TECH

TECHInTheGarageMedia.com

Photography by Jason Scudellari

Photography by Jason Scudellarioday you’d be hard-pressed to find a new car without air conditioning, but in 1962 that wasn’t the case. That year a new Chevy Impala two-door hardtop sport coupe had a factory price of around $2,800, and adding DeLuxe air conditioning bumped the tab by over $360—that’s roughly 13 percent of the base price. As a result, lots of Chevy shoppers back then decided to tough it out and forgo the A/C and cope with hot days by rolling the windows down and turning the windwings out. Of course, all that did was funnel hot air into the passenger compartment, along with the occasional flying insect.

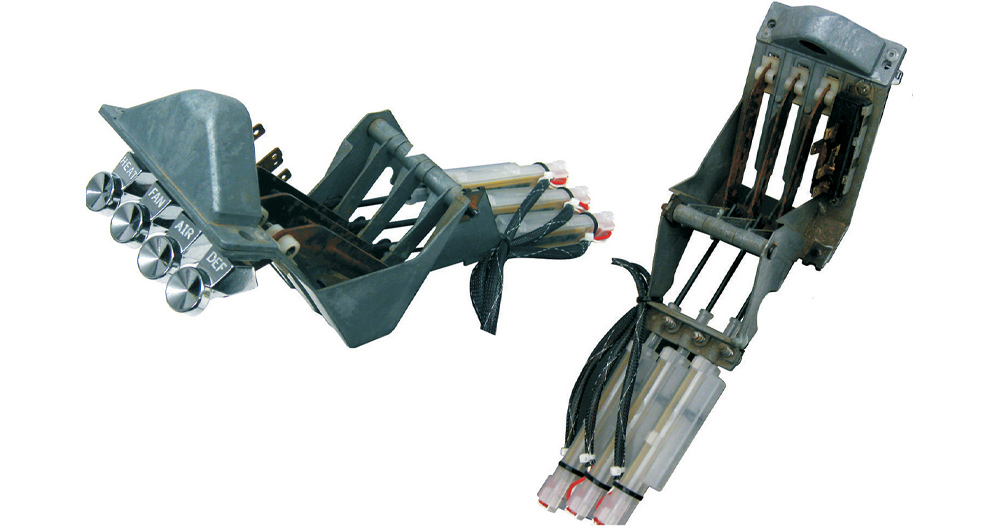

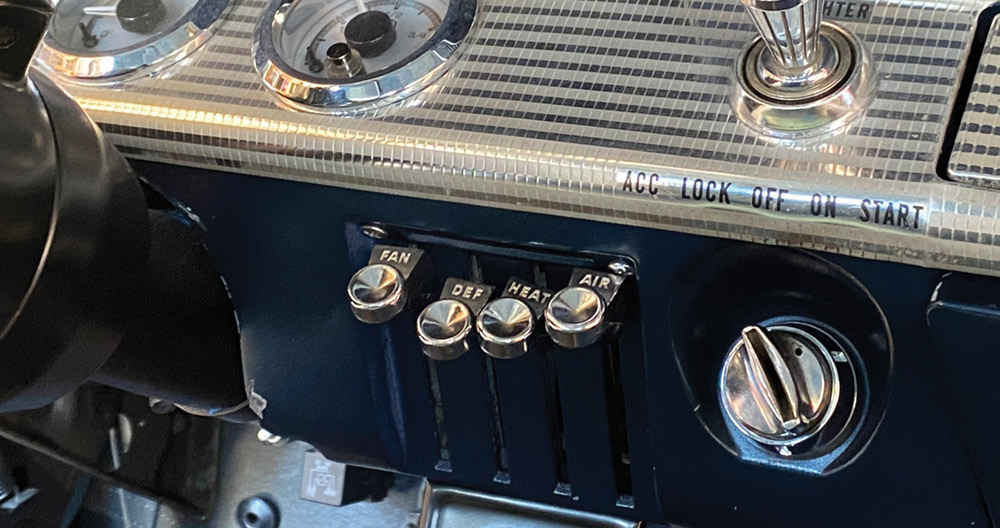

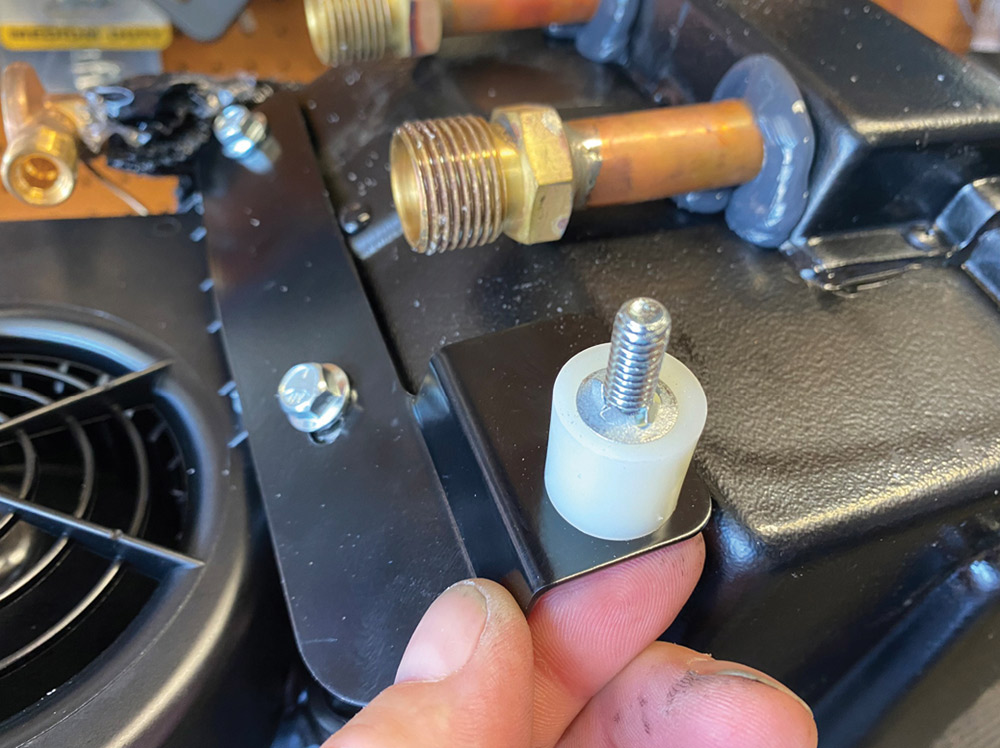

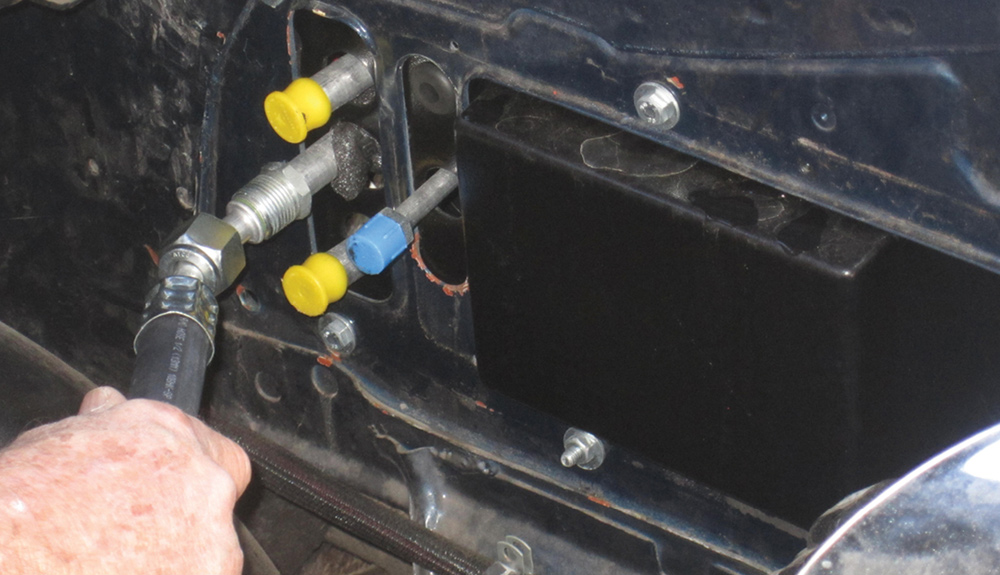

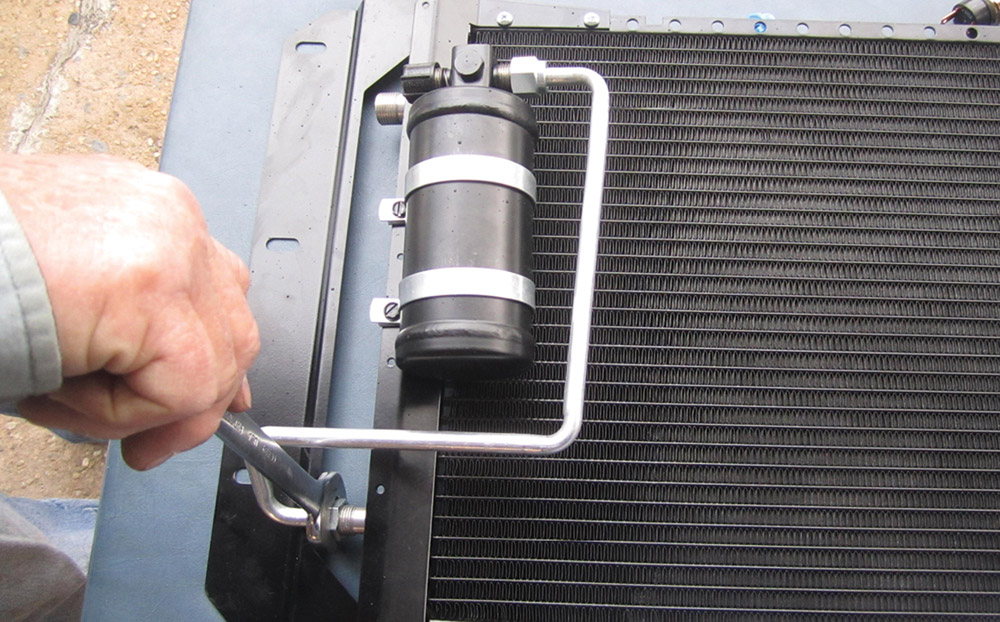

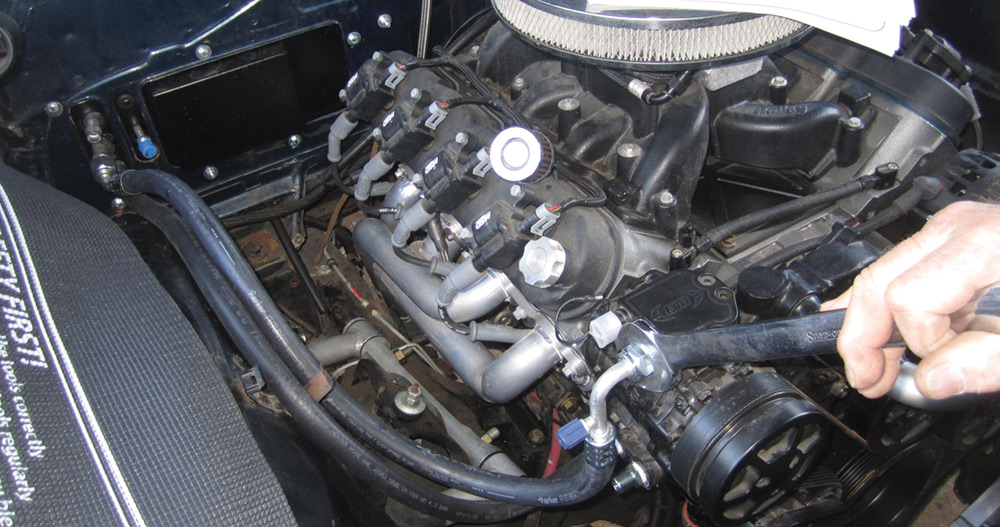

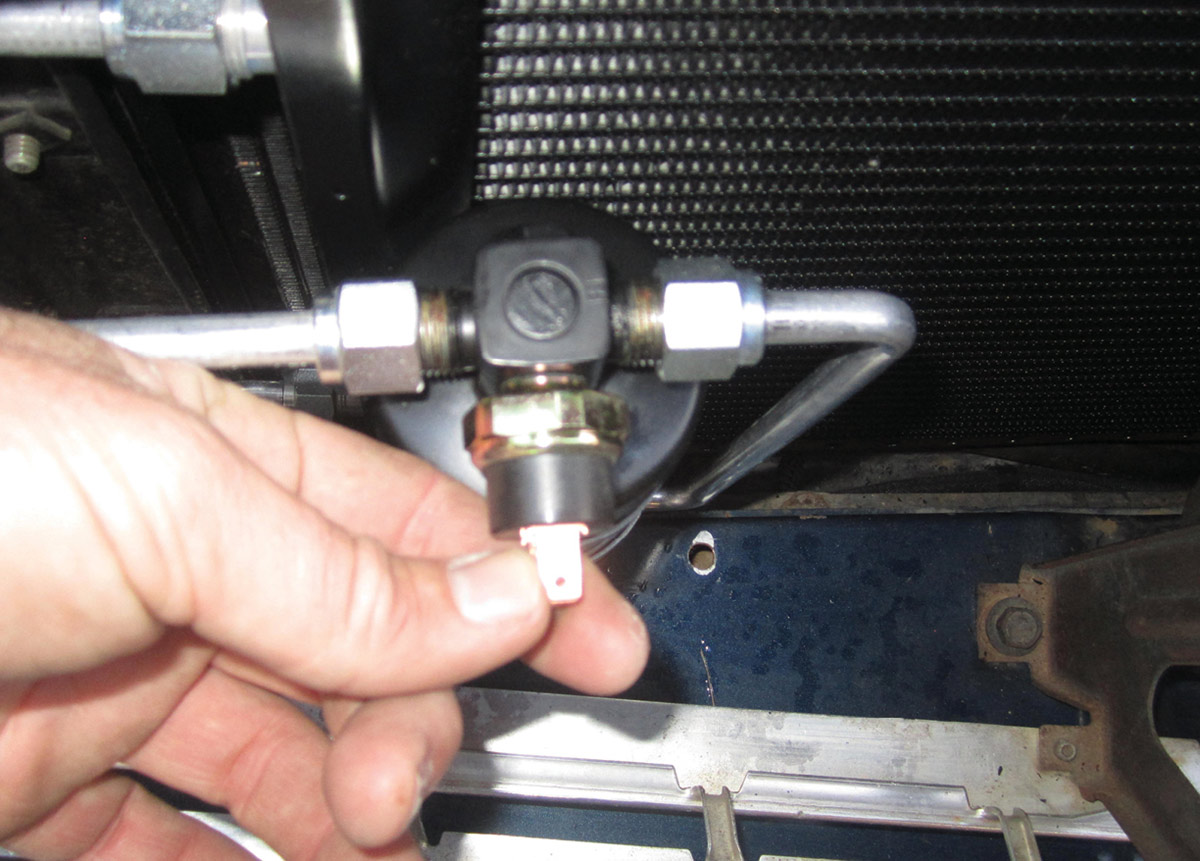

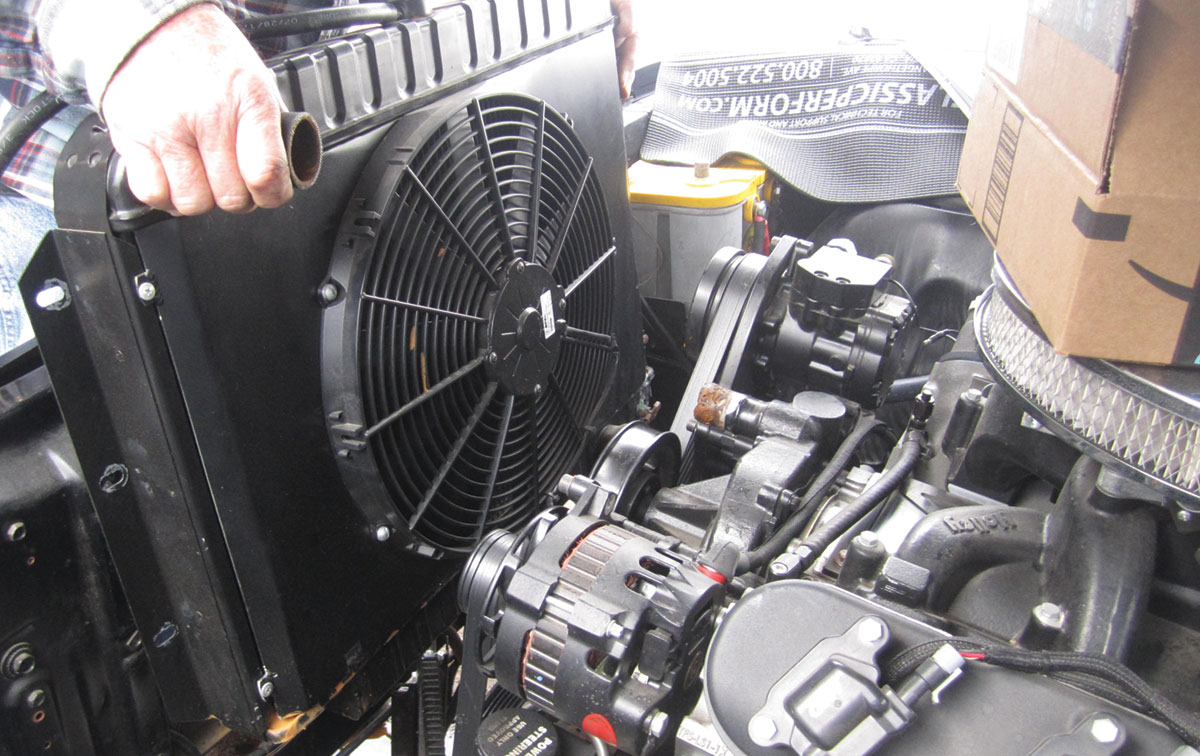

As far back as 1976, Vintage Air has been supplying universal aftermarket A/C systems to make it easy for enthusiasts to keep their early cars and