Tech

Tech

TEXT & PHOTOS BY Chuck Vranas

TEXT & PHOTOS BY Chuck Vranasegardless what model of Chevrolet performance vehicle you drive, the main link to transferring its power resides in the back half of your ride. Once the goods move through your driveshaft, it’s all up to the rearend, suspension, and brakes to make the magic happen. The last thing you need is a weak link when you’re ready to hit the go pedal on the street or track. If you’re driving an original car or one restored to factory specs, its fine to rely on the setup that was engineered for the driveline combination as the car rolled off the production line. However, if you’re planning to up the ante in the horsepower department with more cubic inches, a supercharger, or even turbos, it’s best to map out a plan to handle the increase as it moves out back. It’s a formula that’s served hot rodders for decades where the front-to-rear performance balance needs to be rock solid.

TEXT & PHOTOS BY Chuck Vranas

TEXT & PHOTOS BY Chuck Vranasegardless what model of Chevrolet performance vehicle you drive, the main link to transferring its power resides in the back half of your ride. Once the goods move through your driveshaft, it’s all up to the rearend, suspension, and brakes to make the magic happen. The last thing you need is a weak link when you’re ready to hit the go pedal on the street or track. If you’re driving an original car or one restored to factory specs, its fine to rely on the setup that was engineered for the driveline combination as the car rolled off the production line. However, if you’re planning to up the ante in the horsepower department with more cubic inches, a supercharger, or even turbos, it’s best to map out a plan to handle the increase as it moves out back. It’s a formula that’s served hot rodders for decades where the front-to-rear performance balance needs to be rock solid.

