TECH

TECH

Images by THE AUTHOR

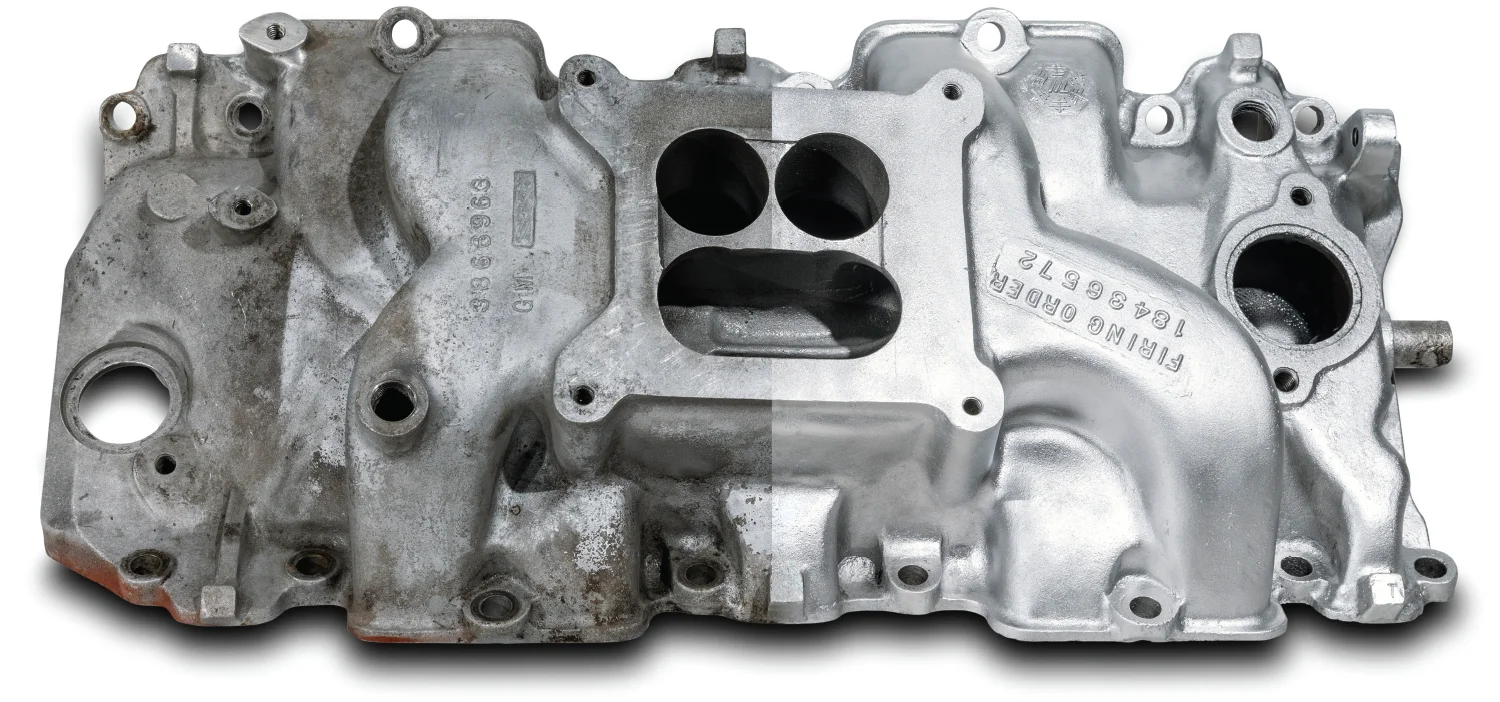

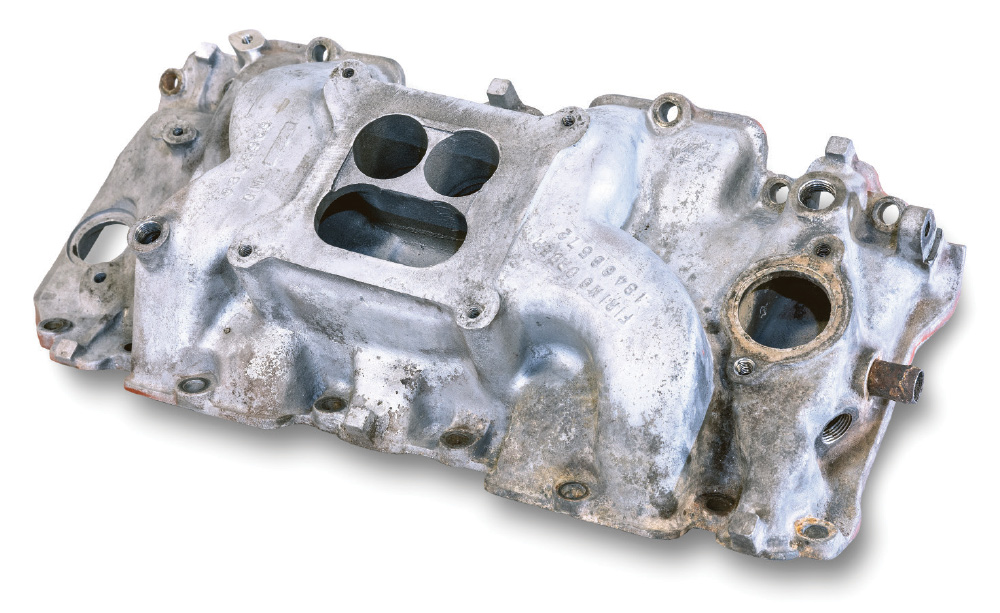

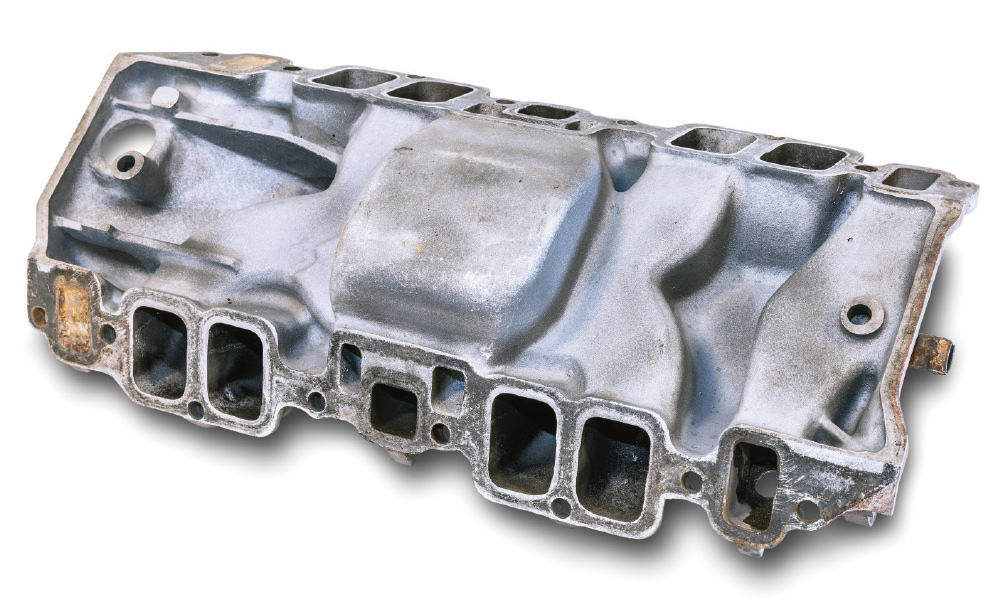

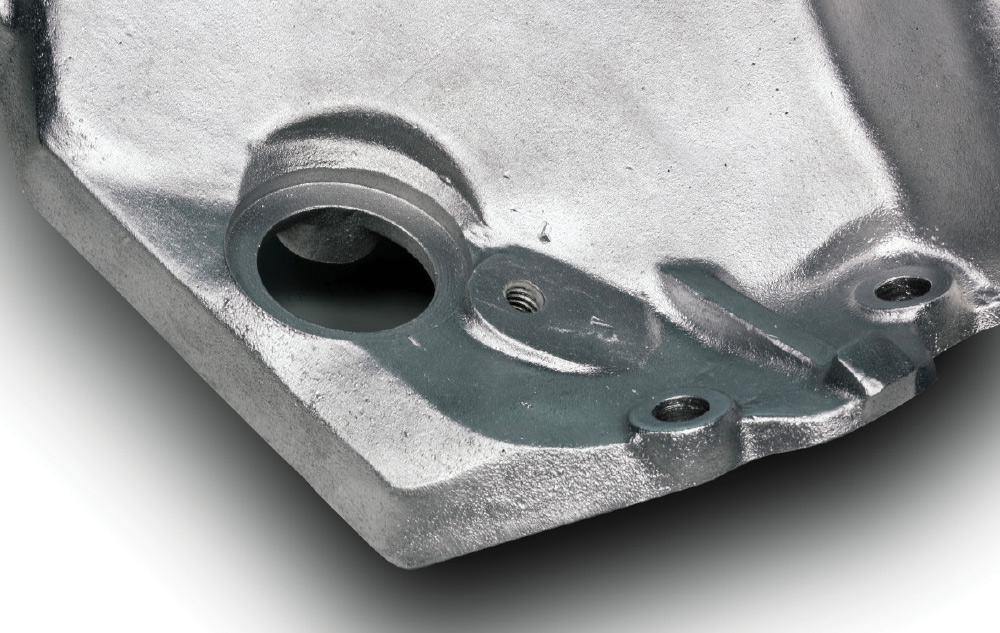

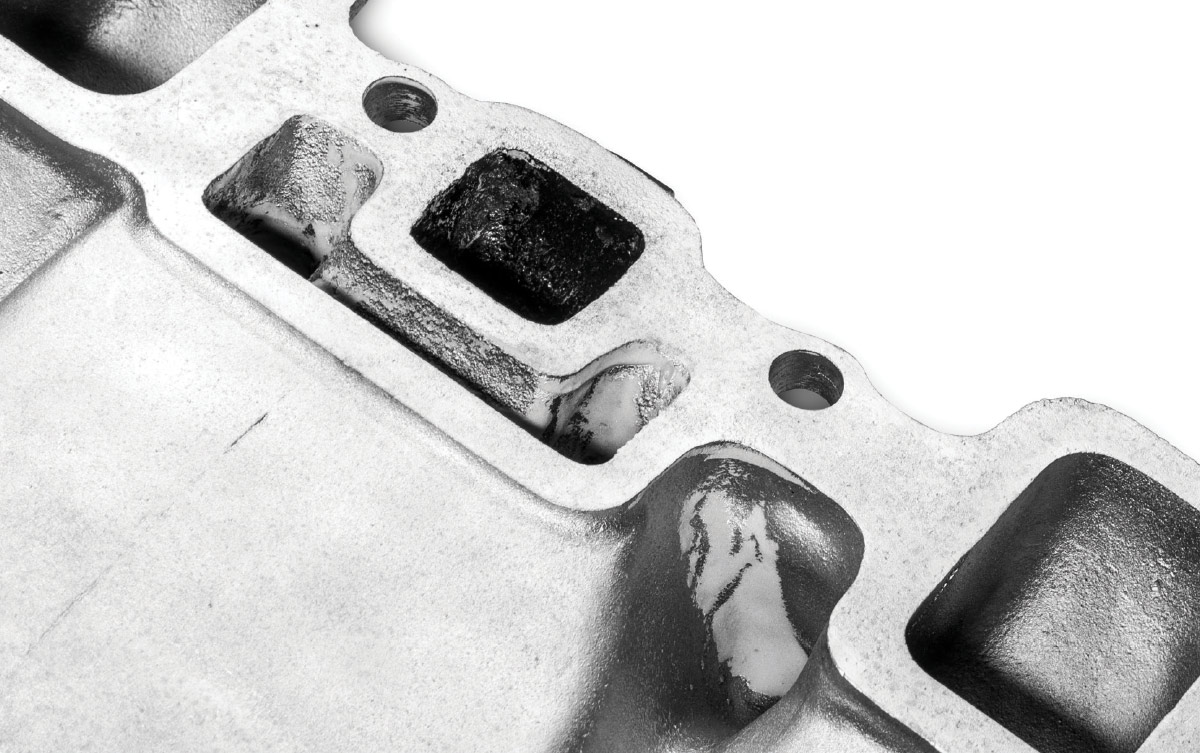

Images by THE AUTHORn the automotive restoration game, there are a wide range of options when it comes to tackling the various processes involved. What defines a restoration can also be interpreted in many degrees. There are several variables that come into play, and for places that are doing high-end concours restorations the need to bring a car back to how it rolled off the assembly line is the bar that is always set and challenge always faced. Knowledge of the correct finishes on the various parts found on a given vehicle require a certain level of knowledge and experience in their application. Painted items are one part of that equation, however, the range of different bare metal items found on a vehicle usually requires a different approach when it comes to their restoration. The easy path sometimes is to simply find a mint N.O.S. replacement, but that is not always an option. When it comes to aluminum parts, there are various ways that shops tackle their restorations in what they deem as the best solution. We’re going to exclusively focus on aluminum parts, and we have the perfect test subject: an L78 intake manifold for a 1965 Corvette that was recently vapor honed at American Muscle Car Restorations (AMCR) in North Kingstown, Rhode Island. They have over the years set the bar to the highest level with many award-winning OEM restorations under their belt. Vapor honing is another tool that they have added to their arsenal of processes that we will be testing on our manifold.

