TECH

TECH

Rattle No More

Increasing Second-Gen Camaro Cabin Comfort

Images by THE AUTHOR

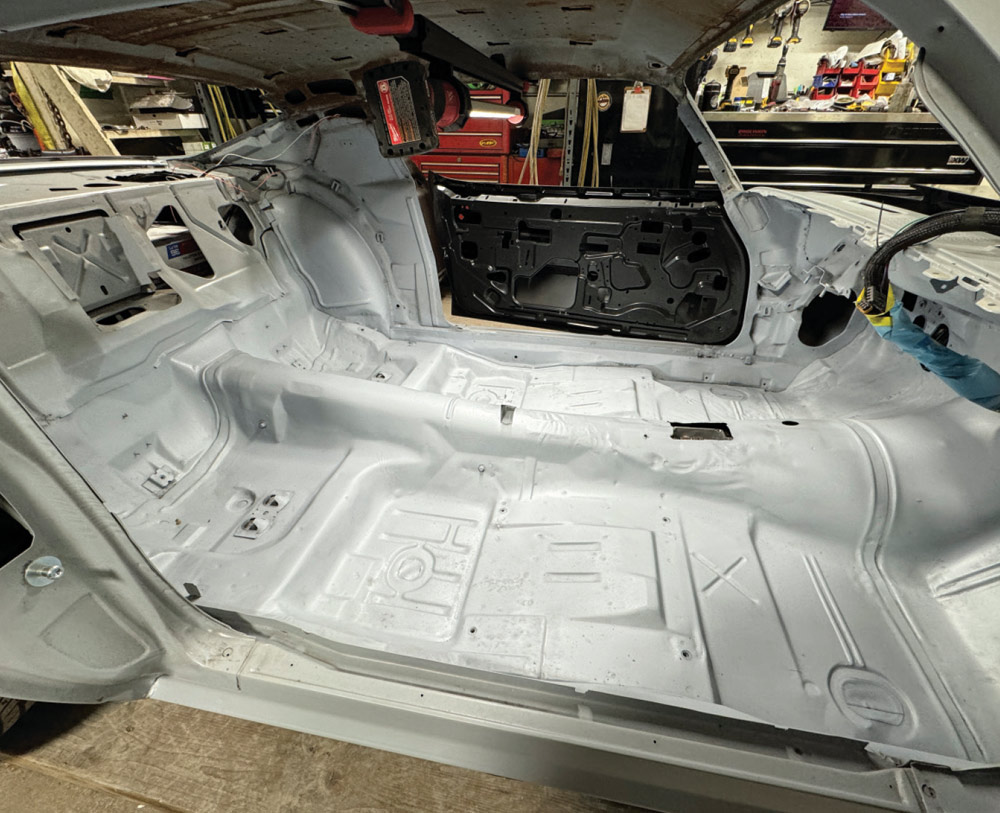

Images by THE AUTHORhere’s nothing worse than hitting the road in your high-performance Chevy and being assaulted by excess heat and vibration as you lay down the miles. Between adding an upgraded driveline and high-flow exhaust, the amount of heat generated has a direct connection through the floorpan. This moves straight into your interior and there’s no way the factory jute-style padding will suffice to handle the job. Regardless of whether you’re taking on a full build or simply making updates, it’s a solid idea to think about upgrading your insulation complemented by sound deadening to help tame all that rattle ’n’ roll generated by the road. We’re here to tell you that there’s a simple solution to the problem, one that you won’t even break a sweat over, when installing products direct from the makers of Flatline Barriers.

Regular readers of All Chevy Performance will recognize the 1971 Camaro showcased across our pages, having followed its transformation from that of a bare shell. Over time, we focused on its suspension, brakes, LS driveline, cooling, exhaust, sheetmetal, and wiring. As we head deep into the interior, our initial thought was to give it a more civilized experience by trying to eliminate excess heat and road noise, especially with it packing an aggressive LS underhood. Recently, we followed up at Procision Industries in Taunton, Massachusetts, where shop owner Pat O’Brien was preparing to move forward by taking on this very subject. After reviewing various offerings on the market, he made a decision to contact Classic Industries, one of the distributors for Flatline Barriers.

