TECH

TECH

Images BY THE AUTHOR

Images BY THE AUTHOR

Images BY THE AUTHOR

Images BY THE AUTHORfew months ago we offered a look into spotting and identifying the GM LS Gen III and IV 4.8L and 5.3L LS engines. Now that you know what to look for, we can offer suggestions on how to pump up the power with these engines. Common sense might dictate that all that’s necessary is to just follow the footsteps of classic small-block Chevy builds, and in a general sense that would be correct.

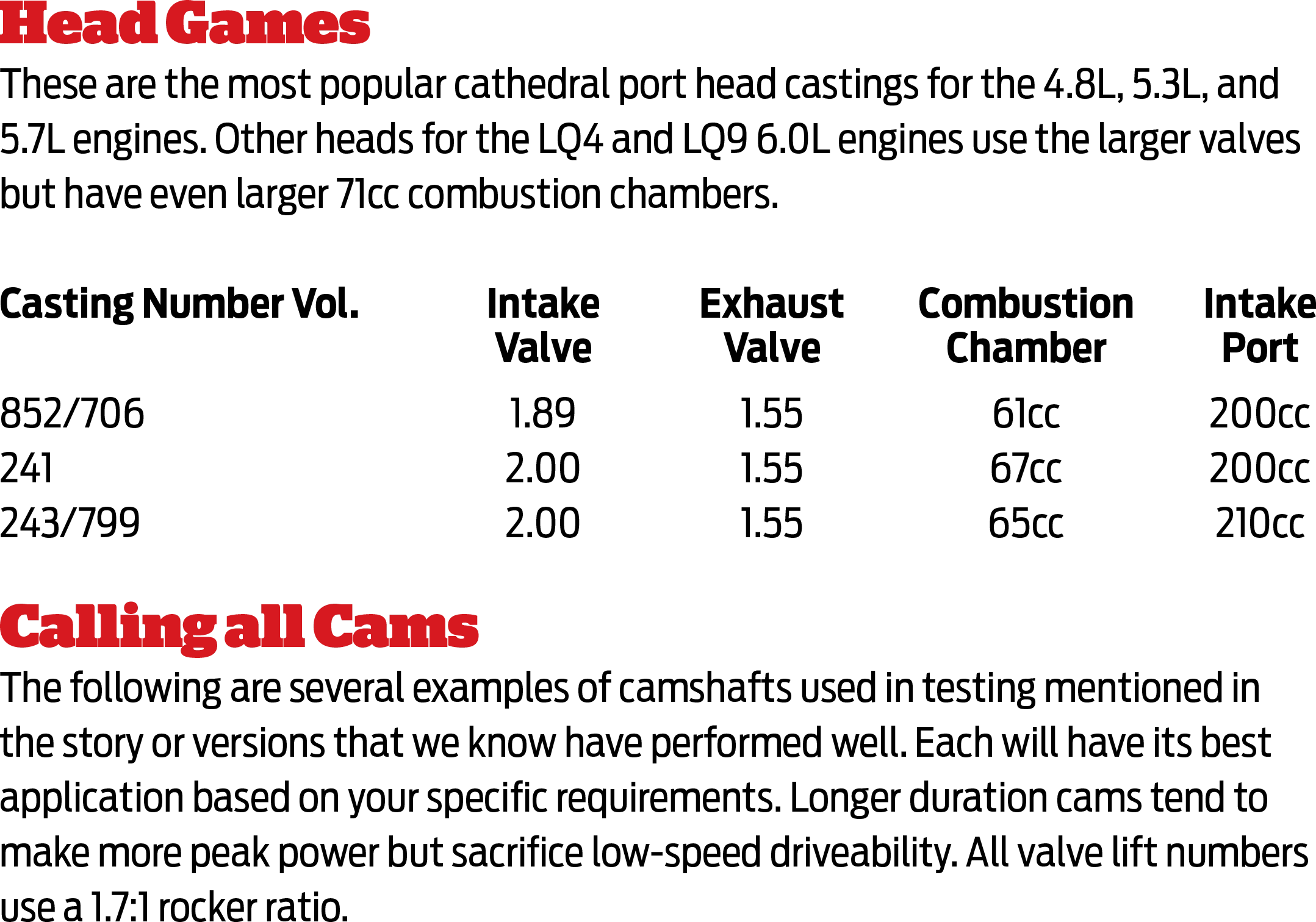

But the Gen III/IV LS engines enjoy far superior flowing cylinder heads compared to the Gen I small-block. Even the most pedestrian cathedral port heads for the 5.3L LM7 engine flows better and enjoys far better combustion efficiency than the best production Gen I head. While stock 5.3L (325ci) truck engines are only rated at 300 hp, the modern factory correction factors are very conservative compared to the normal aftermarket dyno test procedures.

