TECH

TECH

Photography by The Author

Photography by The Authorhe devil is in the details may be an over-used cliché, but it nevertheless has a very practical side to it. Car builders since the beginning of automotive time have been the innovators who prefer to build their machines in much the same way that Dr. Frankenstein built his monster—using parts from departed souls.

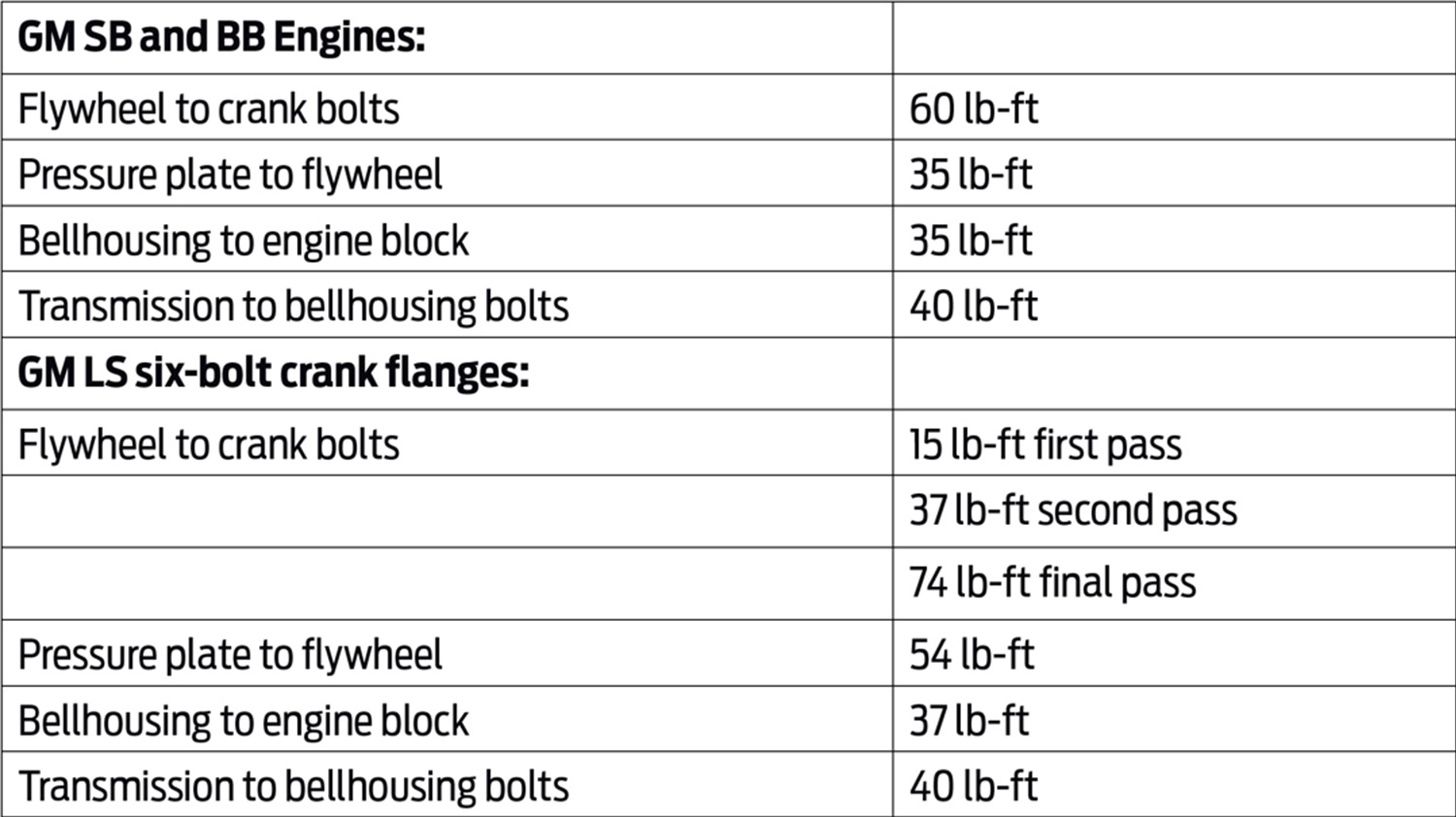

In this particular case, we’re talking about combining manual transmissions between the original Gen I small- and big-block Chevys and its Gen III/IV LS cousin. Everyone knows that the LS bellhousing bolt pattern is the same (with one relocated bolthole). That makes adding a manual transmission a simple, bolt-in deal, yes?

