TECH

TECH

Images by THE AUTHOR

Images by THE AUTHORhe old adage about making power goes: “There’s no replacement for displacement.”

Every dyed-in-the-wool car guy knows it. We’ve all heard it. And we all know the rejoinder is: “Unless you have boost.”

Yes, boost is the answer when it comes to helping little engines make big power. Whether it’s a supercharger or turbo, boost makes magic happen. So, what happens when you have both? What happens when you already have boost and add displacement? That, friends, is the question of the day.

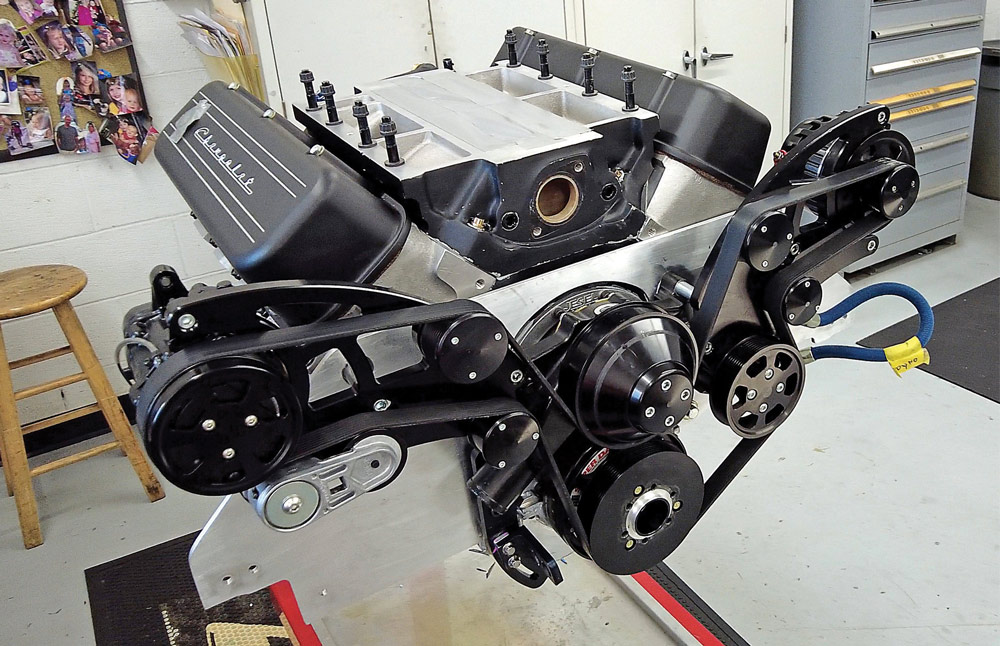

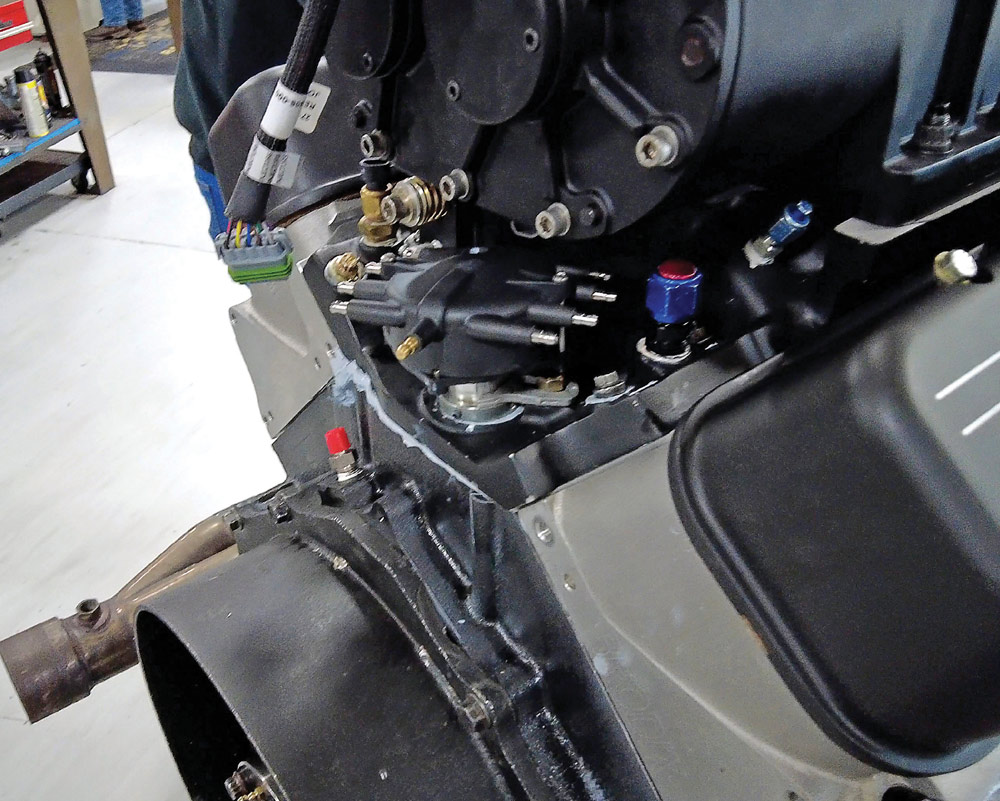

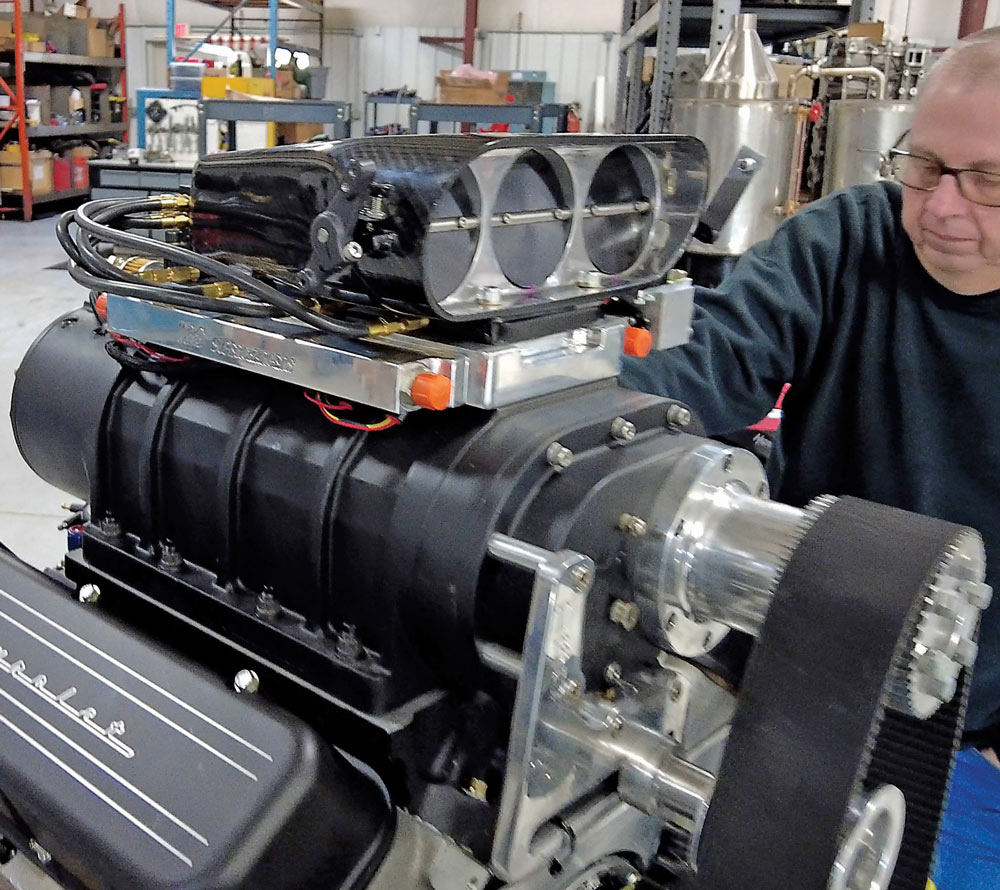

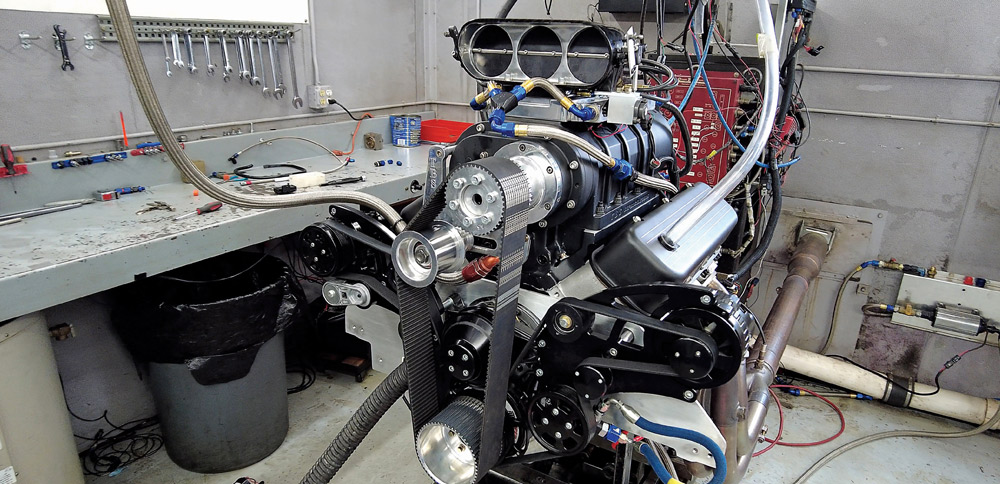

We recently came across a golden opportunity to put this to the test and couldn’t pass up the chance to do a little dyno testing. This became possible when our friends at Automotive Specialists in Concord, North Carolina, were sent a new engine build that the original engine builder was having trouble tuning on the dyno. The engine was a 565ci big-block with a giant 14-71 blower from The Blower Shop (TBS).

