TECH

TECH

Images BY THE AUTHOR

Images BY THE AUTHOR

The issue with early Chevelles is that even a stock small- or big-block Chevy engine with a stock oil pan is a tight fit to the crossmember and steering linkage. Our all-original big-block 1966 Chevelle revealed dimples in the oil pan from the inner tie-rod end grease zerks hitting the oil pan when the steering was twisted to full lock.

This story will only address swapping Gen III and IV LS engines. We will not get into the Gen V direct-injected engine family because these engines demand both different motor mounts and oil pans compared to the Gen III/IV family. It’s also important to point out that the 1964-67 Chevelle and 1967-69 Camaro oil pan and motor mount kit part numbers do not appear to work with the later 1968-72 generation A-bodies. There are specific kits for those cars. Most of this has to do with engine mounts rather than the oil pans. We don’t know this for sure, but likely if a pan will work for a 1964-67 Chevelle, it will also work for an early Camaro and second-generation Chevelles. But this is speculation since we have not tested all the variables.

This story is also aimed solely at fitment of the oil pan to the engine crossmember with regard to a near-stock engine location. Because this is such a complex topic, we will not address LS accessory drives or options for A/C. We will also not address exhaust fitment except to note that the Holley cast-iron LS manifolds will work with the stock and near-stock location engine/frame mounts. Other aftermarket LS headers will need more specific testing that, again, is intentionally not included here.

One of the things that our research uncovered is that not all 1964-67 Chevelle engine crossmembers are shaped the same. Crossmembers for 1964-65 cars are slightly different than for 1967 models.

This makes the pan fitment issue more complex because now it’s like playing three-dimensional chess when it comes to working with variables like different frames, motor mounts, and cast/sheetmetal oil pans. So not all of this information that we have uncovered works for all early Chevelles. We have personally tested most (but not all) of this information. So, don’t be surprised if a cast-aluminum pan and motor mount combination that works on one car will not work in another. This gets into the realities of frame damage, sagging crossmembers, and other issues that are part of dealing with 60-year-old muscle cars.

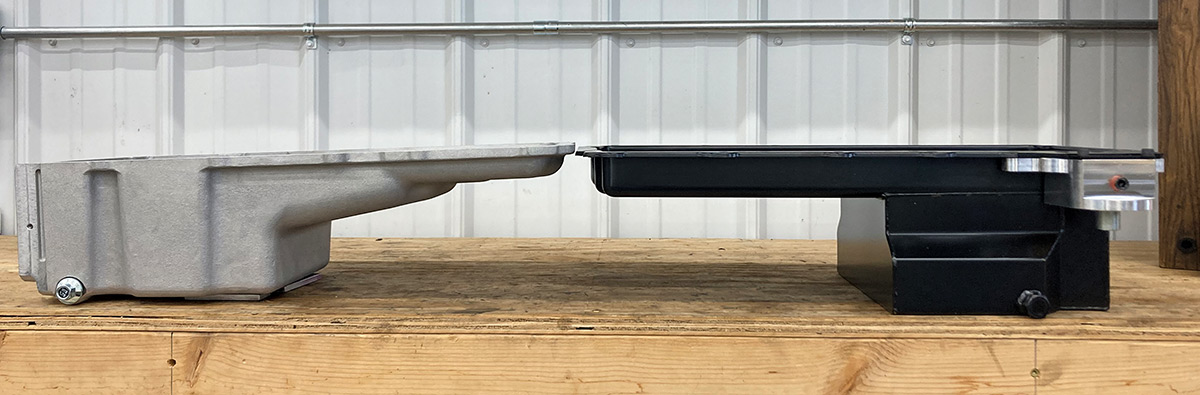

This whole story really revolves around oil pans so let’s start with what will not work. Since the most popular LS swap engines are the 5.3- or 6.0L iron truck engines, these engines came with a very deep rear sump that extends at least 2 inches deeper than the engine crossmember, so these pans will not work. Just for the record, Gen IV 5.3L Tahoe oil pans are slightly shorter by roughly an inch than Silverado truck pans. Early LS engine swappers employed the fourth-gen LS1 Camaro oil pans but these require significant modifications to the sump as it extends too far forward from the rear of the engine. With all the options available today there’s no reason to do this.

There is also plenty of talk about the Chevrolet Performance muscle car pan, which is the oil pan used in LS-powered Hummers. This pan will fit most early Chevelles and Camaros but the sump is roughly 1 inch deeper than the crossmember, making it a prime target for damage. For that reason, it would not be wise to use this pan. To keep track of all these pan specifications, we’ve created an oil pan spec chart listing the important specs for comparison.

The 302-2 and 302-3 will work in most Chevelle applications when used with the clamshell motor mounts kit supplied by Holley. On the other side of the coin, our experience is that this pan will not work if combined with the flat motor mount plate adapters. We will detail all the motor mount styles later in this story.

The 302-4 pan is designed for later Chevy trucks and will not work with Chevelles and Camaros. The 302-5 pan is the latest revision and will fit when combined with the Hooker clamshell-style motor mounts and is also more attractively priced than either the 302-2 or 302-3 pans.

