Tech

TechGrand

Grand

Text & Photos By Jeff Huneycutt

Text & Photos By Jeff Huneycutte’ve all seen the stories about engine builders producing other-worldly amounts of power on so-called “street” engines. And yes, modern engine management systems, turbos, and superchargers all make that easier than ever.

But too often when you read the fine print you realize that the builder may call it a street engine, but nobody in their right mind would really want to live with it in everyday life. Compression so high you can burn only race gas, aggressive ignition timing curves that keep you constantly on the edge of detonation, and engine rebuild intervals that come up faster than tax day when you aren’t ready. Still technically streetable but hardly any fun in the real world.

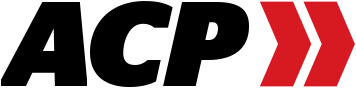

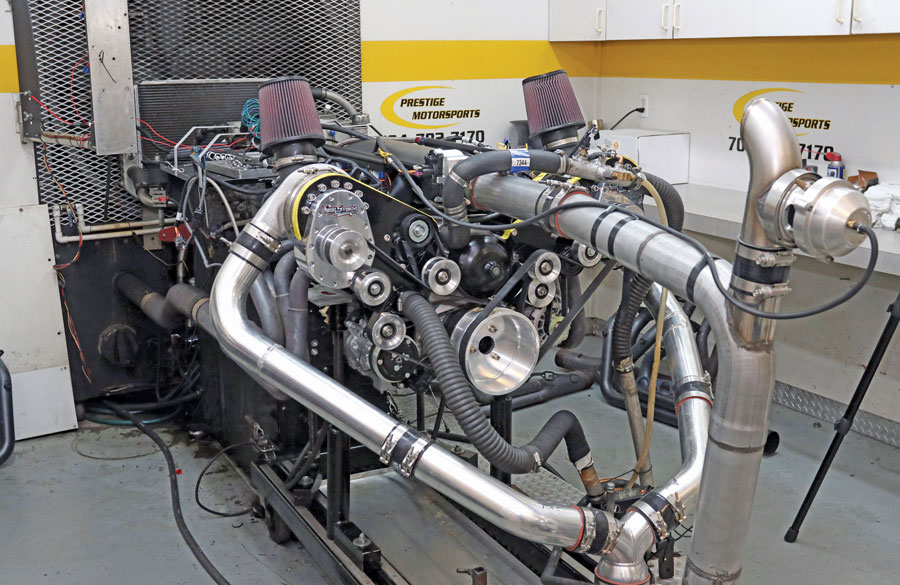

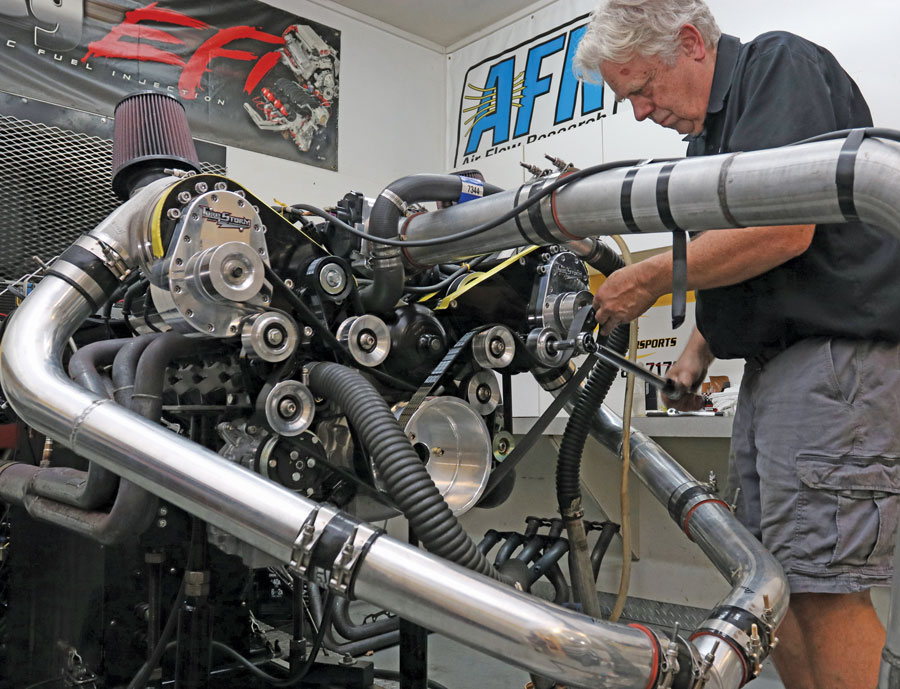

That’s what Prestige Motorsports aims to fix with this supercharged LS build, which has supplied a steady stream of pressurized air thanks to not one but two TorqStorm superchargers. This will be going into a 1969 Camaro and the car’s owner not only demands a dependable rig that he can drive every day, he also wants world-beating power. As a bonus, we think he also got an engine that looks absolutely incredible.

