TECH

TECH Photography by The Author

Photography by The Author

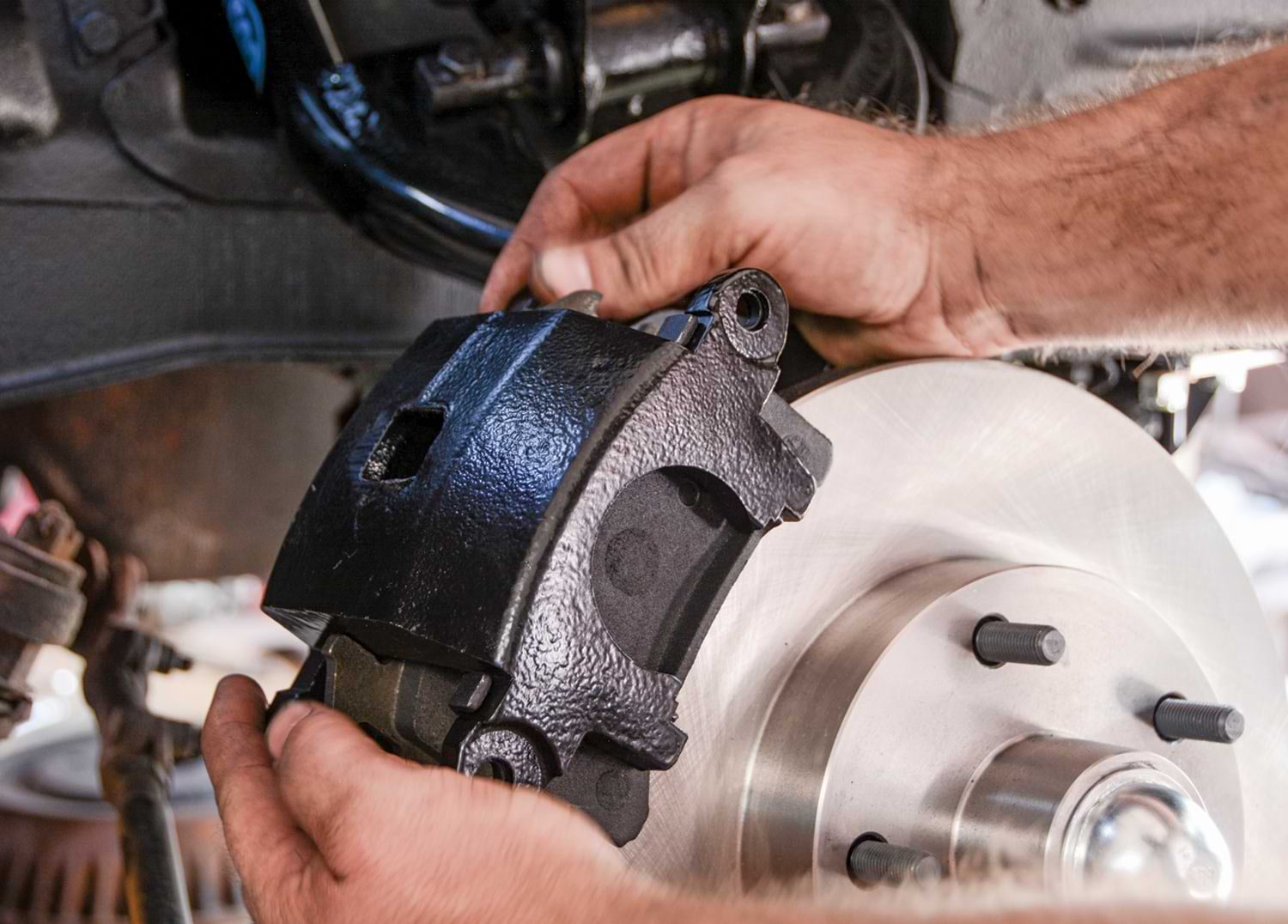

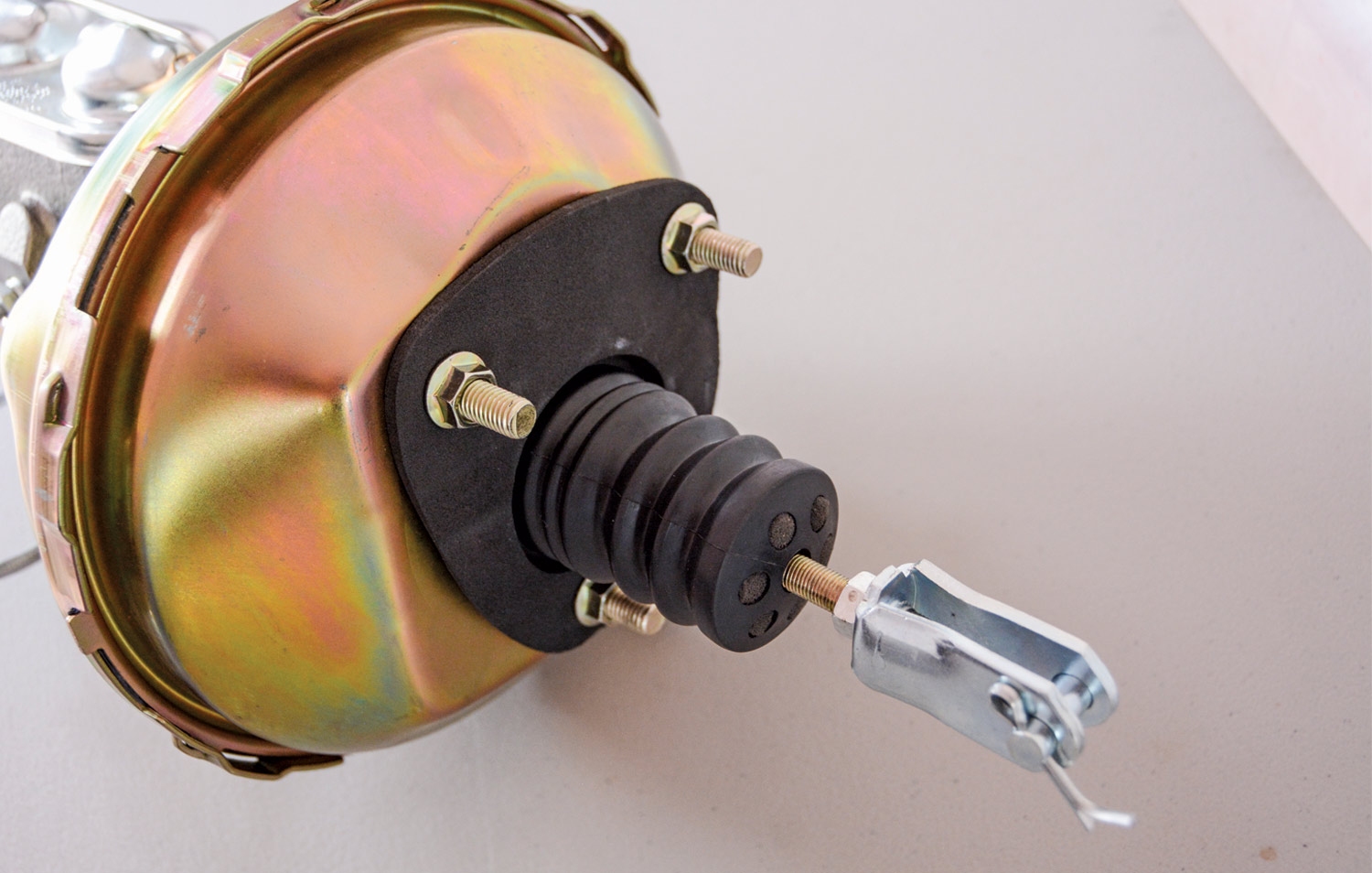

Installing CPP Power Disc Brakes on a ’66 Chevy II

raking systems changed a lot during the ’60s. It was common to see drum brakes and single-pot master cylinders well into the muscle car era, but dual master cylinders were made mandatory by 1967. It can be argued that these early systems were adequate for the time, but we can all agree that trusting your life with a single-reservoir master cylinder is not advised on today’s highways. Drum brakes aren’t quite as dangerous, but they’re not nearly as capable as disc brakes, which weren’t standardized until several years later.