trucks cool. Since then, Vintage Air has continued to incorporate the latest technology in their product line. As an example, at one time OEM and aftermarket climate-control systems used cables or vacuum motors to control the doors that directed airflow in the evaporator case—both systems had limitations due to the limited movement of those doors. Vintage Air’s Gen II and IV systems use fully electronic microprocessor-controlled servo motors to control the operation of those doors, which allows them to travel further. The results are dramatic gains in airflow, superior defrost performance, and true bi-level operation in both heat and A/C modes. Today that technology has been combined with Vintage Air’s SureFit vehicle specific kits that are complete, bolt-in climate-control systems that require no significant modifications to the car (some holes may have to be drilled).

Available for a wide variety of cars and trucks, the SureFit system shown here is for ’61-62 Chevrolet Impalas without factory air (PN 561062). For cars with factory air, Vintage Air offers systems (PN 964062) that use the factory A/C outlets. As with all SureFit systems full OEM-style operations include infinite air temperature blending, infinite blower fan speed adjustment, and high-volume dehumidified defrost mode.

While Vintage Air has made installing a contemporary climate-control system as simple as possible, there are a few additional considerations that will ensure it operates at peak efficiency:

Installing a Vintage Air SureFit system is a great way to get all the benefits of a contemporary climate-control system in your classic Chevy without making major modifications to the car. Think of it as a personal environmental impact statement.

SOURCE

SOURCE