TECH

TECHInTheGarageMedia.com

BY Ron Ceridono  Photography by Rob Fortier

Photography by Rob Fortier

1. Performance Online supplied all the parts and pieces to update our ’65 Chevelle. Virtually everything that was done to it is applicable to ’64-72 GM A-bodies.

BY Ron Ceridono  Photography by Rob Fortier

Photography by Rob Fortier

Brake and Suspension Upgrade for GM A-Bodies

he ’60s were interesting times. The average new house was around $20,000, gas was roughly 30¢ per gallon, miniskirts were popular, and the Rolling Stones were touring the U.S. Of course, for many gearheads, the high point of the decade was the introduction of General Motors’ A-body lineup in 1964. It included the new Chevelle Malibu (and El Camino) as well as the Oldsmobile 4-4-2, Pontiac GTO, and Buick Skylark. A V-8 Malibu carried a window sticker of around $2,600, and the others were similarly priced.

Although GM’s A-bodies were great cars and well received in their day, by today’s standards they have some shortcomings when it comes to stopping power and handling. GM began installing disc brakes on ’65 Corvettes, but the rest of GM’s offerings had to wait until 1967 for a disc brake option. There were some notable A-bodies with lots of go and very little whoa. And while the performance versions of these cars had impressive straight-line performance, thanks to their spongy suspension, bending them around corners at speed often resulted in white-knuckled drivers, while the tires squealed loudly in protest.

Recently, we had the opportunity to follow along as a number of brake and suspension improvements were made to a typical A-body by the team at Performance Online (POL). POL has been in business building and restoring custom and classic cars as well as selling performance products for over 30 years.

Disc Brake Conversion

OEM forged spindles for disc brakes

OEM caliper brackets

OEM dust shields

POL’s forged disc brake steering arms

These kits use single-piston OEM or Wilwood dual-piston calipers—they will not work with OEM four-piston calipers.

