TECH

TECH

Photography by

Photography by lot of time seems to be spent discussing the merits of one particular cooling system feature versus another. Brass/copper radiator versus aluminum. Electric fan versus mechanical. Three-row? Four-row? Dual pass? Thermostat or no? What psi radiator cap? There is a lot to digest, but once it’s said and done, it seems the cooling system is a wrap. But there’s more to reducing the temps of an engine, and, more specifically, the powertrain as a whole, than just the cooling system and its related components.

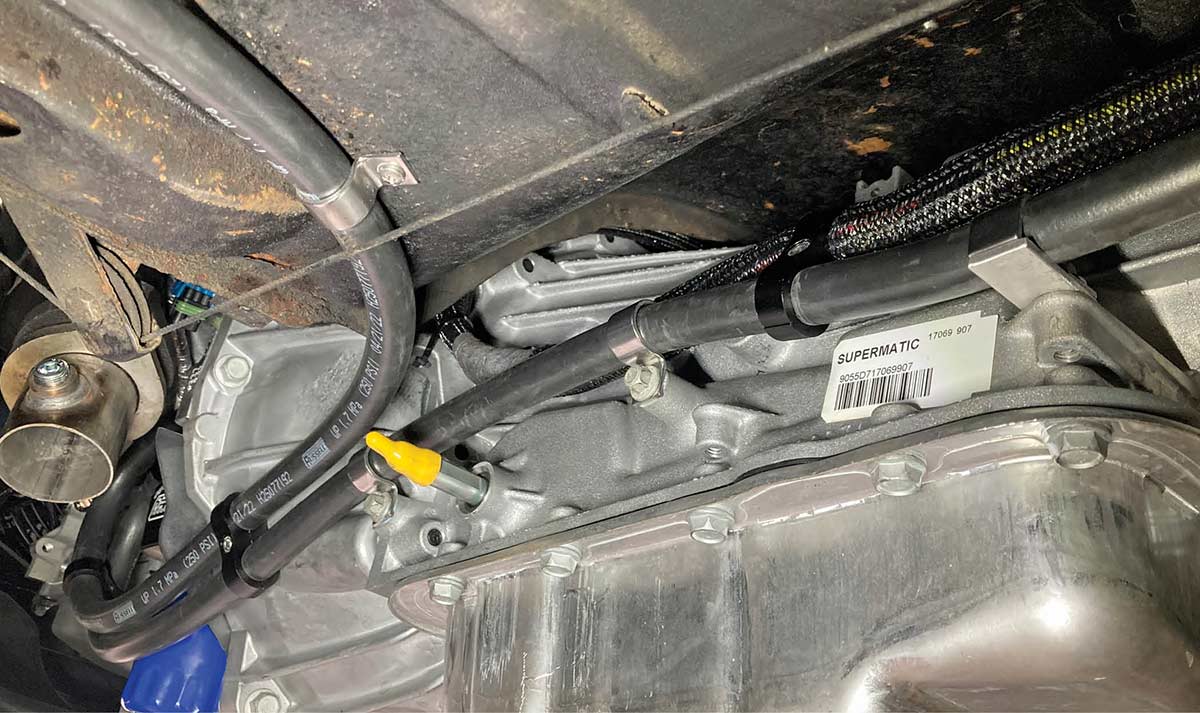

Knee deep in the LS swap on our buddy Bruce Valley’s ’57 Chevy wagon, we had decided not to route the transmission fluid through the radiator. Keeping a hard-working V-8 cool is difficult enough, add to it hot transmission fluid and that poor radiator would be doing all it could to keep up. Instead, we opted to add an external cooler to handle the transmission fluid duties and contacted the guys at Derale Performance to walk us through what we needed to know. After a short phone conversation, we ended up with a longer list of components than we originally intended, due to the education we received from the Derale team.

Originally, engine oil cooling wasn’t given much of a thought and transmission cooling an afterthought, being routed through the radiator where the fluid’s heat was absorbed by the engine coolant (which itself was trying to cool at the same time!). For the most part, this system proved effective, at least until power output increased to a level where it no longer did. Today, it’s understood that nearly all late-model powerplants and anything else making decent power can only benefit from the addition of external coolers.