One 5.3L engine that is often overlooked as a great engine to start with is the LY5 5.3L Gen IV engine. This is a 58X engine that is usually equipped with Flex Fuel capability but is also burdened with AFM. Despite the AFM, its advantage includes a higher 9.9:1 compression ratio with a flat-top piston using either 243 or 799 cylinder heads. These heads feature a larger 65cc chamber and come with larger 2.00-inch intake and 1.58-inch exhaust valves. This package could really shine once the AFM is replaced with a performance cam.

As far as the rest of the 5.3L engines are concerned, they also offer plenty of potential. Add a mild camshaft, a Trailblazer SS intake, and headers and your mild street engine could exceed 400 hp without trying very hard. It’s worth emphasizing that you can make more power with a 325ci LS engine with less cam timing compared to a 355ci small-block Chevy because the LS heads are so much better.

There are plenty of examples online of high-rpm, normally aspirated 5.3L engines making 500 hp with CNC-ported heads, 230-degree-plus duration camshafts, and expensive intake manifolds. While impressive, all these combinations trade off low-speed torque for 7,000-rpm peak power.

The problem with all these combinations is they are not fun to drive on the street. This big cam tradeoff reduces low-speed torque to the point where the engine is downright lame below 3,000 rpm. If this combination is used in an under-3,000-pound car (like an early Nova, for example) with a manual transmission and deep rear gears, this might be acceptable. But for most 3,500-pound street cars and trucks, this big-cam approach is not attractive for street-driven engines that spend most of their time at part throttle below 3,000 rpm.

Instead of waving 500hp combos in your face, it’s our opinion that more All Chevy Performance readers would rather have strong torque right off idle combined with decent peak horsepower. This is a compromise with reduced peak horsepower using a milder cam, but one that will deliver excellent street manners.

So, if we keep the cam timing shorter than 224 degrees at 0.050, this will deliver decent horsepower while also improving the low-speed torque. The best way to improve overall torque curve is to increase compression. A typical LM7 5.3L truck engine sports a conservative 9.5:1 compression to allow the engine to run on 87-octane fuel.

A typical 5.3L Gen III/IV uses a dished piston and a 61cc combustion chamber along with a 0.053-inch head gasket as stock components. The typical piston at TDC is 0.005- to 0.007-inch above the deck height. This is one reason why the MLS head gasket is 0.053-inch thick. Using a thinner head gasket of roughly 0.045-inch thick will still provide sufficient piston-to-head clearance while adding 0.20 to the compression to roughly 9.7:1. This is a minor improvement and should be balanced against the potentially higher cost of a thinner head gasket.

Some enterprising builders might be tempted to add an LS1 (241) or LS6/LS2 (243 or 799) heads with bigger valves for better flow. This swap is counterproductive because the LS1 heads feature 6cc larger chambers while the 243 head is 4cc larger. Both will lower the compression on a stock 5.3L dished piston engine, which is counterproductive.

If you’re serious about raising the compression, you could opt for an aftermarket flat-top piston like a Mahle flat top with valve reliefs, but this will hit you pretty hard in the wallet. One additional advantage of these Mahle pistons is a thinner 1.0/1.0/2.0mm ring package that favorably compares to the standard LS 1.5/1.5/3.0mm. This will improve power slightly by reducing friction.

Another option might be a flat-top hypereutectic replacement piston for the 2007 LY5 5.3L engines. This is a much more affordable idea that can come in well under $200 for a set of eight pistons. This set uses the standard 1.5/1.5/3.0mm ring package.

While we’re on the subject of rings, regardless of whether you choose new pistons or merely reuse the original pistons and re-hone the block, we’d highly recommend Summit’s GPX ring package. This system is the result of a joint venture between Summit and Total Seal that includes a horizontal gas port channel in the top ring that improves power. The second is a Napier design ductile iron ring. The 3mm oil ring package is also improved by slightly lowering the overall tension. This still produces excellent oil control but contributes to improving power by reducing friction.

