TECH

TECH

Photography by The Author

Photography by The Authorhen performing the typical engine swap, there are a few dozen considerations to be made when it comes to upgrading the plumbing system, electrical upgrades, chassis, and even sheetmetal modifications, but the engine compartment itself can be forgotten about. But, there’s no time like now, when that engine compartment is laid bare following the removal of the original engine, to detail the panels and clean things up a bit.

We recently pulled a tired 350 small-block out of our buddy Bruce Valley’s ’57 Chevy Handyman Wagon in anticipation of dropping a new Connect and Cruise LS3 package in its place. While we were certainly excited to get the swap underway, it was decided that the engine compartment could use a little TLC to make it more deserving of such a nice-looking engine. As is typical with older vehicles, Valley’s ’57 had its fair share of modifications made by previous owners over the years. Thankfully, these mods were limited to a handful of extra holes made in the sheetmetal panels of the engine compartment, which will be quickly welded up. Future plans for the wagon call for the installation of a Vintage Air climate-control system, which means the stock heater box cavern as well as the heater control valve hole can be deleted. While Vintage Air provides a bolt-in solution for both of these areas, it was decided that welding these up instead would provide a cleaner finish.

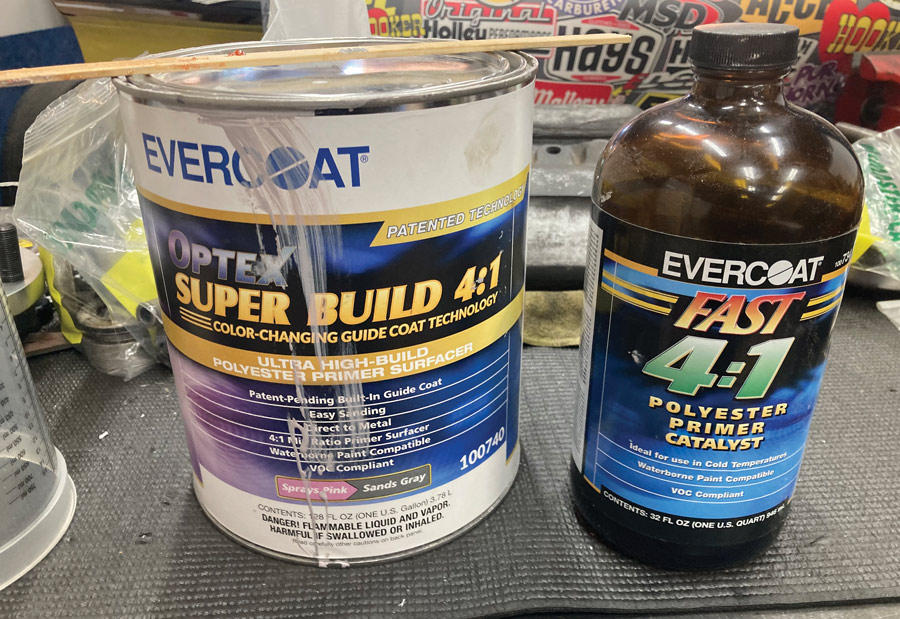

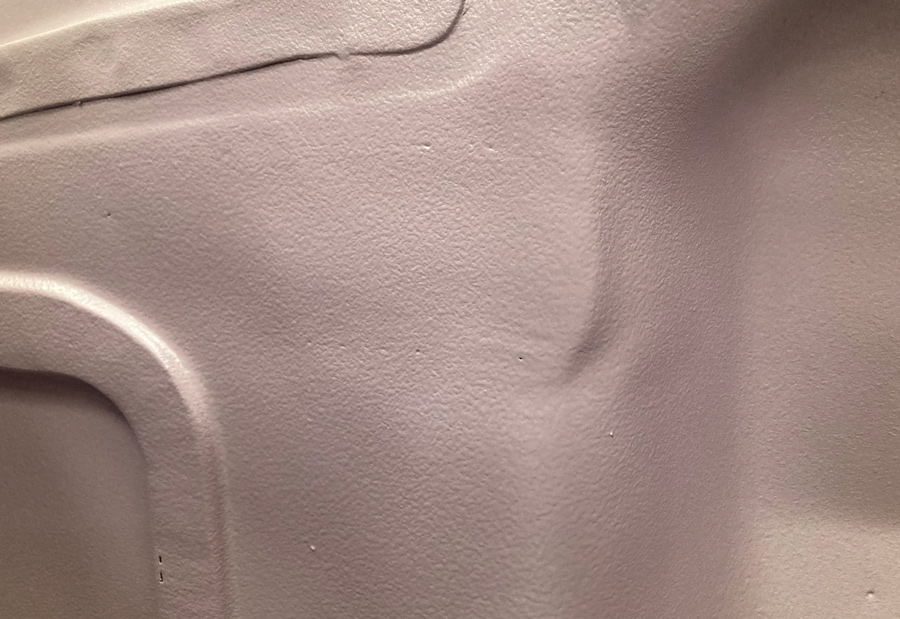

After the initial metalwork was complete, we began the bodywork portion of the repair. A few initial coats of high-build primer were followed by a few hours of block-sanding. From there, we could easily see the areas that needed a bit of body filler repair, which we followed with further sanding. Content with our results, a coat of epoxy primer was applied, followed by the Hot Rod Black topcoat.

With the repairs to the engine compartment complete, we’re ready to drop in the new LS3 drivetrain, but that story is for another time. For now, check out what it took to repair the wagon’s engine bay and what a couple of days’ work can do to improve its appearance.

1. With the small-block removed from the engine bay, we can take in the compartment for all its shortcomings. Like any old car, there’s a myriad of holes–both factory and functionally questionable—that need to be filled before the area can be regarded as being anything but “clean.”

2. Vintage Air provides blanking panels for the abandon OE heater control valve and box openings, but since we’ll have the welder and grinder out already, we might as well take things a step further.

3. On the driver side of the firewall, there are a few additional voids that need to be filled as well; notably the accelerator, clutch rod, and speedo cable holes. Our LS3/4L70E Connect and Cruise package features drive-by-wire throttle control as well as electronic speedo signaling, and the automatic trans defeats the need for a clutch rod, so all these holes can be deleted to clean things up a bit.

4. For the smaller voids, patch panels were fabricated using 20-gauge sheetmetal. Alternatively, the provided Vintage Air block-off plates were trimmed to fit their respective openings and will be welded into place.

SOURCES

SOURCES