The devil of it is, it’s not that simple.

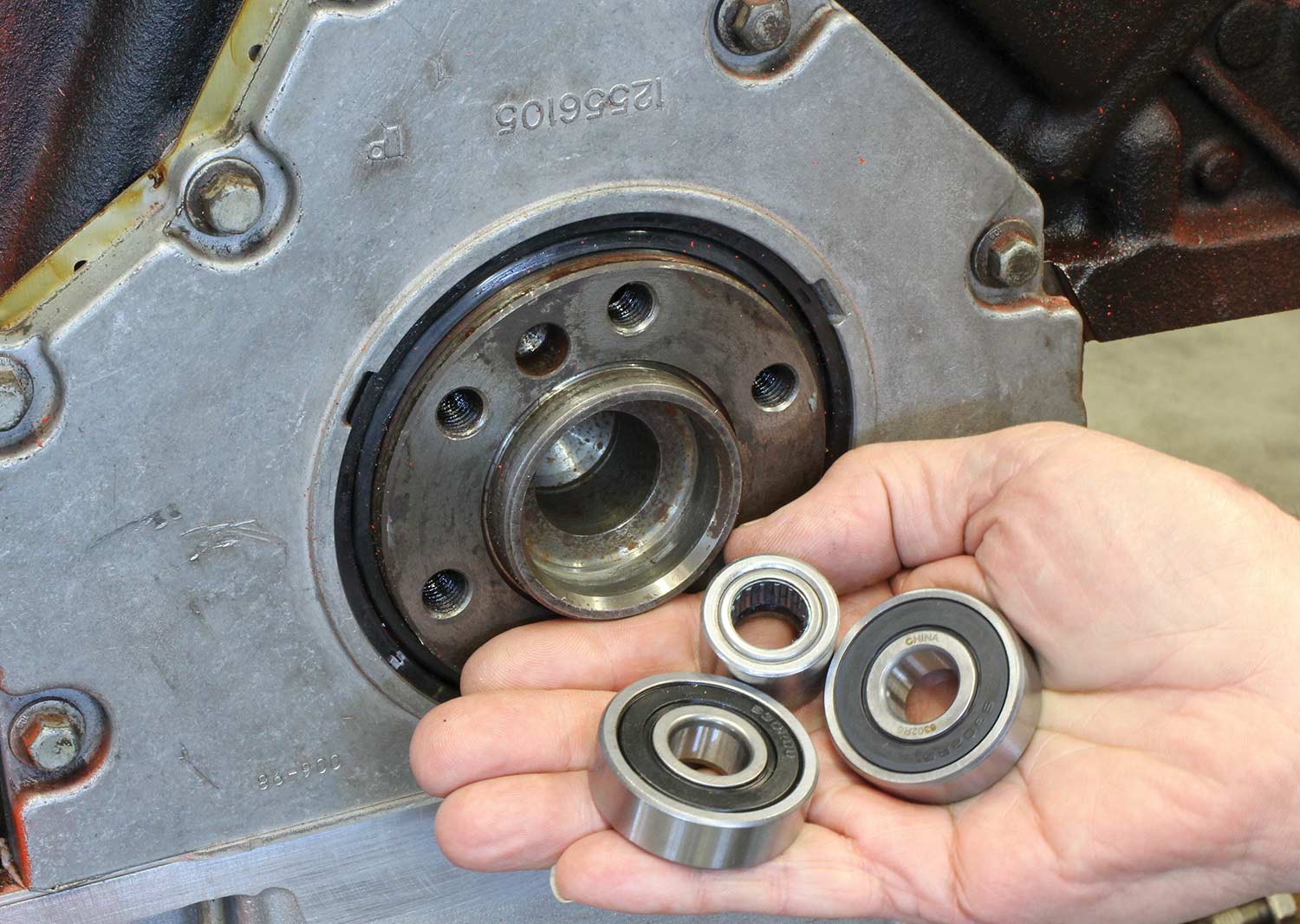

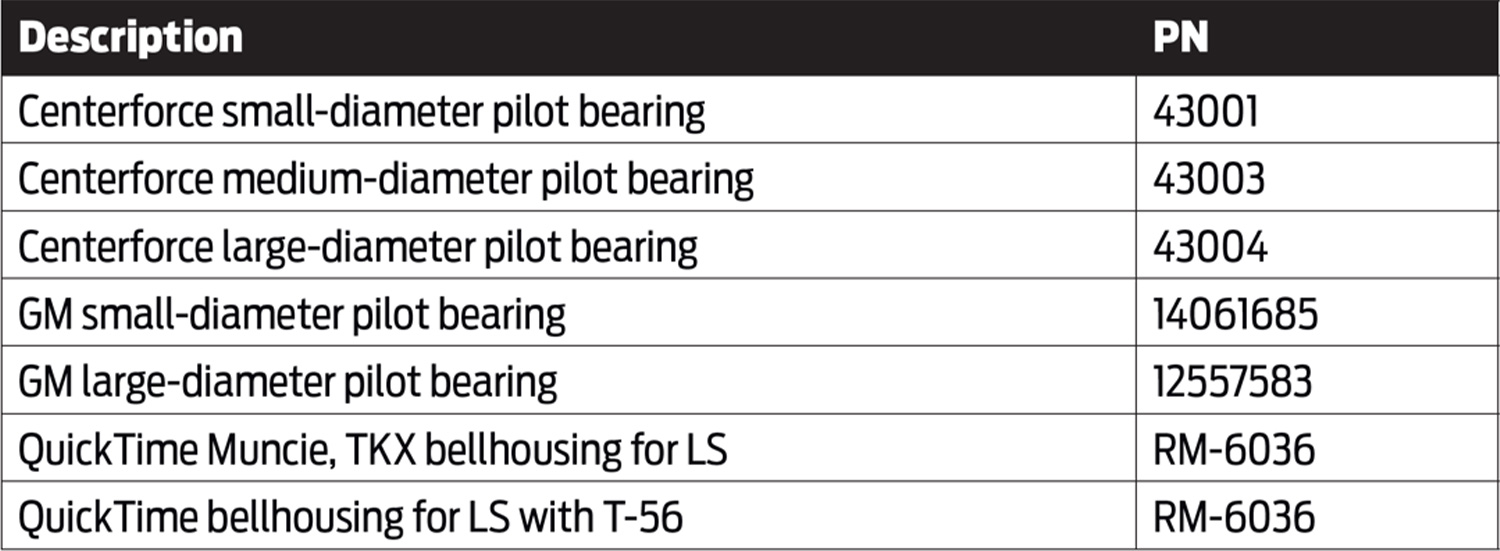

Our friends at TREMEC, Bowler Transmissions, and Centerforce have teamed up to create a roadmap for engine swappers because there are some serious misapplication errors that can occur that carry with them dire consequences if the important details are not given their due. All this revolves around the proper placement of the LS pilot bearing. Centerforce’s Will Baty informed us that there are actually three different pilot bearings for the LS engine and each one must be properly matched with the correct transmission. That’s what this story is all about.

