TECH

TECH

Photography by The Author

Photography by The Authorhe horsepower race continues to escalate. We have production OE engines now achieving over 800 hp and Chrysler is now delivering a four-digit flywheel horsepower number straight off the factory floor. With these outlandish power numbers also comes increased demand for a high-performance fuel delivery system.

On the surface, the solution would seem fairly simple: just add a monster pump capable of delivering fire-hose-capacity fuel at the high pressure needed to feed an 800hp, supercharged engine. But add the requirement of a light-throttle cruise down the highway while knocking down 20 mpg and things become a bit more complicated. In the past, this demanded a return system that could bypass a large amount of fuel returned to the tank.

What is rarely discussed is the fact that bypassing fuel increases the heat generated in the fuel, which generally creates multiple problems as fuel temperatures hit 130-plus degrees F on really hot days from multiple sources, including the heat reflected off the pavement. These high fuel temperatures often cause percolation and vapor lock problems. A typical distillation curve amply illustrates why gasoline functions much differently (in a bad way) at 130 degrees compared to 70 degrees F.

One of the less-than-desirable aspects of a typical return fuel delivery system is that the in-tank pump must run at max capacity 100 percent of the time. This works great for short-duration, drag race applications, but for a high-horsepower street car, this also means a high-volume pump running at max capacity all the time. A full recirculation system adds significant heat to the fuel as it pulls heat from the engine through the fuelrail. This eventually overheats the fuel, which causes cavitation problems at the pump inlet where the pressure is the lowest. All of these details work together to escalate fuel temperatures.

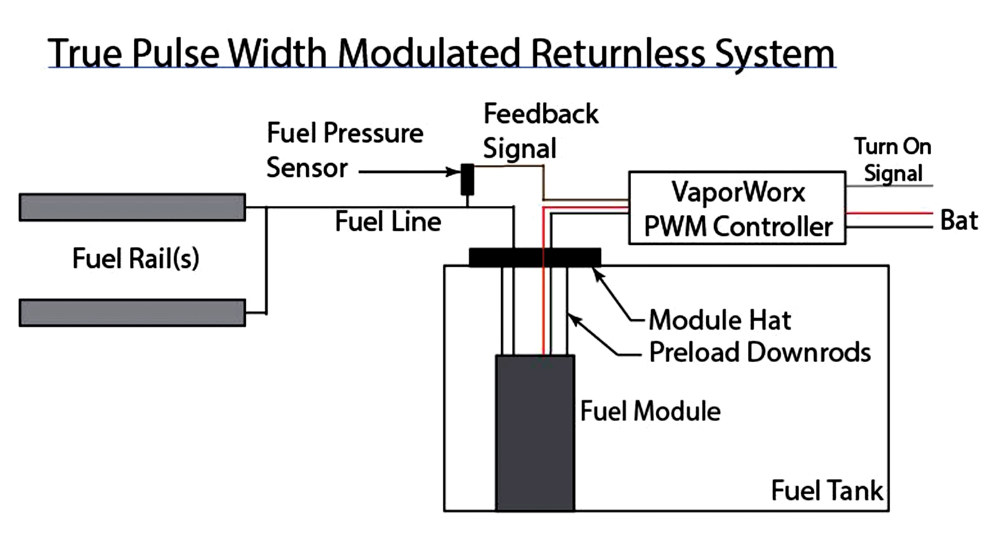

As the high-horsepower aftermarket becomes more sophisticated, it’s interesting how trends point back toward well-researched OE solutions to meet these challenges. Long before there were 800hp OE engines, the new car companies developed a far more sophisticated returnless fuel delivery system. A returnless system controls the fuel pump by way of pulse-width modulation (PWM).

This is a process where voltage is applied in segments (rather than continuously) to produce a desired pump speed. As an example, if 13.5 V of constant voltage is sufficient to produce full-pump capacity, then pulsing that voltage half of the time at 13.5 V will produce a 50 percent capacity pump output. The process is more sophisticated than this simple explanation, but it’s the essence of how PWM works. A main positive aspect of PWM is that the pump no longer runs at 100 percent capacity all of the time. With PWM control, the pump will last much longer, which is why it is not unusual for an OE performance pump to be operating perfectly well beyond 100,000 miles.

