TECH

TECH

Photography by The Author

Photography by The Authorot rodders and racers of all sorts have long understood the advantages to coilover suspension: the spring rate can be easily changed, the shock absorbers are available with fixed, single- and double-adjustable damping characteristics, and ride height can be quickly altered. While coilovers are often found on a variety of vehicles, it was always considered too difficult to retrofit vehicles that came equipped with coil springs from the factory. That all changed with the availability of what can best be described as hybrid coilover kits, like those available from Aldan American.

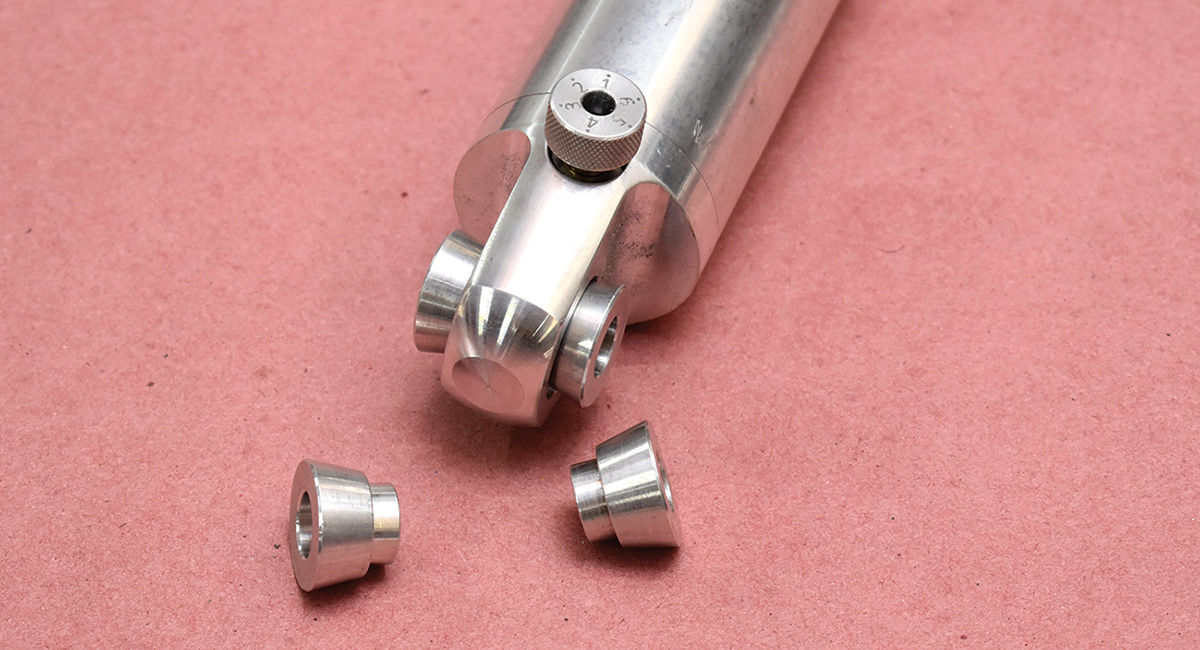

Aldan has been a leading manufacturer of suspension components for well over 40 years. All their shocks and coilover kits are manufactured in the U.S. from lightweight, high-strength 6061-T6 billet aluminum, which makes them incredibly strong and light weight. All use low-friction Viton seals and O-rings, the shock’s shafts are heat-treated, chromed, and finish ground before final assembly to reduce seal friction. All shocks are fully serviceable and rebuildable and come with Aldan’s 100 percent satisfaction guarantee. Now, along with shock absorbers and conventional coilovers, Aldan’s product line includes retrofit coilover kits for a long list of IFS-equipped cars.