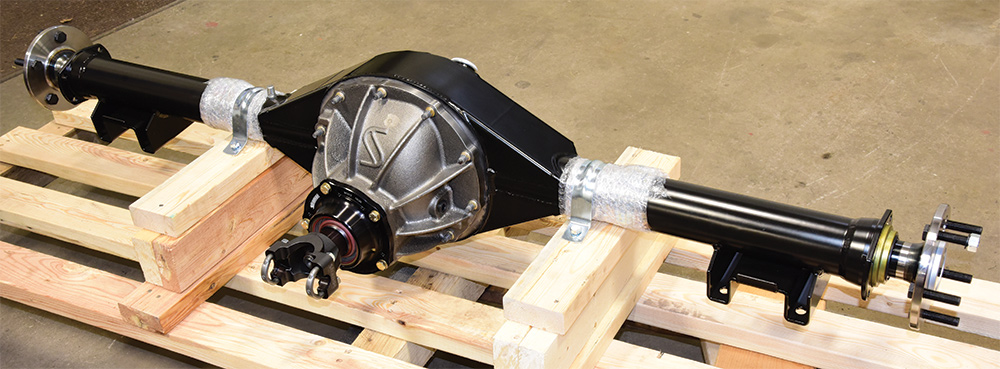

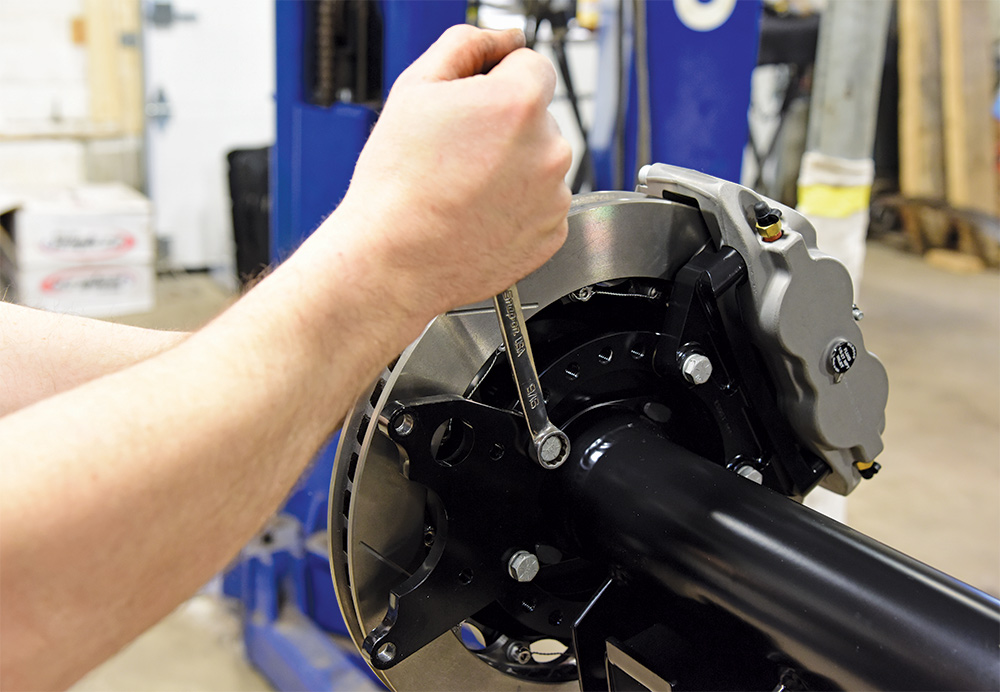

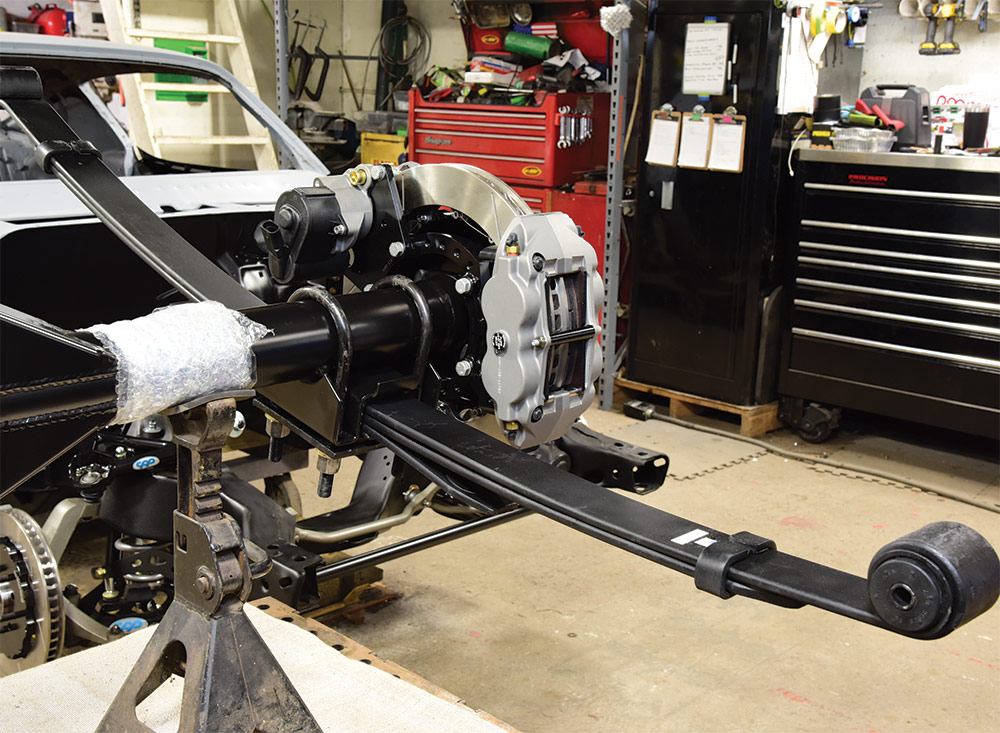

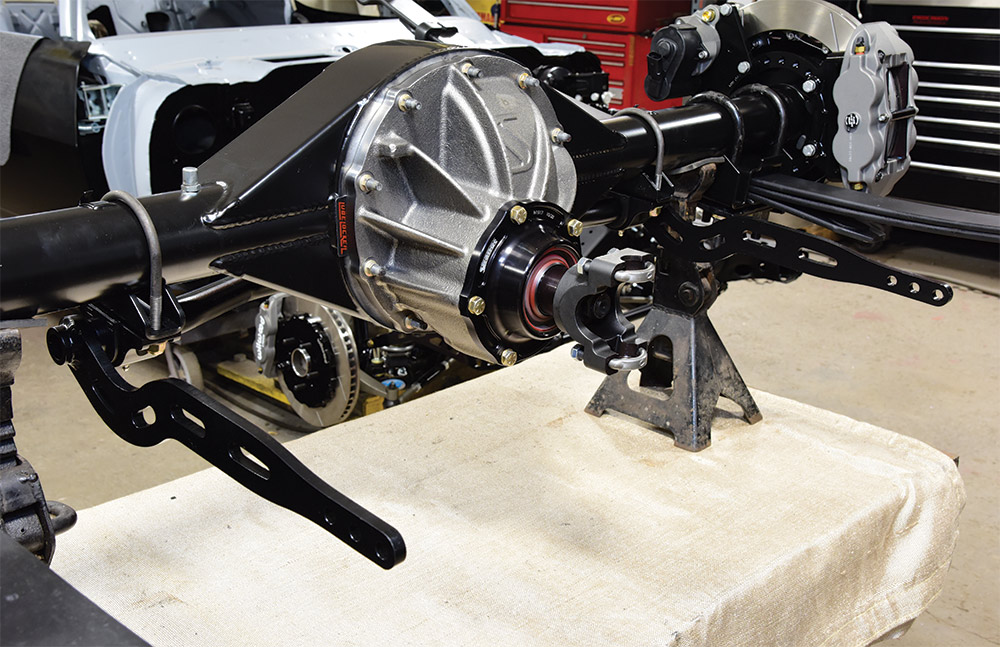

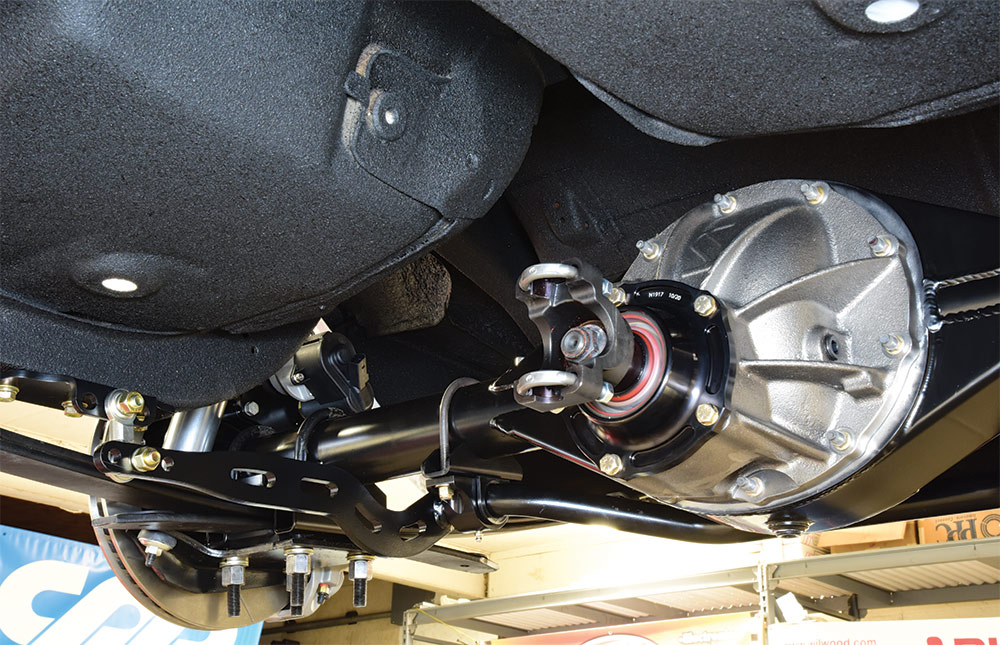

When making the decision to upgrade the tired, original factory, 10-bolt Chevy rear, O’Brien contacted Strange Engineering to custom build a rearend that would address all of his performance needs, including the new, more-powerful LS engine. To handle the job, he started with a Strange 9-inch Ford housing setup with late big Ford ends and leaf spring mounts, seeing as he made the decision to maintain the factory-style leaf spring setup. A Strange S-Series nodular iron centersection was matched to an Eaton Detroit Truetrac, 3.50:1 gears, 31-spline axles, chromoly yoke, and satin black powdercoating for the housing. The completed rearend was then crated, shipped, and ready for full installation once received.

