TECH

TECH

Images by The Author

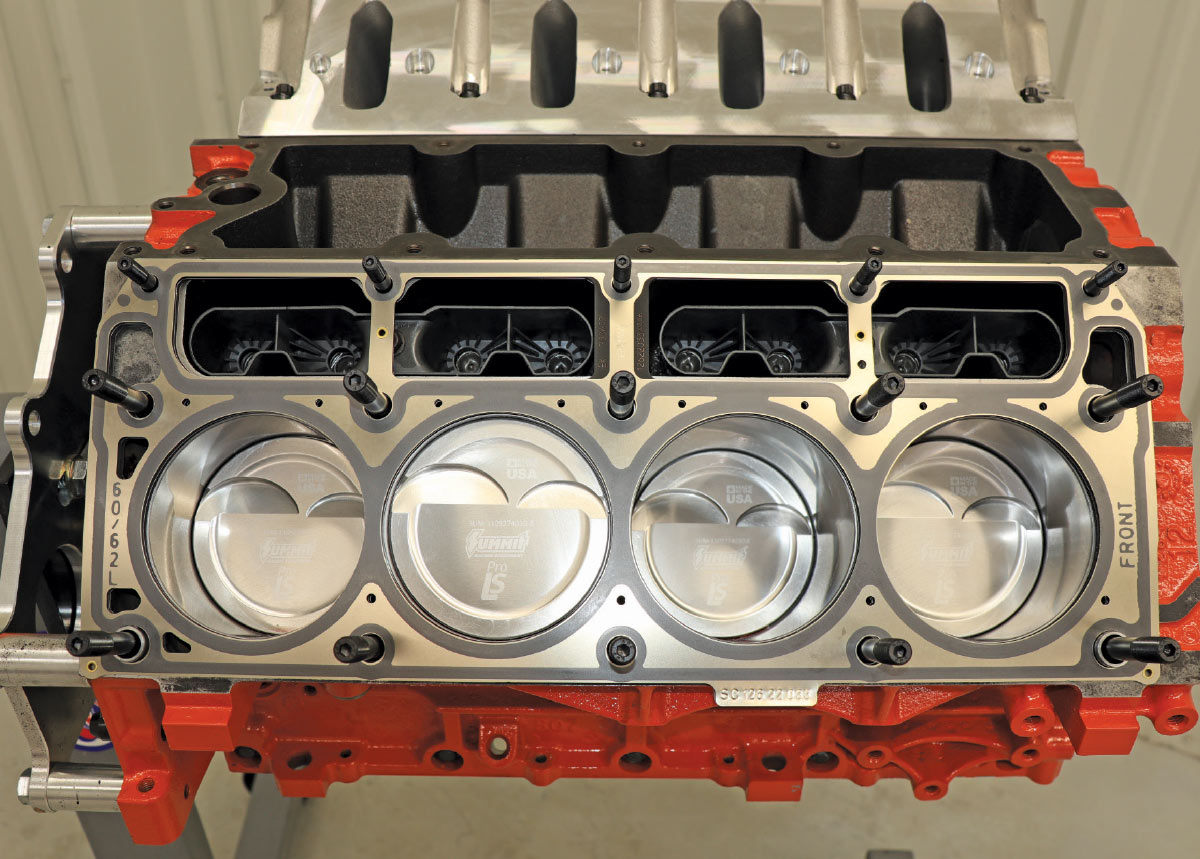

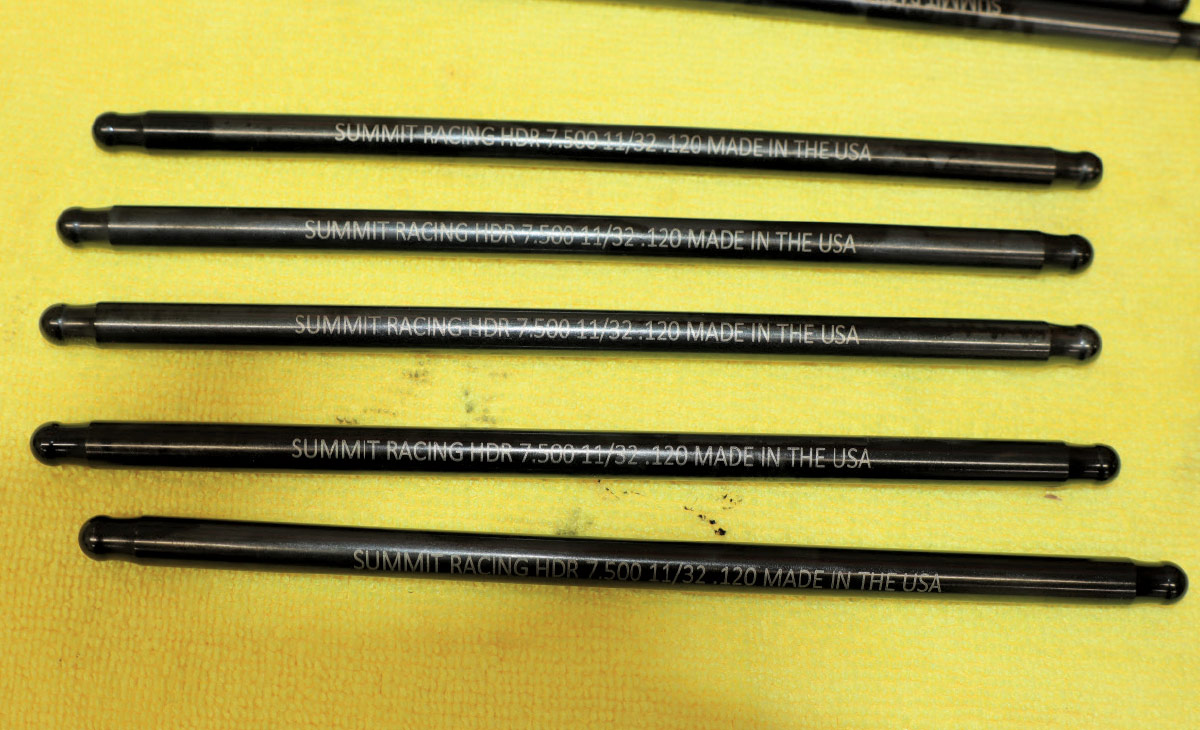

Images by The Authorast month, we started part 1 of the story of 15-year-old Hunter Hay and his dad, Ron, building a 408ci LQ9 stroker engine to run in a drag ’n’ drive 1966 Nova when Hunter turns 16. In part 1, Dunsworth Machine of Enid, Oklahoma, balanced and blueprinted the LQ9 stroker short-block, then Ron and Hunter gathered up the Summit Racing Pro LS 6.0L rotating assembly (PN SUM-R24400308). Dunsworth finessed and carted the LQ9 home in kit form where Ron guided Hunter how to build a high-horsepower engine to endure thrashings.