In the past, attempts have been made to simply cut the continuous supply voltage from 13.5 to half voltage (6.75 V) but this does not work because the pump is designed to operate at 13.5 V. The result is this lower voltage destroys pump efficiency and leads to early pump failure. Pulse width modulation of full voltage achieves the same average voltage (6.75 V) while still applying the full voltage to maintain efficiency.

An analogy to PWM is like riding a bicycle on level ground. By pedaling half the time, you can maintain a given but slightly slower speed compared to the speed generated by pedaling at a constant rate.

This PWM signal is monitored by a highly accurate fuel pressure sensor and computer control based on several other functions such as throttle position (TPS), rate of change of throttle position, manifold absolute pressure (MAP), and others. All of these inputs help determine the PWM signal control of the fuel pump to maintain a constant 58 psi.

In order to achieve constant pressure, the OEs had to design a pump and reservoir that maintained a steady source of fresh fuel at the fuel pump inlet. This was accomplished with the now-familiar tall, white fuel pump reservoir or “bucket” assembly. This design uses a small volume (roughly 20 percent) of fuel bypassed from the fuel to operate several jet pumps that maintain a full fuel level in the bucket at all times, even when tank level is near empty. These jet pumps literally will suck the tank dry unlike traditional “pump-on-a-stick” arrangements where fuel slosh can uncover the pump inlet.

This reservoir design always has fuel at the inlet to maintain a constant fuel pressure. This eliminates the need for external pickups unless the vehicle will be subjected to serious autocross or track day use. Then a pair of in-tank lateral pickups can be added to ensure fresh fuel is fed to the pump even under extreme cornering situations.

VaporWorx owner and system designer Carl Casanova wanted to incorporate this OE system into his ’68 supercharged LS Camaro that has now survived multiple One Lap of America races, which are much like a road racing version of Drag Week with greater distances between racetracks. Just to survive this event and finish is a testament to the car builder’s art.

