get into one of these boxy late-’70s to mid-’80s Malibus and El Caminos, it’s best to make a move soon as they are starting to spike in value. Typically, they were born with a 231ci V-6 and 305 and 350ci V-8s–all of which perform better as paperweights than powerplants by today’s standards. The good news is these cars readily accept a robust small-block or LS engine for a wake-up call. Now that these once-ignored family commuters are gaining popularity within the muscle car world, the aftermarket has begun stepping up their G-body game.

G-body fans have a few choices to go with: a “Malibu pickup” (El Camino), Malibu two-door sport coupe, four-door sedan, and, the ultimate sleeper build, a Malibu four-door station wagon. This editor’s previous rides included an ’82 wagon and an ’82 El Camino, both upgraded with aftermarket suspension and brakes for improved driving performance. Unfortunately, both inherited the gutless 305ci engines. Another benefit is that these cars really light up with aftermarket wheels and a lower stance.

TECH

TECHInTheGarageMedia.com

BY Evan Perkins  Photography by The Author

Photography by The Author

hen Chevrolet’s Gen V engine hit the market, it was a radical change for GM V-8 enthusiasts. The pushrods were still present, the cylinder heads were aluminum and reminiscent of the outgoing LS generation, but the fuel injectors were in a radically different place. Rather than incorporate the muti-port fuel injection that had long been the industry standard, for the Gen V (LT-based) engines, GM chose to add high-tech direct-port injection.

This new style of fuel delivery placed the fuel injector outlet directly in the combustion chamber. The effect is much more control over fuel per cylinder with a host of other efficiencies. However, for the hot rodder, it seemed, well, intimidating as these new systems require extremely high fuel pressures, upwards of 2,000 psi. This is accomplished in OEM vehicles by using an in-tank electric pump paired with a mechanical pump driven off the camshaft.

When swapping an LT into a classic vehicle, such as this ’68 ex-Super Stock Camaro being built at Stoker’s Hot Rod Factory, in Upland, California, the mechanical fuel pump is retained in the engine and only a new low-pressure side needs to be retrofitted.

FEATURE

FEATURE

Photography by The Author

Photography by The Authorrian Henderson has images of a vivid metallic green ’72 Z28 deeply engraved into his memory. As co-proprietor of Super Car Workshop (SCW) in Latrobe, Pennsylvania, Brian is reminded daily of the power of such recollections, as it’s part of what pushes him to search, restore, and collect these muscle car mementos of his youth. Along with his partner, Joe Swezey, SCW continues the good fight, wrenching and restoring these rides back to driveable status and returning them to a life in the public eye.

Back to that Camaro. As a young, burgeoning muscle car aficionado, Brian would travel to nearby Keystone Raceway Park in New Alexandria, Pennsylvania, to get an eyeful of the racing action. One of his favorite cars was that Rally Green Z28 owned by Wally Nicol—a local racing hero who would eventually leave an indelible mark on the young motorhead.

TECH

TECHInTheGarageMedia.com

BY TOMMY LEE BYRD  Photography by The Author

Photography by The Author

hen you’re dealing with a budget beater, it’s hard to justify dumping tons of money into it. Such is the case with our ’77 Nova four-door beater. It’s a little rough, and definitely tired, but for a total investment of $2,000, we’re embracing the low-buck nature of this project. As we’ve been driving it regularly, the Nova developed a squeal in the front brakes, and upon inspection we noticed that the pads were worn down to the wear tabs and the rotor surface appeared to be glazed over badly. This inspired a full overhaul of the front braking system, but we wanted to keep a strict budget to stay in line with the theme of this car.

We hopped onto SummitRacing.com to start shopping around for the least-expensive parts. Our wish list included brake rotors, calipers, pads, flex hoses, and wheel bearings. Summit offers many options for original replacement, as well as upgraded components. When it comes to bang for the buck we couldn’t resist splurging for Summit’s drilled-and-slotted rotors instead of originals. Summit Racing also makes its own brake pads, so we added those to the cart, in addition to the AC Delco replacement brake calipers. Dorman flex hoses and Timken wheel bearings finished our order, until we remembered to grab a can of Summit’s rubberized undercoat so we could give the Nova’s undercarriage a rattle can restoration while it was apart. Our order total came to $298, barely sneaking under the $300 mark.