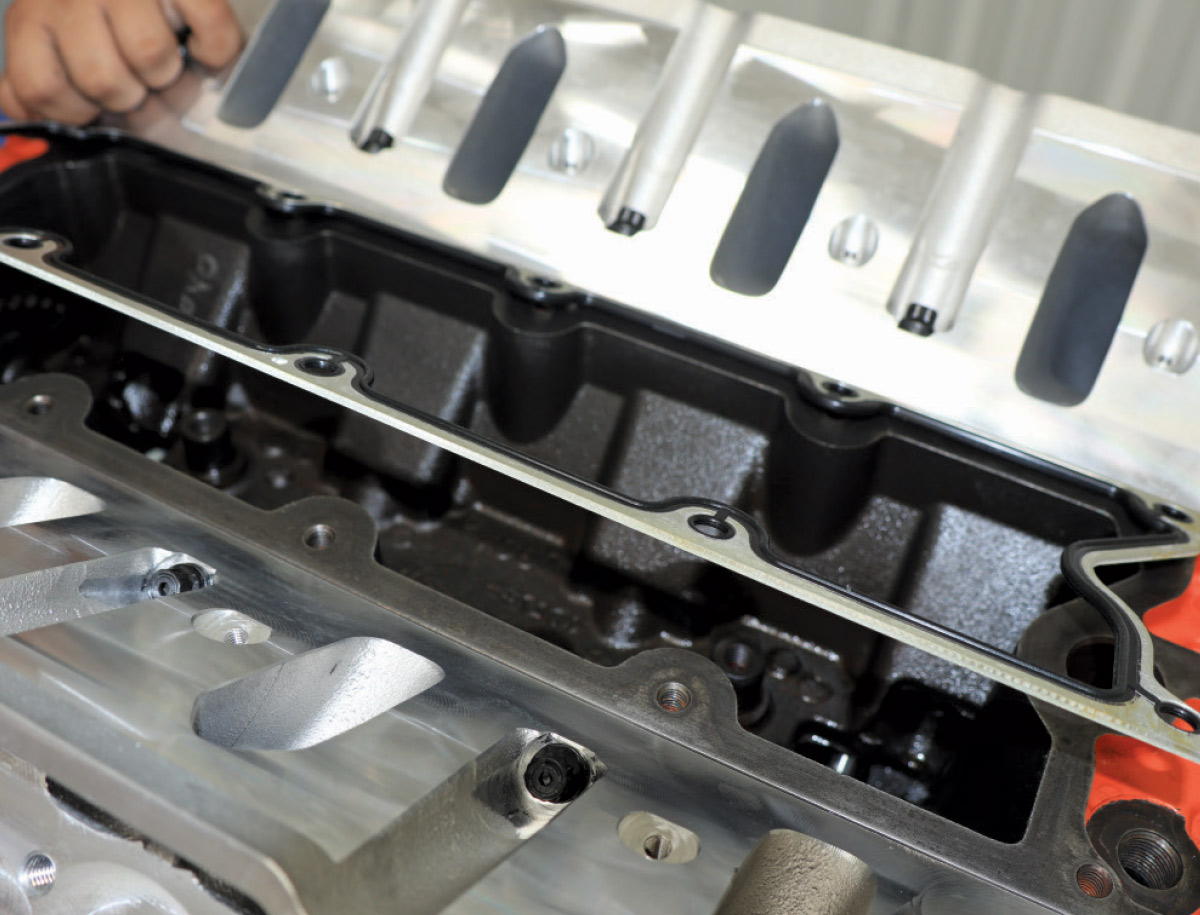

Shane Dillon at Dunsworth knocked the cam bearings in then Hunter fed Summit Racing’s cam (PN SUM-822R1) into the block. In part 1 we focused on the short-block going together but disclosed that Hunter and Ron completed the 408ci LQ9 right up to installing a pair of Trick Flow heads (PN TFS-3061T002) straight from the box.

We concluded part 1 with Ron and Hunter returning the completed engine back to Dunsworth Machine to make a dyno pull to break in the cam and make sure the engine didn’t have any problems. With only 21 degrees advance and a four-barrel carb, the results were 580.9 hp and 545.1 lb-ft of torque. Not bad since extracting the maximum amount of horsepower wasn’t the goal in that state of tune.

