TECH

TECH

Second-Gen

Camaro

to Life

Images BY

Images BY egardless of whether you’re updating your ride or taking on a full build, one of the most vital systems for review should always revolve around wiring. With wiring being the absolute control center of your high-performance Chevy, its daily demands handle everything from engine management to lighting, interior comforts, and gauges to monitor the vitals. Sure, your car had perfect wiring when it left the factory but if you’re wheeling a muscle car that’s over 50 years old, it’s a good idea to revisit its heartbeat to be sure it maintains a clean bill of health.

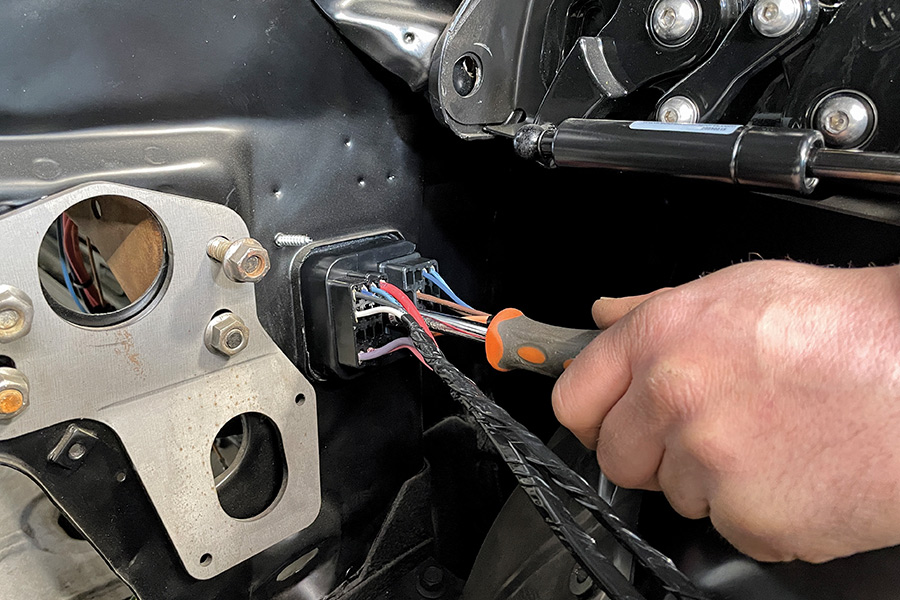

Recently, we followed up at Procision Industries in Taunton, Massachusetts, where shop owner, Pat O’Brien was preparing to move forward on the next step of the build by addressing the wiring. With the car packed with cutting-edge upgrades, including an aggressive 5.3L LC9 LS it was obvious he would need a system that could support all of the updates as well as many of the original factory components. He contacted American Autowire to check out their vast catalog of offerings for vintage Chevys. Their Classic Update Series complete wiring kit (PN 510034) packs all the right parts into one system to accommodate many of the needed modern amenities designed for specific applications exclusively for modified vehicles.