FEATURE

FEATURE

Photography BY Mike Chase

Photography BY Mike Chaseike McClish’s entry into the racing world began a couple generations before him and today he’s carrying the torch of that family tradition. “I can’t remember a time when my dad or grandfather weren’t working on an engine or car of some sort,” Mike reminisces. “That passion goes all the way back when my grandfather raced speedsters on wooden tracks in the very early days of circle track racing.”

Once Mike’s dad was old enough, he followed suit and raced on dirt and asphalt oval tracks back in the ’60s—Sprint Cars and Midgets, mostly. He also worked for Performance Engineering, a company that built racing engines for modifieds. Needless to say, being immersed in cars his whole life, led to him acquiring the racing bug as well.

With all that performance lineage, the third-generation racer always had a cool ride throughout his high school days. “I had a ’56 Chevy truck with a done-up 327 out of a ’Vette,” Mike tells. “The guys I rolled with also had cool cars. One buddy had a badass ’67 Firebird and another drove a really cool ’64 Mustang. We did a lot of cruising, a little racing, and got into some minor mischief, but it was basically harmless fun.”

Today, Mike has a few cars in various build stages—some finished, including this track-savvy ’68 Camaro you see here. He got the idea to build this car from his brother-in-law who had a vintage Mustang with a rowdy Roush engine. Living in Northern California they had access to and took advantage of Sonoma Raceway and Thunder Hill track day events.

TECH

TECH

InTheGarageMedia.com

BY Jeff Huneycutt  Photography by The Author

Photography by The Author

n a perfect world, every car build starts out with a brand-new rolling chassis from Roadster Shop, Art Morrison, Scott’s Hotrods, or some other quality builders. But, in our world, that dream will just have to live in our heads a little bit longer.

Still, there are things you can do on a limited budget to help bring an old chassis back to life. That’s exactly what we were faced with when we dragged this ’80 Corvette home. The engine was shot, the transmission and most of the interior was missing, and, generally speaking, it was a basket case. But we got it for a good price, and the birdcage seemed to be in good shape—if you know anything about old Corvettes, that’s a big deal. So, it seemed worth saving.

This project, however, is experiencing severe mission creep. Chevrolet switched from fiberglass to steel floorpans in either 1976 or 1977, and the steel floors in our ’80 were severely rusted. In order to get the floors cut out and replaced properly, we decided the body needed to come off the chassis to create enough room to do it right.

Feature

Feature Photography by The author

Photography by The authore all feel a connection with cars. Every one of them has a story. It’s why we write about them, and it’s why you buy this fine publication. Some are tedious to write, especially ones that were bought and just sit in a garage like a piece of jewelry. They are wiped down every now and then and maybe make it to the local cruise-in or ice cream shop, racking up a whopping 50 miles a year. No matter how much they cost, those cars have no soul. Those are the hard ones to write.

Then there are cars like Dave and Laura Linn’s ’55 Chevrolet Bel Air two-door hardtop that virtually write themselves. Dave didn’t do all the work himself (he probably could have), but he had all the right friends to help build the car he wanted, so why not use them? The Chesapeake, Virginia, native is a tech survey civil engineer with the United States Army Corps of Engineers by trade. He purchased the Bel Air in 2010 from his chassis builder, Mike Balf of Mike Balf Race Cars (MBRC), who had received it in lieu of payment for backhalving a car. It wasn’t just some car Balf had sitting off to the side waiting for service, though. No, Dave had to pull it out of a farm field in Carrolton, Virginia.