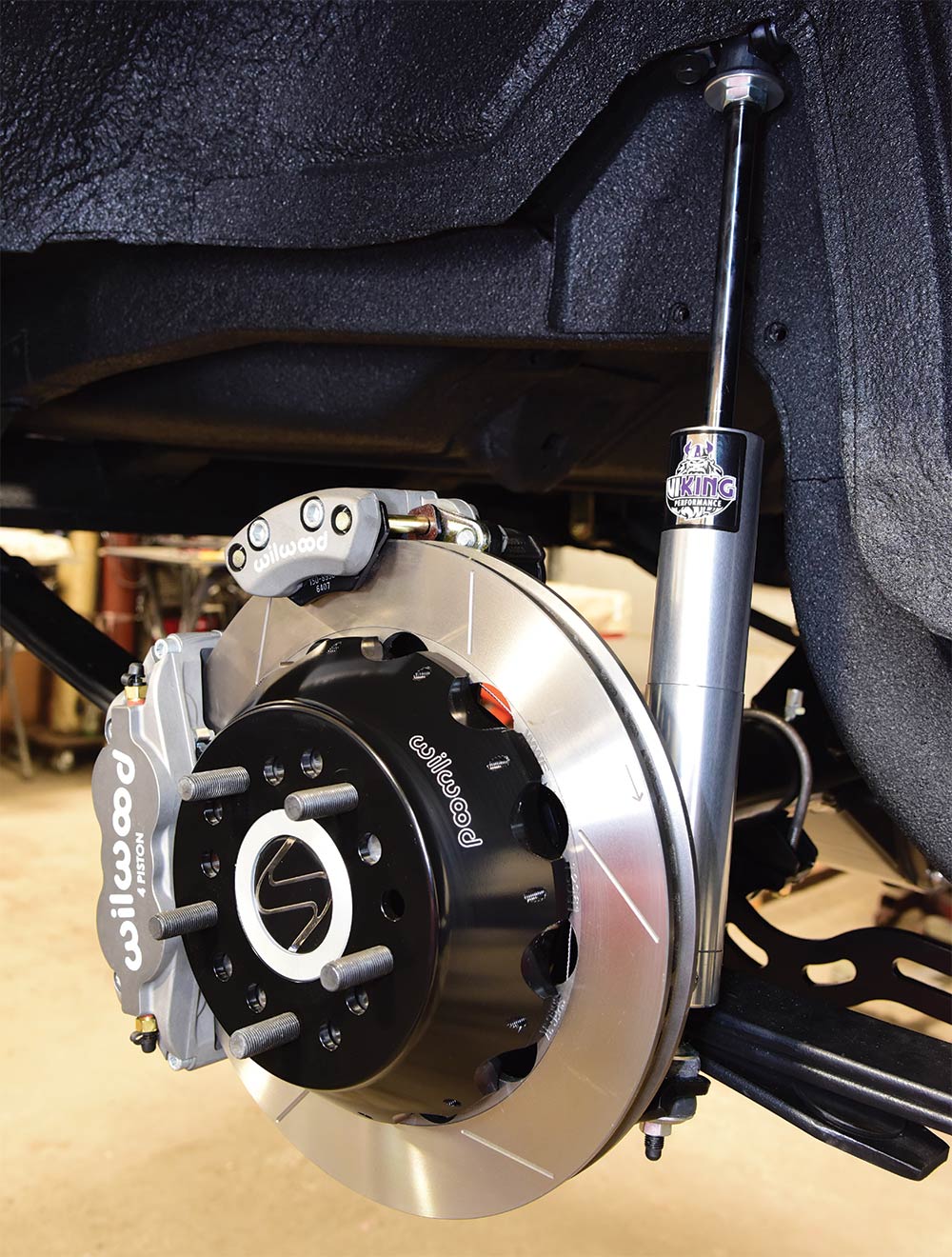

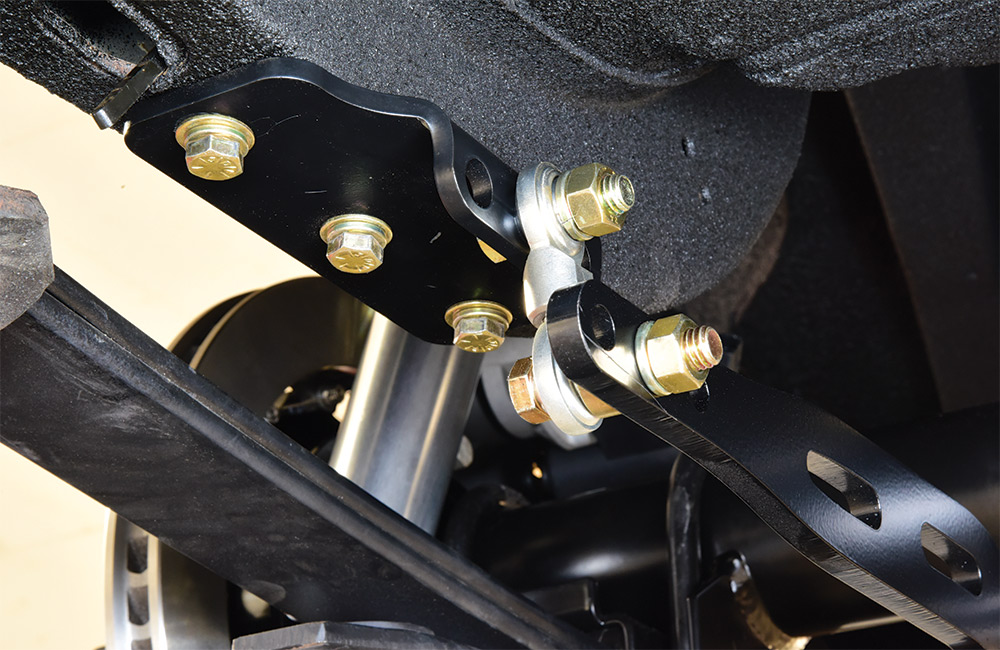

With regard to setting up the rear suspension, it was time to focus on the upgrades by installing the rear half of the Classic Performance Products (CPP) Pro-Touring kit. In this article we’re focusing on the rear portion of the complete Stage II kit, which includes replacement lowered leaf springs, double-adjustable Viking Performance aluminum shocks, and all necessary hardware. These shocks offer 19 different positions of compression and 19 different positions of rebound adjustment for a total of 361 different valve combinations.

