TECH

TECH

Images Courtesy of Roadster Shop

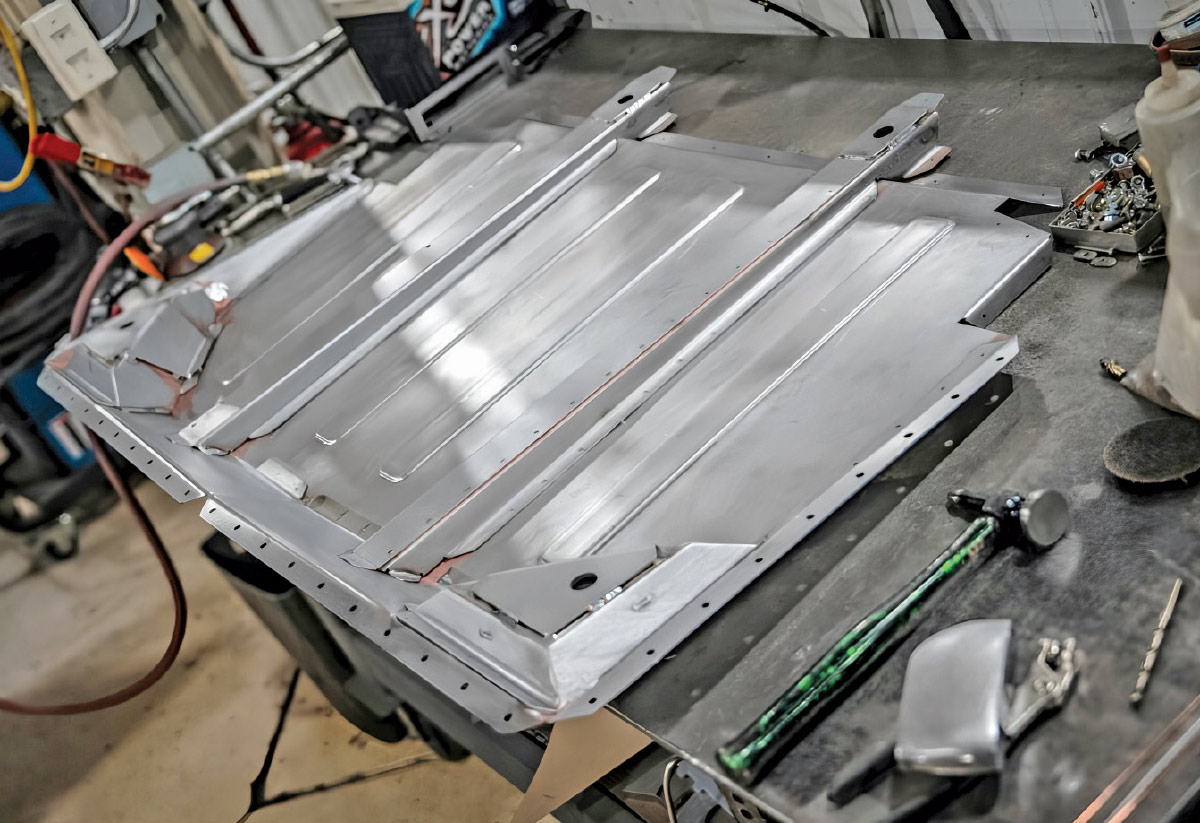

Images Courtesy of Roadster Shopn this article, we’re looking at a 1968 Camaro being built at Roadster Shop. As is typical for a high-end build like this, they started with the best-quality donor vehicle that could be found. After fitting the Camaro body onto one of their Fast Track chassis, they did a complete scan of the body, and Mike O’Brien, the lead engineer at Roadster Shop, carefully designed a new floor to fit over the chassis, which kicks up in the rear to clear the independent rear suspension system.

Doing this work in CAD has many advantages. It was a straightforward process to determine the dimensions and shapes for all the panels, and to pinpoint the location of each reinforcing rib in the floor panels. All Roadster Shop chassis are CAD-designed, so that data was called into play to help design the floor, so it fits neatly to both the body and chassis in every critical area.

This digital information was also used to laser-cut guideplates to use on the Pullmax machine to precisely locate and form each rib. Some of the body mounts are located on the new floor, and these areas were heavily reinforced to provide the necessary strength.

An arched crossmember was placed in the chassis just ahead of the independent rear suspension, so an extension was attached to the new floor panel to clear it.

The rear wheelwells were enlarged to accept the wheels and tires selected for this car. Since aftermarket quarter-panels will be installed on this car, the original quarters were removed to provide access for working in this area.

Extra clearance was needed for the shifter on the transmission, so a new sheetmetal construction was added to the top of the original transmission hump. This was CAD designed, laser cut, precision formed, and carefully TIG welded into place.

A new, smooth firewall was fabricated from heavy-gauge sheetmetal and was fitted to the cowl. This will give the car a much cleaner look when the hood is open.

Lots more work is planned for this project, and next time we’ll look at how the wheelwell flares were designed and fitted to match the new wheels and tires. You may be surprised to see all the steps involved in this job, where lots of effort was expended to achieve a particular look.

SOURCE

SOURCE