TECH

TECH

Photography by The Author

Photography by The Authort is the way of the world today. Technology improves the breed. Flat tappet cams had their day but if performance is your goal, one step that can really complement a good set of cylinder heads is the upgrade to a hydraulic roller cam. Yes, the cost to convert to a hydraulic roller is higher than just replacing a flat tappet cam. But there are multiple advantages to a hydraulic roller cam engine that we’ll go over before we show how easy it is to convert an ’86 and later model 350ci small-block Chevy over to a roller.

To update a pre-’86, two-piece rear main seal small-block Chevy to a roller, beyond just the cost of the cam and lifters, the conversion will also require a reinforced timing cover and a cam button to limit forward cam movement. This requires a button that presses against the inside of the timing cover to minimize forward cam travel.

Advertiser

- American Autowire11

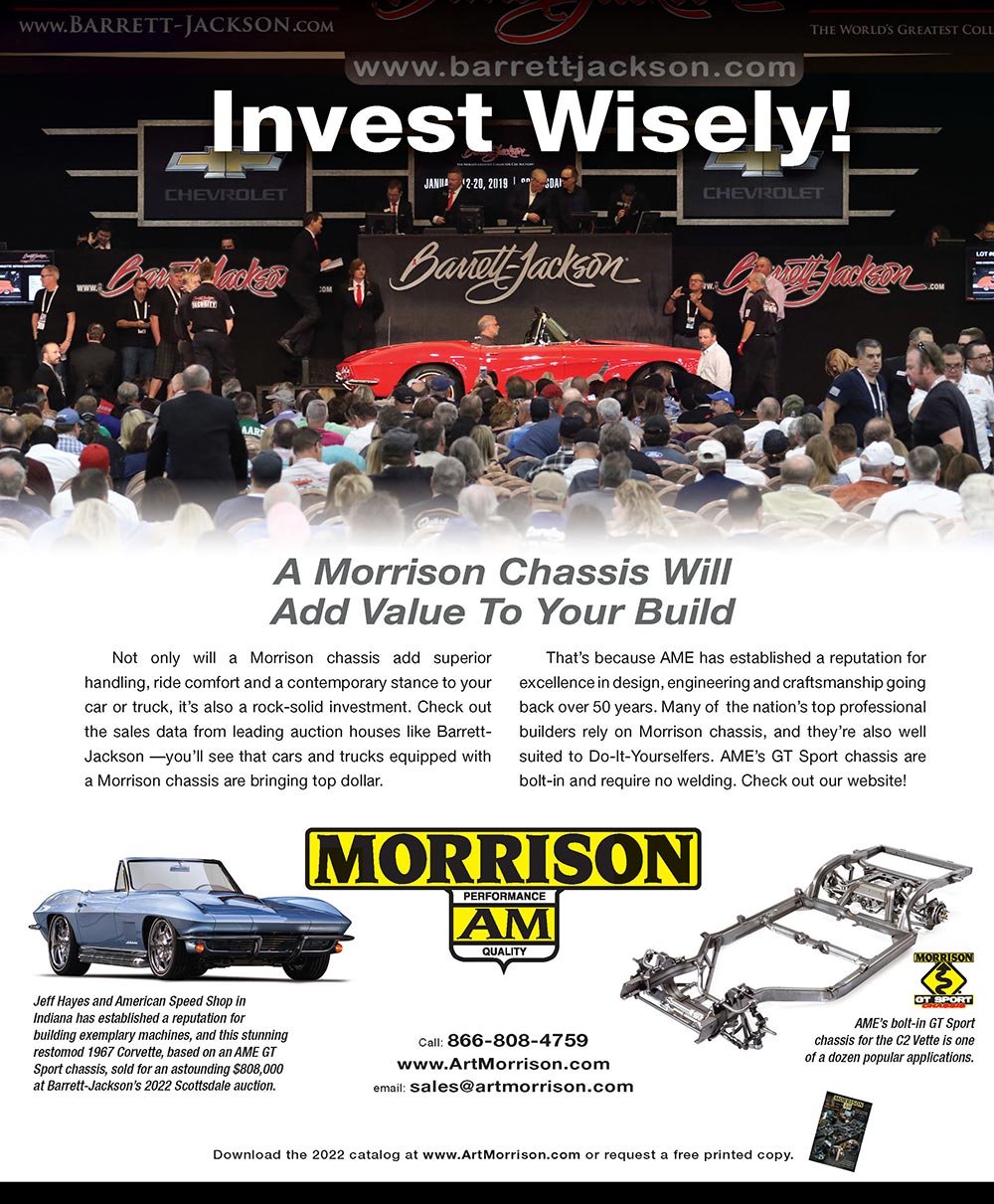

- Art Morrison Enterprises55

- Auto Metal Direct27

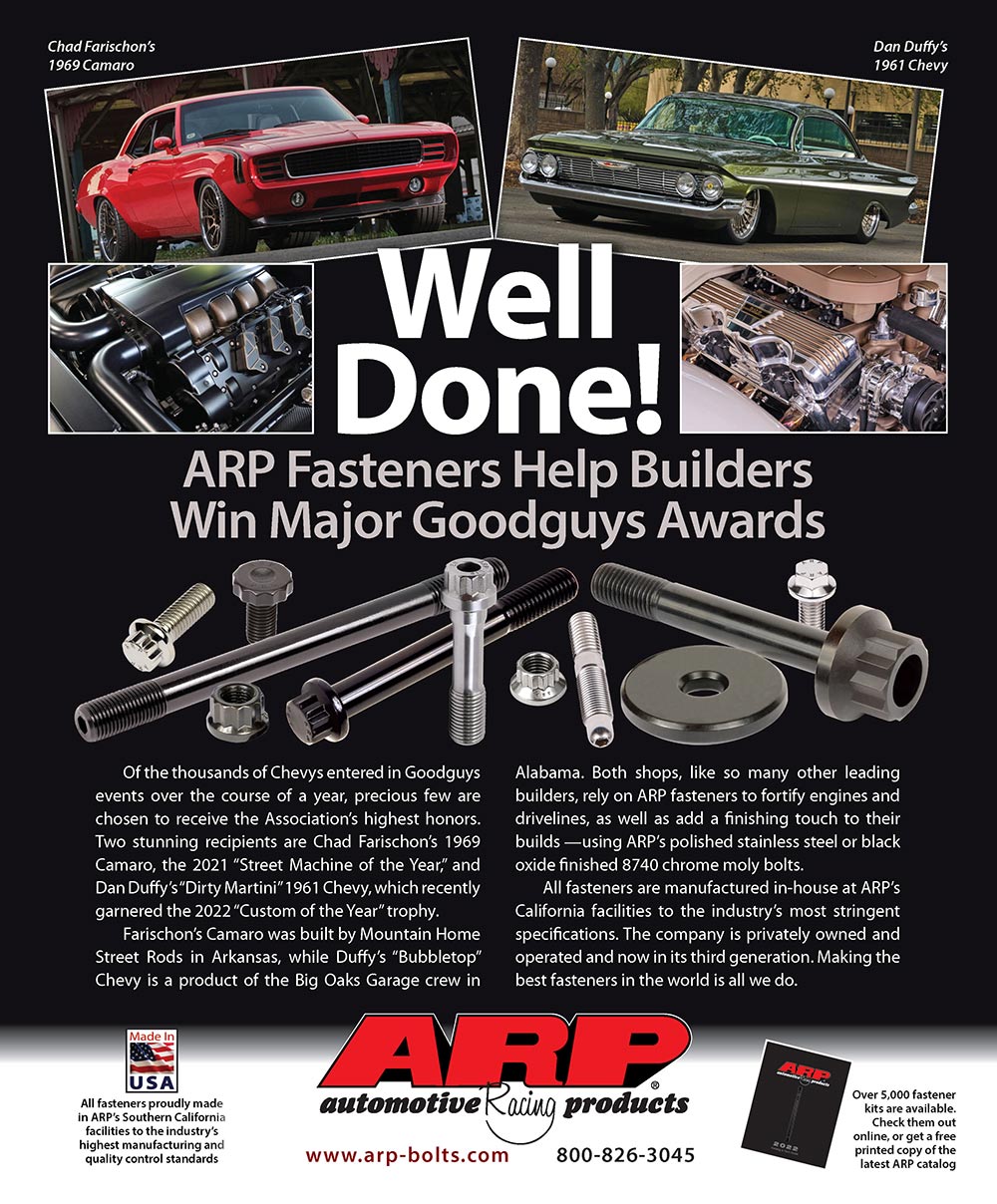

- Automotive Racing Products33

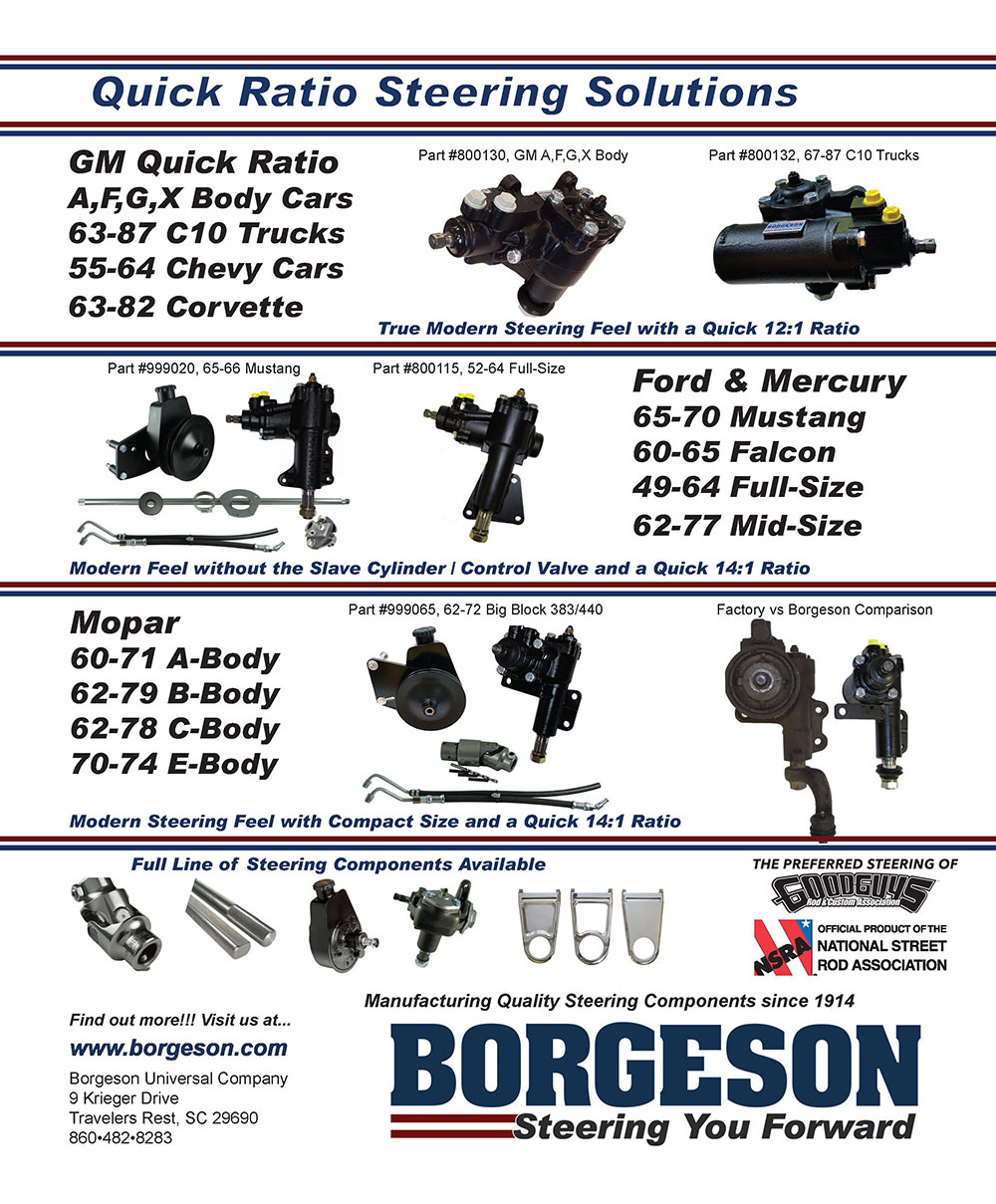

- Borgeson Universal Co.29

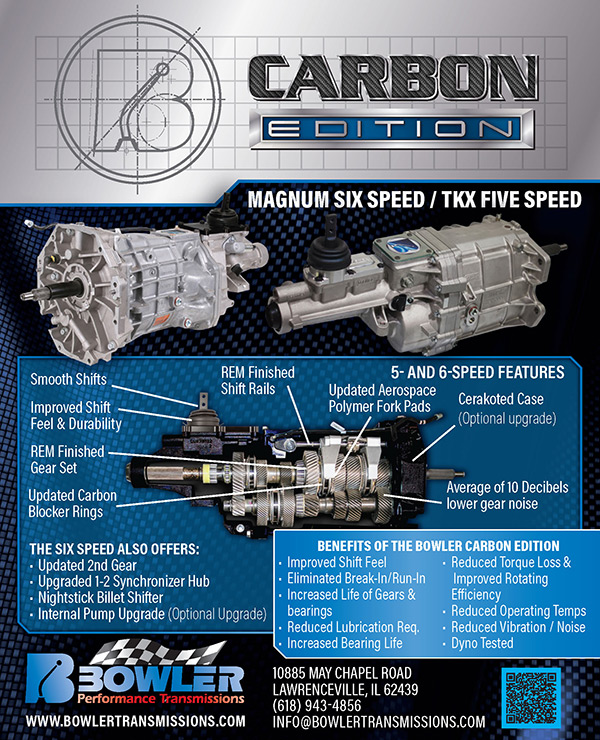

- Bowler Performance Transmissions87