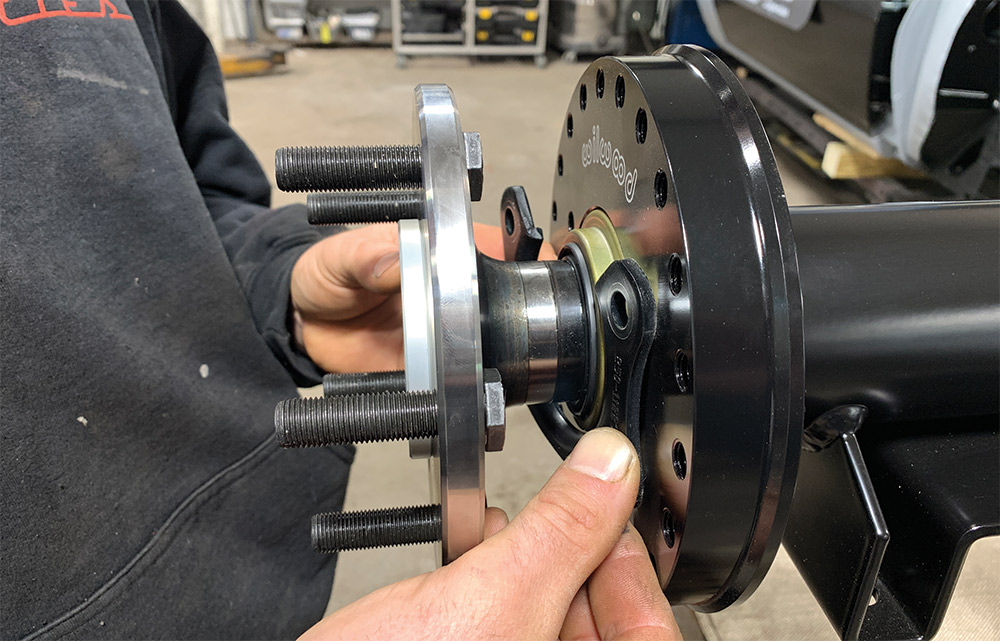

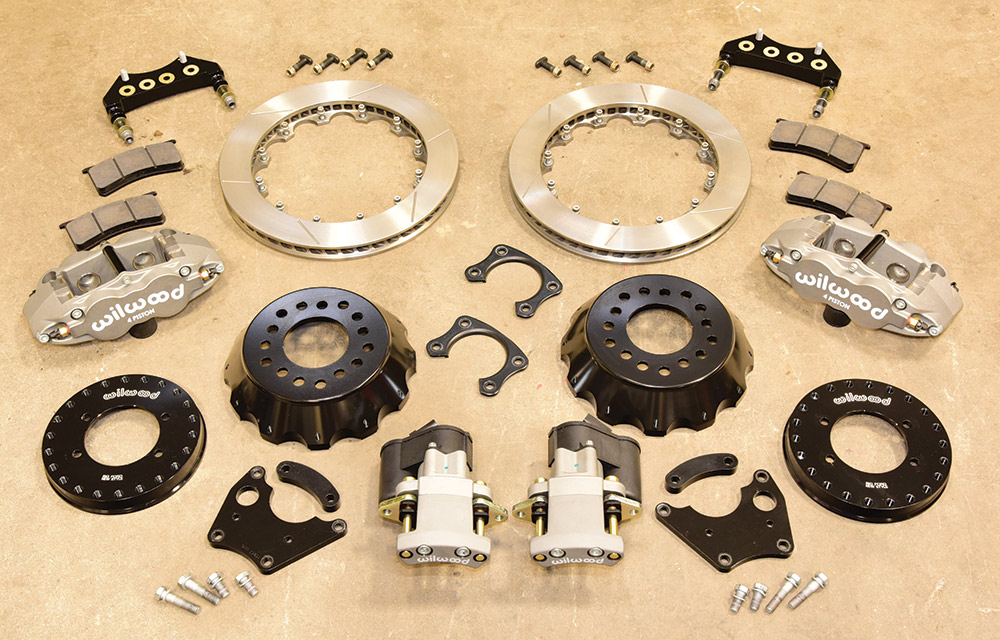

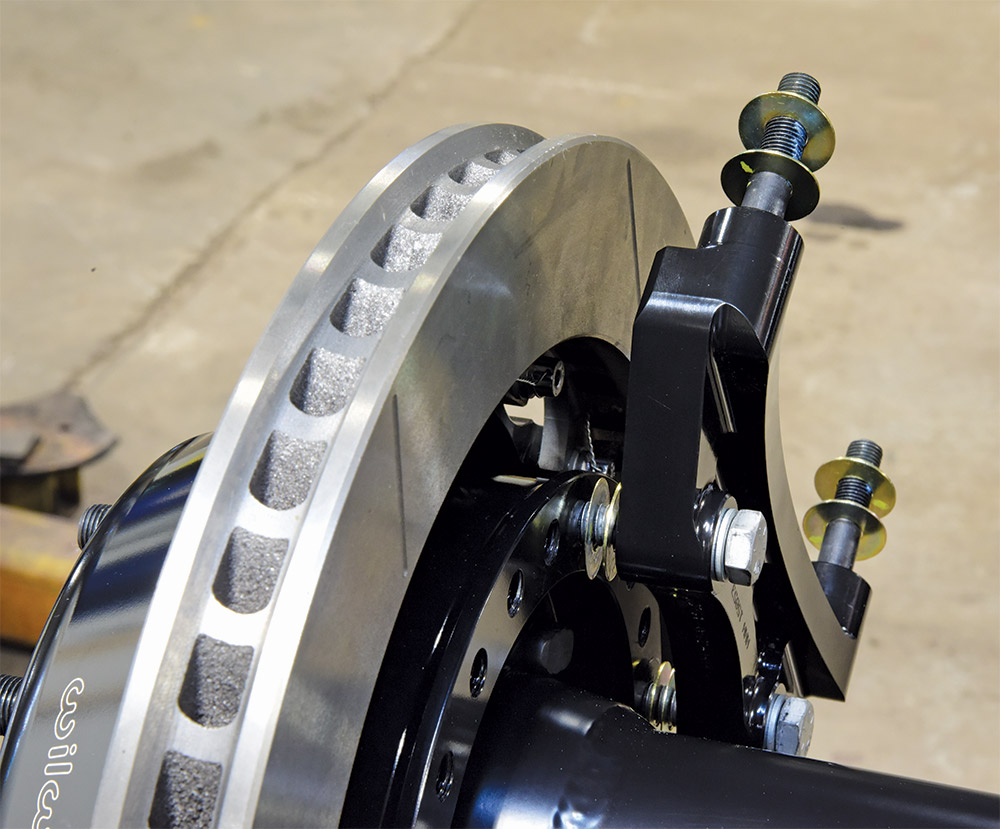

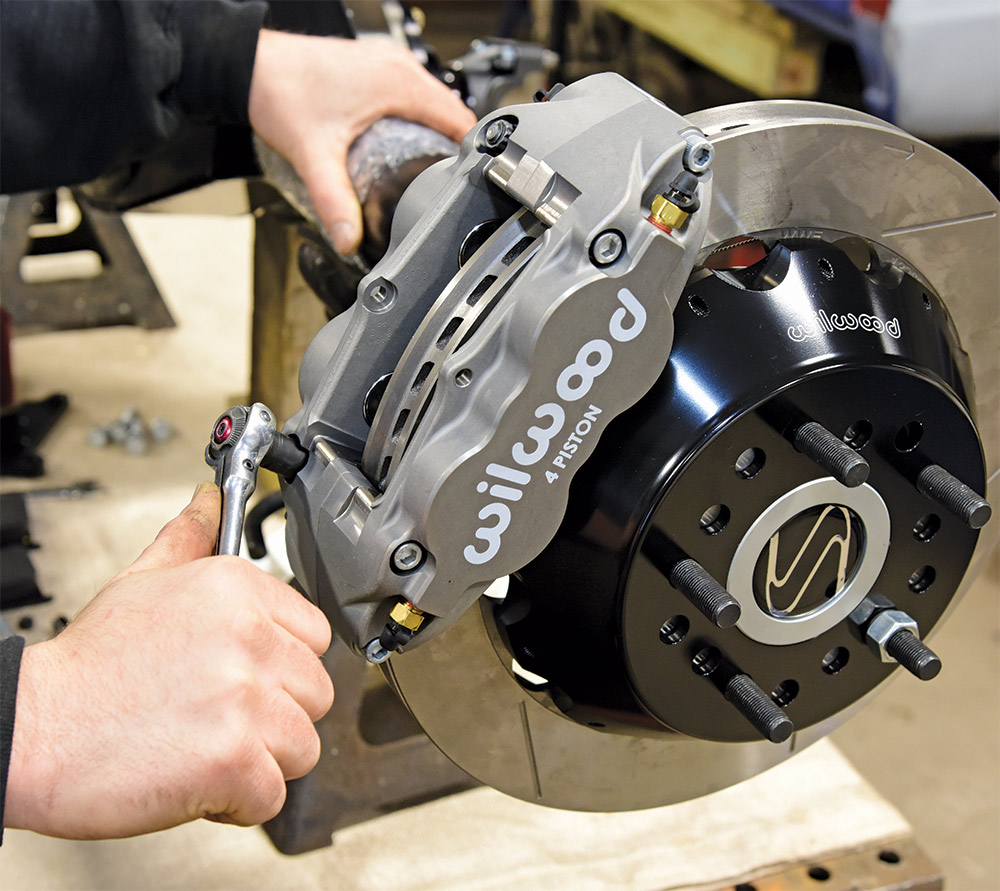

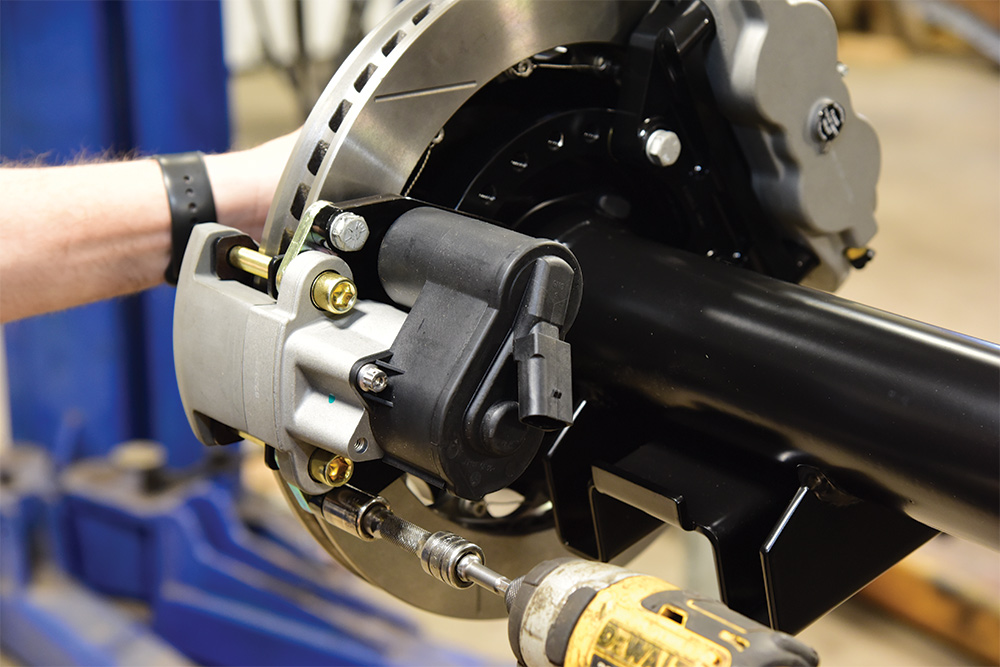

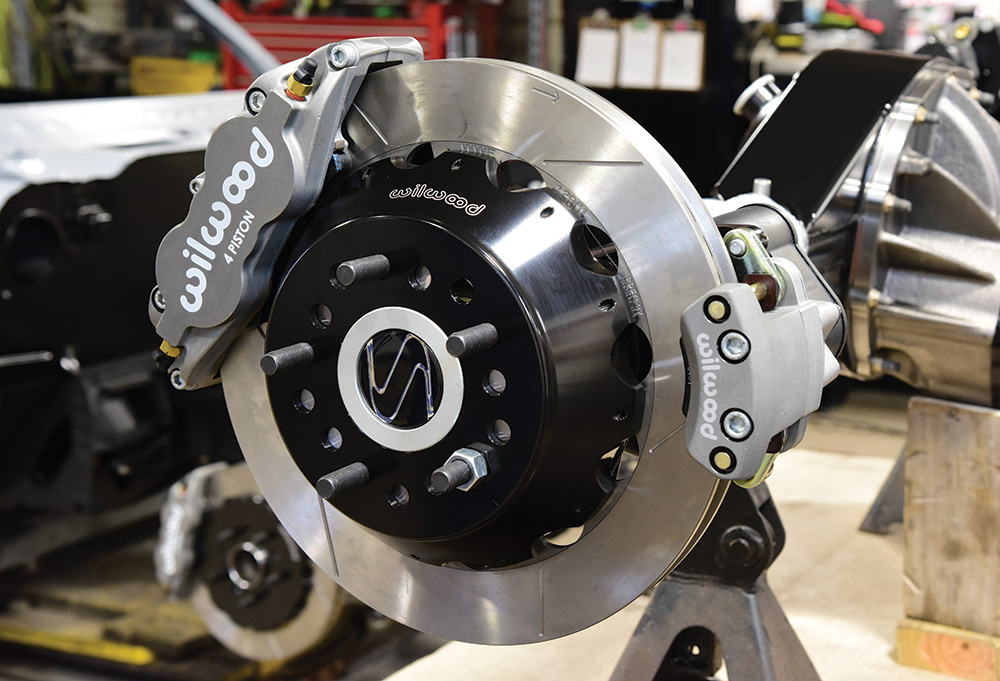

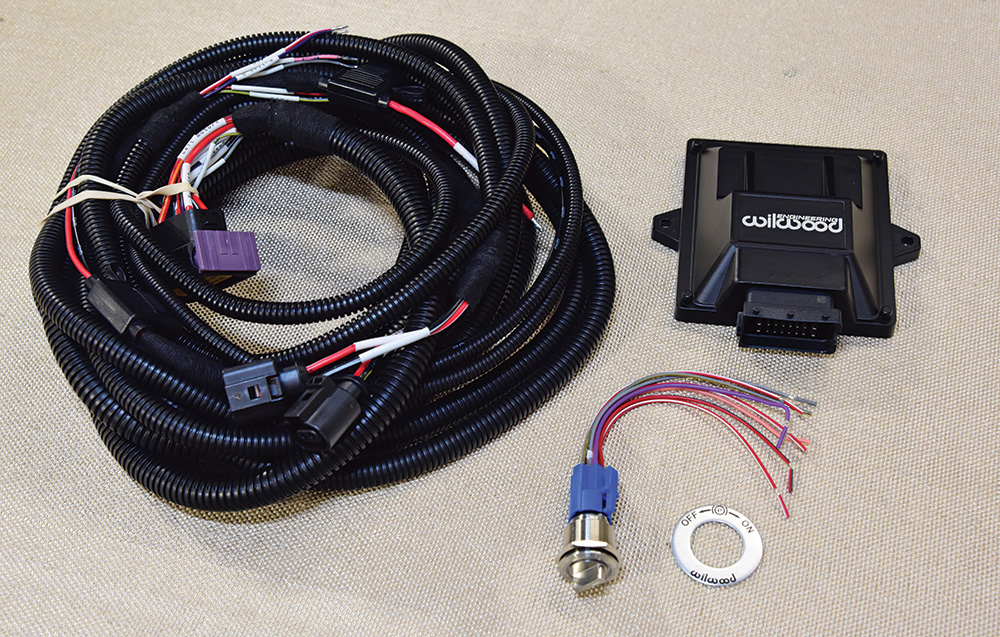