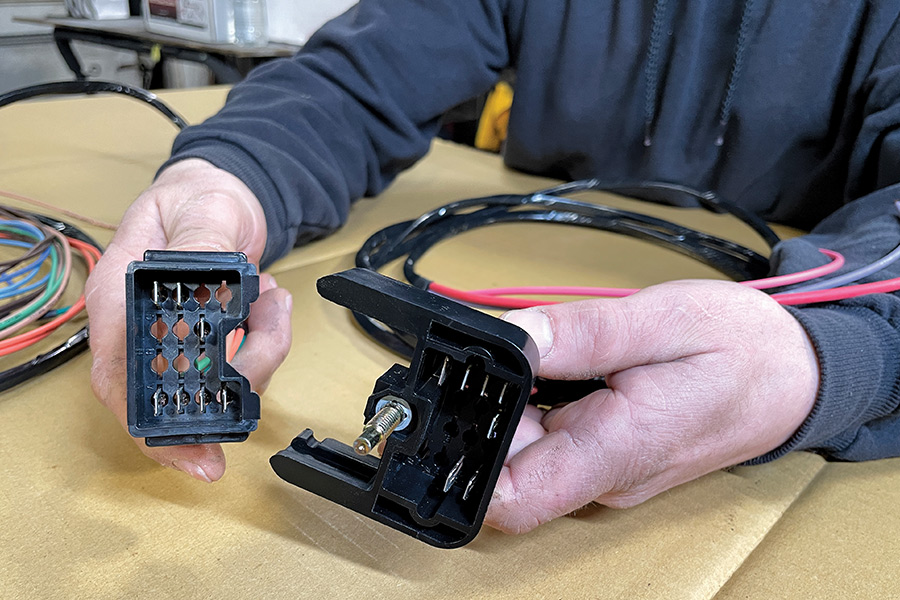

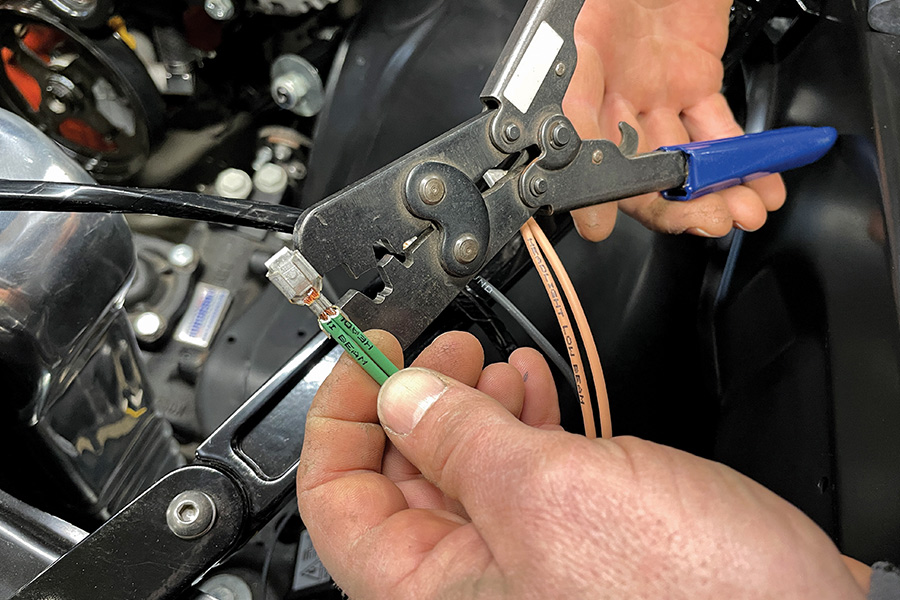

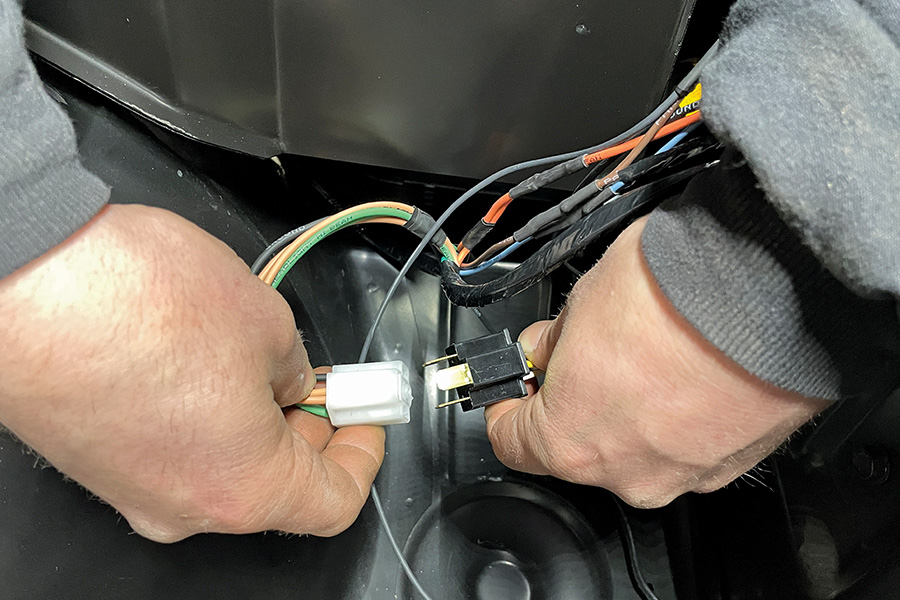

The Classic Update kits are designed for builds requiring far more circuits than would have been available on the original factory harness. While each kit supports rewiring of all the original basic needs from headlights to taillights and everything in between, it also accommodates modern updates including EFI, aftermarket gauge combinations, and common supporting modifications. Many of the kit features include an updated ATC fuse panel and fuses matched to modern GXL wiring throughout featuring wire functions labeled every 3-5 inches, a prebuilt dash harness with exclusive gauge cluster quick disconnect for use with stock or aftermarket instruments, and six-way power accessory plug to use as a source for aftermarket accessories. Their engine and lighting harnesses feature extra-long leads for either stock or custom routing with the ability to accommodate modern driveline needs with original-style bulkhead connectors included.

