TECH

TECH BY ACP STAFF

BY ACP STAFFhere’s nothing more rewarding than bringing a cool car out of mothballs and putting it back on the road. Ironically, one of the temptations that we enthusiasts have to fight off is the urge to tear such a garage queen apart and rebuild it from the ground up. That often ends up with the car sitting for an even longer period of time in project jail. A better option is to make that rediscovered gem reliable so it can be driven and enjoyed first, then make updates as time and your budget allows.

Like most cars that have been sitting for an extended period, time had not been particularly kind to the 1964 Chevelle shown here. A number of critical components have deteriorated over the years and will have to be replaced to ensure reliability. Typically, those parts are starting, ignition, and cooling system related. Fortunately, installing any of those items isn’t difficult to do and they are readily available from Duralast.

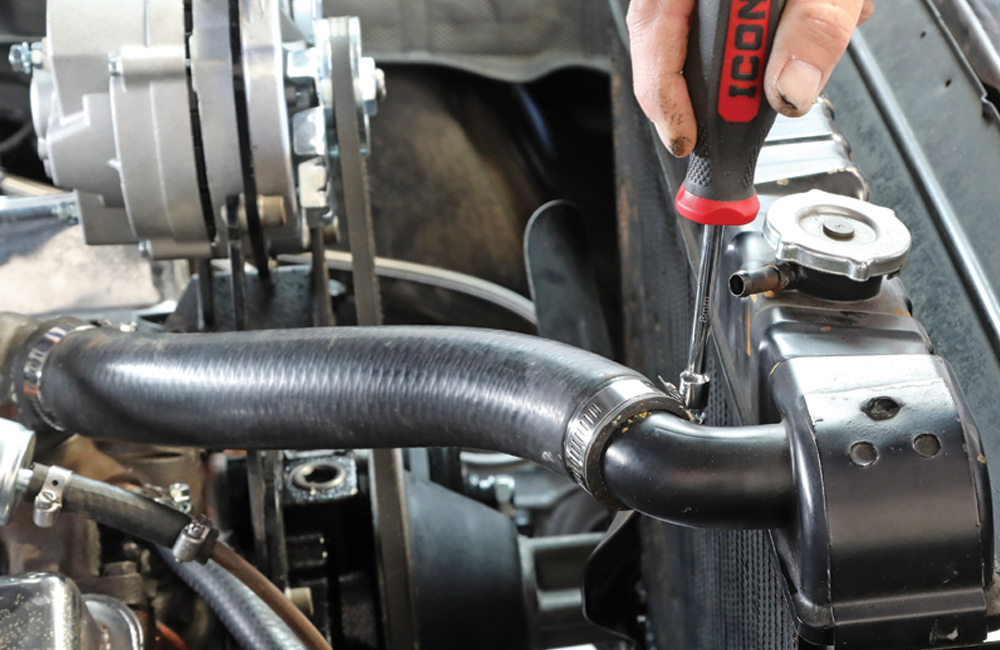

One of the first things we inspected was the cooling system. While the radiator was sound, it needed to be thoroughly flushed and as expected all the hoses, thermostat, and radiator cap were due for replacement. It was no surprise that the battery was also junk, however, even after a Duralast replacement was installed, the original starter still wasn’t up to the task of spinning the small-block. A new Duralast mini starter cured that problem and we were rewarded with the sound of the engine turning over with a twist of the key.

Finally, new fuel, air, and oil filters were put in place, fresh coolant was added, and the engine was topped with oil. With affordable, quality parts from Duralast, along with some time and TLC, our 1964 Chevelle is out of the garage and back on the road again. That’s where it belongs.

6. The Duralast water pump is all new not rebuilt. These pumps come black coated—so there is no need to paint prior to installation—have a dual bolt pattern that allows them to be used with a standard fan or a clutch type, and come with a limited lifetime warranty.

SOURCE

SOURCE