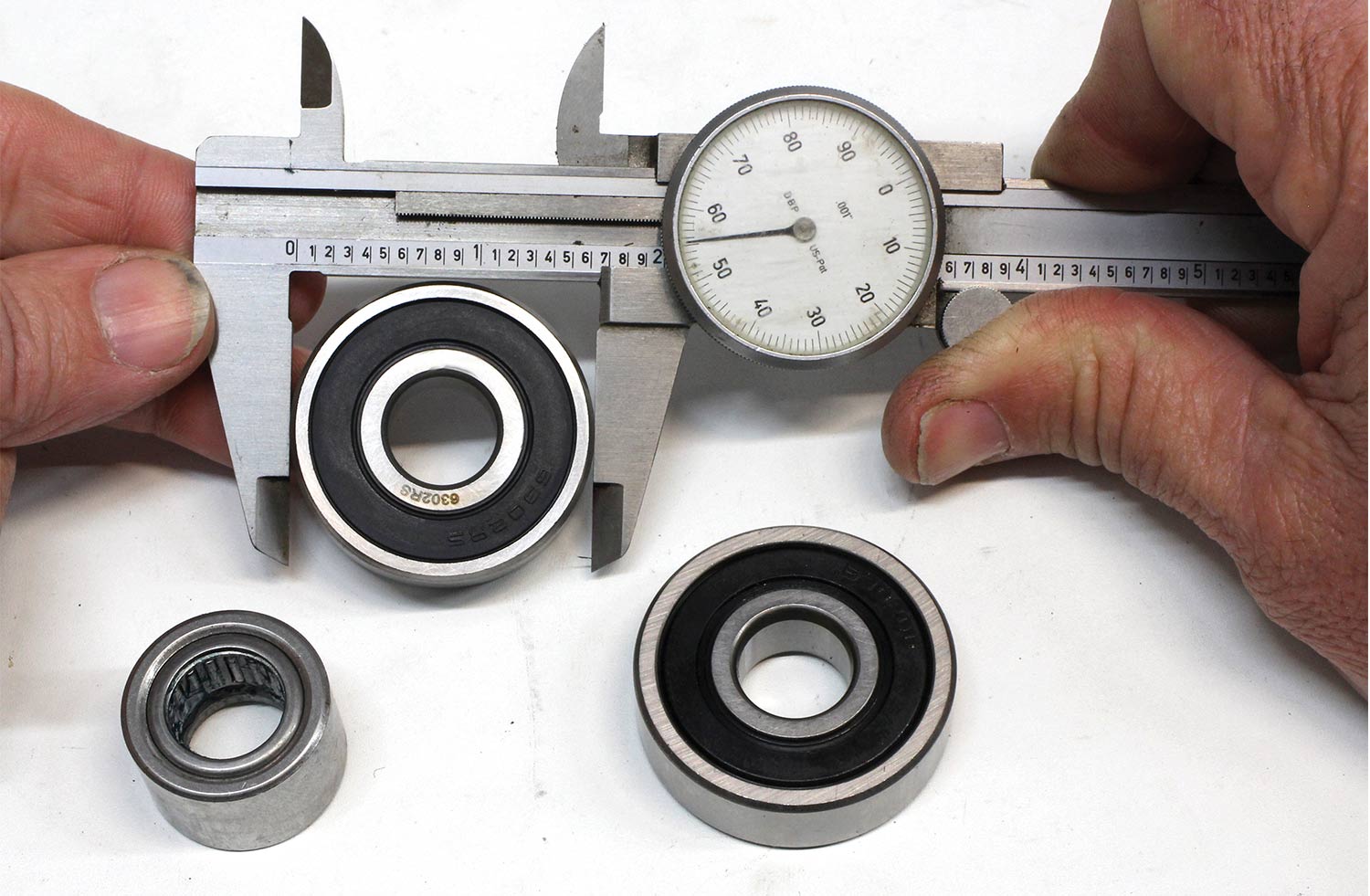

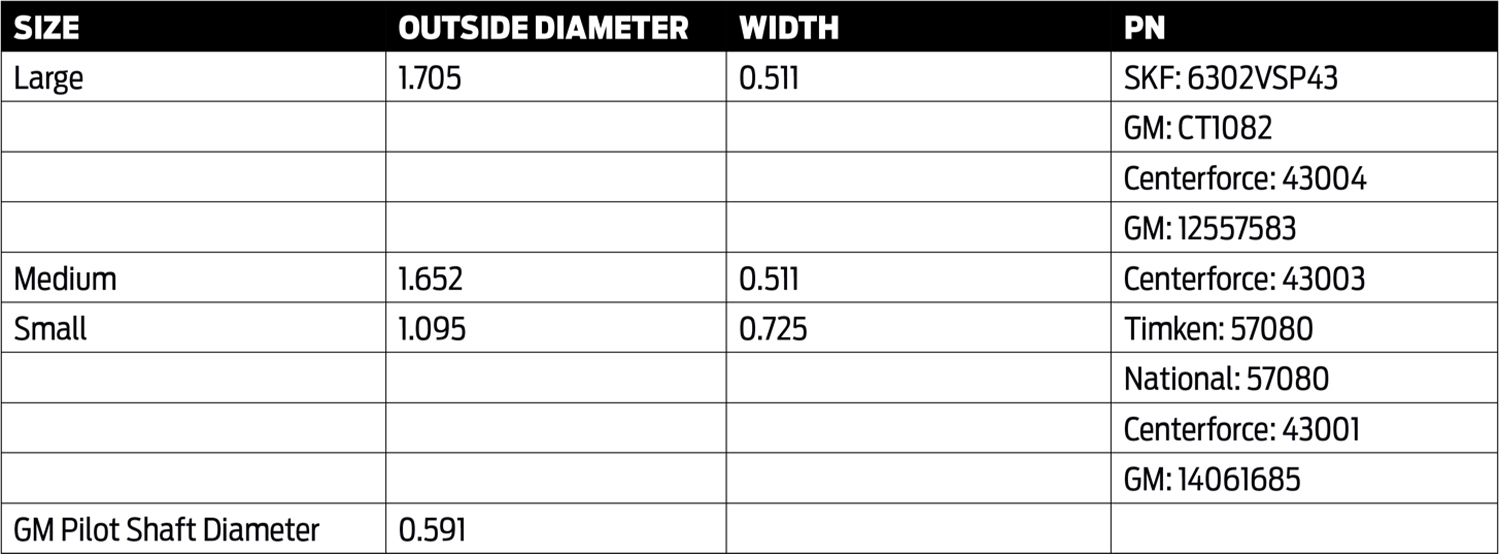

Let’s start with the fact that there are two different locations for a pilot bearing in a typical LS crankshaft flange: a deep and a shallow position. The small-diameter, deep position is closely akin to the original small-block Chevy orientation both in size and position. The second position is both much larger in diameter and closer to the transmission. There is a third pilot bearing diameter that is slightly smaller than the large diameter that is used in some aftermarket crankshafts and also in various Chevrolet Performance LSX crate engines as well as in some production LS3, LSA, and LS9 applications.