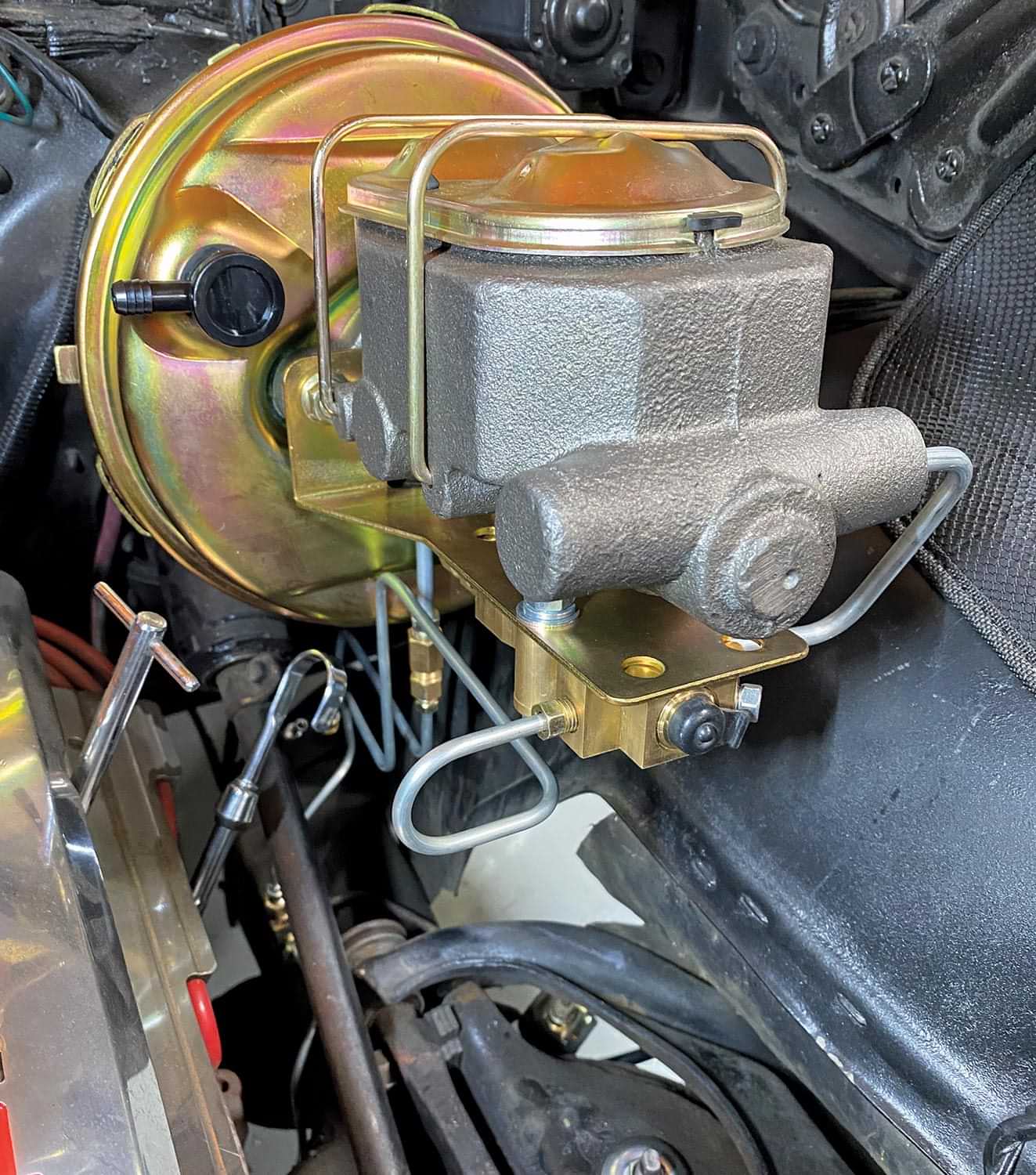

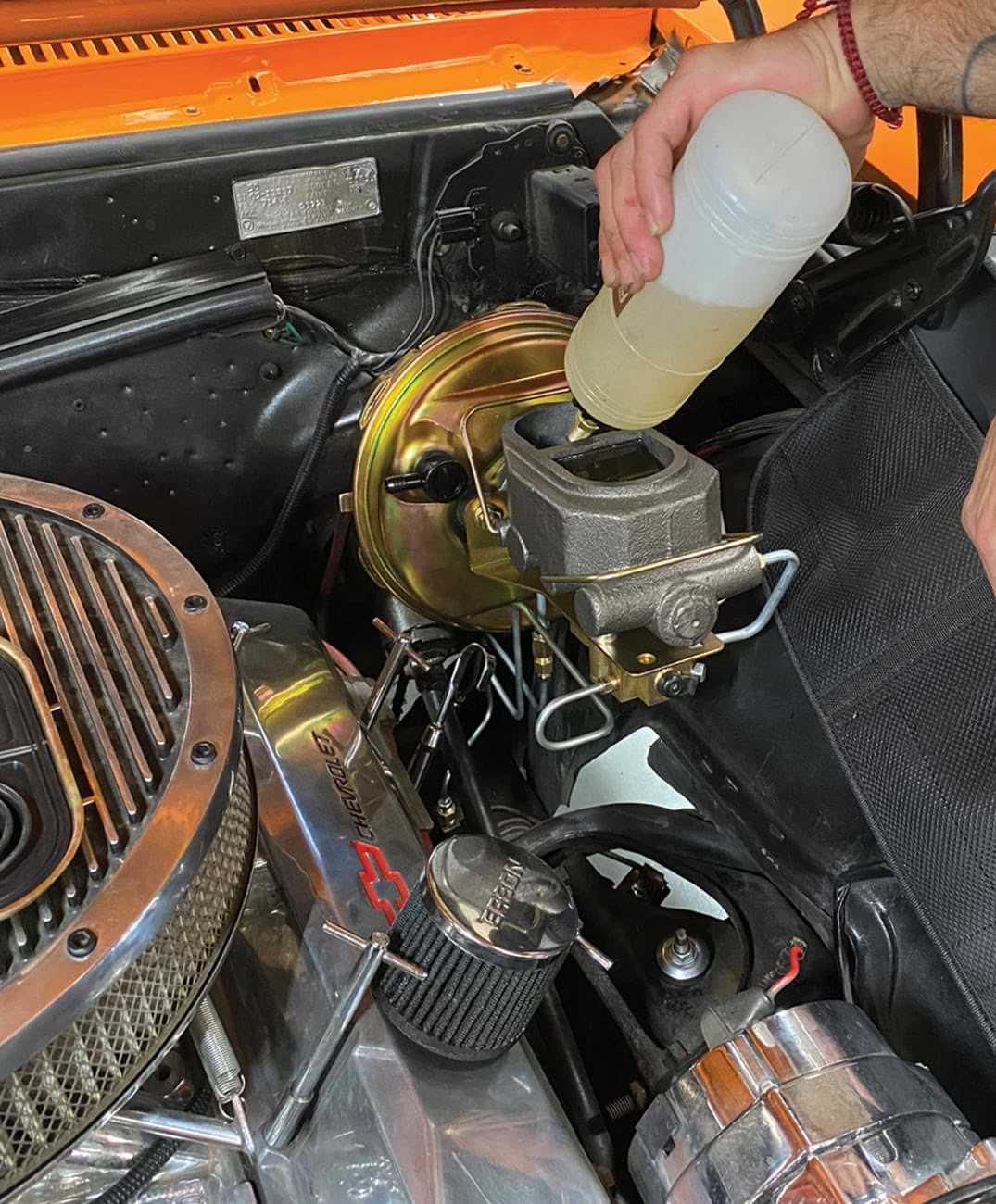

POL’s master cylinder and booster kit includes:

