TECH

TECH

Images by THE AUTHOR

Images by THE AUTHORlumbing a fuel system on a new build or after an engine swap can be a daunting experience to the uninitiated, but with a little help from your friends here at All Chevy Performance the task can be simplified so that anyone with a handful of the proper tools can get the job done right. But, plumbing the fuel system on a ’69 Camaro back in 1969 is a totally different affair than the way we’d prefer it to be done today. New methods and materials have introduced a modern modus operandi when it comes to the fuel system in general. That first-gen Camaro relied on gravity and suction to feed the mechanical pump mounted off the side of its small-block engine, feeding less than 10 psi to the carburetor. A steel hard line running fore and aft connected by some low-pressure rubber hose and a couple hose clamps were all that was required. Filters, regulators, and return lines were non-existent for the most part—that is until electronic fuel injection came into vogue a decade or so later.

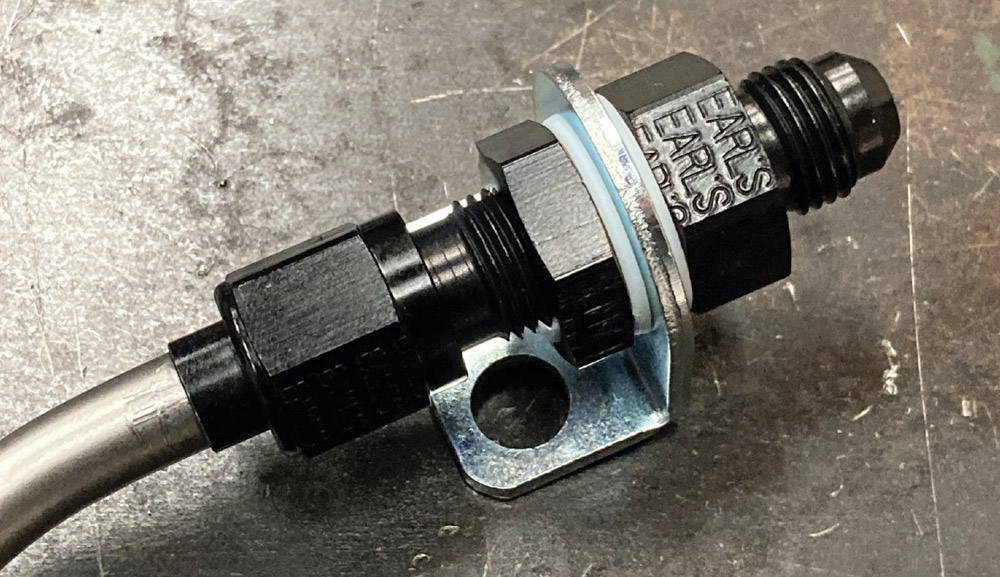

With the advent of bolt-on fuel injection systems and crate engines utilizing OE injection systems, today’s fuel system requirements look a little bit different. For starters, the pressure has increased by about 50 pounds. This requires different hose and fittings, at the very least. In addition to the increase in pressure, EFI requires very clean fuel and responds very poorly to any contaminants contained within. That increase in pressure also needs to remain constant, as any drop can result in poor performance. Careful filtering and regulating therefore is a must in EFI systems. An increase in pressure also requires a more dependable fitting than the venerable barb fitting and hose clamp. A fitting that doesn’t require constant attention and won’t come loose and leak is mandatory. The result is the adoption of specialized hose and hose ends that are assembled to suit and use the AN system.

The AN system was established during World War II between the Army Air Corps and the Navy (AN) to develop a joint standard fitting system used to connect flexible hose to rigid metal tubing using a 35-degree flare, a female tube nut and sleeve, mated to a corresponding male fitting. Sizing is noted by 16ths of an inch for each number (AN-6 = 6/16 or 3/8 inch). The ease of creating a leakproof seal due to the simplicity of forming a single 35-degree flare, makes the AN system very attractive to car builders and the military alike.

When it comes to fluid plumbing, be it brake, fuel, coolant, or transmission fluid, in the Clampdown Competition shop, AN is the only way to go. It’s simple to form and the availability of a myriad of fitting combinations beats the old barb and clamp fittings with a large-sized hammer. The reliability of an assembled fitting is also very attractive to the builder whose work may go off to parts unknown, never to be checked again.

Like many vintage vehicles, the gas tank in our buddy Bruce Valley’s 1957 Chevy Handyman wagon was in great shape, but it lacked the requirements of a modern EFI-equipped engine. A single outlet built into the sending unit wasn’t going to cut it when it came time to feed the fuel requirements of the LS3 that we’d previously swapped in the wagon. No provision for a return was another problem, and we certainly did not want to mount the fuel pump on the framerail as that results in a noisy pump and the ambient heat underneath the vehicle tends to shorten the life of said pump as well. Our best option was to swap the stock tank with a new one that was equipped to handle modern EFI. With that as our starting point, we set out to build a fuel system that will provide years of reliable operation with minimal maintenance.

SOURCES

SOURCES