This story is more about making the twin TorqStorm kit work and testing it on the dyno, but so you can have the complete background we need to go over the build a bit. This is a 427ci LS thanks to a 4.125-inch bore and 4.00-inch stroke.

The block is a high-strength, cast-iron LS Next Block from Dart. It has been outfitted with a crank and 6.125-inch-long connecting rods from Eagle. Finishing up the rotating assembly are a set of D.S.S. Racing forged pistons with a 22cc dish.

The cylinder heads are a set of Prestige Motorsports’ own aluminum LS3 castings. They’ve been CNC cut with 255cc intake runners and 68cc combustion chambers. Combined with the 4-inch stroke, that makes the combustion ratio a boost-friendly 9.6:1.

The camshaft is a hydraulic roller from Comp Cams. It has been ground with 238 degrees of duration for the intakes and 248 for the exhausts—both at 0.050 tappet lift. It has a wide 114-degree lobe separation angle, and with the 1.7:1 ratio rocker arms, total valve lift is 0.604 for the 2.165-inch-diameter intake valves and 0.597 for the 1.590-inch exhausts.

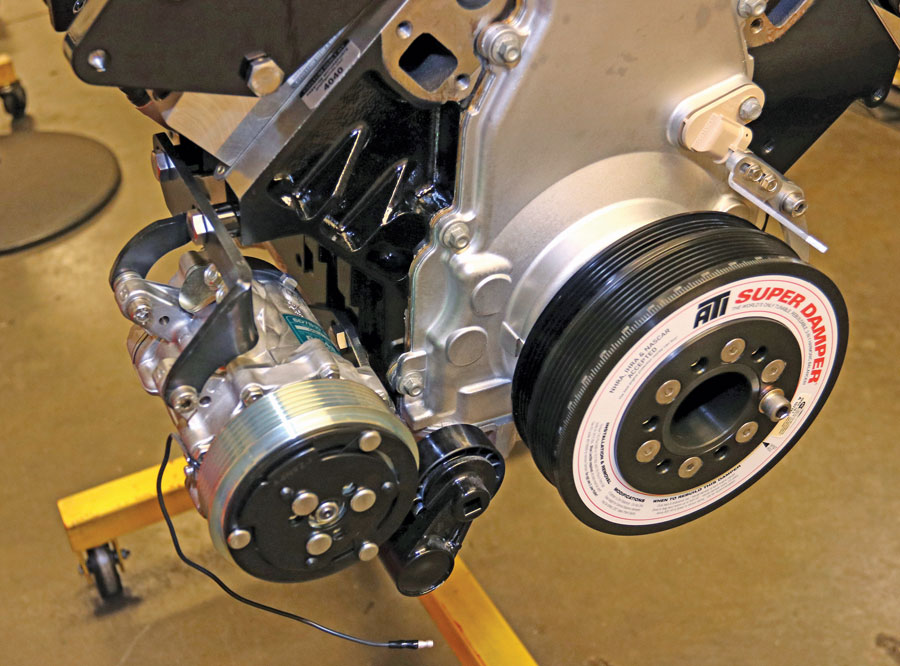

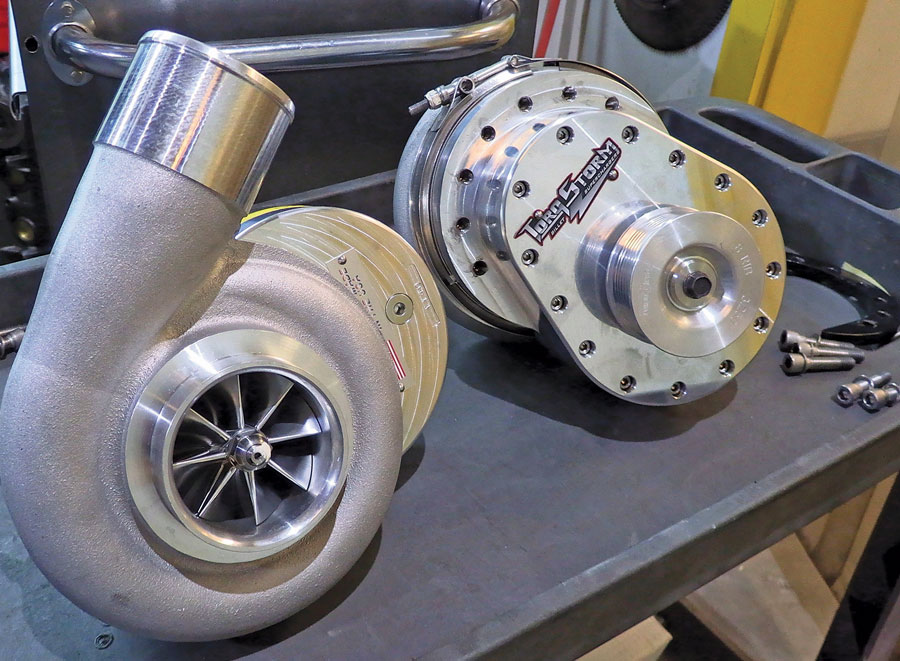

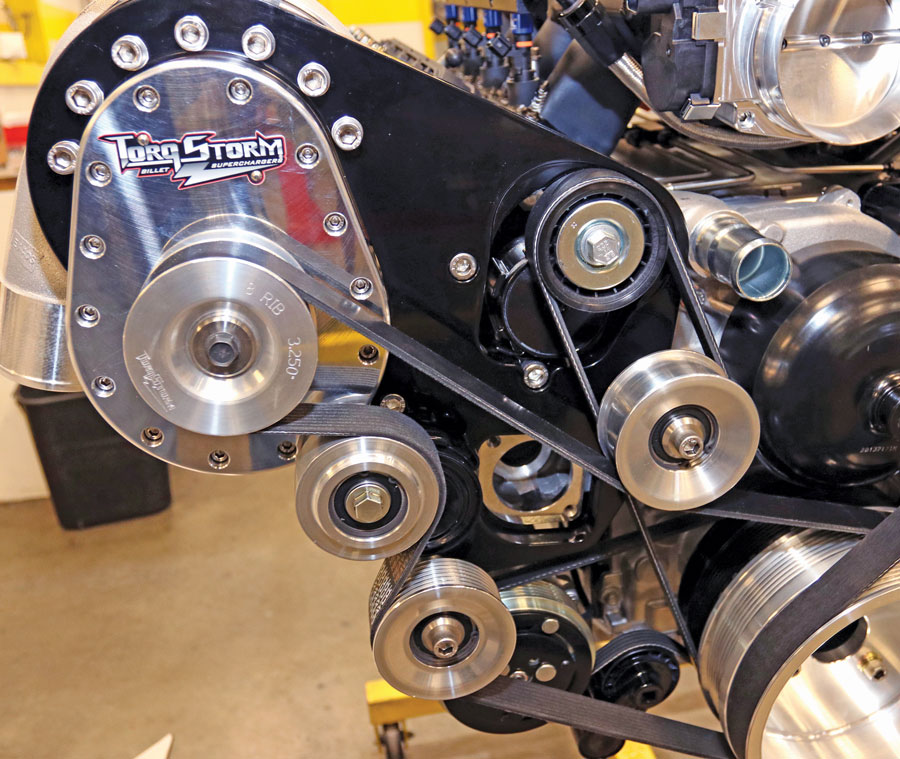

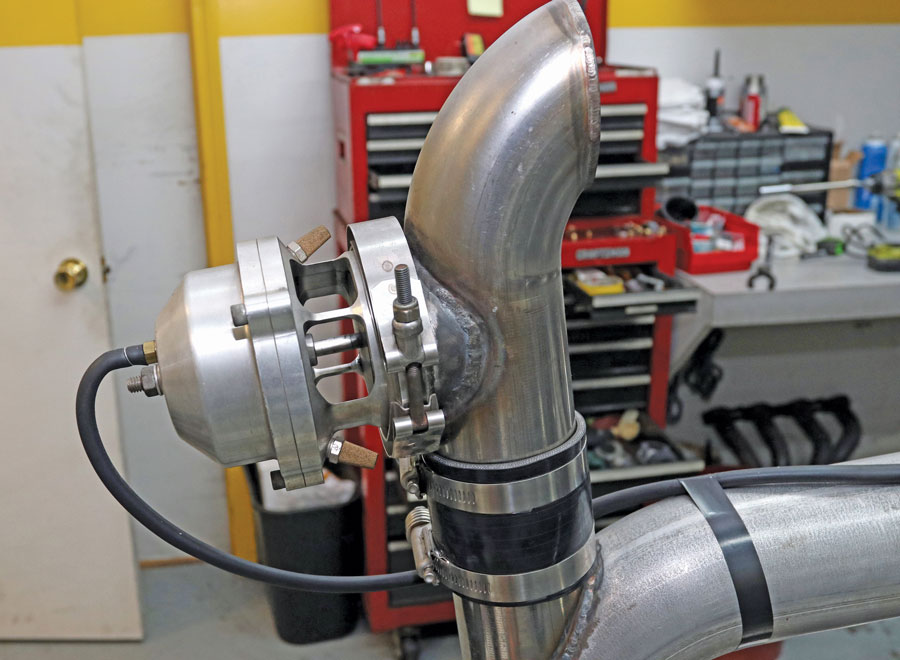