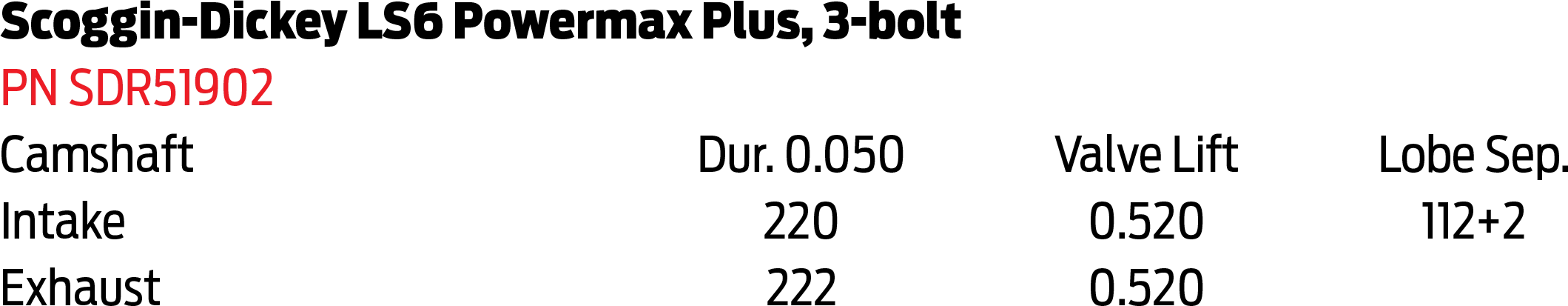

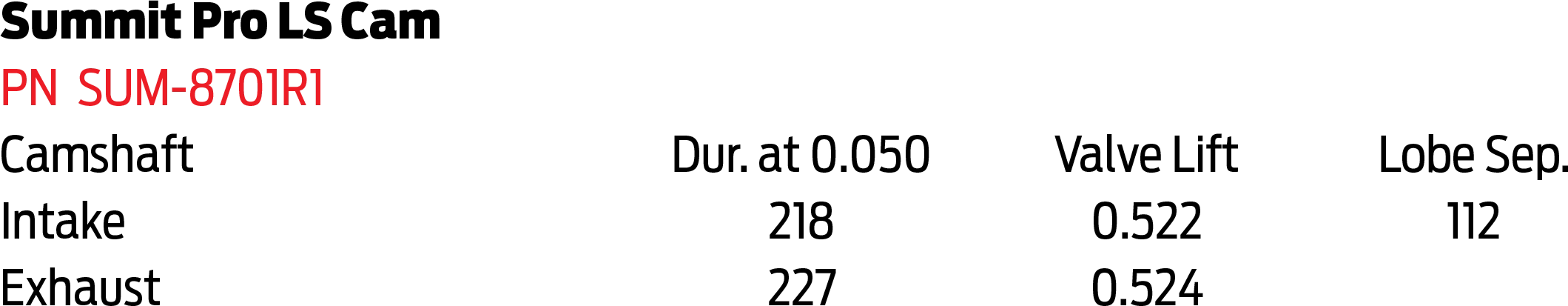

Earlier we mentioned the idea of a more conservative cam package and we’ve listed several cams that will fit into that arena that have proven themselves to add both significant power while not sacrificing low-speed torque. In searching around, we found an interesting video from Scoggin Dickey Performance Center (SDPC) where our friend Kurt Urban pulled the handle on the dyno to test several cams on a 5.3L Gen IV engine using the stock long-block along with headers and a Trailblazer SS intake manifold.

SDPC tested four cams from stock at 360 hp and 395 lb-ft of torque to an LS6 PowerMax Plus that made 448 hp and 433 lb-ft of torque. This was an amazing 88hp gain over the stock cam. This cam did lose some torque below 3,000 rpm but still pushed the torque peak 39 lb-ft higher than the stock cam.

While this was impressive, the slightly less aggressive LS6 PowerMax version caught our attention. In this test, the more conservative cam made 430 hp at 6,000 rpm along with 426 lb-ft of torque while also idling at a near-stock 15 inches of vacuum. Those are some strong numbers for a 325ci engine that equates to 1.32 hp/ci—70 hp and 31 lb-ft of torque over the stock numbers.

Both of these cams can operate with only LS6-style valvesprings that are literally a bolt-in addition to any cathedral port head. But perhaps the best part of all is that this SDPC PowerMax LS6 cam is priced at well under $300, compared to other aftermarket hydraulic roller cams for the LS that command $400 to $500.

