Bumper Tuck

Fresh Floors & Custom Firewall

TOC

TOC

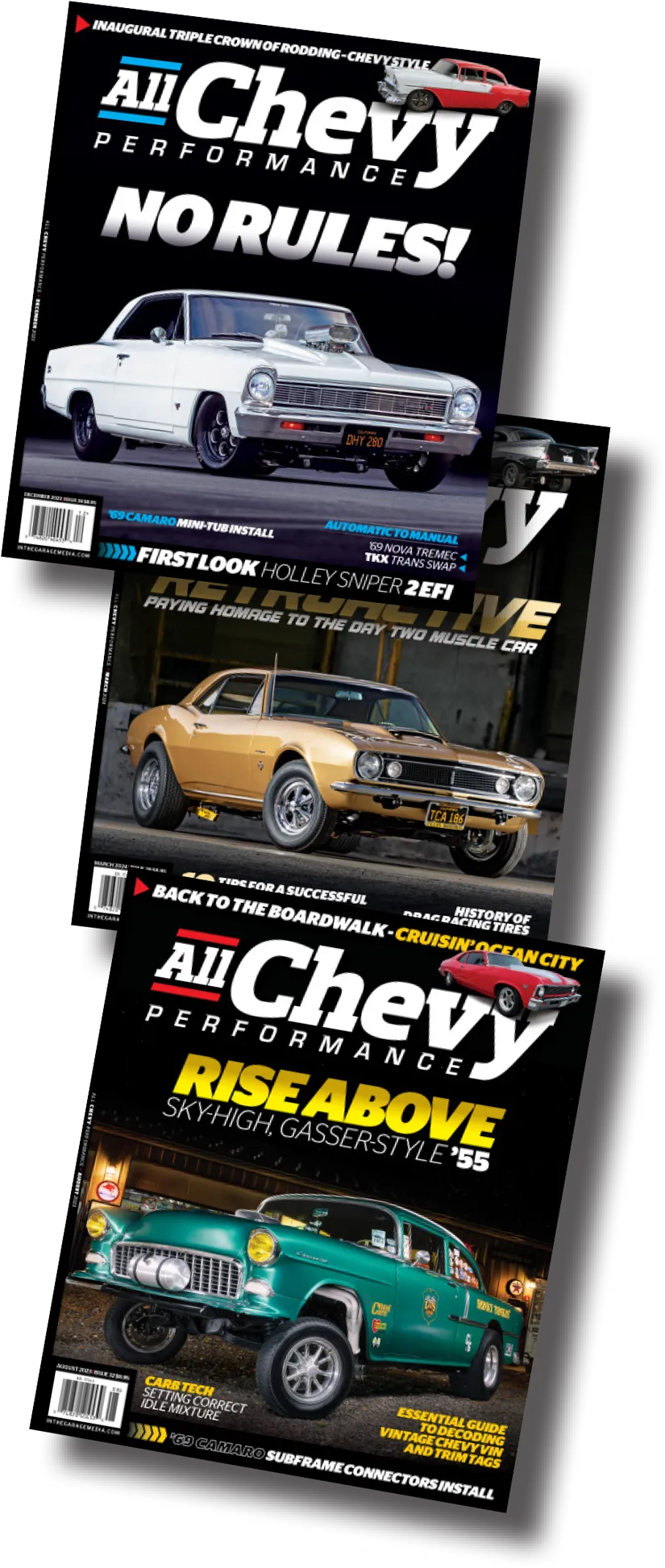

Cover image by Fuelish Media.