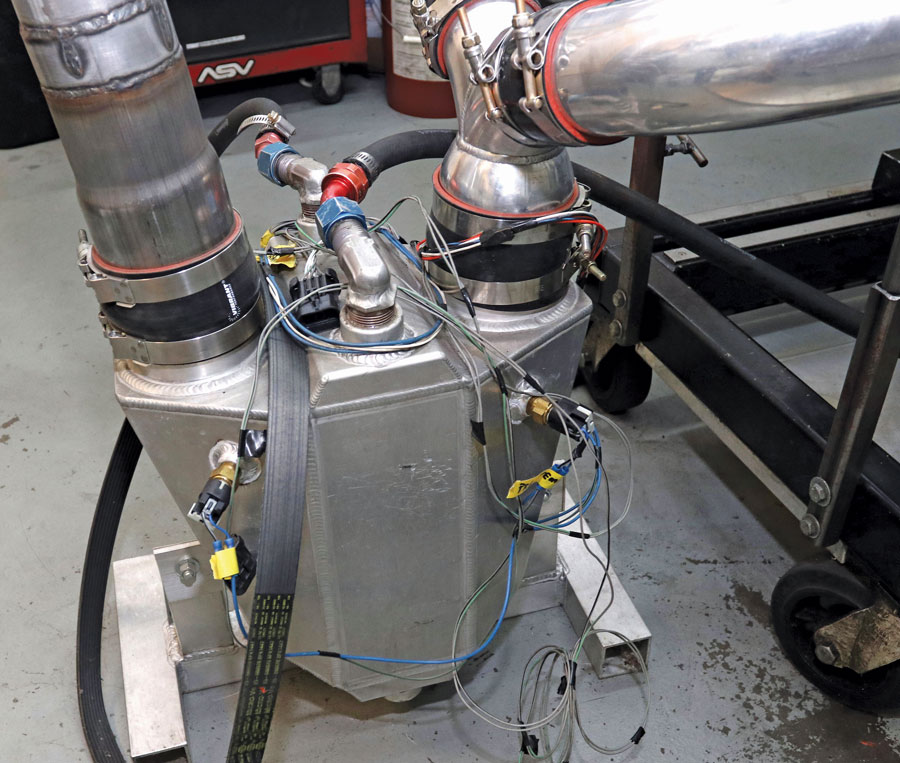

The heart of the system is obviously the twin TorqStorm superchargers. Individually, each can flow 1,250 cfm and support 700 hp. Together, they are rated for over 1,200 hp. They feature self-contained oiling systems, straight-cut gears, ceramic ball bearings, and a 76mm impeller. The rest of the kit is also filled with the good stuff. This is TorqStorm’s 2XR version, so in addition to a pair of blow-off valves, a Sanden A/C compressor, a Type 2 power steering pump, and a Powermaster 165-amp alternator, they also provide a quality ATI damper and eight-rib belt drives to spin the two superchargers.