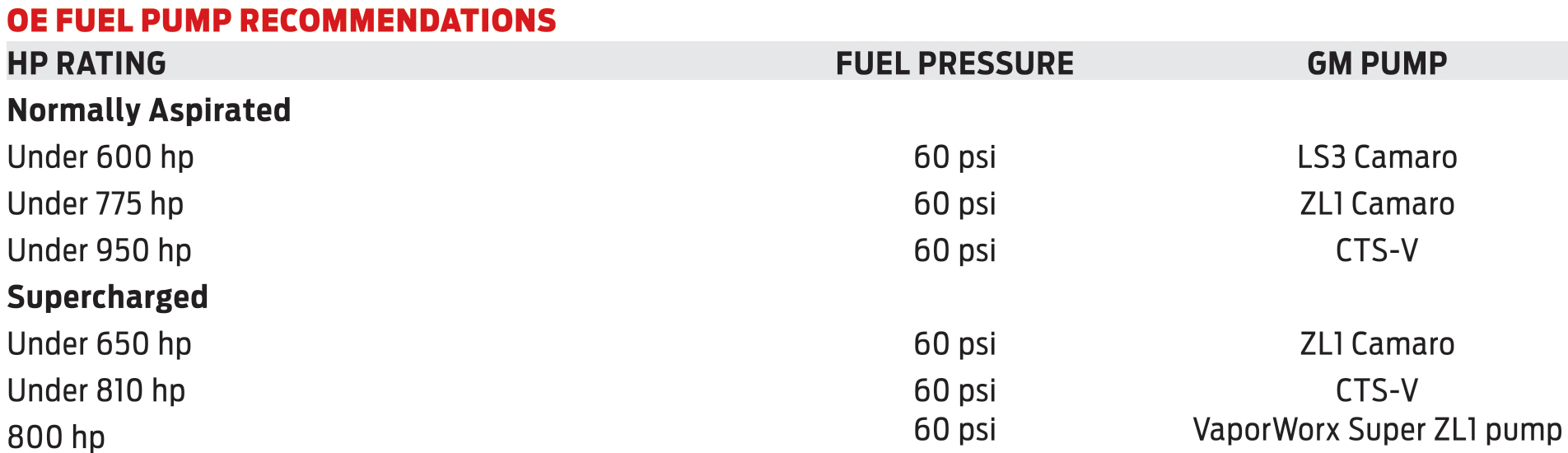

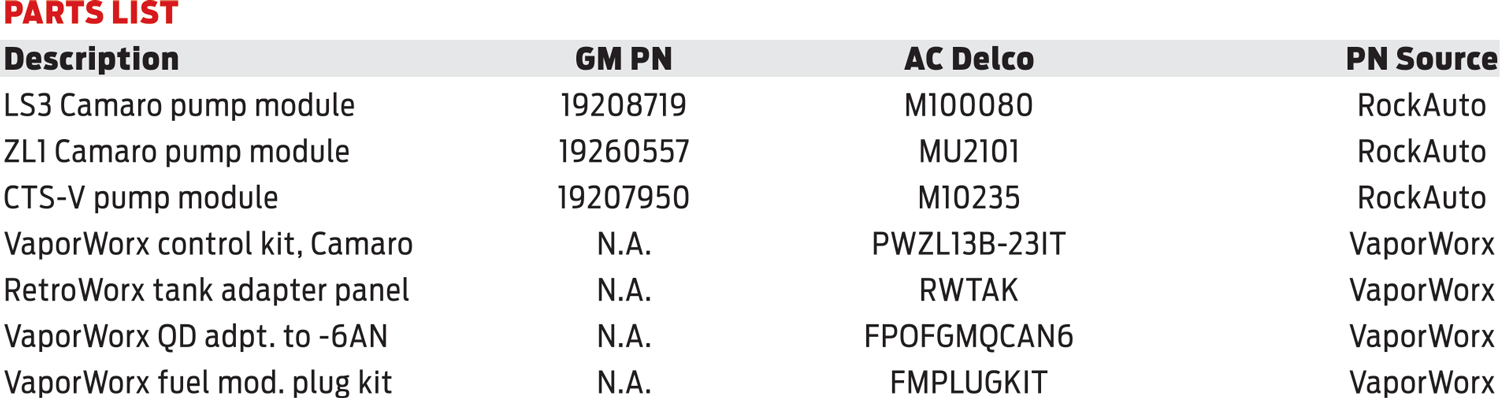

Casanova realized that the OE performance pumps are more than capable of supplying sufficient fuel even up to 900 normally aspirated (NA) horsepower and even more with dual-pump systems. The big challenge was to find a way to integrate the OE PWM technology into a simple, stand-alone electronic module. The result is the PressureWorx controller package. For a 600hp, NA application, for example, the universal ZL1 controller is the best application. Casanova says that fully 80 percent of his market is similar systems.