Wes Allison, “Rotten” Rodney Bauman, Shawn Brereton, Tommy Lee Byrd, Ron Ceridono, Grant Cox, John Gilbert, Tavis Highlander, Jeff Huneycutt, Barry Kluczyk, Scotty Lachenauer, Jason Lubken, John Machaqueiro, Ryan Manson, Jason Matthew, Josh Mishler, NotStock Photography, Todd Ryden, Jason Scudellari, Jeff Smith, Tim Sutton, Wes Taylor, and Chuck Vranas – Writers and Photographers

Travis Weeks Advertising Sales Manager

Patrick Walsh Sales Representative

ads@inthegaragemedia.com

AllChevyPerformance.com

ClassicTruckPerformance.com

ModernRodding.com

InTheGarageMedia.com

inthegaragemedia.com “Online Store”

For bulk back issues of 10 copies or more, contact store@inthegaragemedia.com

info@inthegaragemedia.com

Editorial contributions are welcomed but editors recommend that contributors query first. Contribution inquiries should first be emailed to info@inthegaragemedia.com. Do not mail via USPS as we assume no responsibility for loss or damage thereto. IN THE GARAGE MEDIA, INC. reserves the right to use material at its discretion, and we reserve the right to edit material to meet our requirements. Upon publication, payment will be made at our current rate, and that said, payment will cover author’s and contributor’s rights of the contribution. Contributors’ act of emailing contribution shall constitute and express warranty that material is original and no infringement on the rights of others.

Copyright (c) 2025 IN THE GARAGE MEDIA, INC.

PRINTED IN U.S.A.

Cleveland, OH

(216) 281-8777

firing up

firing up

BY NICK LICATA

BY NICK LICATA

t’s been said “imitation is the sincerest form of flattery,” and when we borrow certain aspects of a car we’d like to tie into our own build, many of us tend to reach back to a certain car that impacted our lives at a young age. We then take that image and combine it with a car we’ve seen more recently, then integrate those ideas into a build that is likely to have a look and style all its own. Typically, no one would be inclined to build a car exactly like someone else’s, unless said build is paying homage to a historical vehicle, such as a Yenko Camaro or Grand Sport Corvette, built with the exact color, stripes, and graphics, while utilizing period-correct or similar wheels and tires with the intentions of making the car look as close to the original as possible. Beyond that, it’s rare to come across two cars of the same model and year with exact features. While some cars might look familiar, most custom restomods feature a design that’s uniquely tailored to the owner’s personal taste and vision.

Back in the ’60s and early ’70s wheel options were limited, which meant many hot rods and muscle cars had a similar look, one that many builders today use as a template due to its timeless hot rod look. But during the ’80s, ’90s, and early ’00s, build style and especially wheels went through, let’s say, a series of “trendy” or “experimental” phases—many of which were tasteless and simply unattractive.

As time moved on, wheels gradually got larger in diameter and 18-inchers became the norm, but not everyone was on board. Old-school hot rodders refused to conform to using these “massive,” modern-size wheels, but eventually even the most hardcore vintage muscle car guys came around and warmed up to the idea of using 18-, 19-, and even 20-inch wheels. With the right design and proper fitment between the fenders and quarter-panels, big rollers give even the most docile hot rod a more aggressive demeanor. Yes, we can agree to disagree on this.

PARTS BIN

PARTS BIN

CHEVY CONCEPTS

CHEVY CONCEPTSInTheGarageMedia.com

Text & Rendering by Tavis Highlander

Text & Rendering by Tavis Highlander

olor, stance, and wheels hit hard from a long distance on this 1967 Corvette. Smooth, extended rocker skirts match up with a new front lower fascia to create a more hunkered-down appearance. Out back you’ll find a custom rear valance with integrated exhaust tips. Both front and rear bumpers have been heavily tucked in and shaped to fit the body. The rear bumpers have been especially reshaped from stock with only horizontal elements remaining. The factory fender gills have been replaced with a small vent and polished trim. Around the car you’ll find that polished bits of trim have been retained or created to add some elegance to the car. Dark Jade Green metallic paint definitely highlights all that brightwork.