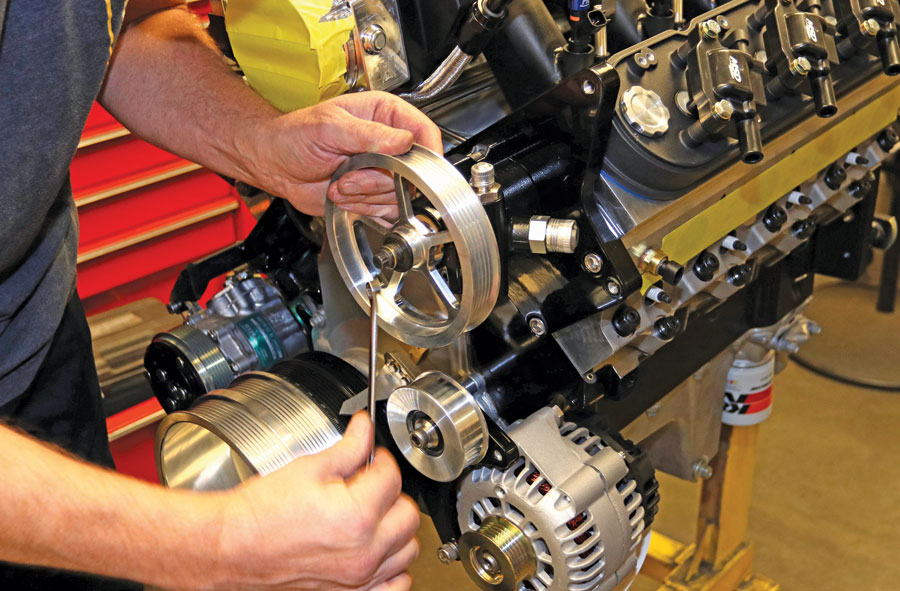

Installing what TorqStorm calls their Twin Charger Kit was straightforward and uneventful. Prestige Motorsports’ lead assembler Larry Broeker simply followed the detailed instructions with the kit. Everything necessary is included except for a water pump.

And before we knew it we were on the engine dyno. The Twin Charger Kit certainly looks impressive mounted up with a centrifugal supercharger on either side of the LS, but looks aren’t the primary objective. We’re here for power, and that’s what we are testing for.