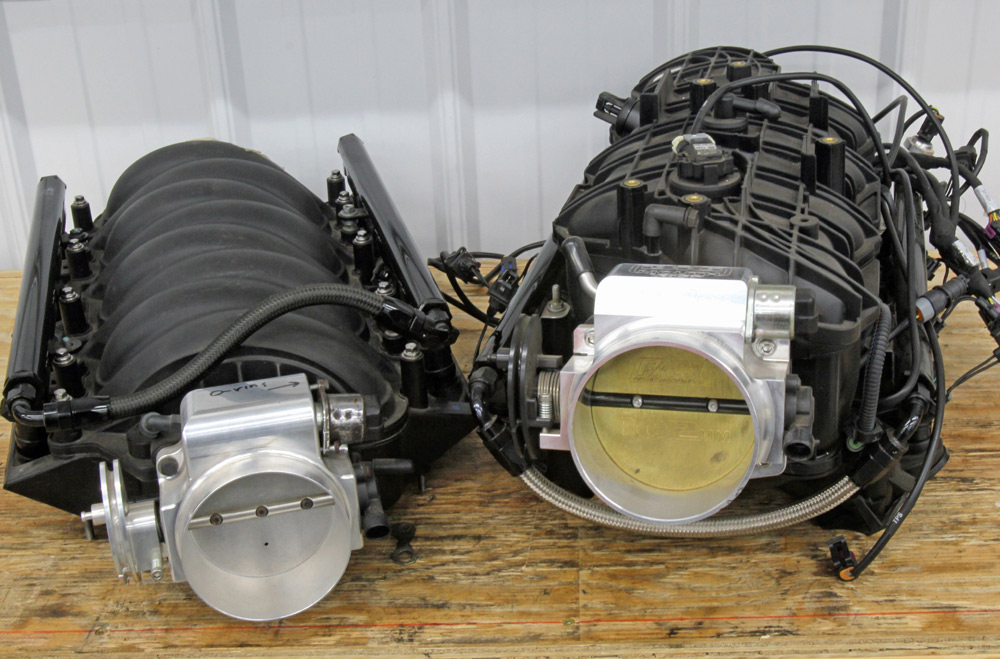

In keeping with this same line of testing, each of these configurations was fitted with the Trailblazer SS SUV intake. Part of the SDPC test was a look at the difference between the stock LM7 intake and its smaller 78mm throttle body versus the Trailblazer SS intake with a 92mm throttle body. With the bigger PowerMax Plus LS6 cam in place, the Trailblazer SS intake made 26 more hp and 25 more lb-ft of torque, so that should clue you in on how well the Trailblazer SS intake performs. Not only that but the manifold is also very affordable and can be purchased either at SDPC or Summit.

This manifold will require a fuel line, injectors, and a throttle body to complete its use along with some kind of ECU for control. While a GM ECU is certainly a player with the right amount of tuning, Holley makes an affordable Terminator X stand-alone EFI system that can make all that tuning incredibly fast and easy. You could also invest in a Terminator-X MAX version that will control the GM four-speed automatics like the 4L60E and 4L80E transmissions.

Of course, you can also opt for a carbureted version of a 5.3L engine with the addition of several aluminum intakes. Ignition control is not a problem because MSD makes a simple control box that offers the options of either custom ignition curves or one of several built-in curves. But it’s worth it to look at the total cost of a carb’d system versus EFI. You may be surprised at how closely they compare when pricing all-new parts.

We don’t want to forget about the little brother 4.8L engine in case there are those interested in one of these mini motors. A few years ago, we bolted in a Comp 219/227 cam with 0.607-/ 0.614-inch lift on a junkyard 4.8L with a carbureted intake and headers. With stock heads this engine made an impressive 393 hp at 6,800 rpm. Then we bolted on a set of ported West Coast Racing Cylinder Heads and pumped the horsepower to 432 for a 39hp gain at 7,000 rpm!

Those are frankly some very impressive numbers for a 293ci engine, equating to a ridiculous 1.47 hp/ci. Granted, this is a little engine that doesn’t make much torque below 3,000 rpm, but it’s nevertheless remarkable. We bolted this little-engine-that-could into our 1966 Chevelle and hit it with a 150hp nitrous shot and ran 7.26 at 96 mph in the eighth-mile. That equates to mid 11s at near 120 mph in the quarter-mile.

All of this points to plenty of potential with the under-appreciated Gen III/IV 5.3L and 4.8L LS engines. Sure, a 6.0L or a 6.2L will always make more power, but the price of entry on those bigger engines just keeps going up. For a mild street engine, you certainly could do far worse than a 5.3L Gen III/IV.

These upgrades are responsible for a considerable increase in both torque and horsepower right off the assembly line. The stock LM7 Gen III 5.3L can make roughly 350 hp with headers and a tune using the stock ECU. But a stock GDI L83 5.3L engine is capable of 400 hp in a similar configuration with headers. Add a mild camshaft and these Gen V 5.3L L83 engines can make 460 to 470 hp.

One interesting option is with adapters from ICT Billet. You can install either a cathedral port or rectangle port Gen III/IV port injection intake manifold on a Gen V engine and run it with a Gen IV 58x ECU like a Terminator X. This will require revisions to certain components like in-cylinder injector plugs, but the process is not difficult. This might be an attractive option for someone with a pile of Gen IV parts who would like to step up to a more powerful Gen V 5.3L engine.

This change to Gen V does not come without affecting your wallet. Because these engines are newer, they command higher prices even for used engines. Plus, if you want to convert to an aftermarket ECU like the Holley Terminator X MAX that will run the direct injection system, this will be more expensive as well. But the possibility of making 500 hp with a stock short-block, a mild cam, and a slightly better intake manifold, this approach offers a more powerful future even at only 5.3 liters.

SOURCES

SOURCES