TECH

TECH

Images by The Author

Images by The Authorhen it comes to casual cruisers or even daily drivers, it’s easy to overlook certain items, especially if there isn’t any noticeable damage. The phrase “out of sight, out of mind” rings true in many situations as long as performance isn’t compromised. In the case of our trusty 1964 Chevelle four-door cruiser, the rear suspension has been trucking along for 60 years without any real maintenance. The coils were cut many years ago to lower the ride height, and we’ve been pleased with the ride quality and stability on the highway, so upgrading the suspension never made it very high on the to-do list.

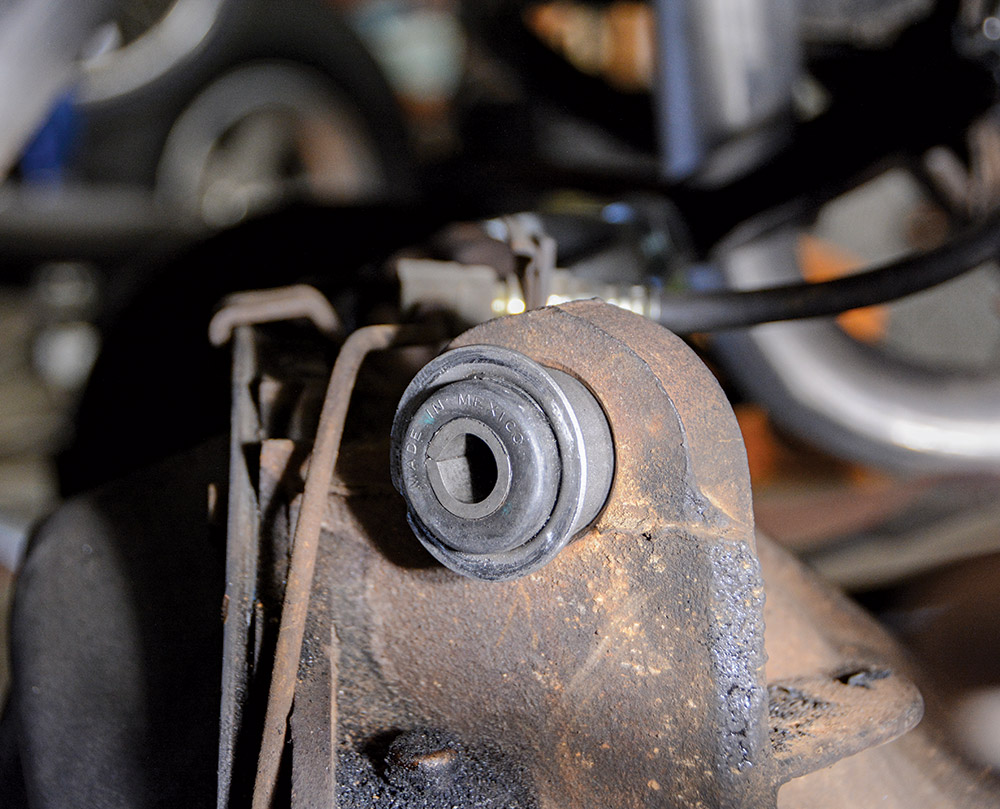

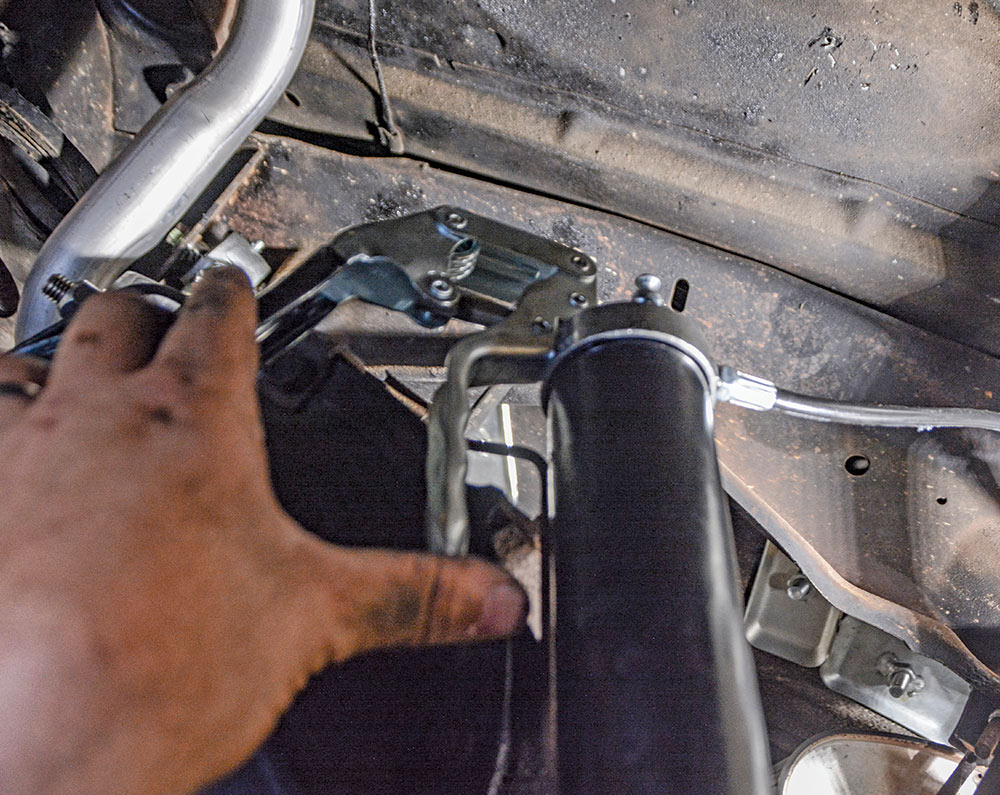

A while back, we decided to upgrade the front of the car with tubular front control arms. Classic Performance Products (CPP) manufactures the kit, so as we browsed classicperform.com we noticed a few options for rear control arms. Knowing that the bushings were likely toast, we thought it would be a practical upgrade to toss the stamped steel control arms in the scrap pile and replace them with tubular units from CPP. We found the appropriate kit (PN PT6467RTCA-KB) and added a pair of CPP Nitrogen Shocks (PN CPP-1007) as an upgrade to our parts store shocks.

We didn’t want to completely remove the rearend housing, so we performed the install using a floor jack and jack stands in the garage floor. If we wanted to take the install to the next level, we could’ve disconnected the driveshaft and the flexible brake hose to roll the rearend out into the open. Instead, we swapped one control arm at a time, which made for a very simple install.

Overall, we spent a weekend in the shop and used general hand tools to get the job done. Now that it’s back on the ground, we noticed a huge difference in ride quality, as the new bushings offer smooth and quiet operation. Like many of our installs on this 1964 Chevelle, it’s all about practicality, so a weekend project that made a noticeable difference is always rewarding.

Follow along to see how we tackled the CPP triangulated four-link rear suspension install, as the same tactics can be used for any 1964-1972 General Motors A-body car.

SOURCES

SOURCES