TECH

TECH

Images by Taylor Kempkes

Images by Taylor Kempkesack in the early days of hot rodding, necessity was the mother of invention, as crafty gearheads would fabricate their own speed parts due to a lack of aftermarket support. Now, we have a tremendous offering of components at our fingertips, but even then, the aftermarket doesn’t support every build and every application. When this is the case, custom fabrication steps back into the fold, allowing for handcrafted fitment and custom design. While some fabrication projects can be tackled by a beginner, others get a little more complicated. We’d classify custom long-tube stainless steel headers as a pro-level task, but with the proper tools, skills, and patience, it can be done.

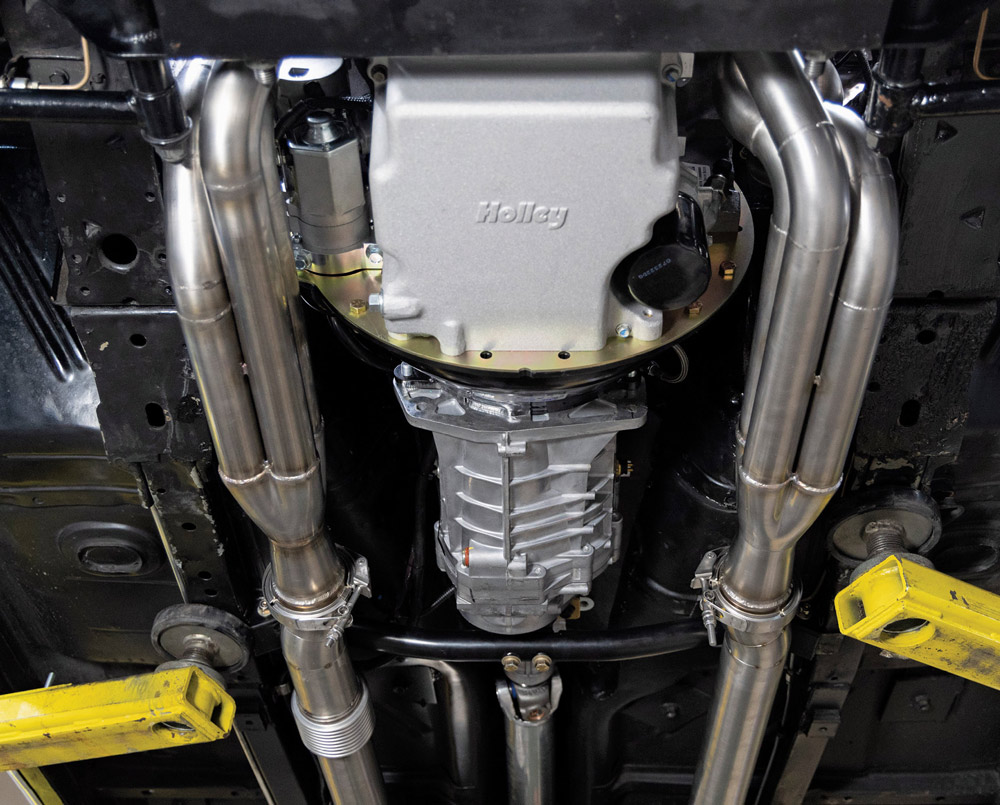

We recently had the opportunity to follow along as Old Anvil Speed Shop in Orange, California, built a set of headers for a wild ’67 Nova, which has an LS engine topped with a tunnel ram and two four-barrel carburetors. This old-school combination is bolted to an aftermarket subframe, but it’s still a tight fit in the small Nova engine bay. Nick Andreos and Brandon Gerringer at Old Anvil Speed Shop handled the fabrication job, starting with 304 stainless steel 180-degree mandrel bends. There are a few options for header flanges, but the custom look of the cast stainless steel flanges is hard to beat.

There are many specialized tools that aid in the fabrication process, and you’ll see them at work in this article. Mock-up tools are a lifesaver for header fabrication, as is a lift to access the top side and bottom side effortlessly. As with any fabrication project, there is a lot of mocking up, test-fitting and tweaking, so having easy access to all angles is essential. Stainless steel can be tricky to work with, as it doesn’t cut or weld as easily as mild steel, but the results are far superior when it comes to the appearance and longevity of the headers.

The guys at Old Anvil Speed Shop spent approximately one week building these headers, so they certainly come in at a higher price than your average off-the-shelf headers. In the case of this wild ’67 Nova, the custom touch and excellent fitment is worth every penny.

Follow along as a pile of tubing gets sliced, diced, and welded into a custom set of stainless steel headers that takes this Nova to the next level.

SOURCES

SOURCES