That same theory works just as well to keep the fluid of an automatic transmission in check and within the range of optimum operation. This is imperative when it comes to the street performance aspect of many of our classic Chevys where that transmission is responsible for transmitting massive amounts of torque and horsepower to the rear wheels of a fairly heavy vintage sedan. Managing all that power can generate some serious heat, and heat is the enemy of the automatic transmission. Too much and things go bad in a hurry. So, the responsibilities of the transmission cooler are of utmost importance.

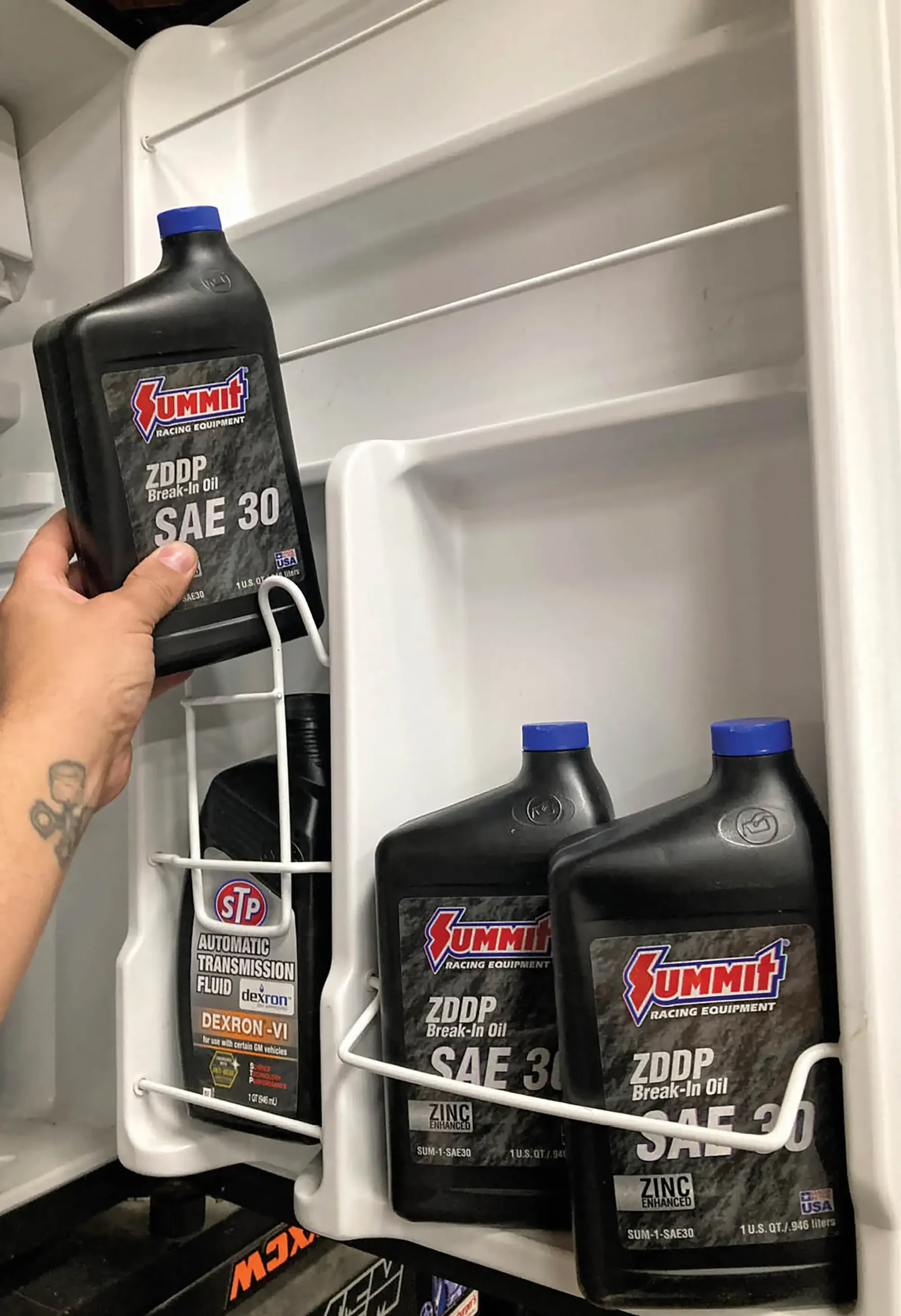

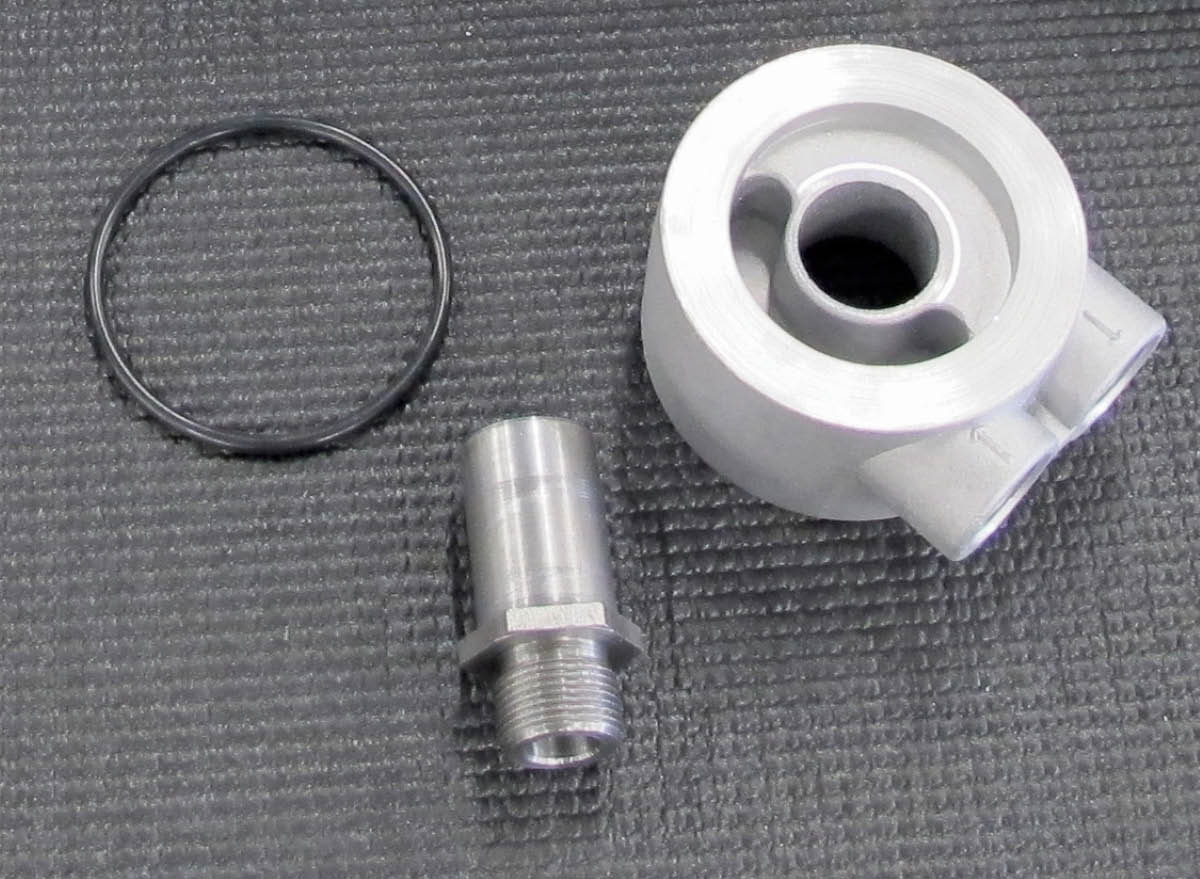

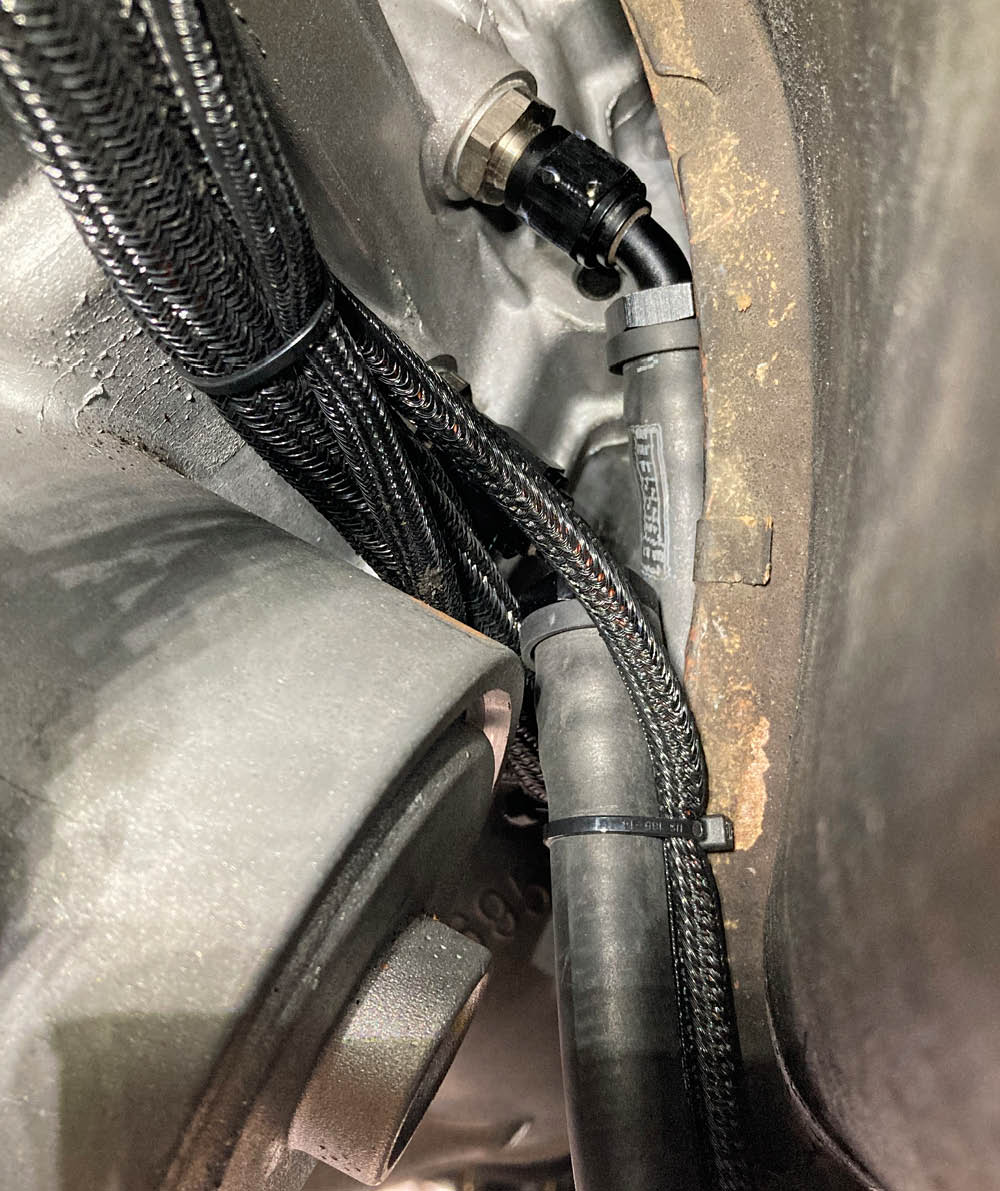

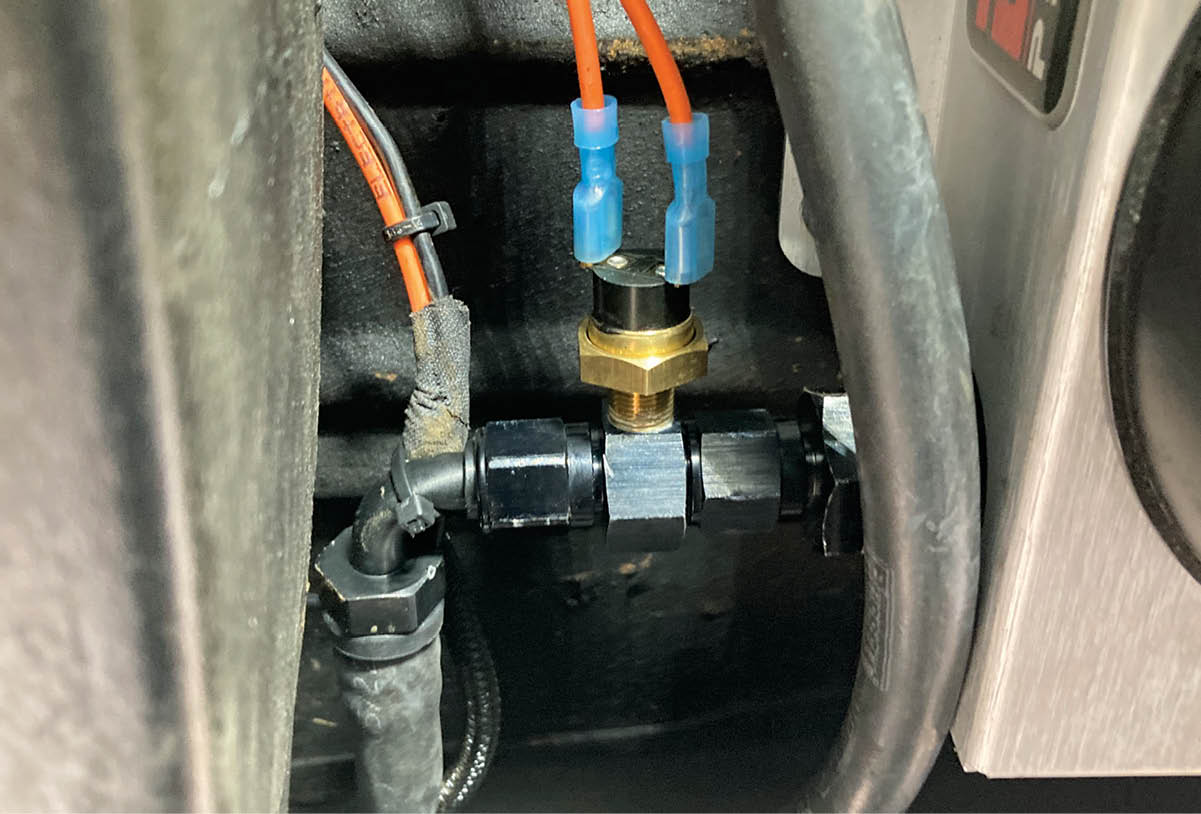

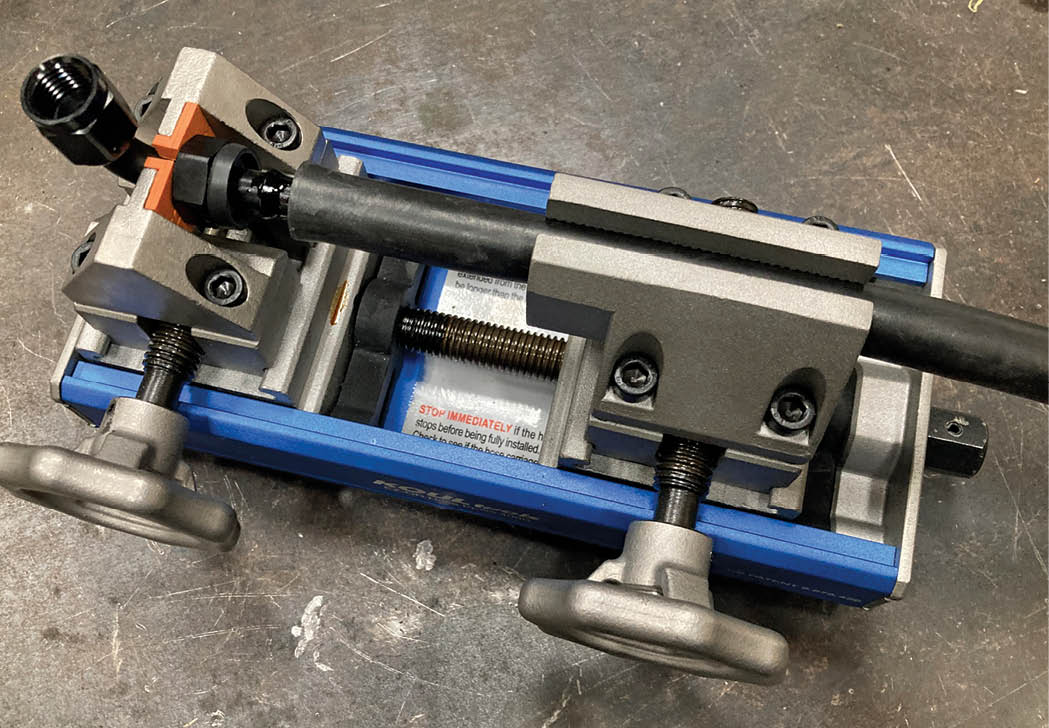

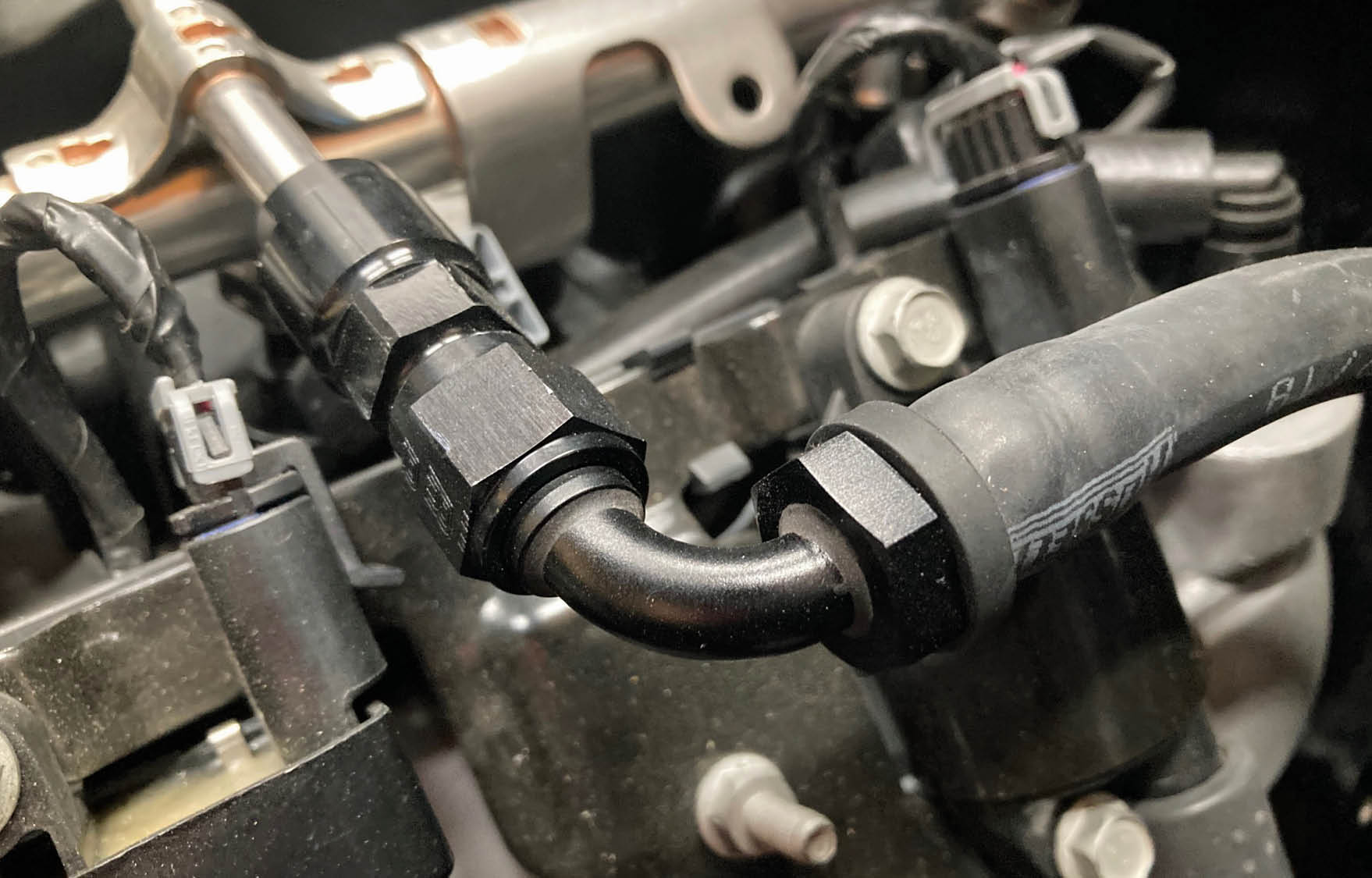

Heeding Derale’s advice, we opted to use an external cooler for both the engine oil and the transmission fluid on our LS swap in addition to an electric fan controller, which we’ll cover in a future story. The addition of an external cooler is a fairly simple affair, consisting of choosing the proper location, installing the cooler, and routing the lines from the engine/trans to said cooler. But there are a few tips and tricks that we hope to be gleaned from our install, including the proper selection of hose, clamps, and fittings.

SOURCES

SOURCES