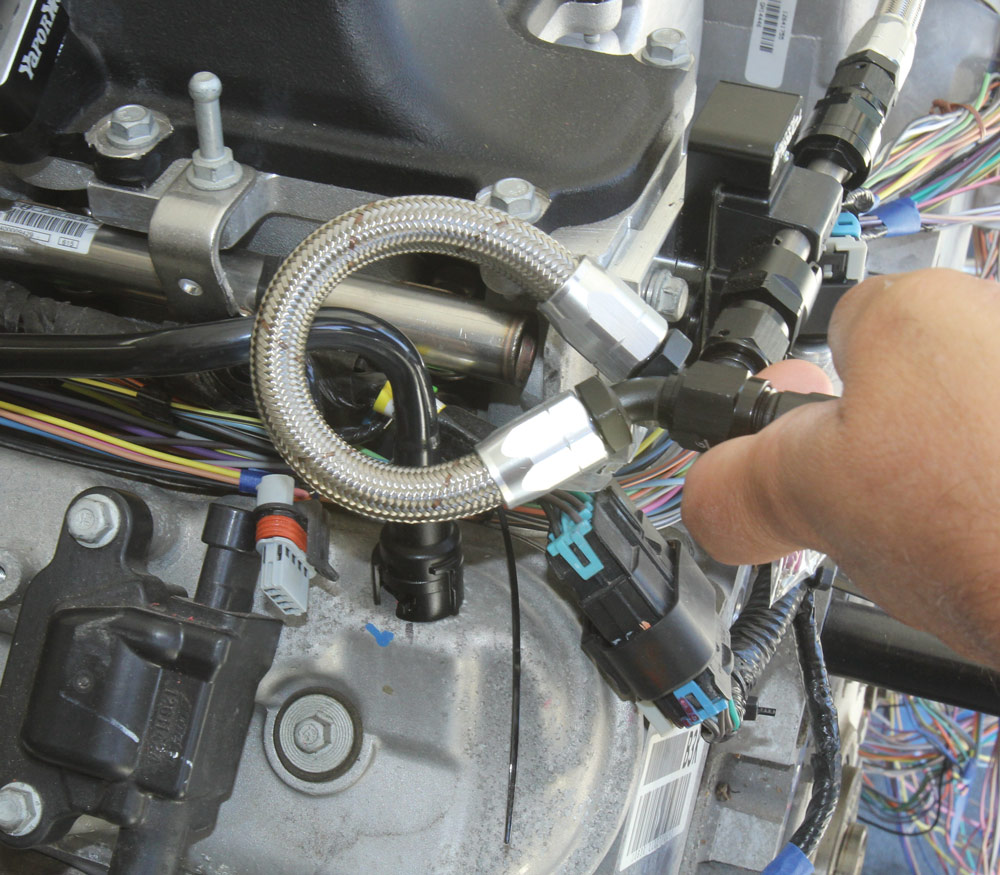

The key to the VaporWorx system is the PressureWorx PWM controller that is very simple to install and adjust. To wire it, you merely connect battery positive and pump positive wires and ground wires. The only other wiring is connected to the pressure sensor and switched power. With the pump powered up and the engine running, you use the included tool to adjust the fuel pressure to the desired psi. Once it’s adjusted, that might be the last time you ever have to think about it. If there is a desire for manifold referenced fuel pressure, just connect two wires to the engine MAP sensor or use a VaporWorx-supplied MAP sensor to achieve a 1:1 manifold referenced fuel pressure.

This is the heart of the system but there may be questions as to its durability. As a testament to this, Casanova’s own Camaro now has over 75,000 miles on the controller in his car.

Casanova initially designed this system to replicate the factory returnless design, which offers significant advantages. However, higher horsepower applications can still benefit from a return-style system, so VaporWorx has expanded its design to offer control over dual-pump systems working within a return-style configuration.

There are many more options to the VaporWorx PWM concept such as systems specifically for the LT direct-injection Gen V engines. However, this overview should offer enough information to reinforce that this is a highly refined system that uses OE technology that can now be employed by nearly any performance enthusiast in search of the best fuel delivery system available.