- Classic Industries23

- Classic Instruments63

- Classic Performance Products4-5, 89, 92

- Dakota Digital91

- FiTech EFI75

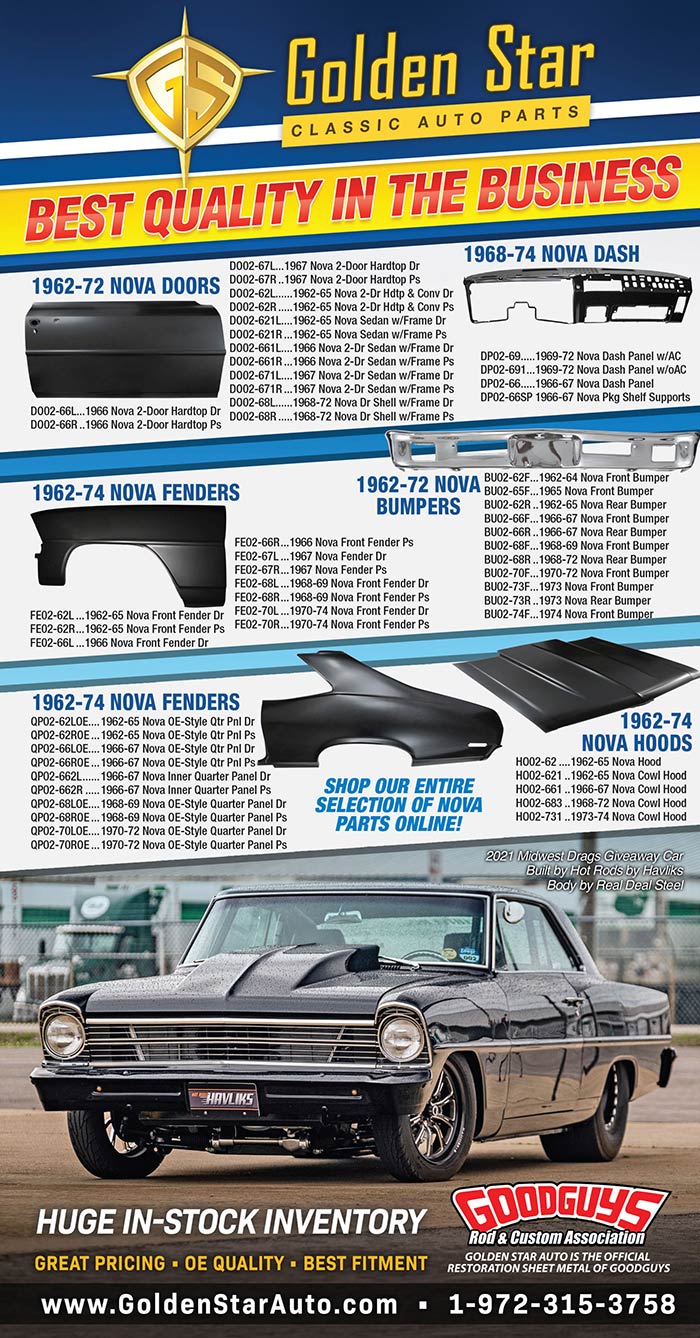

- Golden Star Classic Auto Parts7

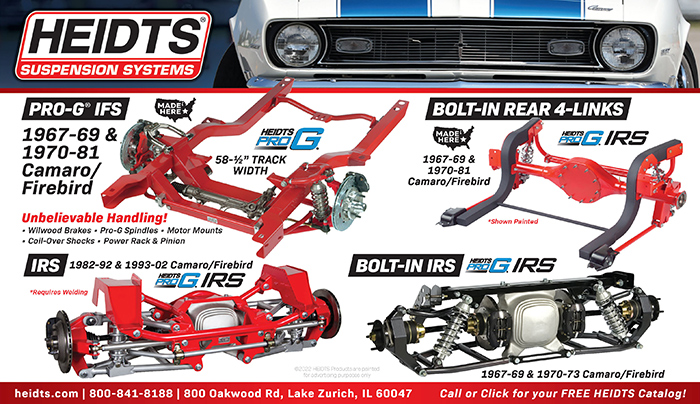

- Heidts Suspension Systems83

- Lokar2

- National Street Rod Association61

