TECH

TECHInTheGarageMedia.com

Part 4: Front Buildup

BY All Chevy Performance Staff

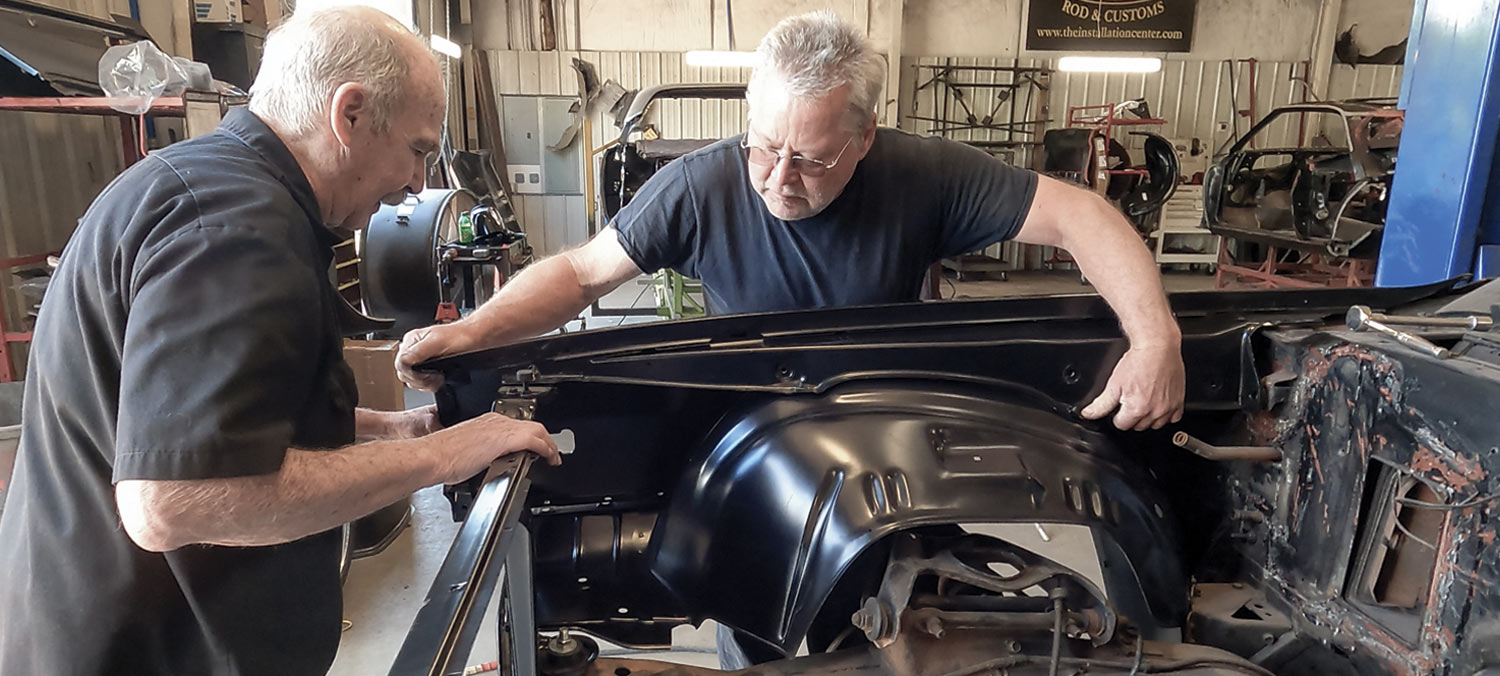

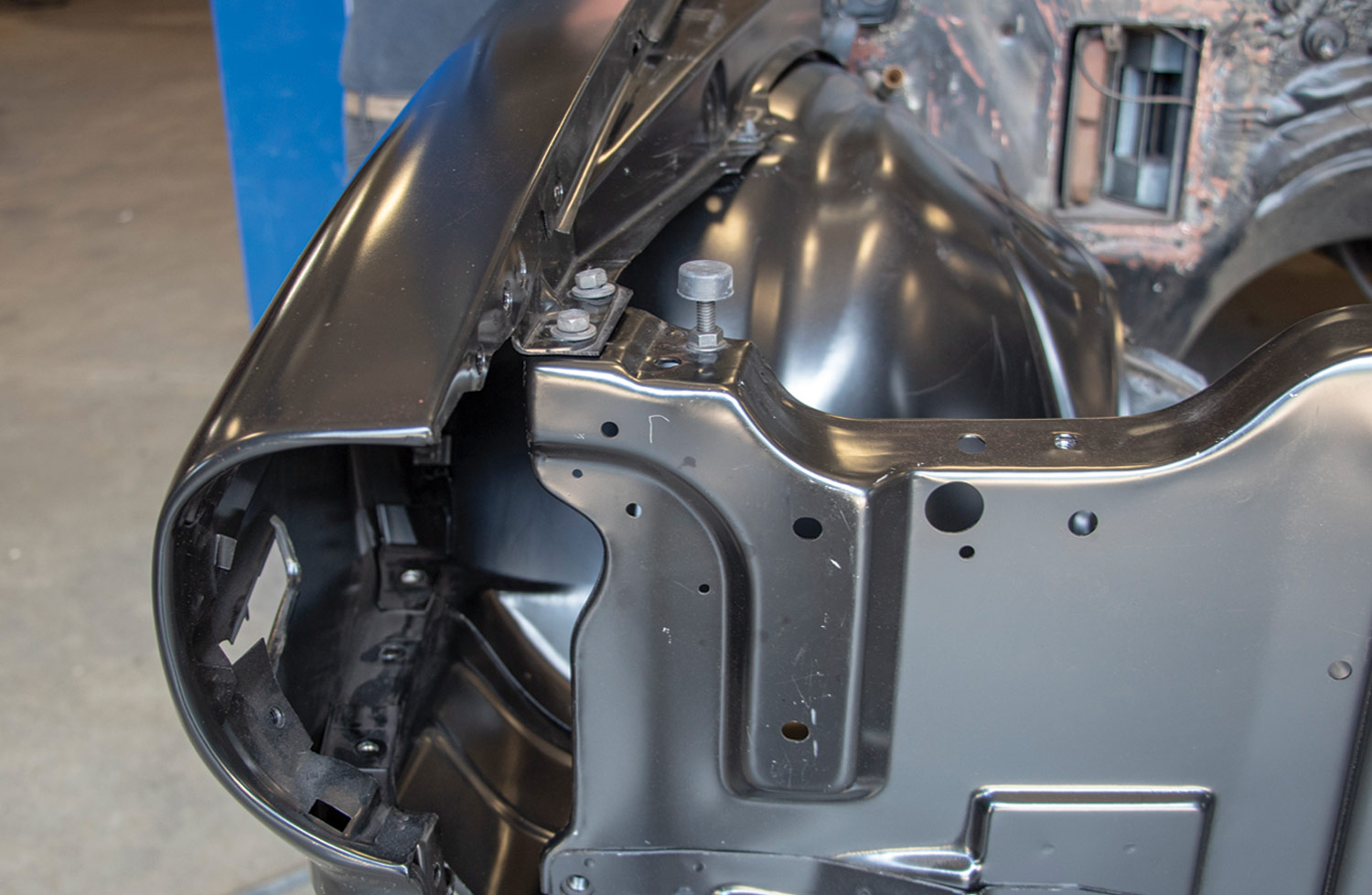

BY All Chevy Performance Staffe are back with Craig Hopkins of The Installation Center and this Auto Metal Direct (AMD) second-gen Camaro conversion. In part four of our multi-part series, we are converting this ’78 Camaro into the ’71-73 steel bumper version. We removed the entire back end of the car, turning it into that iconic round-taillight version, and now we are working on the front end to get that highly sought-after early second-gen look. The great thing about the front-end swap is that everything bolts right up without any real modifications—from the hood and fenders, to the core support and bumper, we show you just how easy this can be.

Follow along and see their approach to this conversion.

In the next issue, we will cover the rest of the lighting and trim install to complete this conversion with AMD. Catch it all right here in All Chevy Performance.