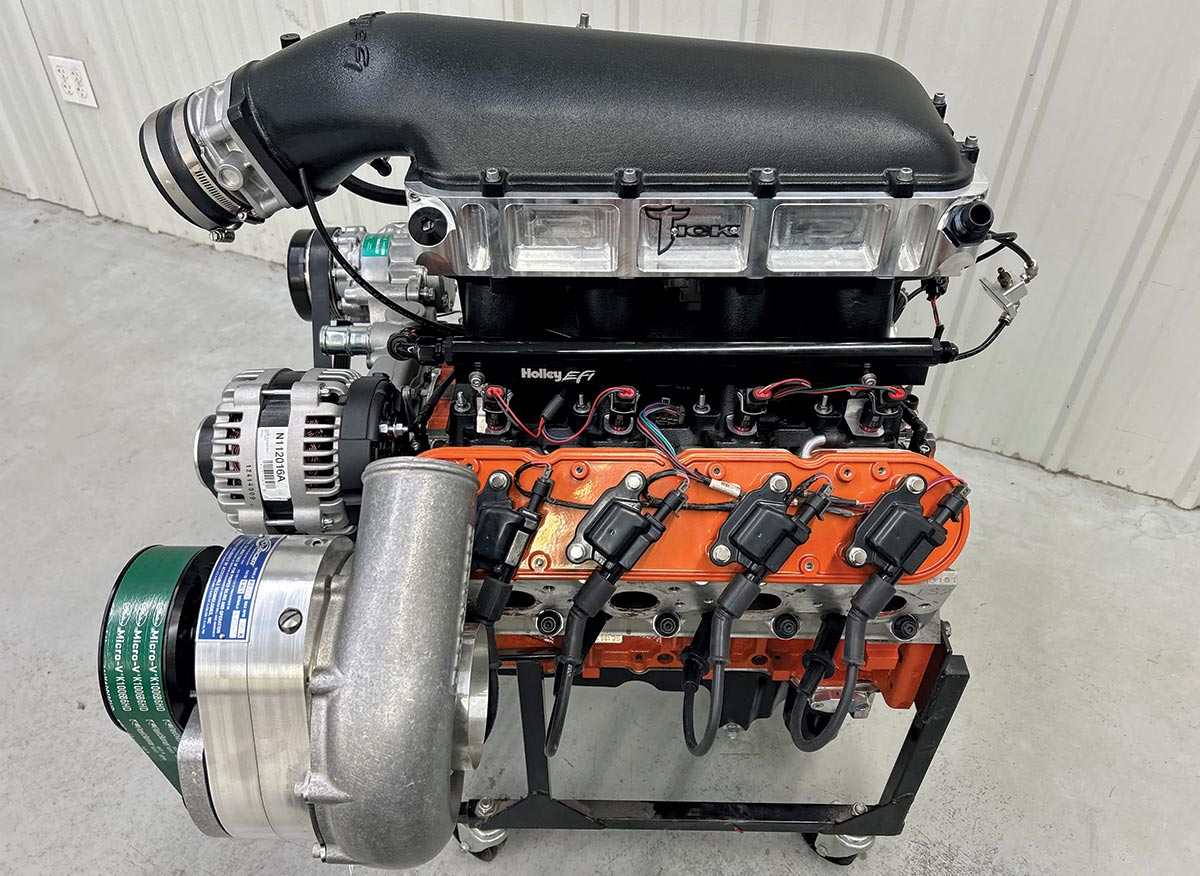

In part 2, our focus is returning to the photos we took of the top-end going together during the time Hunter and Ron were building the LQ9. At the end of part 1 we teased the possibility of capping the LQ9 off with a ProCharger supercharger because at that stage it was only a dream.