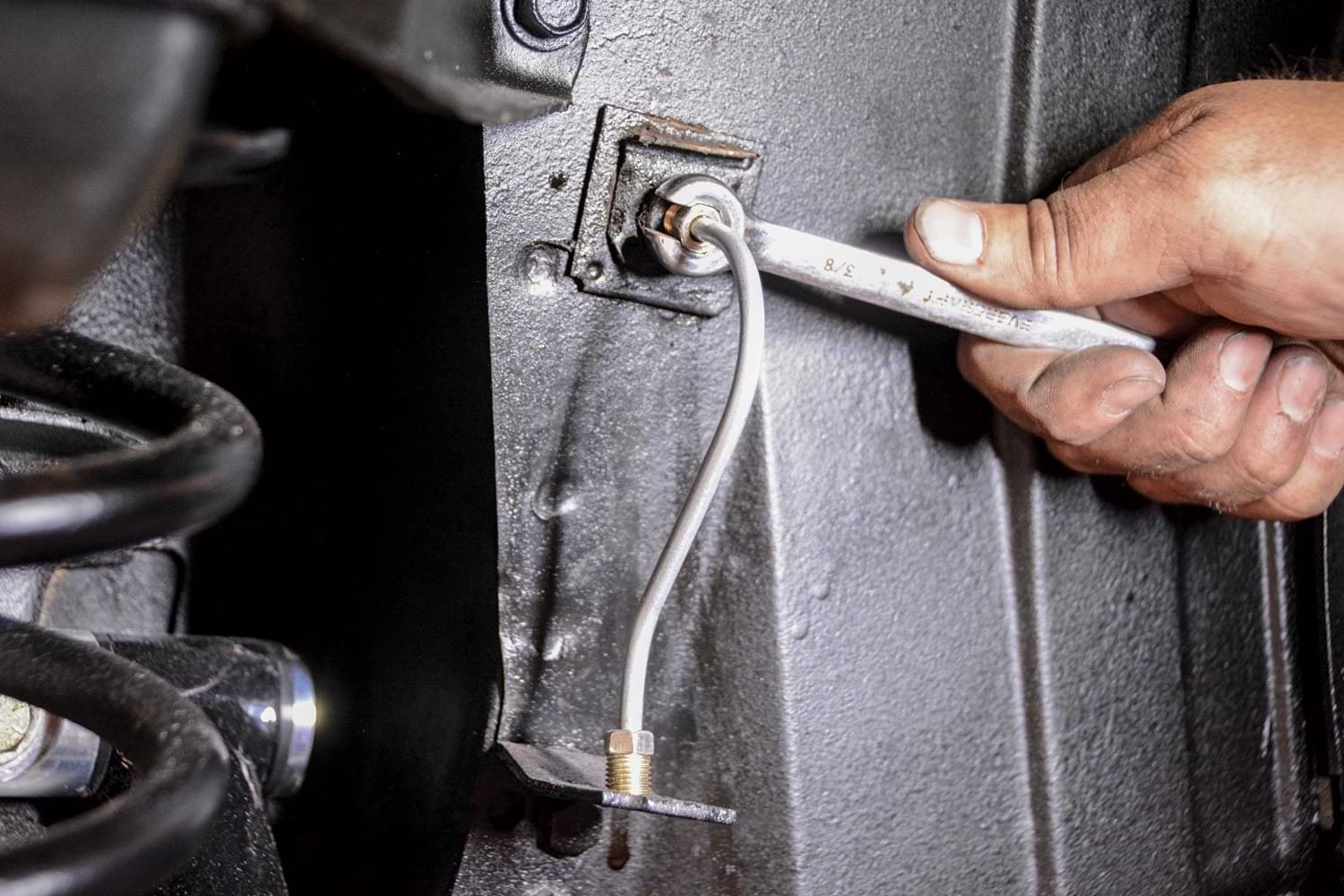

It’s always important to bed the rotors on the first drive, and we tested for leaks before setting out on our testdrive. In order to break in the pads and bed the rotors, we must get up to about 35 mph and then apply moderate brake pressure down to 5 mph. We repeated this two or three more times, then increased the speed to 50 mph and strongly pressed the brake pedal, nearly bringing the car to a stop. We applied strong braking four to five more times, and then drove a few miles to allow the brakes to cool off. Be sure to do this in an open area where you won’t be encountering any traffic.

After getting back home and double-checking for leaks, we gave the reservoir one more look to make sure fluid levels are in spec. Now it’s time to enjoy our new braking performance and hit the road with our old-school Chevy II.

SOURCE

SOURCE