One variable that directly affects the fitment of any of these pans is the angle of the engine in the car. A severe tilt of the engine (front to back) of more than 2 or 3 degrees will decrease the clearance between the vertical portion of the Holley cast oil pan and the engine crossmember.

This angle is mainly determined by the position of the transmission mount to the crossmember. When using the 302-2, 302-3, or 302-5 Holley oil pans with the Holley clamshell motor mounts we combined them with a Hooker-fabricated crossmember to position a 4L60E automatic transmission. This required a 1-inch-tall spacer between the Hooker crossmember and the transmission mount. This raised the back of the transmission, which reduced the engine and transmission angle and improved the clearance between the oil pan sump and the engine crossmember.

As you can see, there are several variables that affect oil pan clearance. One advantage of a cast pan is its added strength because they include provisions for the two lower bellhousing bolts for late-model transmissions like the 4L60 and T-56. A final point is most aftermarket oil pans will require a different dipstick and tube assembly, which is an additional cost that must be considered.

One important item to consider when choosing a sheetmetal pan is the oil filter location. Most sheetmetal pans require an aluminum oil filter adapter. This allows you to use a spin-on oil filter in the stock location. Some pans will be fitted with -8 or -10 AN fittings that require a remote-mounted oil filter. These pans are generally more affordable but require expensive AN fittings and mounts for a remote filter that is a hassle to locate.

Most sheetmetal pans offer a thin front cross section that will clear the Chevelle’s steering linkage and crossmember. This flat forward portion is usually extended rearward to a right angle for the sump that is back far enough to clear the engine crossmember. These pans offer more room to the crossmember and steering linkage and can be used with the flat-style LS motor mount adapters that use the traditional small- or big-block Chevy motor mounts while retaining the stock frame mounts.

Some of these fabricated pans will also offer a sump with built-in or optional trap doors for maintaining the oil in the sump area. For mild street engines these are not essential but do offer a way to maintain oil in the sump during spirited driving. Many of these pans will also offer sump kick-outs that can increase oil capacity.

In our experience, sheetmetal pans offer more clearance for many different motor mounts while the cast pans appear to be more sensitive to these clearances. If you are unsure, sheetmetal pans will generally fit better than cast pans especially with flat motor mount adapters.

We’ve used these simple mount systems several times generally with Champ, Moroso, and Summit sheetmetal pans with great success. These mounts position the engine slightly lower in the chassis and there are adjustable plates to re-position the engine forward or back from the original stock bellhousing placement. While you could use stock replacement rubber motor mounts with these flat plate adapters, we always use the Energy Suspension polyurethane mounts as they offer internal limiters that prevent these mounts form separating, which was a problem with the OE rubber mounts when used in high-performance applications.

Holley now offers an alternative motor mount approach using the fourth-gen Camaro LS clamshell motor mounts. This kit replaces the traditional Chevelle frame mount with a steel saddle still using a long 7/16-inch through bolt. This mount arrangement places the engine slightly higher in the frame, allowing room for the Holley cast 302-2, 302-3, or 302-5 cast pans.

Having performed multiple LS engine swaps, several important points become apparent. The flat-plate motor mounts work best with the very shallow front sheetmetal oil pans that offer more clearance to the crossmember. We’ve had interference issues with some no-name cast-aluminum pans around the trailing edge of the crossmember to the oil pan even with the slightly taller clamshell motor mounts.

This occurred with the Holley metal mounts that position the engine slightly forward. With the steel clamshell frame mounts that move the engine rearward, this could minimize this problem, and it appears there will still be room to install the bellhousing bolts to mount the transmission.

We used one of these crossmembers in our 1967 Chevelle LS conversion along with a 4L60 four-speed automatic overdrive trans. We were able to place this transmission under the stock floorpan with only minor hammer clearancing on the passenger side floorpan. In order to create a decent 1.5- to 2-degree down angle for the engine and transmission, we added a 1-inch spacer between the Hooker crossmember and the transmission mount, which also required 1-inch-longer bolts. Holley sells this spacer, or you could easily fabricate this from a 1-inch-thick piece of aluminum.

A swap using a 4L80E automatic under a 1966 Chevelle required some extensive floorpan cutting and raising of the tunnel along with modifications even to the Hooker crossmember in order to fit the trans under the floorpan. The 4L80E is tight but it will fit.

As a final note, there are a bunch of no-name, cast-aluminum oil pans on the market available through Internet retail outlets like Temu and others. Most, if not all of these pans do not offer dimensions, instructions, or returns. A friend recently tried to save a few bucks by purchasing one of these no-name pans and then spent days trying to fit it in his Chevelle. After spending entirely too much time and money experimenting with several motor mounts, he finally gave up. He ultimately spent more time and money than if he had just selected a designer kit from the start.

If you really understand all the subtle nuances of all these different pans and mounts, you could probably uncover an inexpensive selection of parts that will work for you. Or, you can simply save yourself weeks of investigation and opt for a system that is designed to work together. Hopefully this story has shed some light on this complex topic.

SOURCES

SOURCES