9-inch-diameter power booster (8-inch, dual diaphragm is optional)

1-inch bore master cylinder

Proportioning valve with bracket and lines

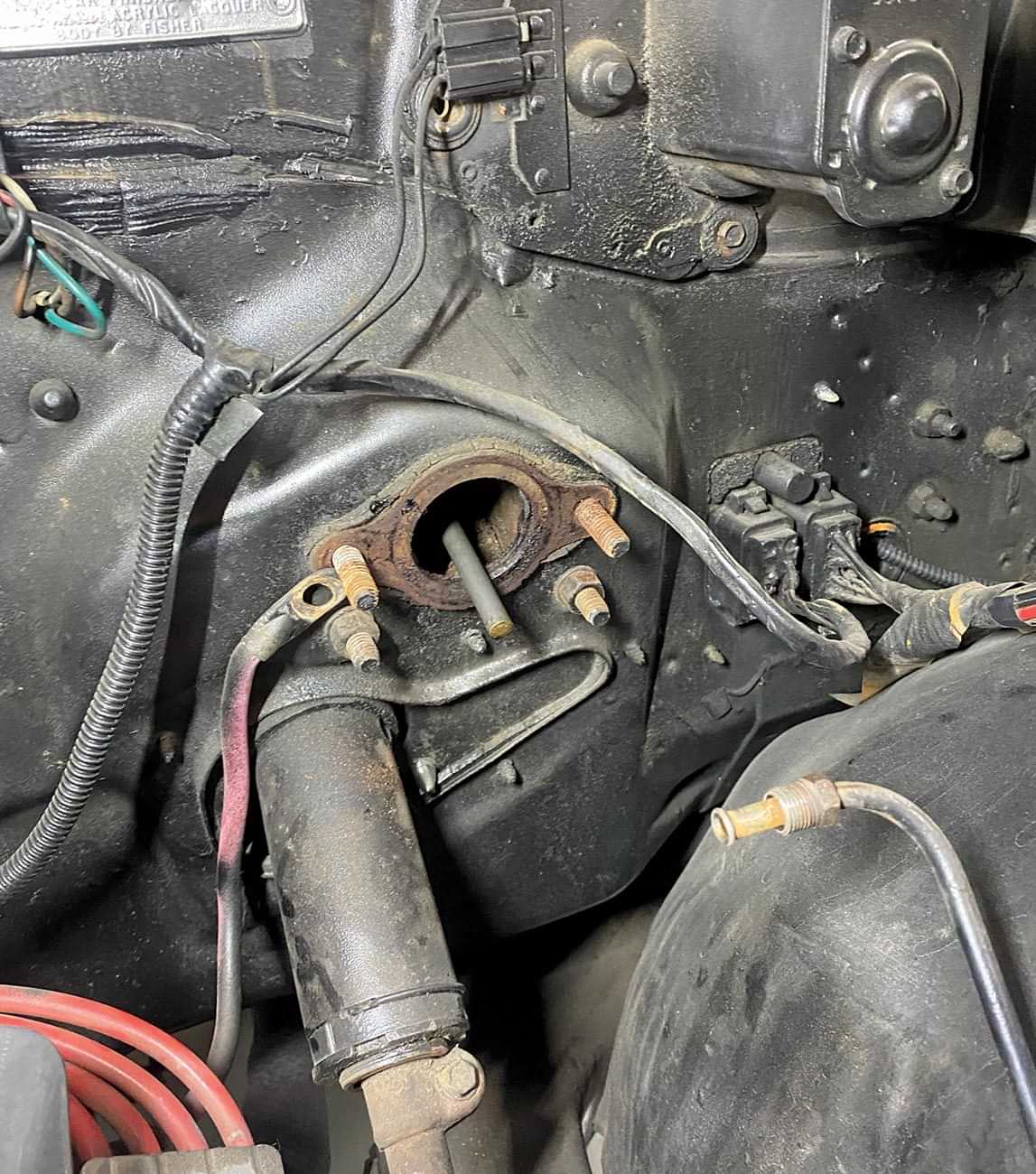

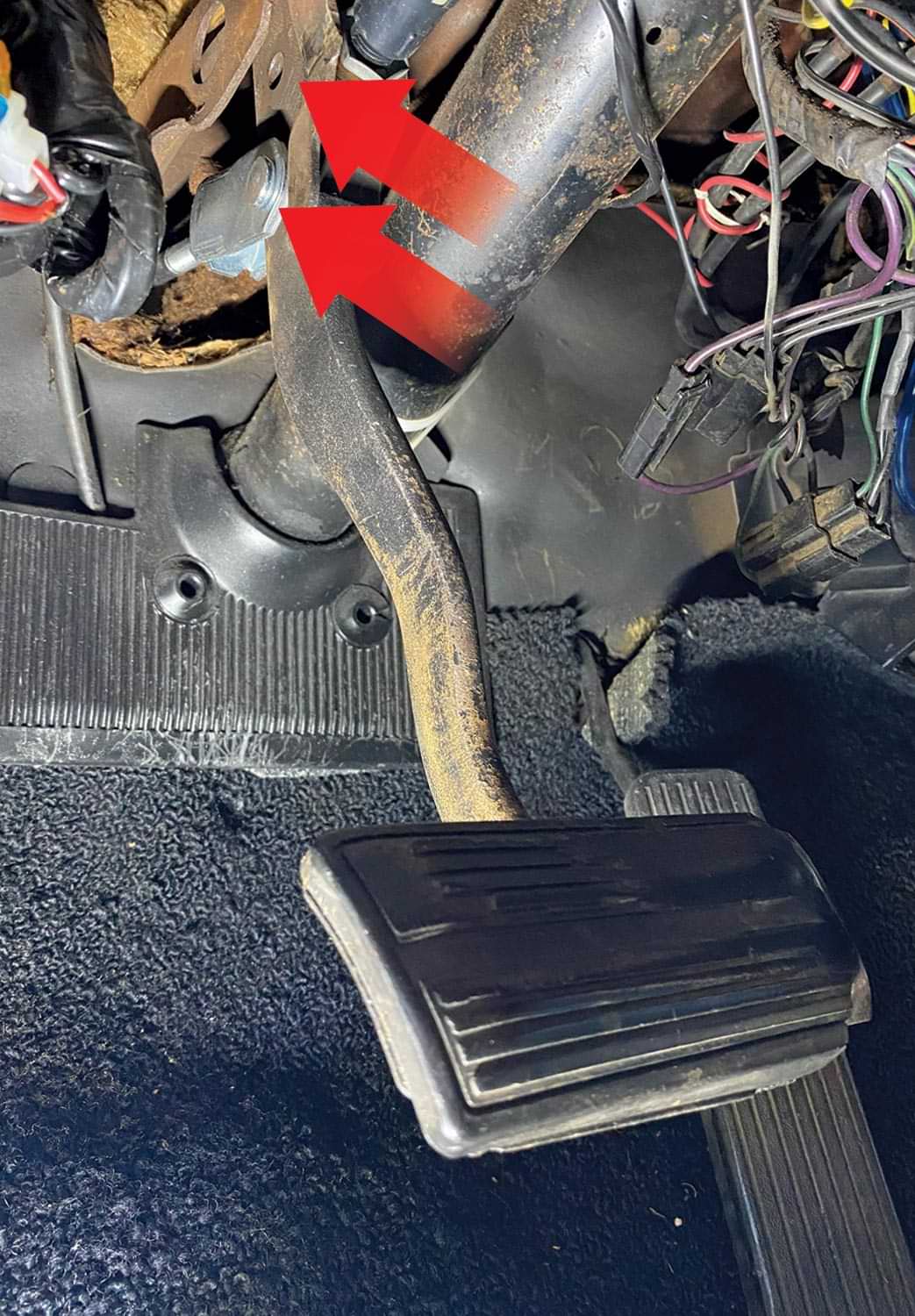

It should be noted that when installing a vacuum booster the angled mounting bracket will result in the integral pushrod connecting to the brake pedal at a lower point than the manual master cylinder push rod did (see photo 17). If the lower hole isn’t there, one will have to be drilled.

Inner and outer tie-rod ends

High-performance tie-rod adjusting sleeves

Idler arm (GM used 13/16– and 7/8-inch-diameter idler arms on A-bodies—check with POL for your application)

To completely rejuvenate the steering system we also installed a new centerlink.

Rear springs are available in stock, 2- or 3-inch drop. Stock height spring rate is 138 lb/in, lowered have a slightly stiffer 152 lb/in spring rate.

To adjust the shocks, they are fully collapsed, then the shafts are rotated to the desired setting:

Valving ratios are:

Front: 90/10, 80/20, and 60/40

Rear: 70/30, 50/50, and 40/60

Kit includes:

11/8-inch-diameter front antisway bar

1-inch-diameter rear antisway bar

Polyurethane bushings

Making Great Cars Better