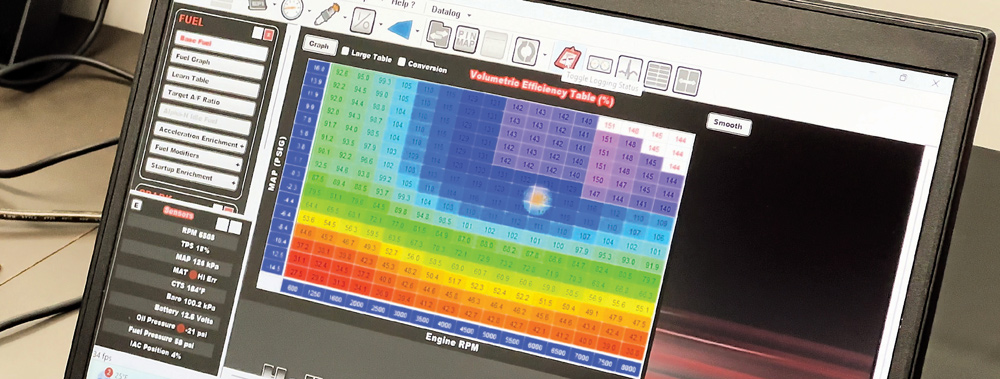

EFI and cylinder head specialist Jeff Dorton had the engine with a Holley Dominator ECU up and running in no time. With a little tuning, the engine was able to make peaks of 1,111.4 hp at 6,500 rpm and 940.4 lb-ft of torque at 5,500. That is plenty for most of us, but the engine’s owner was unhappy. He was led to believe the engine would make over 1,200 hp and was surprised to find that the displacement was just 565 ci and not 632 like he wanted.