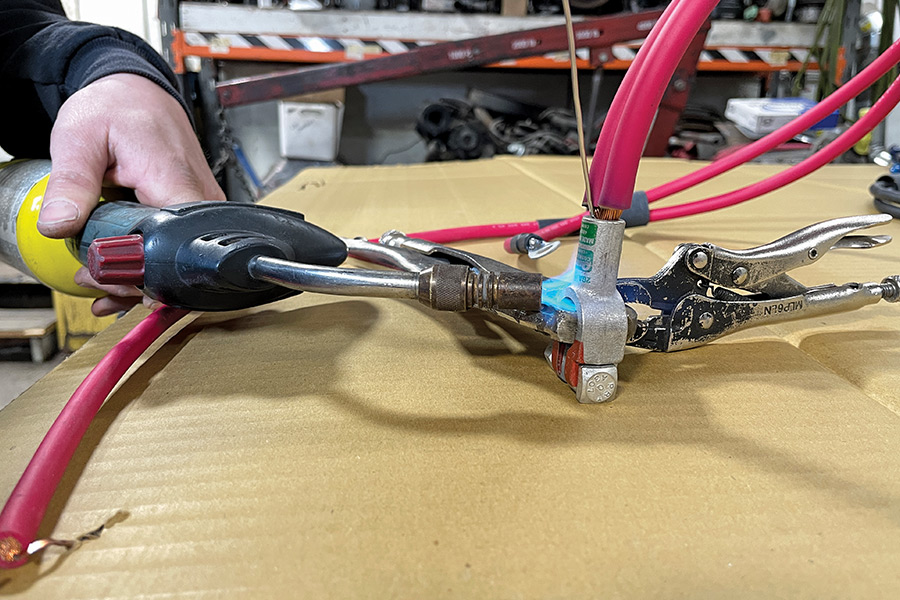

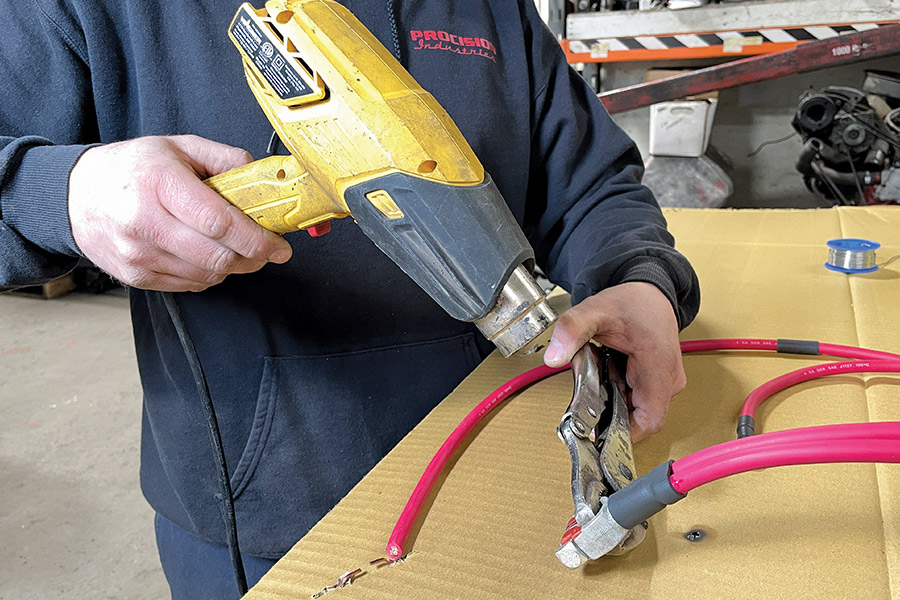

Another exclusive is their 175-amp Mega Fuse kit that comes complete with six-gauge charge cable for supporting high-output charging systems and internally regulated alternators. For our application, we also selected their accessory component add-ons, including trunk light assembly (PN CA03102), glovebox light assembly (PN 18000), and vinyl, non-adhesive harness tape (PN R0067108). For ease of installation, each kit arrives with extremely well-illustrated and detailed instructions included, as well as all components being clearly marked and ready.