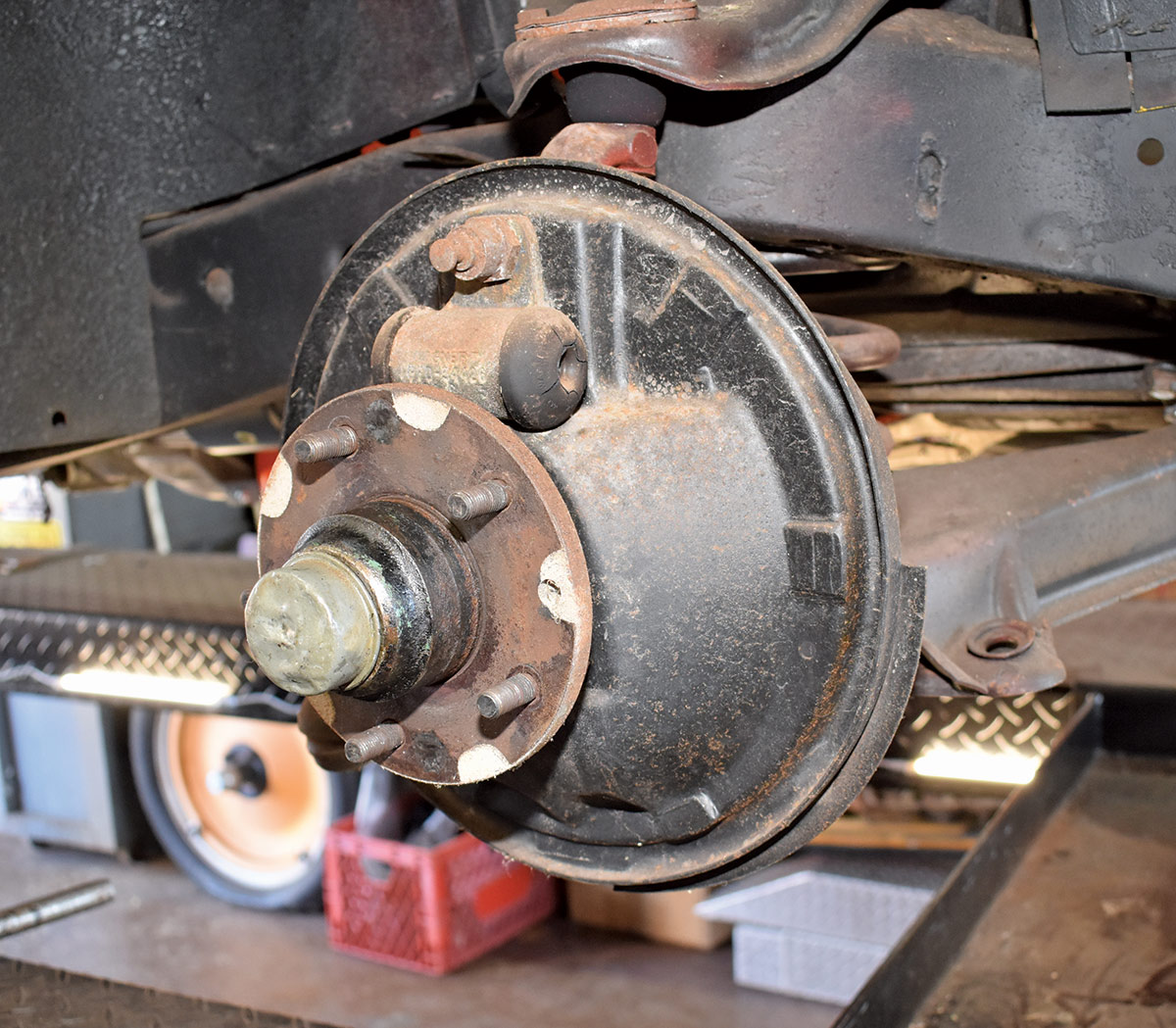

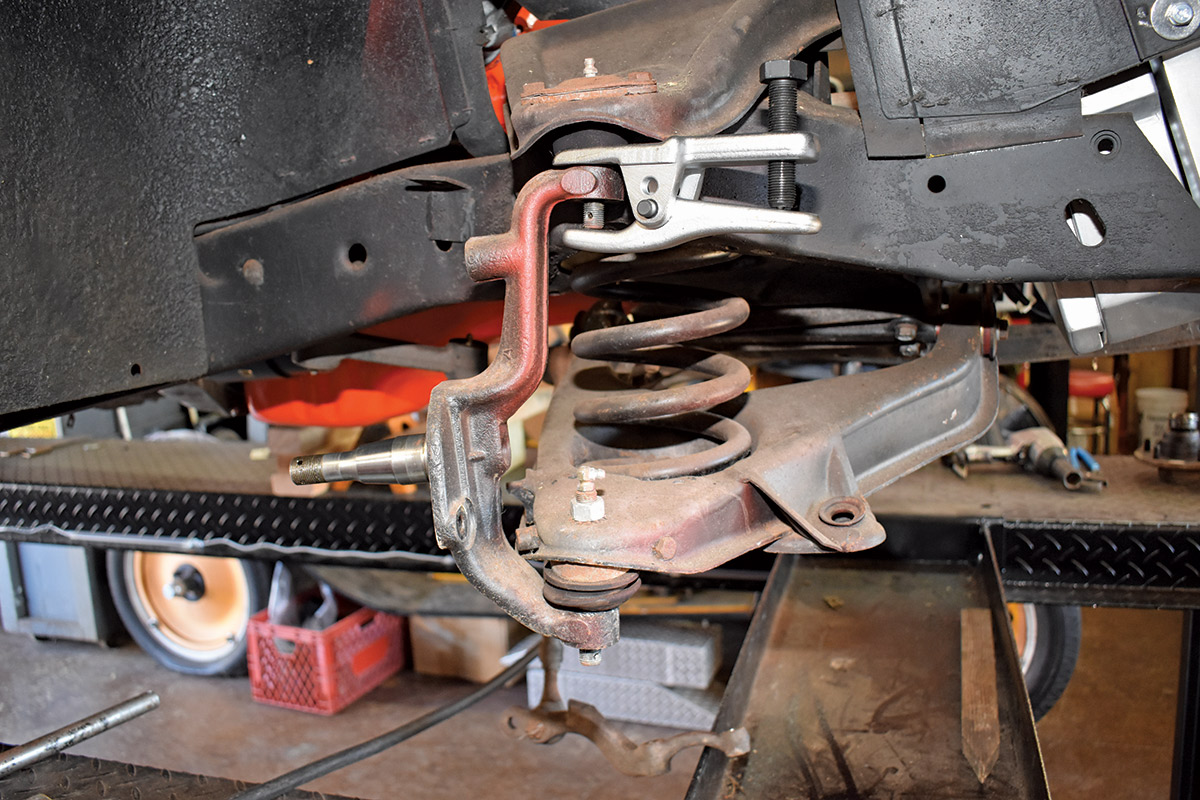

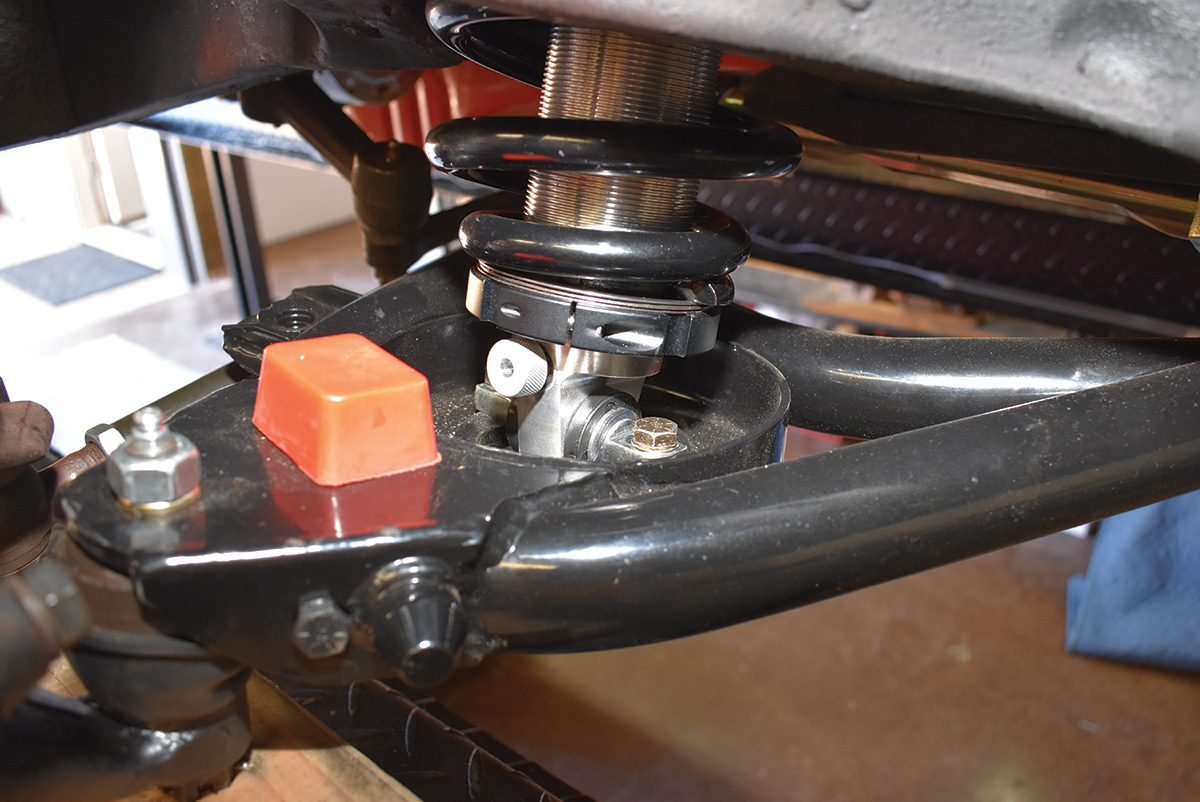

What makes these coilover conversion kits work are the unique coil springs that fit into the car’s original upper spring pockets in the chassis on one end, with small-diameter “pig tails” that fit onto the shock’s threaded adjusters on the other. Like conventional coilover springs, these conversion springs are available in a wide variety of spring rates to provide the ride and handling qualities to fit your specific application. One of Aldan’s coilover kits that caught our attention was PN 300134 that fits ’58-70 fullsize Chevrolets and ’63-82 Corvettes—just what we needed for our split-window Vette project.

While the Aldan kit we opted for was applicable to a variety of Chevy products, we began to wonder what other parts would have such a broad application and stumbled onto something surprising: Speedway Motors offers tubular upper and lower control arms for fullsize ’58-64 Chevrolet cars. While the upper control arms wouldn’t fit our Corvette, the lowers