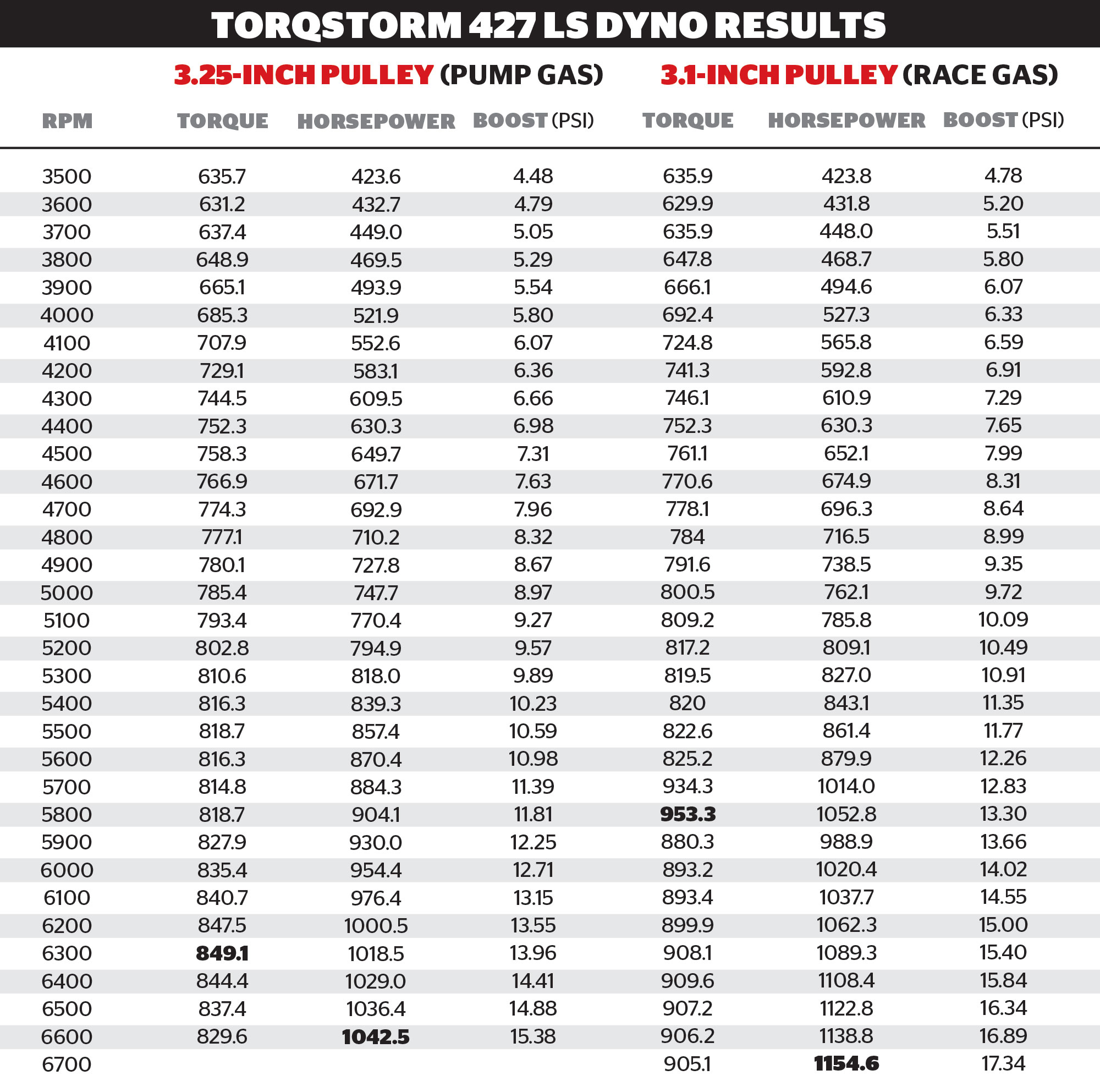

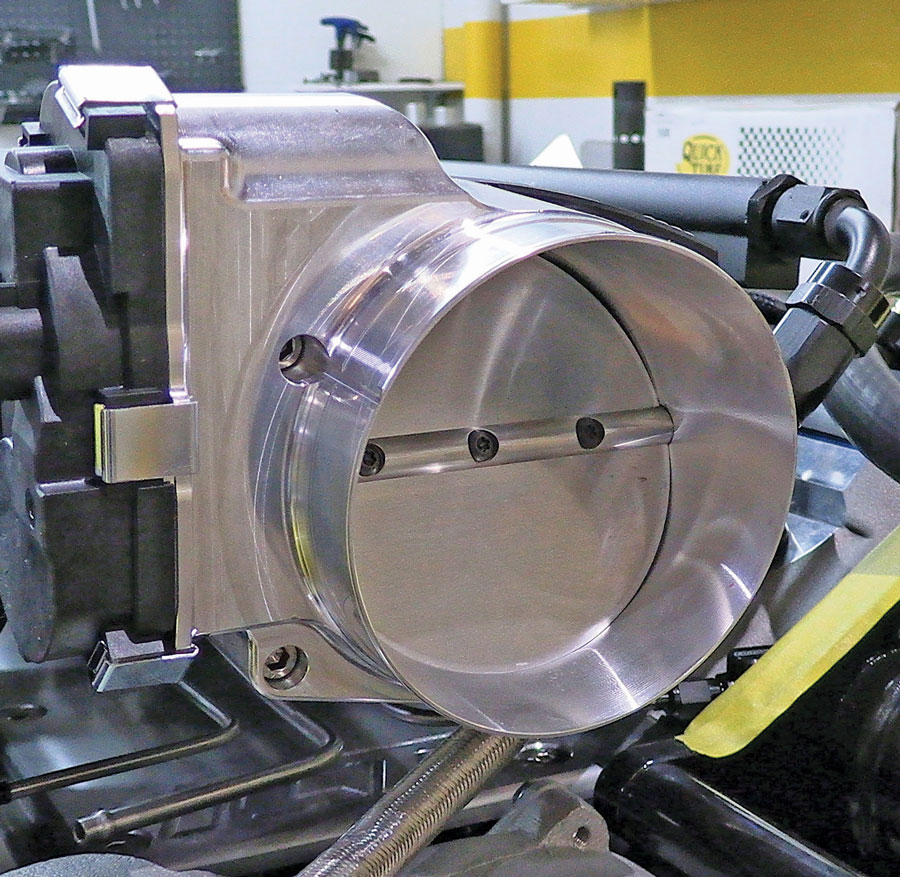

Prestige started out looking for a dependable street tune. So we had the larger 3.250-inch-diameter pulleys installed on the superchargers and 93-octane pump gas in the dyno’s fuel tanks. Prestige used a Holley Terminator X ECU to manage the engine’s systems, and after a few minutes the self-learning system was up to speed, the rings were seated, and we were ready to start making power pulls.