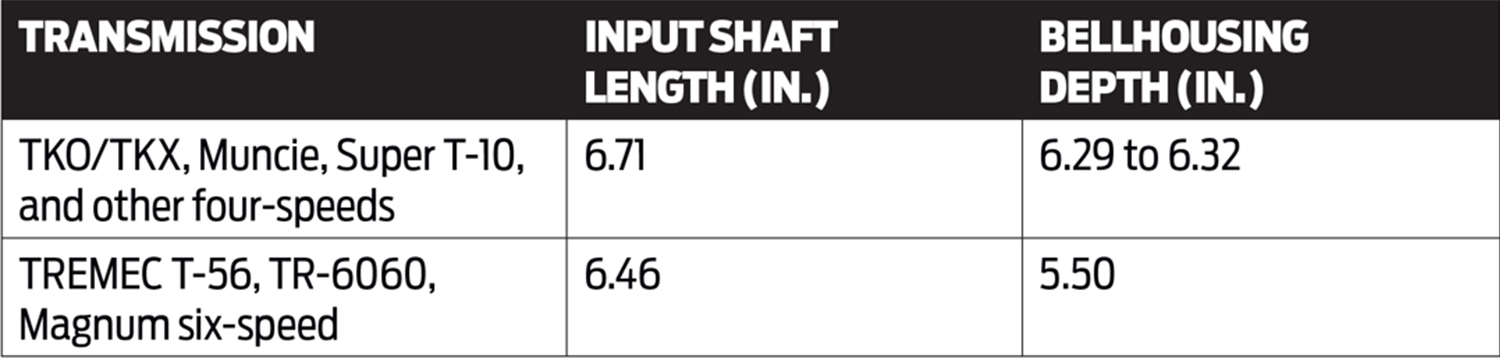

Where things begin to get sticky is when we add in the variable of two different input shaft lengths between the family of Muncie four-speed/Super T-10/TKO/TKX five-speeds and the later TREMEC T-56 and Magnum six-speeds. The input shaft length is different between these two transmissions. As you can see from the accompanying chart on page 86, the older version transmission input shaft length is 6.71 inches, while the later TREMEC six-speeds are shorter by 0.250 inch at 6.46 inches. This means it’s critical that the installer match the pilot bearing position with the input shaft length.