would—the trick is they have to be swapped side for side (and yes, we checked all the dimensions and it works). The only drawbacks to this swap are the sway bar mounts and the steering stops end up being on the wrong side of the arms, but we’ll deal with that as we’ll be using a custom sway bar anyway. So why go to all the trouble? Simply put, the Chevy control arms cost almost half as much as the Corvette versions.

For the initial damping settings of Aldan double-adjustable shocks, Nelson suggests turning the rebound adjustment knob all the way clockwise to full stiff then backing off 10 clicks, which is the center of the adjustment range. For compression damping for our installation, he suggested setting the knob on number 1 of the six positions available. Be aware the compression knob doesn’t have a stop and will rotate 360 degrees. As the adjuster is a barrel valve, if the knob is rotated past 6, it returns to position 1.

To fine-tune the shocks, Nelson has a simple-yet-effective procedure: Drive the car over a bump or through a dip in the road at 15-20 mph. If the suspension feels too soft, increase the compression damping. If it is too harsh, decrease the damping. For rebound damping use the “Nelson seatbelt test.” Using the same “compression” road test if the rebound setting is too stiff—that is, if the seatbelt feels like it tightens up on return after compression—simply decrease the rebound setting to soften the motion.

While our subject shown here was a Corvette, Aldan makes complete coilover conversion kits for GM A-, B-, F-, G-, and X-bodies. That alphabet soup means there are kits available for fullsize Chevrolets, Novas, Chevelles, Camaros, Monte Carlos, Malibus, and El Caminos. In other words, just about anything adorned with a Bowtie from 1955 to 2018 can be equipped with Aldan retrofit coilovers. The upgrade from stock suspension to coilovers is easy to do and the results will provide a better ride and improved handling as a result of the adjustability available—ride height can be easily altered as well.

Converting to coilovers will make you wonder why you didn’t do it sooner, no matter what Chevrolet you drive.

SOURCES

SOURCES