After a few test runs we determined that while on pump gas the engine was happiest with 23 degrees of ignition timing all in. The high-flowing CNC-cut heads wouldn’t show too much boost (boost is a measure of resistance to flow), but we did see 15 pounds at the top of the pull. And the power? A very healthy 849.1 lb-ft at 6,300 rpm and 1,042.5 hp when we pulled the handle at the top of the pull at 6,600 rpm. The engine was still making boost, and there’s no doubt we could have seen more power—both the valvetrains and the superchargers could have handled it—but on pump gas Prestige had already determined to end the pull at this point.

This definitely has the makings of a real street beast. Besides those power peaks, this setup made 635.7 lb-ft of torque when we started the pull at 3,500 rpm and it was still making well over 800 by the time we ended the pull at 6,600. That’s a tire-melter at any rpm or gear just by mashing the fun pedal!

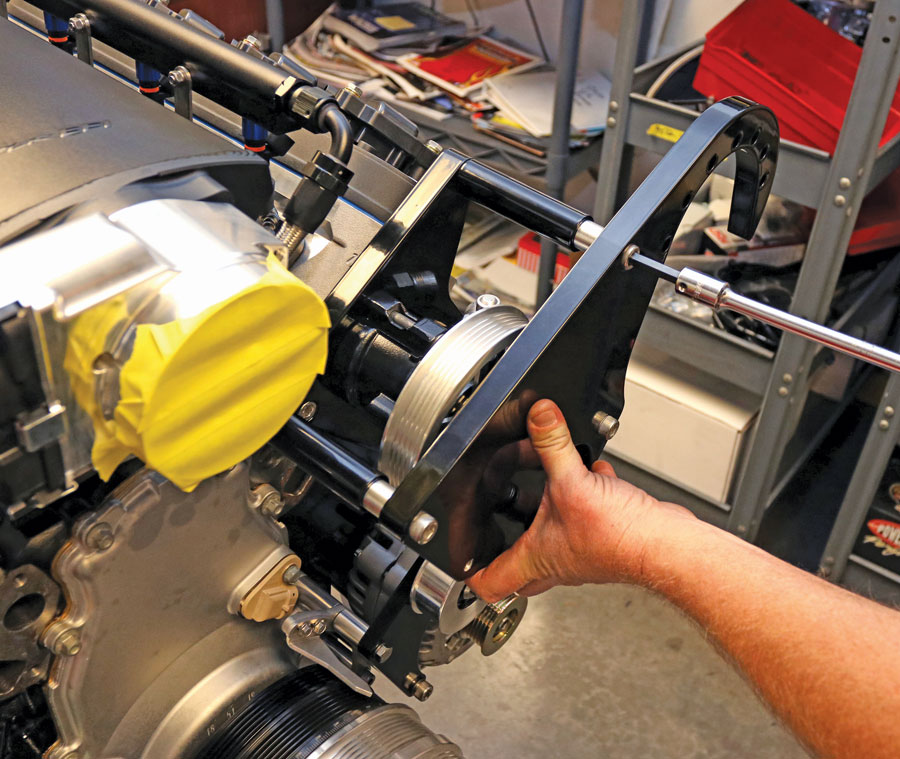

But, of course, we couldn’t leave well enough alone. So Prestige swapped out the 3.25-inch drive pulleys for a pair of smaller, 3.100 inchers. The idea is the smaller pulleys—compared to the main pulley on the crankshaft—will spin the twin superchargers harder, making more boost. To prepare for this we also switched out the pump gas for a few gallons of VP’s C16 race fuel.

This time around the boost jumped up to around 17 pounds, and the power also improved proportionately. This time around we had the torque peak break the 900 mark with 909.6 lb-ft and horsepower went up by approximately 110 with 1,154.6. Once again, we still hadn’t seen the power peak when we pulled this handle, this time at 6,700 rpm.

After seeing the TorqStorm twin supercharger kit in action, we are very impressed. It is important to note that we tested this on a big-inch engine with a great-flowing set of CNC LS3 heads. If this kit is installed on an engine that doesn’t flow air quite as well as, say, an LS1 with cathedral port heads, the boost would be even more beneficial.

Still, any time you can make well over a grand on the horsepower meter while burning pump gas, we call that a win!

SOURCES

SOURCESTorqStorm

(616) 226-9476

torqstorm.com