Let’s play out the worst-case scenario where we’ve combined a nice LS3 with the new TREMEC Magnum six-speed overdrive transmission. Without measuring anything, the builder uses one of the factory large-diameter pilot bearings (because bigger is better, right?) along with an LS flywheel and clutch assembly followed by the appropriate Magnum-style bellhousing. Funny thing is that when attempting to join the transmission to the bellhousing, it refused to fit flush up against the bellhousing. It was roughly 1/4 inch away from fitting flush and no amount of coaxing would make it fit flush. The installer then decided to use the bellhousing bolts to pull the trans into place. It was a tough fight and now it feels like the input is bound up into the back of the engine.

That’s exactly what’s happened.

In this case, the larger diameter pilot bearing was placed in the rearmost position and then combined with a transmission that uses an input shaft that is longer combined with a shallow bellhousing. With the rearmost pilot bearing in place, the input shaft pilot is now pressing into the bearing because the bearing is in the wrong location.

The remedy to this situation is the large-diameter pilot must be removed and the smaller pilot bearing installed in the farther forward location. Now the pilot bearing is in the correct location and properly supported and the transmission slides in nicely with the proper clearance and nothing binds. Birds sing, the sun rises in the east, and all is right with the world.

Will Baty at Centerforce told us they’ve witnessed this mistake more than once and it can have rather dire consequences. If the transmission is forced into the crankshaft and then the engine is started, this will not only potentially seriously damage the transmission but will also immediately mangle the thrust bearing in the engine, which will require the engine to be completely disassembled in order to repair the damage. That’s when the birds stop singing.

The other way to screw this up is almost as bad as the first scenario. In this version, the builder is bolting a new TREMEC TKX into an equally nice QuickTime bellhousing behind the same LS engine. Not realizing the situation, the builder installed the small-diameter pilot bearing. He pressed it into place and then installed the bellhousing and transmission and it all slid into place nice and easy.