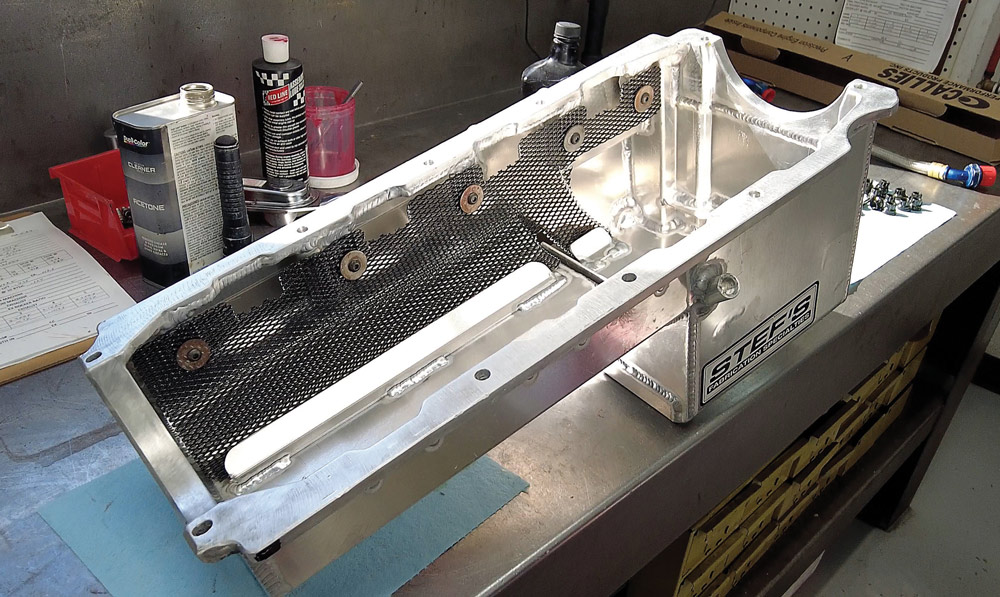

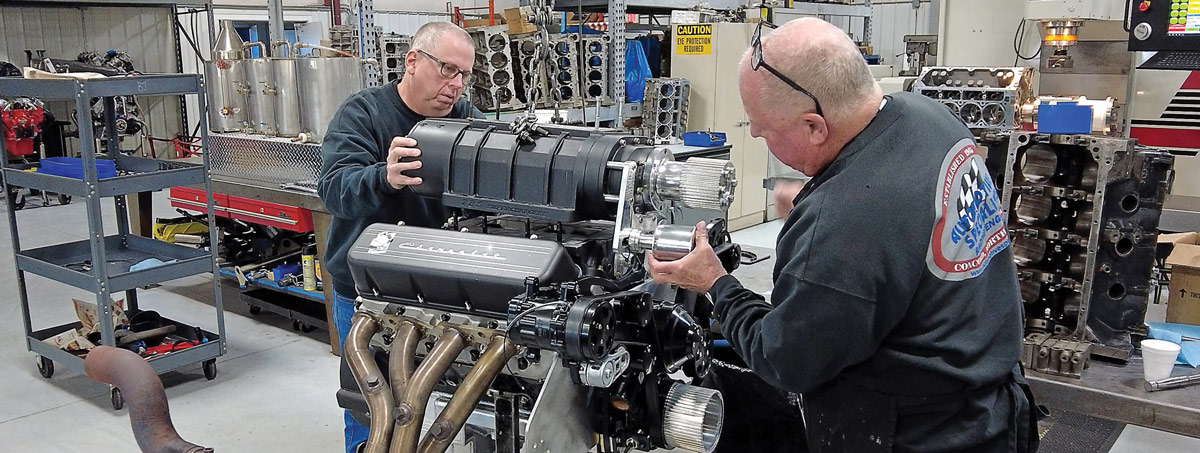

So, the owner asked Automotive Specialists to keep the engine and fix the issues. To help keep costs contained, together they made the decision to build a brand-new, 632ci short-block and use the cylinder head, blower, and other components. Then the old short-block, which was still perfectly good, could be sold or used on another project.

