TECH

TECH

Photography by The Author

Photography by The Authorlthough drag racing is simple in nature, there are many factors that go into a successful pass down the dragstrip. Horsepower, traction, and aerodynamics are the three key elements in straight-line racing, and all three of those factors have evolved immensely since drag racing started gaining notoriety in the ’50s. In this article, we’re focusing on the development of drag racing tires and how a few companies helped inspire those changes and improve traction for all types of vehicles.

Early drag racers drew inspiration from land speed racers, who already had a couple decades of trial and error under their belt. Whether on dry lake beds or sand, these racers fought for traction, but they had a long enough runway to power through the tire spin and ultimately reach the car’s top speed after a few miles of intense acceleration. With drag racing, a distance of 1,320 feet was made industry standard by the end of the ’50s. The quarter-mile distance put an emphasis on traction, as the winner of a side-by-side drag race was often determined by who could launch the car quicker.

As horsepower escalated and drag racers took serious measures to increase acceleration, they took a page out of the circle track racer’s book with recapped tires. Circle track racers would have local tire shops apply new tread to their tires using different tread sizes and rubber compounds. Recapped tires with smooth tread became the standard rear tire for many dragsters and competition roadsters of the mid ’50s.

In 1957, M&H Tire Company, a father-and-son business from Massachusetts, changed the drag racing world with the first purpose-built drag racing slick. Built as a brand-new tire with soft rubber tread, the M&H Racemaster Dragster slick was an instant success. Even with the newfound traction, dragsters of the era would still smoke the rear tires for the first half of the track, but the heat buildup gave the slicks more bite down track and significantly increased speed. Many tire companies jumped on the bandwagon, including Bruce, Casler, Hurst, Inglewood, Moxley, and many more. Although many companies were still recapping tires for drag racing use, M&H proved to be the industry leader with innovative compounds and a growing list of sizes to fit dragsters and stock-bodied cars.

During the early ’60s, dragsters were still the king of the dragstrip, but Super Stock got the attention of the Big Three auto manufacturers. Factory-produced drag cars became a hot topic, thanks to special engines and lightweight body panels, but another big revolution was coming in the form of purpose-built Super Stock tires. At the time, NHRA Super Stock required a 7-inch maximum tread width and at least two grooves of tread on the tire, so M&H built a new soft rubber tire with the least amount of tread that would pass NHRA tech.

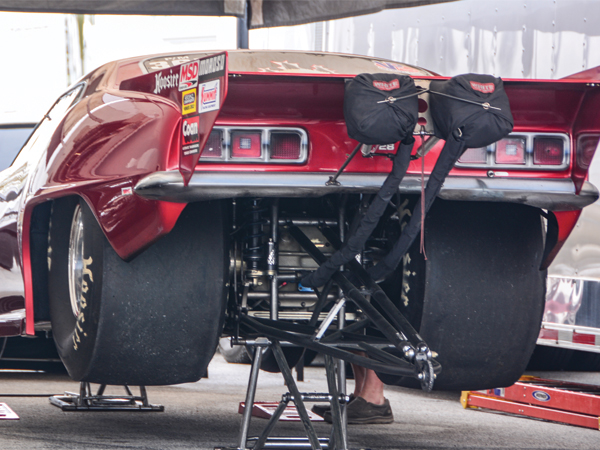

During the ’60s, much larger tire companies came onto the scene. Firestone tried its hand with a very short run of Dragster slicks and Super Stock slicks. Then, Goodyear entered the market in 1964 and took the drag racing world by storm with the Blue Streak product line. This tire not only had excellent traction but it also had a very soft sidewall, which would become known as the wrinkle wall because of the wrinkling action when the cars left the line. The added flex of the sidewall allowed the tire to bite, especially when run at low pressure. Slicks often use 10 psi or less, depending on the weight of the car and suspension setup.

Around this time is also when burnouts became common practice. A crew member would apply rosin to the track surface and the car would burn through the dust to create a little extra grip. Racers sometimes did multiple burnouts or dry hops to ensure sufficient traction, which played into the showmanship during the match racing days. As tire technology evolved, the rosin was no longer necessary, and track crews began spraying water in the burnout box to make it easier to get the tires spinning. Dry hops continued to be popular well into the ’80s and ’90s.

During the early ’70s, Firestone came back into the drag racing world with the famous Drag 500 tire, which was a popular choice on early Pro Stock cars, and later a favorite for Super Stock cars. Firestone’s compounds were excellent for full-bodied door cars, while M&H and Goodyear continued to battle for supremacy amongst the Top Fuel and Funny Car ranks. Tires and wheels continued to grow throughout the ’70s, with widths exceeding 16 inches and diameters coming in around 34 inches. For door slammers with a narrowed rearend, the most common was the 14.0/32.0-15 slick, a size that is still popular to this day.

Compounds continued to evolve as horsepower increased year by year, but something big happened in the ’80s and ’90s that changed how drag racers viewed traction. Track prep became much more elaborate, even at small tracks, and this sticky surface added to the capability of drag racing tires. You may hear track prep materials referred to as VHT or Track Bite, but whatever name you have for it this glue is responsible for taking drag racing to the next level.

The next challenge came when outlaw street cars came onto the scene in the ’90s. Some classes allowed for any size tire, while others limited the tire size to 10.5 inches wide and some required street tires. Mickey Thompson claims the Sportsman Pro was the first DOT-approved race tire in 1991, but other tire companies had already dabbled in treaded drag racing tires with great success. M&H marketed treaded racing tires as early as 1972, and McCreary followed suit with a great line of grippy street tires.

In 1995, BFGoodrich introduced its Comp T/A tire, a revolutionary radial tire with a soft compound. The tire was designed for use in NMCA Stock ET Challenge racing but would be a favorite for street cars everywhere. This tire led to further drag radial development, and Mickey Thompson has dominated the drag radial market for the past 20 years with the ET Street Radial and later the ET Street Radial Pro. Drag radials are much more efficient and stable, allowing the use of higher pressures (15-18 psi typically), but they are finicky if your horsepower application and suspension setup isn’t dialed in.

In 2024, the drag racing world is in another state of flux, as drag radials continue to dominate on prepped surfaces, while the no-prep world is using old-school tactics in the ultimate battle for traction. Because of the lack of glue on the racing surface, racers get creative with weight transfer, just like they did in the ’60s, before tire technology caught up to the horsepower levels. Hoosier D06 and C07 slicks are a favorite among No Prep racers, but other tires are going after some of the No Prep market share, like the Phoenix PH18S and Mickey Thompson’s new “Low Traction” product line.

In the world of professional drag racing, most Pro classes use Goodyear tires, while Pro Modified cars lean toward the Hoosier. Outlaw street cars still rely on Mickey Thompson drag radials, and you’ll see a smattering of brands in the bracket racing ranks. M&H Racemaster, the originator of purpose-built drag racing tires is still cranking out tires for a huge range of applications. Although all drag racing brands have evolved, the roots are still there and the innovation continues to progress. Whether you’re wanting your daily driver to hook up on a test and tune night or you’re trying to apply 2,000 hp on a sketchy surface, the evolution of drag racing tires plays a big part in how you get from point A to point B in the quickest way possible.

SOURCES

SOURCES