To bring the second-gen’s lighting into the modern age, O’Brien used an updated system from Dapper Lighting. Dapper features an extensive group of options available for creating a truly custom-tailored system for your individual needs. Sourced through Classic Industries, O’Brien selected their LED Seven Series headlight kit, which integrates the latest in projector lighting technology into the slimmest 7-inch headlamp design on the market today. Their exclusive thermo-regulated LED optical module allows for a massive increase in light at less than half the draw of power. Designed as a true plug-and-play replacement for stock sealed beams in classic cars, the lights fit into most factory headlight buckets without modification. There’s even an option when building your system to include OEM-style glass lenses for a vintage look. With unlimited possibilities thanks to the ability to select your own housing colors, lens types, and halos it gives car owners the opportunity to fuse some personal style into their rides.

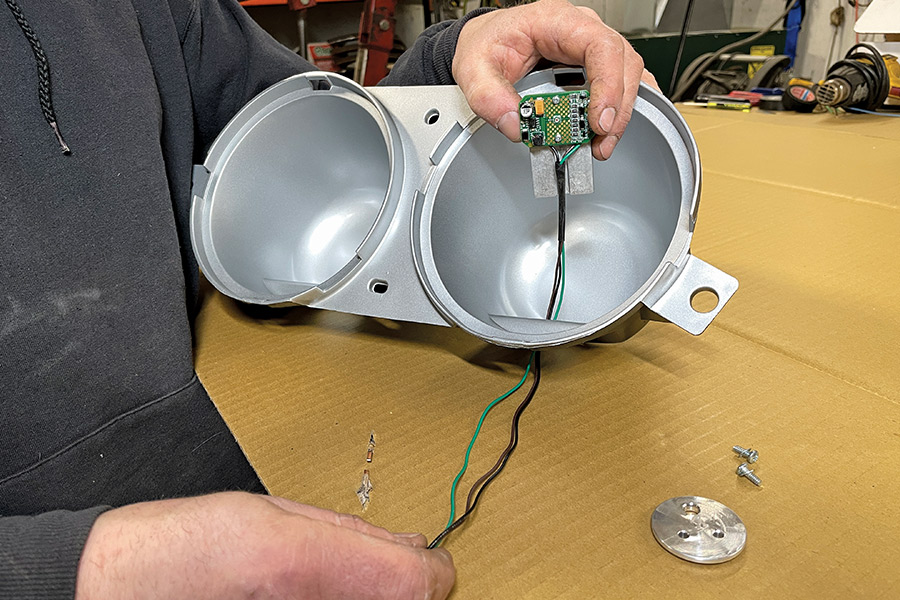

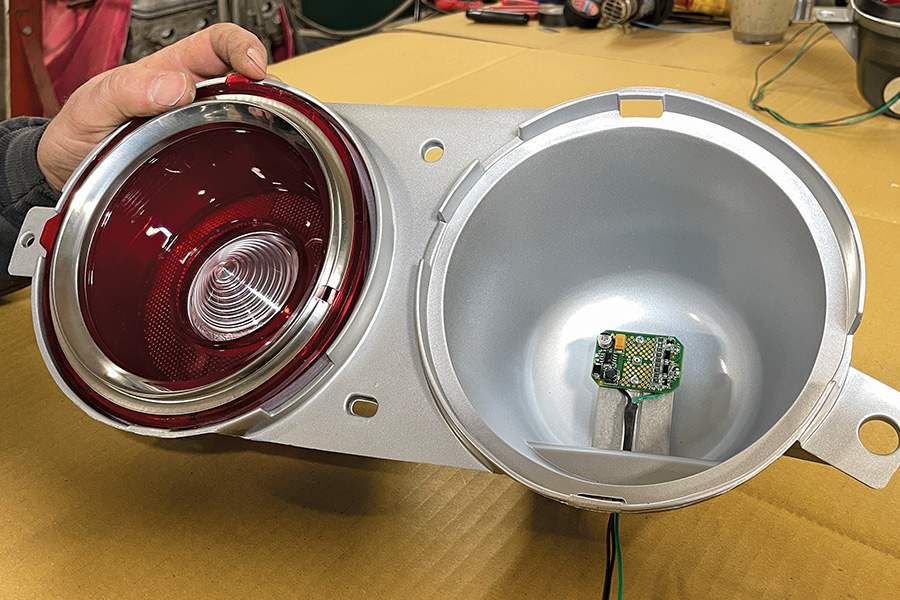

Wanting to bring plenty of visibility to the back of the car for additional safety, O’Brien hit up Dakota Digital for one of their LED Brake/Taillight Module Systems (PN LAT-NR100). Engineered to utilize the original wiring harness, installation is a snap to make the update to your factory taillight assembly.

SOURCES

SOURCES