That’s great news for us because rarely does an engine go across the dyno twice with a single significant change that we can test. It’s just too costly in terms of both time and money. Since both versions will be on the same dyno, it’s an excellent opportunity to see just how those additional cubic inches will affect the power curve—especially considering we’re adding boost to the equation.

Yes, both horsepower and torque should go up. But how much? And will the upper rpm range or the lower be more affected? Typically, the horsepower-per-cubic-inch ratio decreases as the cubic inches go up (that’s why it’s usually unfair to compare horsepower per cubic inch between a tiny four-cylinder and a big-inch V-8), so since this is one of the biggest gasoline street engines you can build, will the horsepower improvements be disappointing?

Only one way to find out.

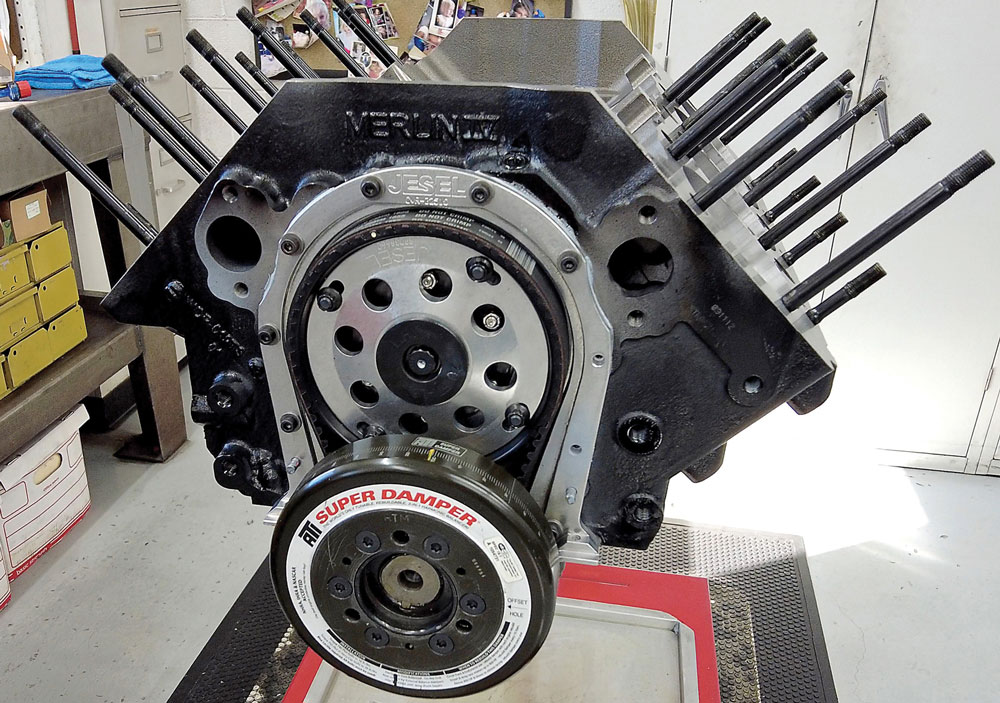

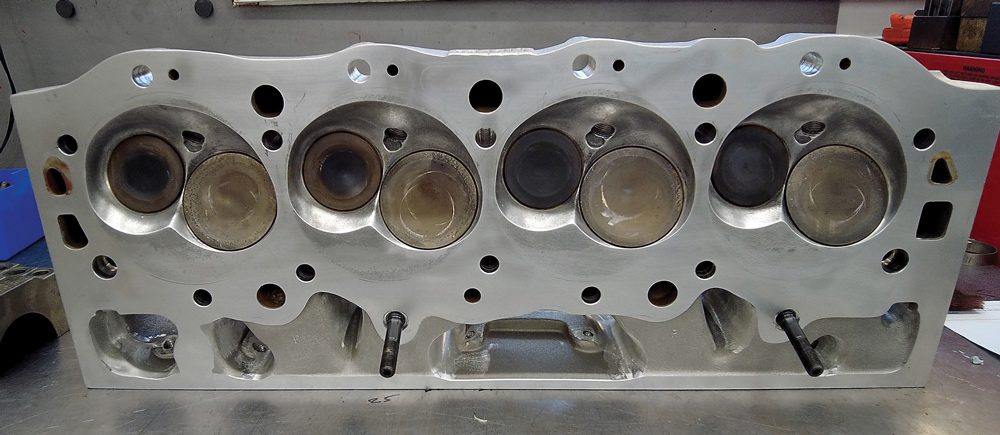

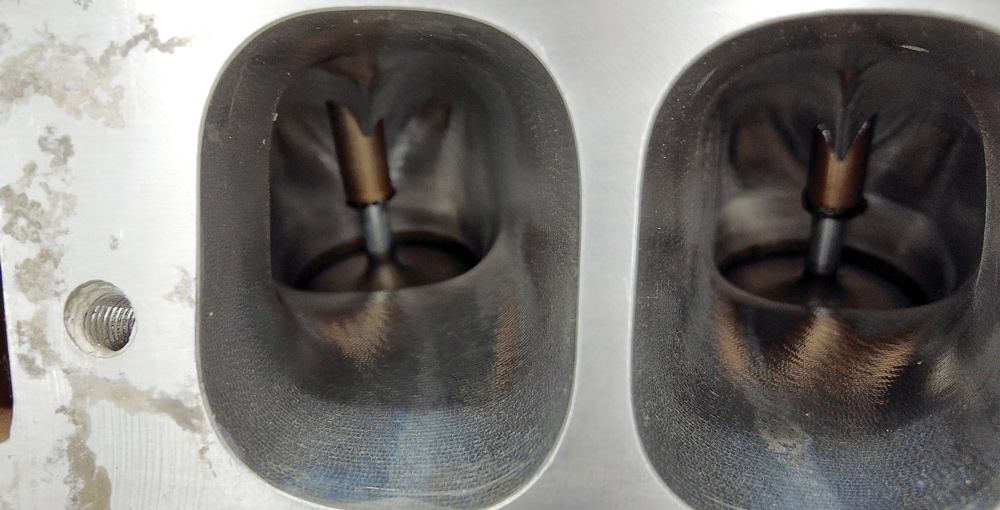

The 565ci Chevrolet big-block usually is derived with a 4.600-inch bore and 4.250-inch stroke. Even for an aftermarket block, 4.625 inches is usually the absolute limit for the bore size, so for a 632ci engine with an additional 67 ci, the 4.600-inch bore is kept while the stroke is lengthened a full 1/2 inch to 4.750. That, of course, basically requires a 10.200-inch tall-deck block to fit all the stroke without crashing piston skirts into the crankshaft’s counterweights at BDC.

In addition to the cubic inches, the additional stroke also makes for a couple of other differences. The big one is compression ratio—both the original configuration and Automotive Specialists’ updated 632 used flat-top pistons. The same Brodix cylinder heads with 123cc combustion chambers were also kept. So, thanks to the extra stroke, compression ratio jumped from 8.8:1 for the 565 build to 9.64:1 for the 632.

You might think that this negates the test to see how cubic inches affect power, but we’d disagree. Increased compression is a natural by-product of adding cubic inches. You’d actually have to make additional changes to lower compression again, so in our book more inches and higher compression go hand-in-hand.

