TECH

TECH

Images BY THE AUTHOR

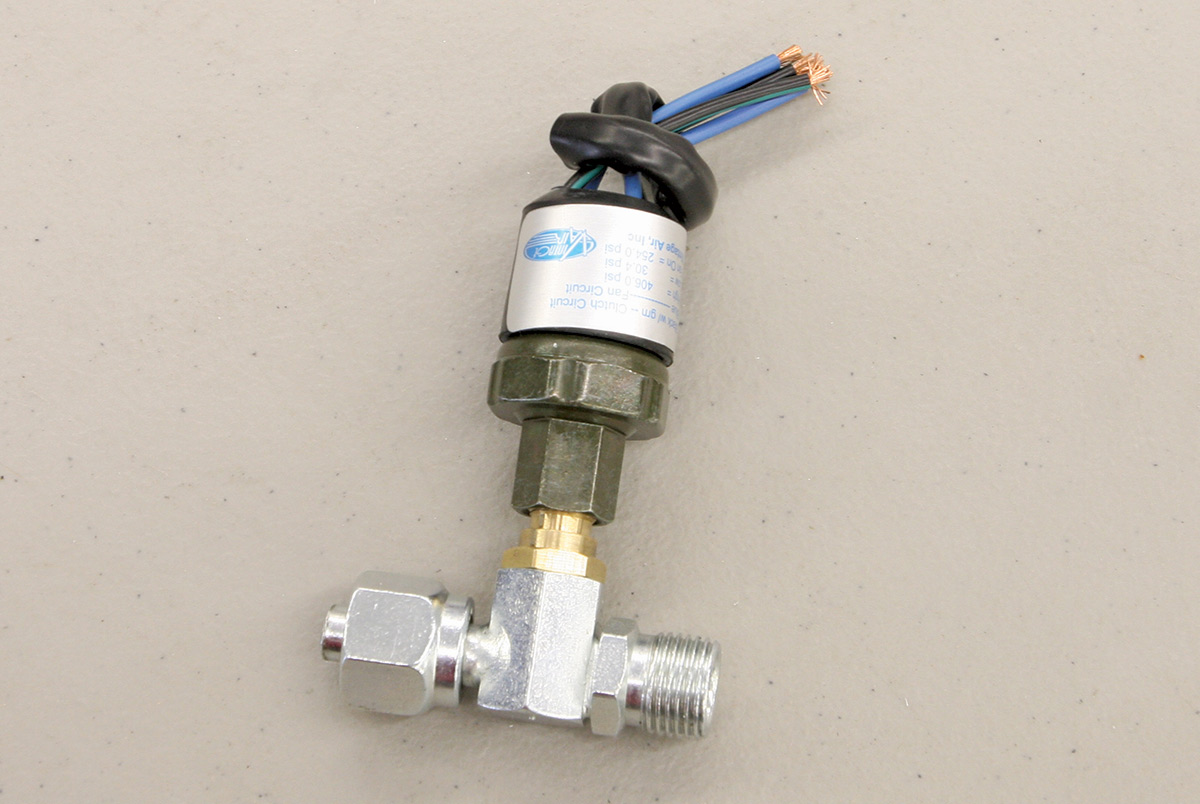

Images BY THE AUTHORast month, we concluded the installation of a Gen 5 Vintage Air SureFit kit in our 1957 Chevy Handyman Wagon by installing the evaporator unit. The defroster vents were installed and hoses attached, as was the center vent, and hoses were routed in preparation for the side vents. The drain was in place to route any condensation outside the vehicle and the four hard lines were installed and routed through the firewall. It would seem that we were on the downhill slope, and for all intents and purposes, we were, but there’s still a lot of work to be done.