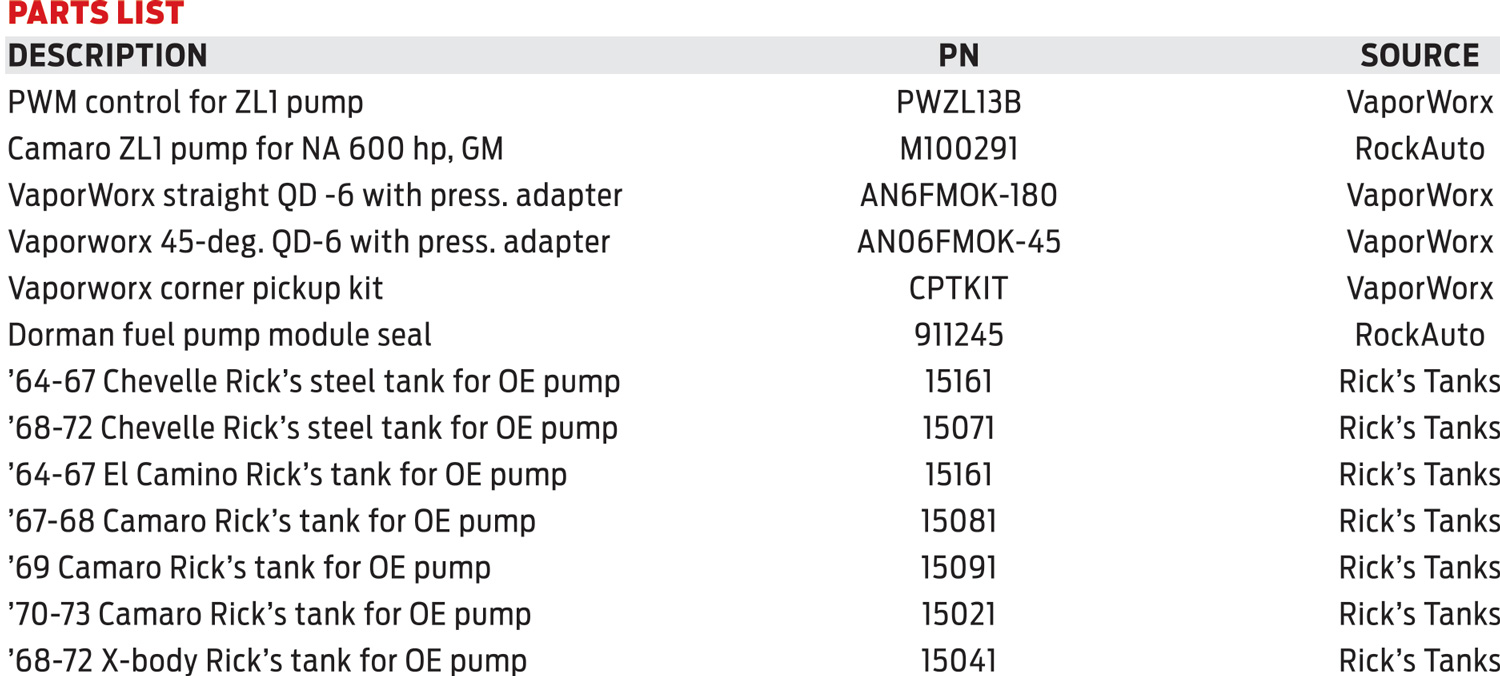

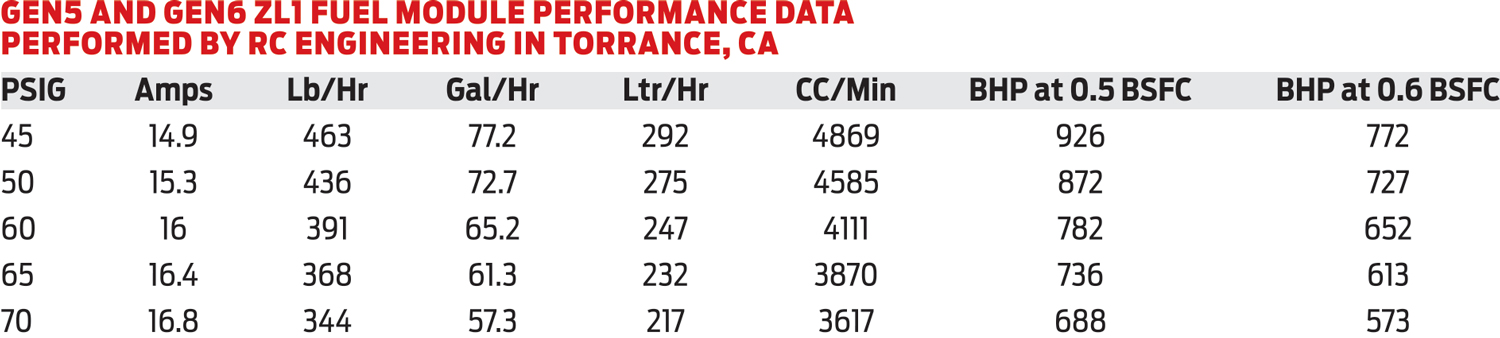

Amps: Amperage required to run the pump at the rated pressure

Lb/Hr: Pounds per hour of fuel delivered by the pump

Gal/Hr: Gallons of gasoline per hour

Ltr/Hr: Liters of gasoline per hour

CC/Min: Cubic centimeters of gasoline delivered per minute

BSFC: Brake Specific Fuel Consumption. This is the amount of fuel in pounds required to produce 1 hp for 1 hour. NA engines are rated at 0.50 BSFC lb/hp/hr while supercharged engines up to 800 hp are typically rated at 0.60 lb/hp/hr.

BHP at 0.5 BSFC: Horsepower potential at a brake specific fuel consumption of 0.5

SOURCES

SOURCES