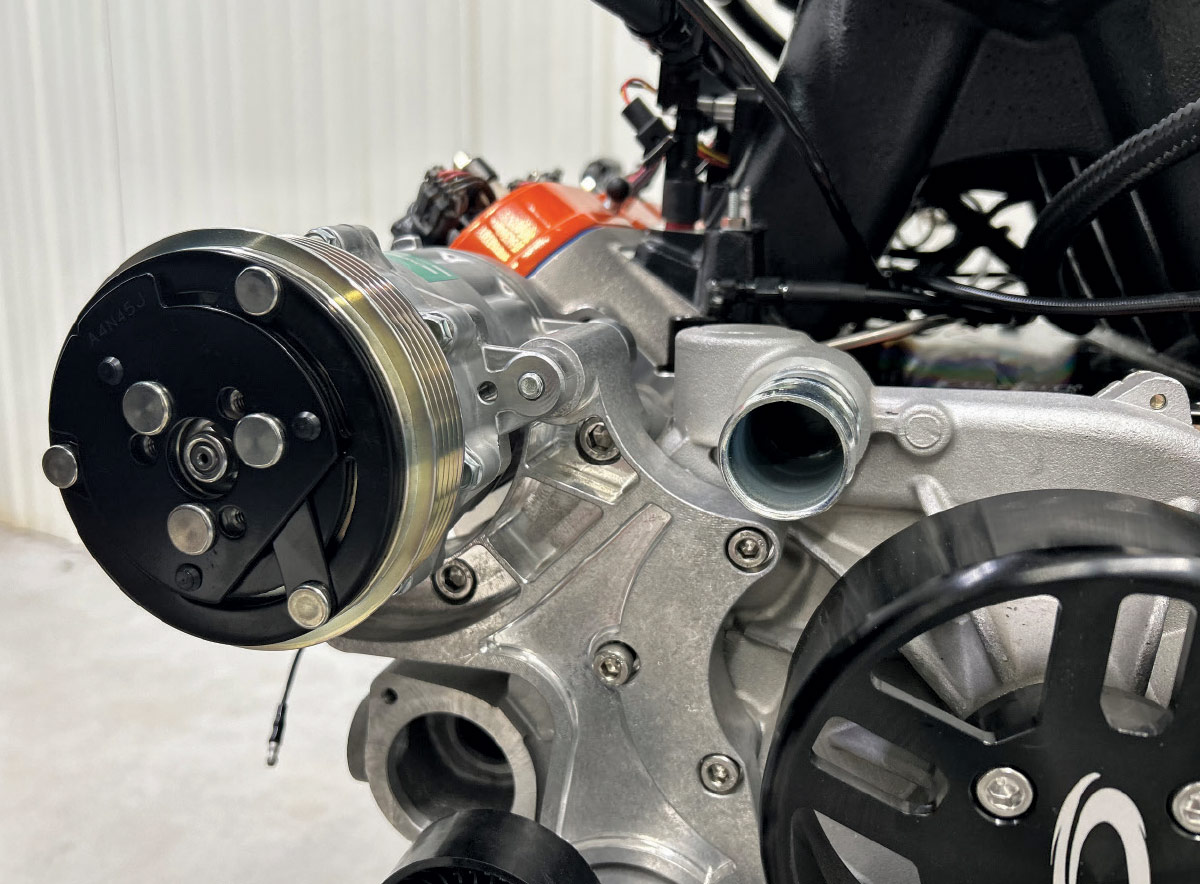

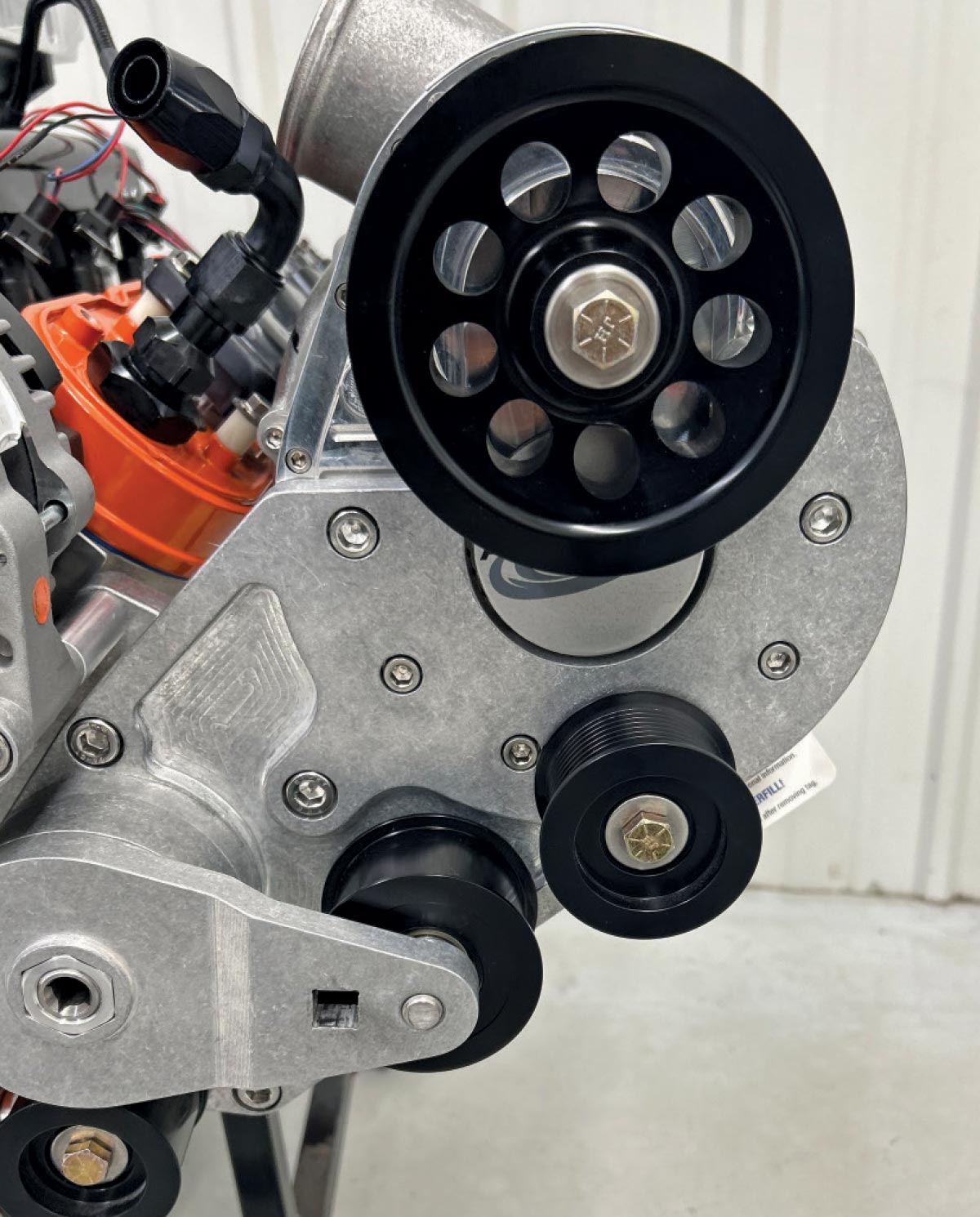

Enter Hunter’s grandpa, Harold “Papa” Clay, with an early Christmas present for Hunter: an F-1A-94 ProCharger supercharger complete with a 1LS400 LS Accessory drive kit. A few weeks after Christmas 2024 Hunter and Ron were back at Dunsworth Machine to make a few dyno pulls with the supercharger installed. Blowers and turbochargers amongst gearheads are often referred to as power adders, but after dyno testing the 408ci LQ9 and producing nearly twice the amount of horsepower we’re calling the ProCharger a “power doubler.” The key to extracting the horsepower was tuner Jonathon Lorg downloading Holley’s program for the Holley EFI management system (PN HLY-554-114) and manipulating the data logging from setting the idle for the Holley drive-by-wire pedal (PN HLY-145-160) to achieving maximum power. The results with a 5-inch pulley, 16 pounds of boost, and 18 degrees advance, the blown LQ9 produced 1,025.3 hp and 822.9 lb-ft of torque.

Is building a 1,025hp 408ci LQ9 something that can be repeated by the average DIY guy at home? All the parts from the stroker kit to engine oil were mail-ordered from Summit Racing and were not modified in any way, so that’s a “yes.” The tricky part is finding a machine shop like Dunsworth Machine that is capable of precision work and has testing facilities. That’s not exactly a “no,” that’s a “maybe.”

SOURCES

SOURCES(580) 233-5812

(580) 716-3020