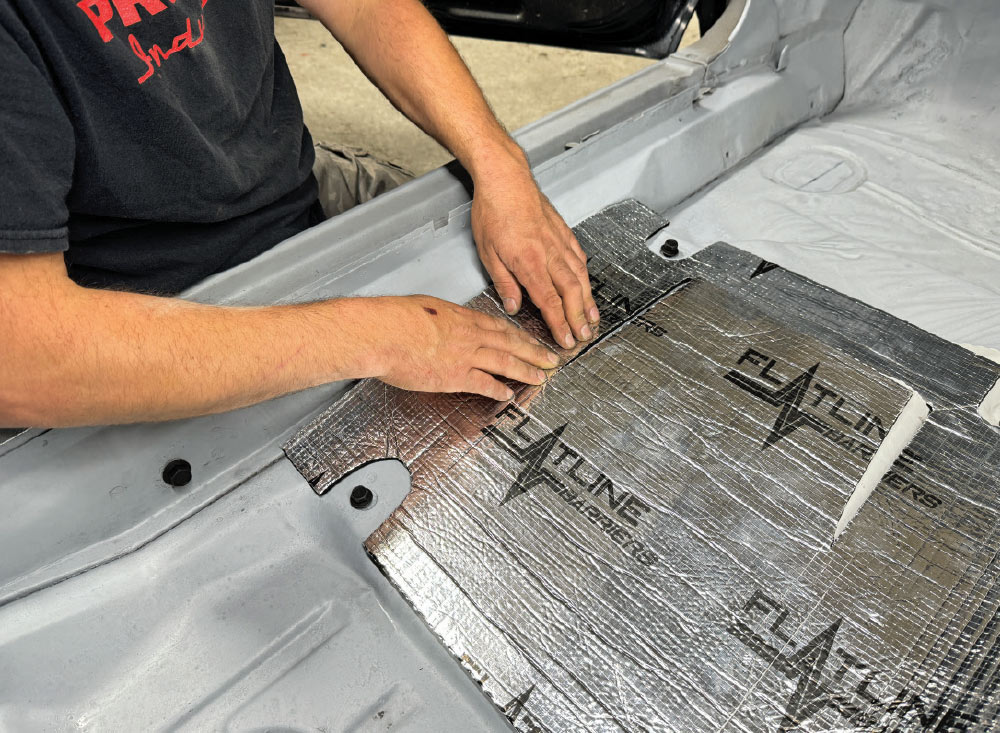

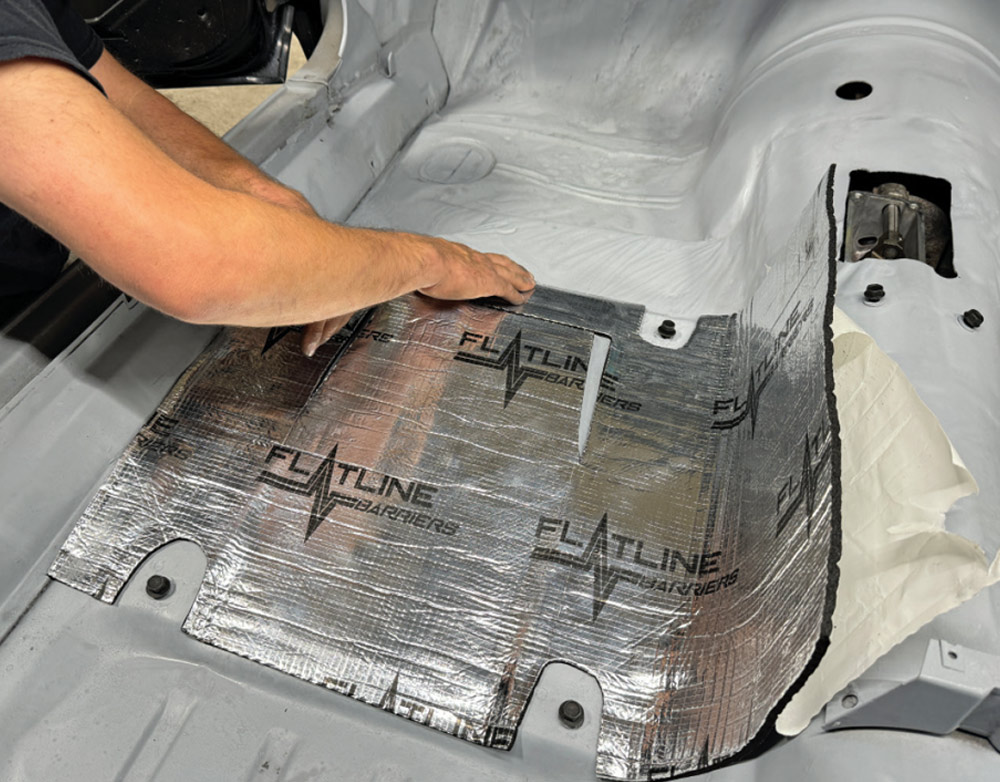

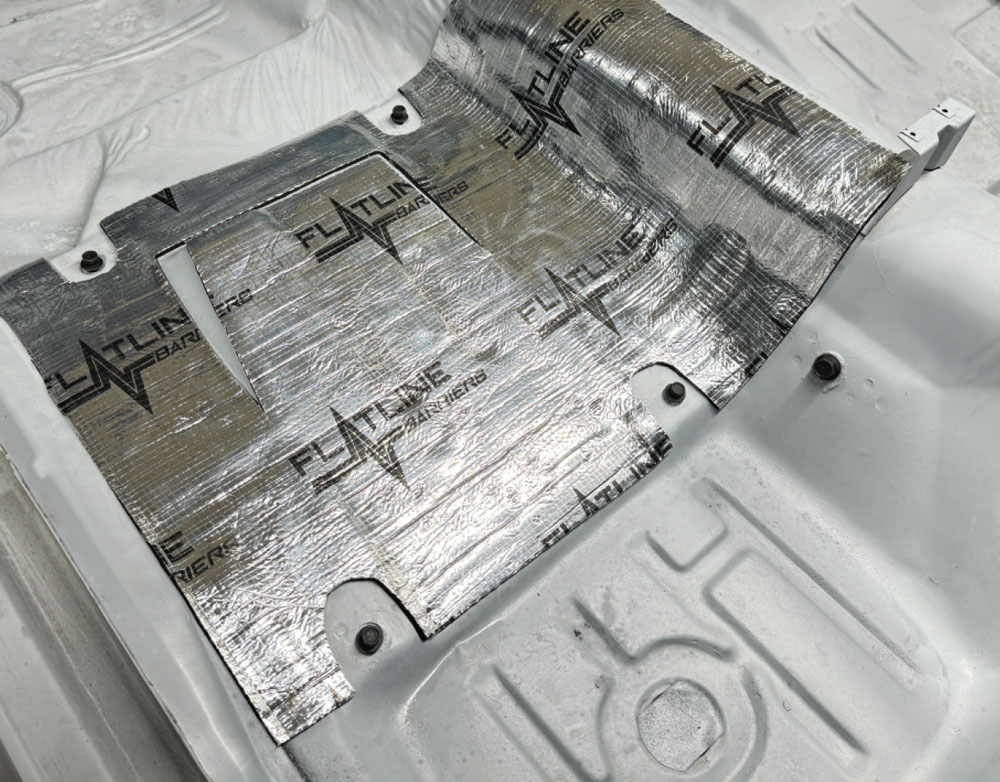

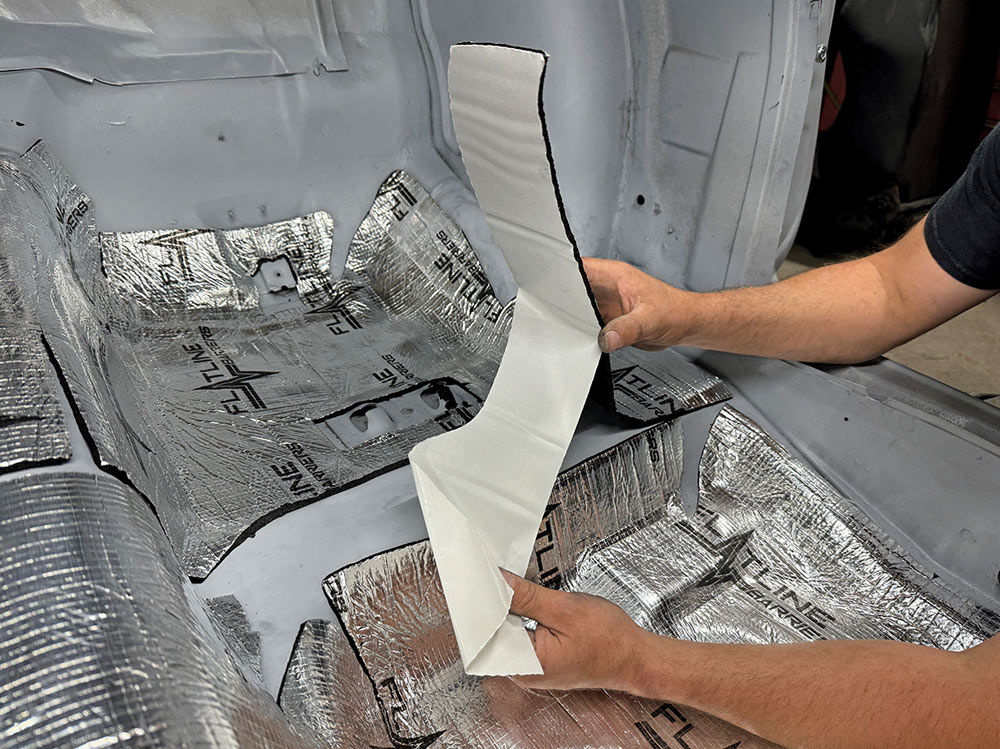

If your company slogan is “Where heat and sound meet their maker,” you’d better be able to live up to it. We’re here to tell you that the product, comprised of an external aluminum thermal barrier, eliminates radiant heat while its second layer of ultra-lightweight foam silences unwanted noise, vibration, and resonance with a totally light-as-a-feather formula. With its simple peel ’n’ stick application requiring no special tools except for hand pressure and a razor (or scissors) to occasionally trim, it’s a snap to install, especially for a DIY afternoon project once the area is prepped. It’s also important to note that the product is extremely flexible and able to be installed in any ambient temperature.

Flatline Barriers has engineered complete precut kits for an exact fit in an endless array of muscle cars and trucks while also offering universal kits for custom applications. For our installation, we selected three individual precut kits to cover the floor, roof, and door areas with part numbers TABF2012, TABF2031, and TABF2004, respectively. By raising the bar, they have incorporated cutting-edge technology and materials to create a true lightweight solution in significantly reducing unwanted heat and sound from your interior. Follow along as we show just how simple and effective an afternoon install can be.

SOURCES

SOURCES