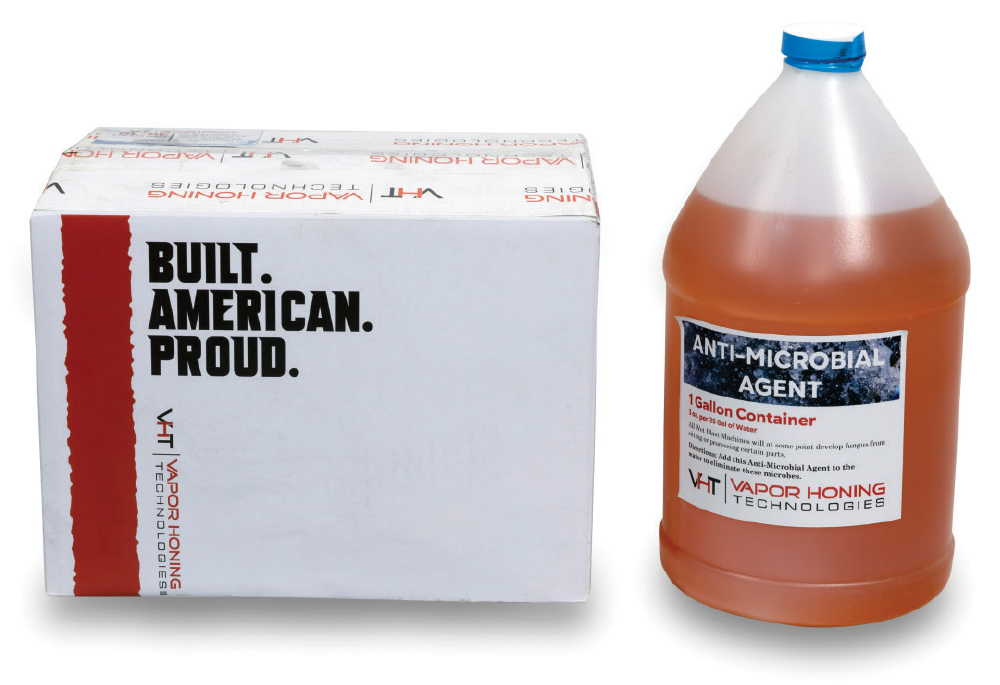

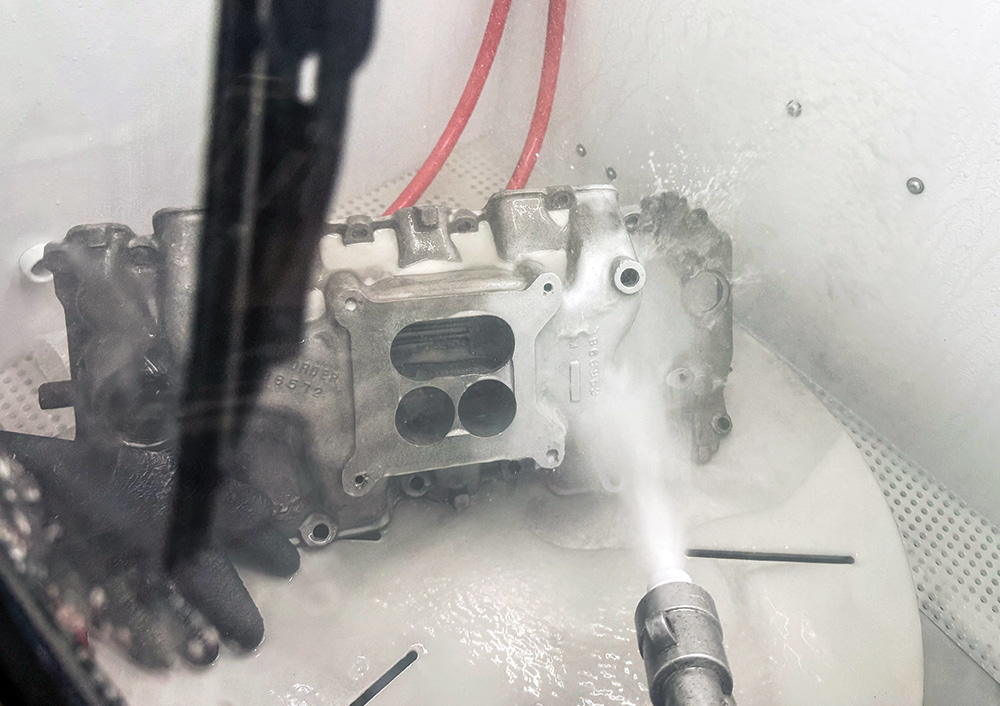

You might be asking, ‘What is vapor honing?’ You may have heard of it also referred to as wet blasting or slurry blasting. By whatever name you’re familiar with, it is a process that utilizes a mixture of abrasive media, water, and compressed air to clean, polish, deburr, or finish a surface. The choice of abrasive media is critical and depends on the material of the workpiece and the desired finish.

For an aluminum part that is going to be used in an OEM restoration, getting it back to original condition with the correct finish is the desired outcome. The folks at AMCR have switched over to this vapor honing technology to restore aluminum parts, however, prior to the use of this procedure they were getting the same results from a 10-step process that they had developed and perfected. This single-step switch has allowed them to significantly reduce the overall time spent on a given part while still achieving the same results.

The end result with these parts and the reduction in time translates to less manhours used and a cost savings for their clients.

SOURCES

SOURCES