For starters, we still need to install the radiator and condenser unit. The previous small-block that was in our 1957 had a meager mechanical fan that pulled just enough air to keep the mild motor happy. With the installation of a hot-rodded LS3, this obviously wasn’t going to do, so we turned to DeWitts to help us sort out our cooling requirements. Since the addition of the A/C and its requisite condenser will add some additional heat load to the overall system, it’s paramount that the cooling system be at peak performance to ensure the A/C system blows air as cool as the Arctic snow. DeWitts’ recommendation of their LS Swap Aluminum Radiator with included electric fan filled the required void with room to spare

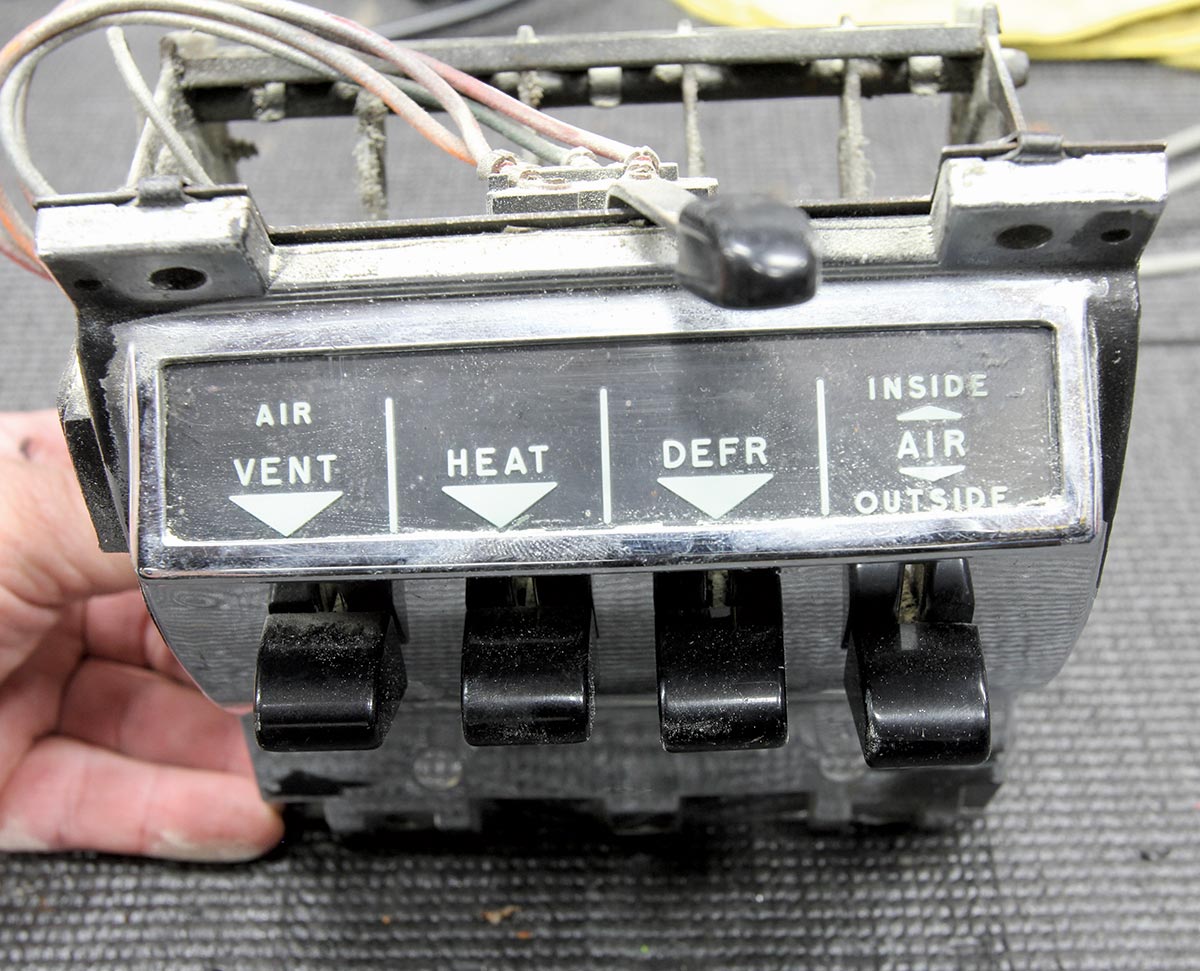

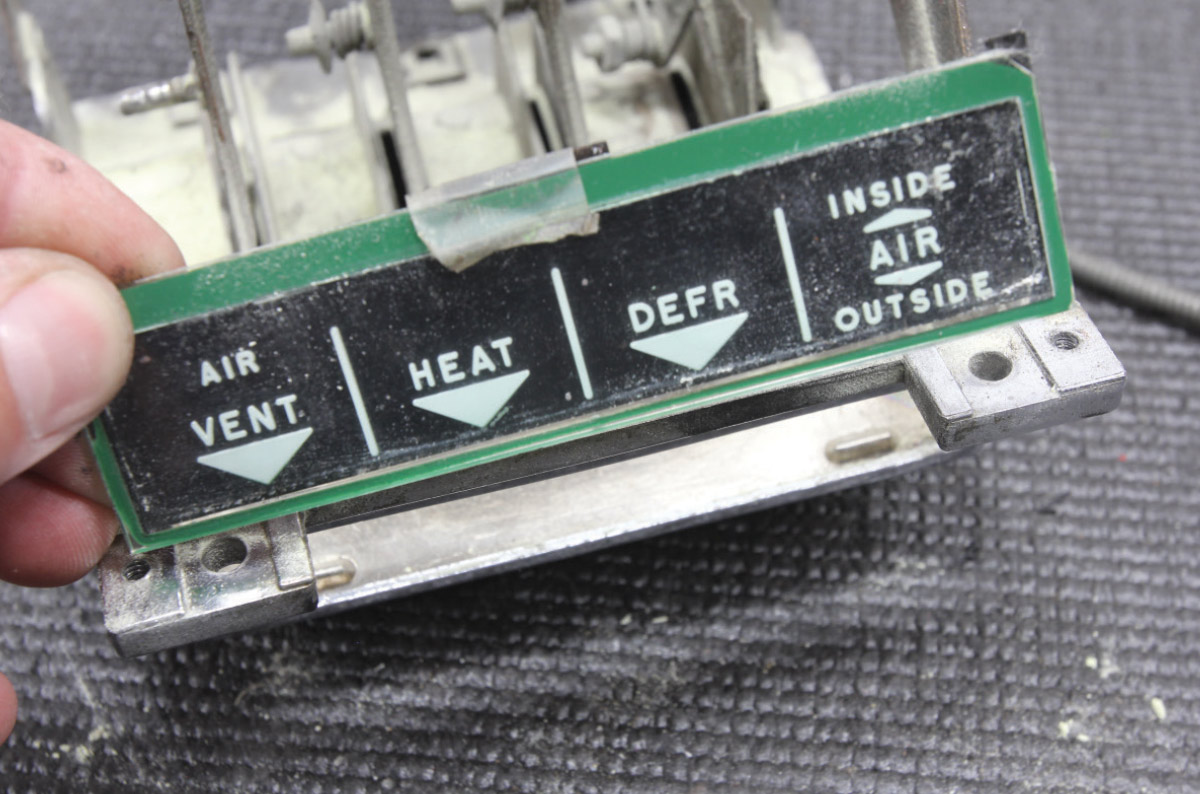

Once the system was plumbed, our attention turned to the inside of the car where the wiring was buttoned up and the control panel modified to accept the electronic cable converter assemblies that will translate the position of each lever to the evap unit’s ECU communicating the changes desired electronically, whether they be in the mode, temp, or blower speed realm. At this point, the two side louvers are installed using Vintage Air’s provided brackets and components and the remaining ducting ran to each.

Satisfied with our install, we made the short trek to our local automotive A/C shop where they charged the system with 1.8 pounds of R134a, no more, no less. After a run-through of the calibration sequence to ensure the ECU is receiving the proper signal from the control panel, we were happy campers, cruising cool with our newly climatized Chevy.

SOURCES

SOURCES