TECH

TECH

Photography by THE AUTHOR

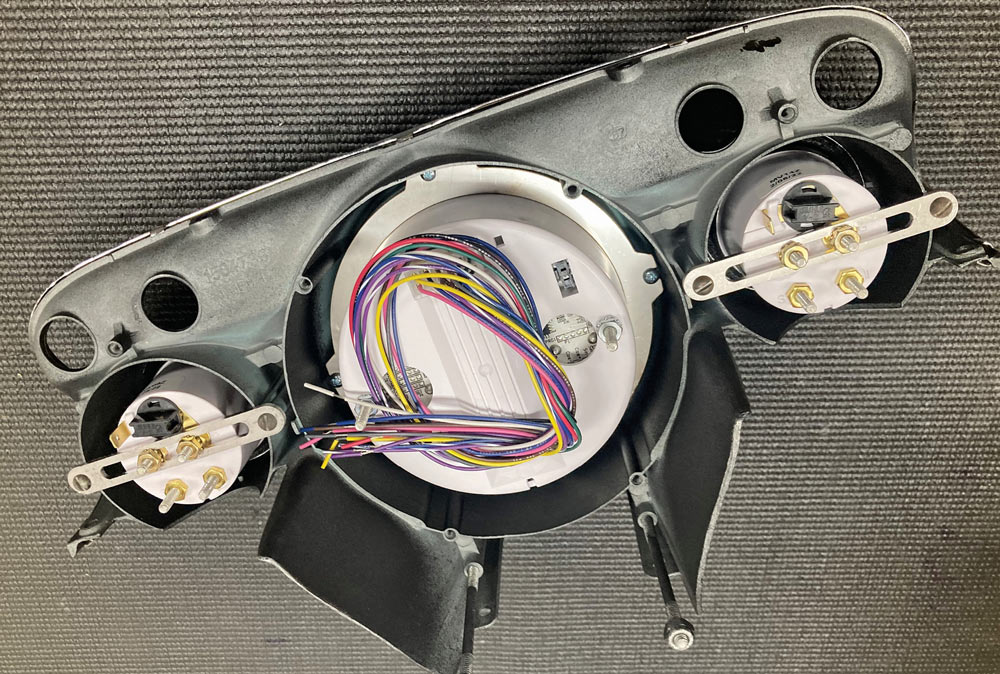

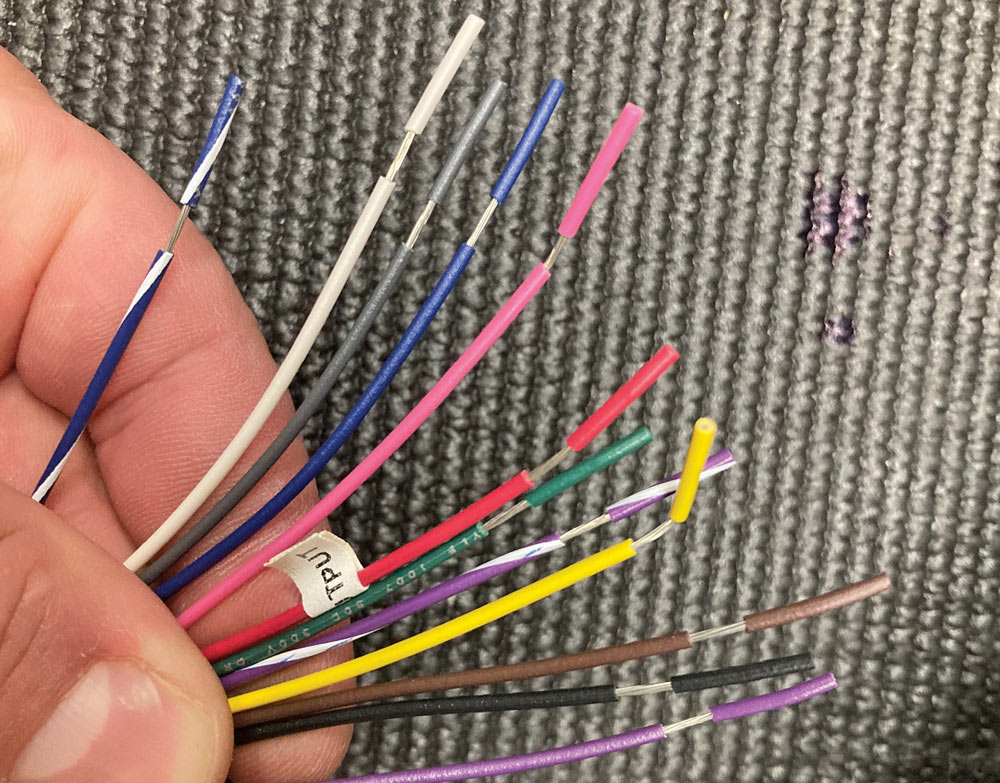

Photography by THE AUTHORhen it comes to the gauge cluster of most classic Chevys, few provided much information past vehicle speed, fuel level, and an engine temp that ranged between hot and cold. In fact, the dash cluster in our project ’57 reflects just that, which leaves, literally, more information to be desired than is actually provided. Engine speed, oil pressure, and the state of the charging system was left up to the driver’s imagination, lest an “idiot light” or two. With today’s trend of ever-higher horsepower drivetrains and ever-increasing electrical loads, the need to keep a closer eye on the goings-on under the hood has never been greater.

In the case of our ’57 Chevy, the temp gauge provides a simple range of temps, the speedo reads inaccurately, and the fuel gauge suffers from “needle bounce.” The aforementioned lack of oil pressure, engine speed, and charging state from the cluster means we’ll be driving blind when it comes to the situation underhood.