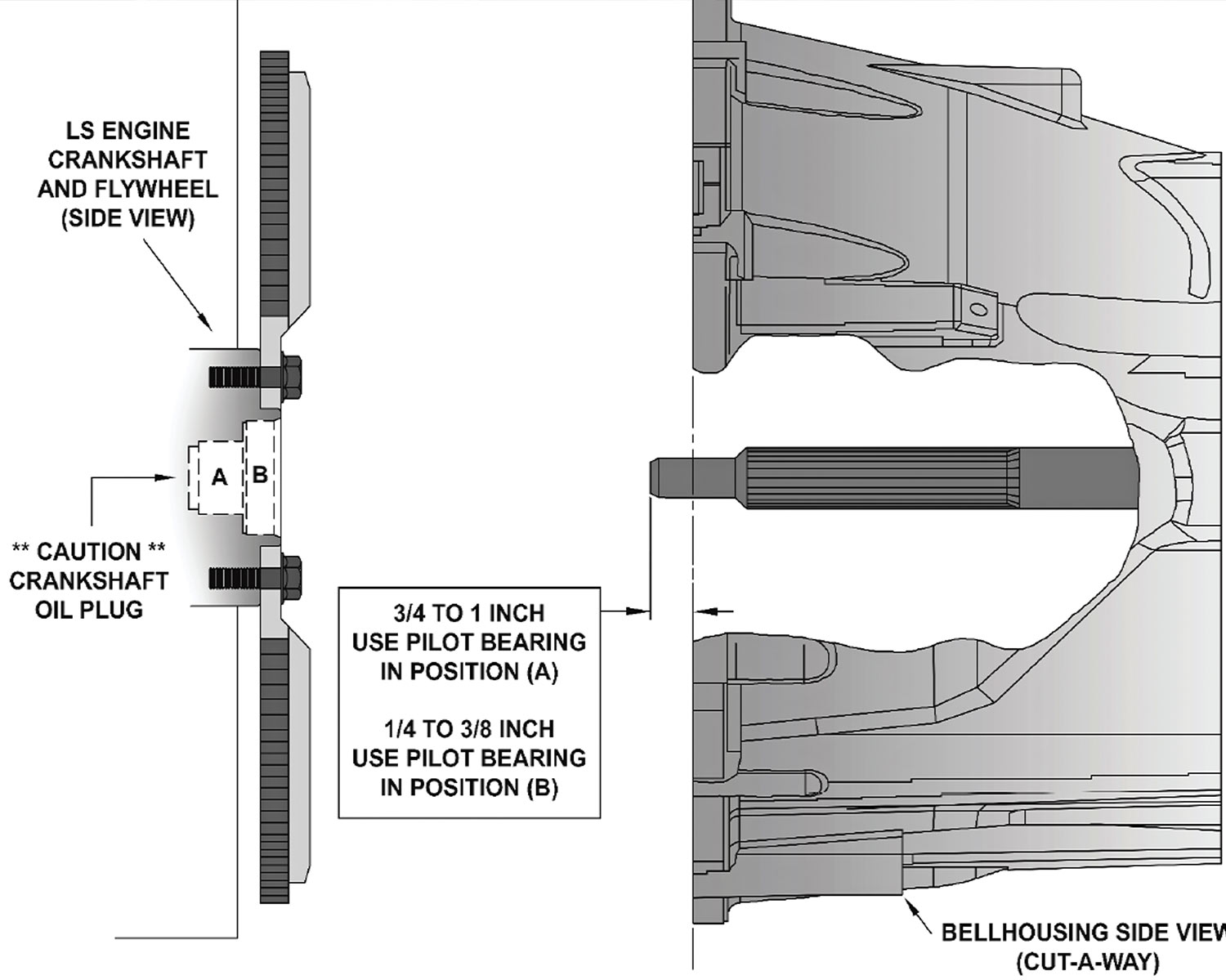

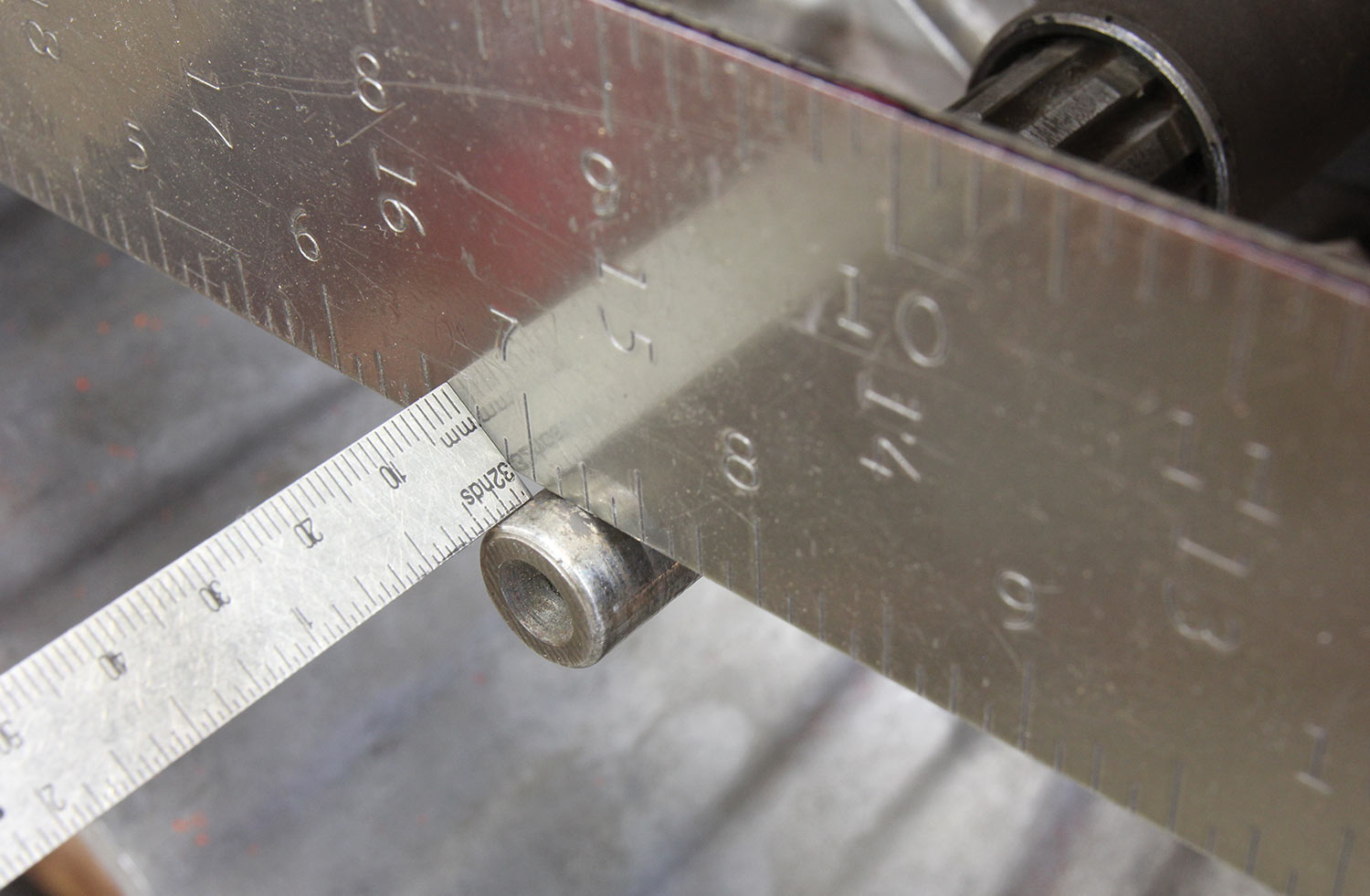

Unfortunately, the short input shaft is not long enough to reach the forward-placed pilot bearing. This leaves the input shaft unsupported, which means the transmission will be balky and likely be difficult to shift at any speed. This also places damaging side loads on the input shaft. This will cause significant early transmission damage to the input shaft bearing as well as the clutch. The fix is simply pressing in the larger pilot bearing so that the input shaft is properly supported. The technicians at Centerforce and TREMEC are aware of this problem and have created an illustration to show the relationship of the input shaft relative to the bellhousing and the LS crankshaft. All you do is bolt the transmission to the bellhousing you intend to use and measure how far the pilot shaft extends beyond the bellhousing flange. This will tell you which pilot bearing to install in the engine. If the pilot shaft extends only 1/4 to 3/8 inch from the bellhousing flange, then the large-diameter bearing in the rearward location in the crankshaft is used. If the pilot extends 3/4 to 1 inch beyond the bellhousing flange, then the smaller, deeper pilot bearing is used.

Another important point that we won’t get into in this story is also checking to make sure the bellhousing is properly aligned with crankshaft centerline. This is especially critical with newer transmissions like the T-56, Magnum, and TREMEC TKO/TKX transmissions because they use a tapered roller bearing to support the input shaft. These bearings do not react well to a misaligned input shaft. The bellhousing alignment spec is 0.005 inch (0.010 inch total indictor runout), which is a very tight spec. It’s important to check this spec because out-of-spec misalignment will produce all kinds of clutch engagement and shift-quality problems.

When it comes to mixing and matching high-performance parts, it’s important to make sure all the parts play well together. Measuring all the components before assembly will alert you to any potential problem. This is a step that is easy to manage and costs very little to get it right. Your new, high-tech transmission will reward your diligence with smooth, high-rpm shifts that will make you a player in the “Mister Shifter” sweepstakes. And, of course, the birds will once again sing.

SOURCES

SOURCES