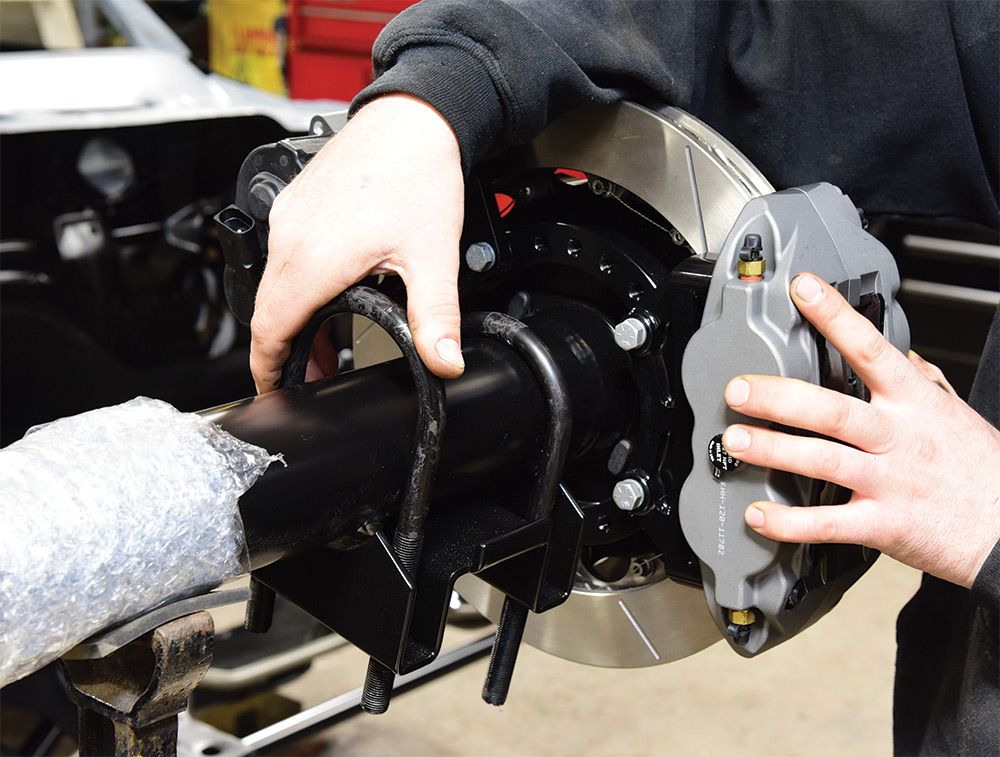

Finally, it was time to jettison the old factory drum brakes and bring the car into the new world with razor-sharp stopping power by contacting Wilwood Disc Brakes. To perfectly complement the Wilwood upgrades to the front of the car (covered in our last installment), O’Brien selected their Forged Narrow Superlite 4R Big Brake Rear Electronic Parking Brake kit. The kit packs a punch, featuring their Forged Narrow Superlite 4R four-piston calipers in Type III hard-anodized finish, GT slotted two-piece rotors, and electronic parking brake (EPB) caliper. The distinctive EPB caliper offers a high-torque static grip for parking without needing to incorporate the standard-style mechanical cable.

Let’s follow along as O’Brien brings this second-gen Camaro to the next level of performance.

SOURCES

SOURCES