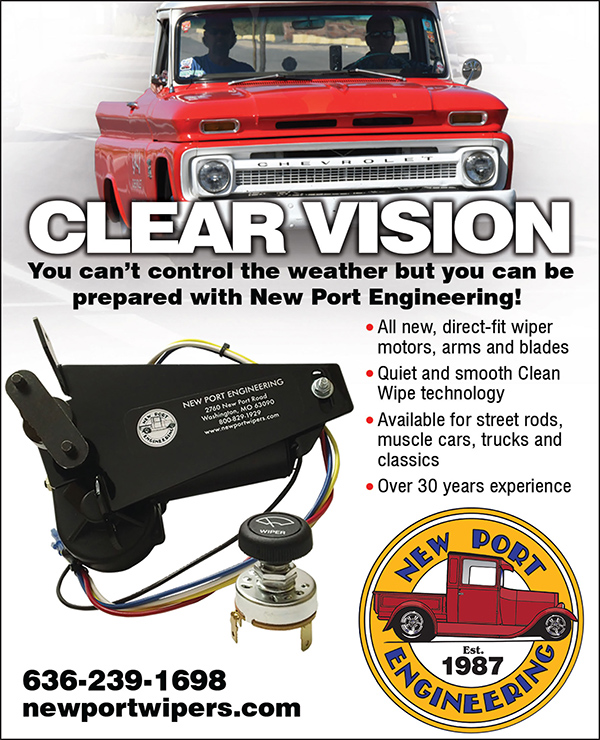

- New Port Engineering87

- Original Parts Group41

- PerTronix9

- Powermaster Performance75

- Scott’s Hotrods63

- Speedway Motors31

- Summit Racing Equipment13

- Vintage Air6

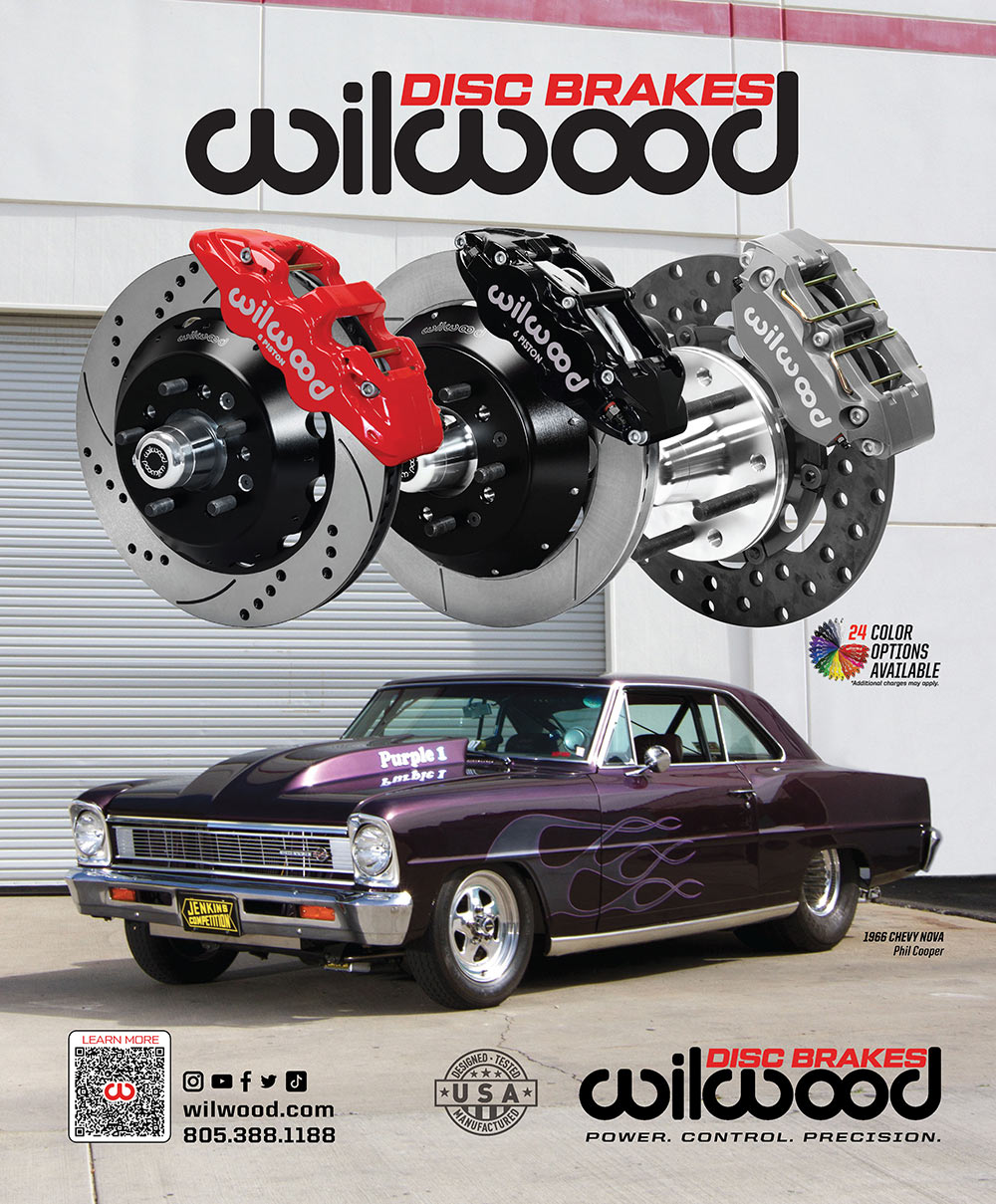

- Wilwood Engineering47

- Year One89