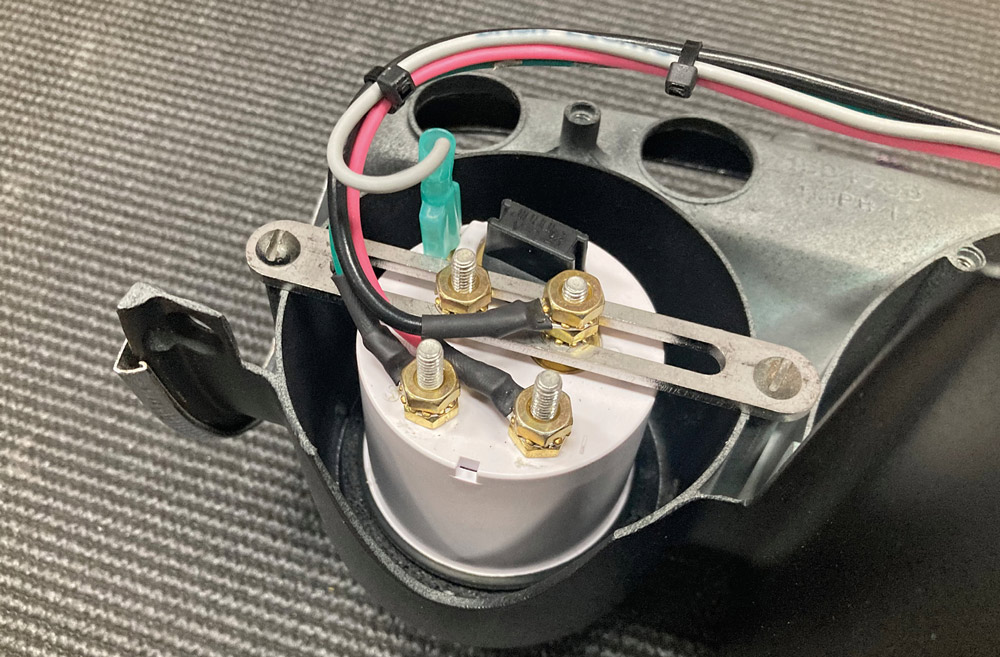

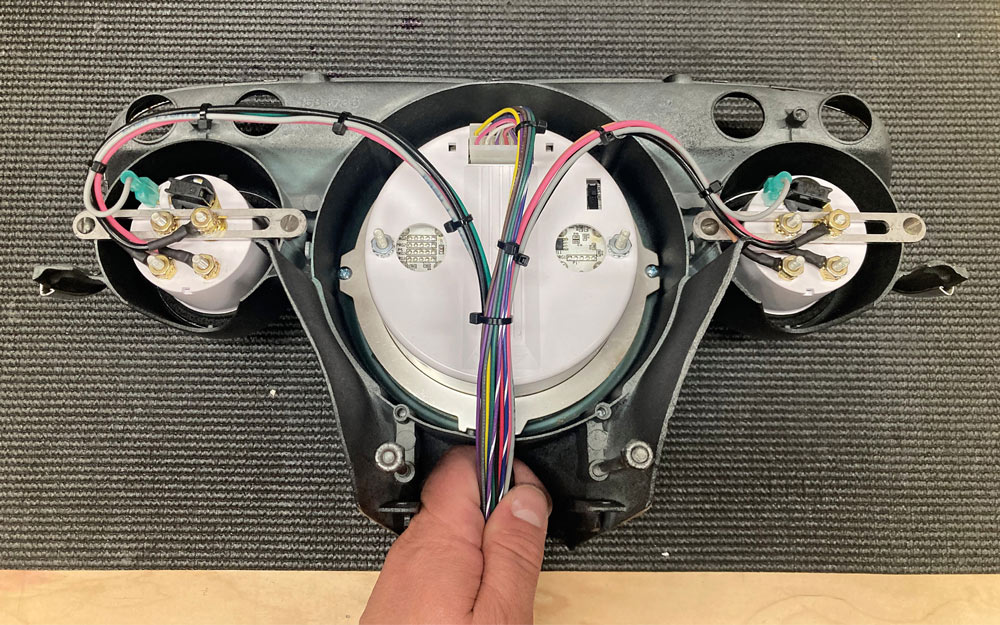

Thankfully, there are companies like Classic Instruments that step in and provide a wide range of gauge options that improve the coverage for nearly every classic Chevy on the market. Not only that, but they do so in a plug-and-play manner, many times using the stock gauge housing and bezels. The result is an updated gauge cluster that looks the part but performs superior.

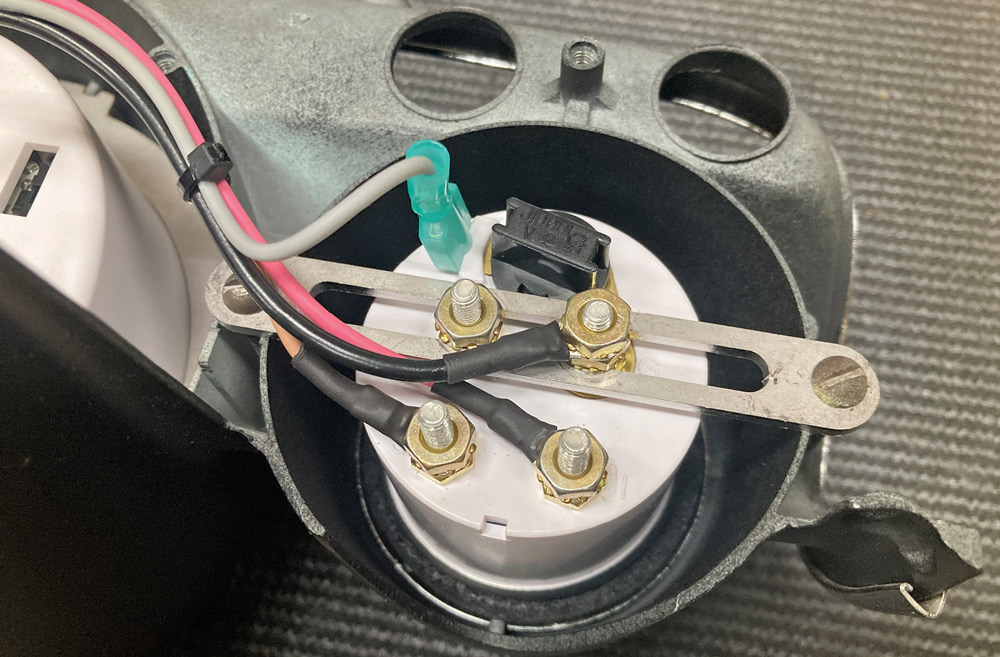

Classic Instruments’ line of Direct Fit gauges are perfect for those builders who want an increase in coverage without cutting additional holes in the dash or adding pod-mounted gauges to the A-pillar or steering column. For the ’57, incorporating a number of separate gauges in a single, central gauge allows Classic to include more information in the same real estate as stock, without any modifications to the original gauge housing. Flanking the center cluster are a pair of electric gauges providing accurate engine temperature and fuel level. The result is a huge improvement in information relayed to the driver in a package that looks like it came from the factory, a win-win in anybody’s book!

SOURCES

SOURCES