TECH

TECH

Images by the Author

Images by the Authoronfident stopping power is a must in a high-performance Chevy. In addition to big rotors and multi-piston calipers, the power-assist system helps deliver that feeling of immediate responsiveness.

From the factory, the power braking system on almost all classic Chevy models comes in the form of vacuum assist—a simple and effective method that uses vacuum generated by the engine to multiply the driver’s force on the brake pedal. On stock, naturally aspirated engines it is an excellent system and, apart from the occasional failed diaphragm or faulty check valve, it’s largely bulletproof.

The dynamics change with performance upgrades such as an aggressive camshaft with big duration specifications or a power adder such as a supercharger or turbocharger. They typically reduce or all but eliminate the vacuum necessary for effective power braking assistance. The same goes for diesel engines.

Vacuum canisters and even electric vacuum pumps can help, but hydro boost assistance is an increasingly popular choice that eliminates vacuum altogether and instead relies on the power steering system to pressurize the brakes. As with vacuum-assist, hydro boost is not a new technology and has been used for years mostly in heavy-duty truck applications. In performance cars it offers a couple of significant advantages, including increased braking power and improved braking feel.

Because the hydraulic pressure generated by the power steering pump is much more powerful than the engine-generated vacuum—between 800 and 1,400 psi—the hydro boost system typically delivers much greater braking force. That translates into a much more consistent and responsive pedal feel that is also generally more precise and can be modulated more effectively. A hydro boost system also does not put a load on the engine, as does a vacuum-based system. That can provide a marginal boost in performance and efficiency.

Beyond the performance benefits, a hydro boost system also eliminates the need for a bulky power booster behind the brake master cylinder. Consequently, there’s more clearance under the hood of many vehicles to accommodate the valve covers or exhaust manifolds/headers of big-block and LS swaps. The hydro booster used in this project, for example, was no wider than the Wilwood-supplied master cylinder.

Speaking of the project, it was the low-vacuum production of a lopey camshaft in the 383 small-block of a 1972 Chevelle that prompted the change to a hydro boost system. It coincided with an upgrade to a Wilwood-based, four-wheel disc brake setup, all of which were installed at Detroit-area Stellar Rod and Custom. The hydro boost kit cost about $510 but another $350 or so in a separate hose-and-fitting kit was also required.

With a typical Saginaw-style power steering system featuring a three-hose setup, the hydro boost takes a high-pressure feed from the power steering pump to the brake booster to provide the power assist and routes it back with another high-pressure line to the steering box for the power steering assistance. That’s two of the hoses. The third is a low-pressure return to the pump.

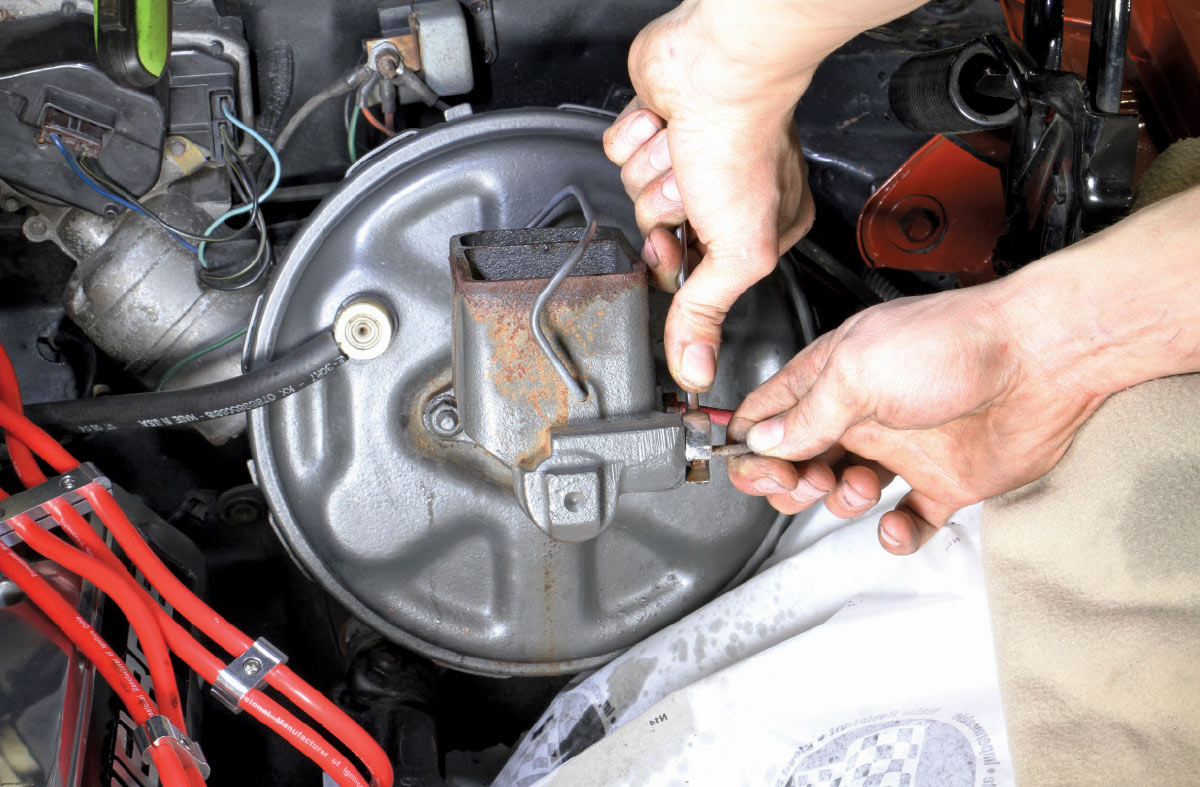

Installation isn’t particularly difficult from a wrench-turning perspective, but it involves bending several new hard lines for the brake system as well as adding a couple new hydraulic hoses. For this project, the shop had the requisite hard line benders but had to send out to get the supplied hydraulic hose fittings properly crimped. We suspect most home enthusiasts would be in the same boat. Fortunately, many tire/rubber shops can do the job while you wait.

It’s also important to remember there are two pushrods in this system and neither one of them is on the master cylinder. One pushrod that attaches the hydro boost to the brake pedal inside the car and a pushrod on the engine side of the hydro boost that engages the master cylinder. When you press on the brake pedal (hydro boost or vacuum booster) you are pressing on the power unit. As the power unit gets that force it applies the given force outlet to the master cylinder. That pushrod on the hydro boost/vacuum booster to the master cylinder needs to be adjusted unless it was from the company you purchased the whole unit from. If the hydro boost/vacuum booster was purchased from one company and the master cylinder from another, that pushrod adjustment is very important—more so than the hydro boost to pedal adjustment.

In the end, the Chevelle’s all-new braking system feels remarkably more responsive. In addition to the capability of the Wilwood four-wheel discs, the hydraulic power of the hydro boost system adds an assuring degree of confidence when the foot hits the pedal. It’s high-performance braking for a high-performance muscle car.

SOURCES

SOURCES