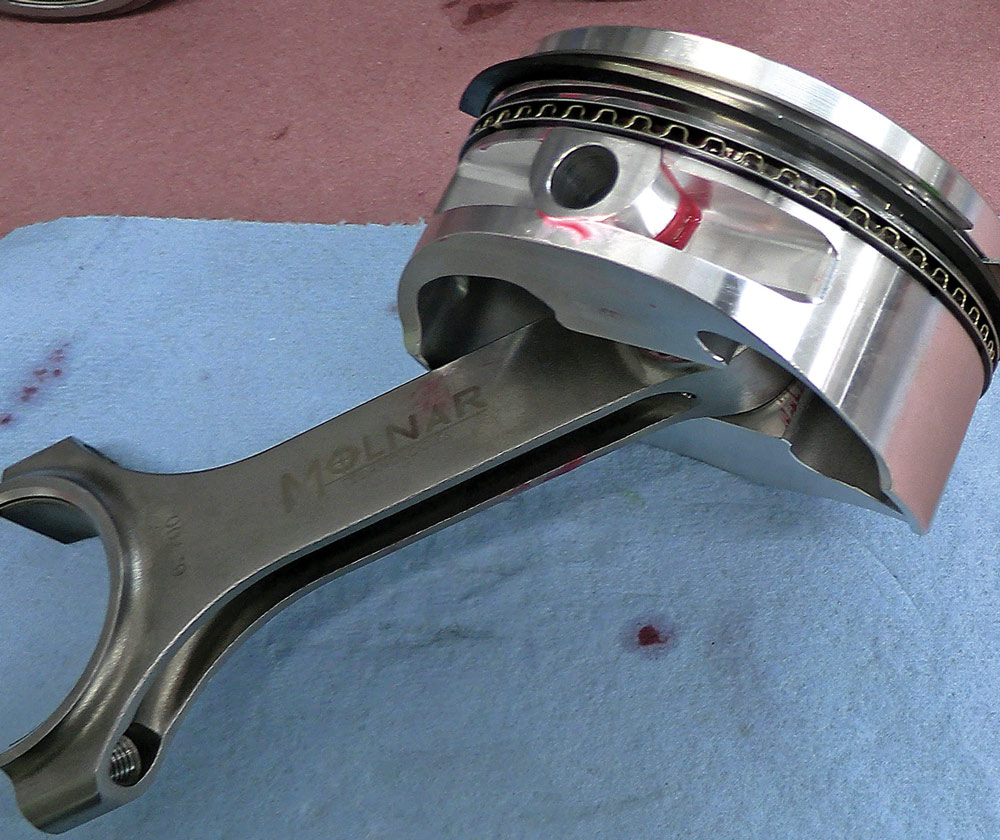

Another change that’s a by-product of the additional stroke is the rod/stroke ratio. A lot of people place a lot more importance into rod/stroke ratio than we do, so we’ll touch on it. The 565 combo in a 10.2-inch deck height block is a 4.250-inch stroke with 6.800-long connecting rods. That makes the rod/stroke ratio 1.6:1. The 632 with the same block uses a 4.750-inch stroke with slightly shorter 6.700 rods. As a result, the ratio dips to 1.4:1. Whether that is a little or a lot depends on your perspective (for comparison, a stock stroke 350 Chevy small-block with 5.7-inch connecting rods is also 1.6:1), but the change in ratio really won’t affect power production. If anything, it is more of a long-term concern because the shortened ratio will increase lateral loading between the pistons and the cylinder wall, and bore wear eventually becomes something to keep an eye on.

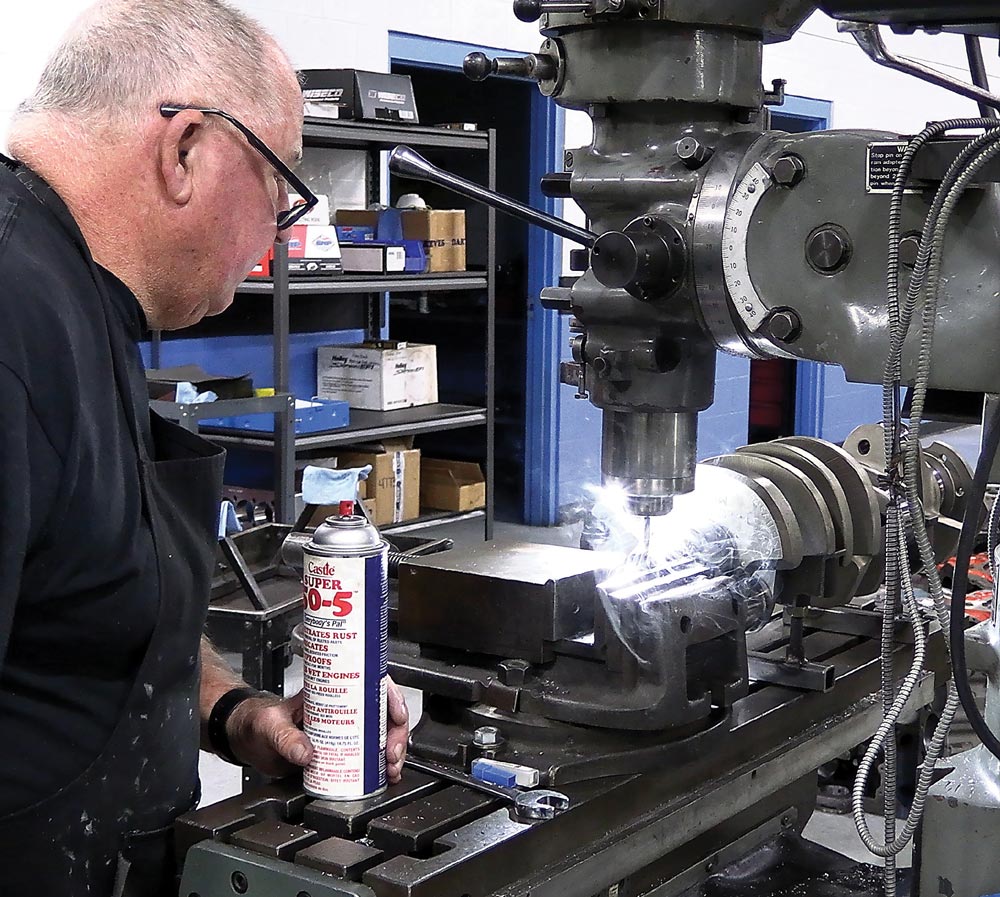

Finally, there’s one last change that’s worth noting even though it didn’t affect horsepower. Because of the additional 1/2 inch of stroke, engine builder Keith Dorton switched to a camshaft ground on a reduced-base circle. The basic specs were the same, just on a smaller lobe diameter to ensure that there will be no contact between the camshaft and the big ends of the connecting rods as they swing by.

So how did it do? Glad you asked.

On the engine dyno with the 565ci setup we saw peaks of 1,111.4 hp and 940.4 lb-ft of torque. Because it limits the rpm ramp speed, an engine dyno can damage the pistons in a high-torque engine if you begin the pull too low in the rpm range. That’s why the pull is from 5,000 to 6,500 rpm. But the averages in that range were a very healthy 1,013.3 hp and 962.2 lb-ft of torque.

Then the engine was pulled down, inspected, and cleaned, and then rebuilt with the new short-block. When Keith and Jeff Dorton got it back on the dyno in its 632ci form, it produced peaks of 1,253 hp and 1,106 lb-ft of torque. That’s improvements of 141.6 hp and 165.6 lb-ft of torque. The averages improved by 157.3 and 109.4 respectively to 1,170.6 hp and 1,071.6 lb-ft of torque.

So, the improvements are solid but not outrageous. On the dyno chart, the shape of the horsepower and torque curves were basically consistent across the pull without any real drop-off as the rpm increased. An average gain of 157.3 hp by adding 67 ci comes out to 2.35 hp/ci, which sounds about right with approximately 12 pounds of boost. We never even changed the blower pulley. If anything, there might be a little more power to be squeezed out of the 632 because the 160-lb/hr injectors were at 80 percent duty cycle. But the customer is happy with the new power numbers and can’t wait to put the big-block into his Chevelle. We’re happy with a great day on the dyno and need to get things cleaned up so we can bring you another engine test next time!

SOURCES

SOURCES(800) 448-1223

xceldyne.com