FEATURE

FEATURE

Images by THE AUTHOR

Images by THE AUTHORave you ever heard someone say, “I’m going to build my dream car someday”? Of course you have—we’ve all heard and even said it before. The real question is, how many of these folks (ourselves included) have lived up to that statement? Most of us can locate and buy the model vehicle we want, only to spend an entire lifetime slowly chipping away at achieving the dream. Very few people actually build these “dream vehicles” up to world-class status—but when they do, it sure is a sight to behold.

Jeremiah Belk of Spring, Texas, has always been a fan of the second-gen Nova. It wasn’t until he had the means to build a car worth bragging about that he was able to forge ahead on his journey. “I was inspired by my late Uncle Bryan,” Jeremiah says. “He had a 1966 Chevelle that I grew up working on and playing with, so I naturally fell in love with Chevrolet muscle cars.”

TECH

TECH

Images BY THE AUTHOR

Images BY THE AUTHORumpers are not something typically high on the build priority list, but if you’re building any kind of custom or street machine, or even a hot rod, you really need the bumpers tucked to fit perfectly and certainly tighter than factory.

Recently, while touring Mick’s Paint in Pomona, California, we came across Jeff Pont’s 1969 Camaro that was undergoing a complete makeover from front to rear bumper. Now, Pont’s a detail guy so he likes things to fit, and fit better ’n’ factory, and the stock bumpers were just not cutting it. Stepping up to the task was Pauly Rivera, Mick’s crafty fabricator, to make the factory bumpers fit, well, like they should have from the factory with no visible fasteners. In this case, the bumpers were eventually to be painted body color and not chrome plated. Were they to have been chromed, then a whole lot more finish work would have been necessary.

FEATURE

FEATUREBy Fuelish Media  Images by THE AUTHOR

Images by THE AUTHOR

By Fuelish Media  Images by THE AUTHOR

Images by THE AUTHOR

hen it comes to building a specialized vehicle designed to go fast and handle like a dream, a unique set of skills is required. A builder must not only be able to gather the right group of components to get the job done but also know how to fine-tune them to create a harmoniously functioning machine. What can’t be bought must be made, and what doesn’t fit must be strategically formed to put all the pieces together.

Rob Lindsay is one such custom vehicle builder who knows how to assemble a custom and capable automobile, and he understands what it takes to make it perform at the highest level possible. While Rob is well-versed in fabricating high-end off-road prerunner chassis systems, he can also get down in the performance and race arena, too. Naturally, he dabbles in the world of Pro Touring muscle cars as well, which is why we are all gathered here today.

TECH

TECHSpark Plug Fundamentals

There’s More to These Simple Components Than Lighting a Fire

Images by THE AUTHOR

Images by THE AUTHORhe spark plug is the one component that has been shared by every spark-ignited internal combustion engine since the earliest days. Oddly, the engine that powered the first Wright Brothers airplane was gasoline-fueled but did not use spark plugs. Instead, the engine builder, Charlie Taylor, employed a set of contact points located in the “T”-style cylinder head to create a spark. But for the rest of the automotive world, the spark plug has been in existence in one form or another since the 1860s.

Today, spark plugs have become smaller, more efficient, and now in modern electronically fuel-injected street engines can perform admirably for 100,000 miles or more. But what happens when we build a performance engine like a small- or big-block Chevy or an LS/LT engine with compression, a bigger camshaft, and better cylinder heads? Selecting the proper spark plug becomes a critical process, which is what we will address in this story.

The first step would be to identify the proper construction of the spark plug for your application. This starts by identifying the plug’s basic configuration. The first issue is what the spark plug manufacturers call thread reach. This is the length of the threaded portion of the spark plug where it engages the cylinder head.

FEATURE

FEATURE Images by THE AUTHOR

Images by THE AUTHOR

hen we think back on our high school days, there are always a ton of great memories and stories. The older we get and the further we are from that time in our lives, the more we are reminded of the good times. For Glenn Arledge of Columbus, South Carolina, a lot of those teenage years revolved around a 1968 Camaro RS. From cruising with friends to date nights, that car was always a big part of his life. Glenn bought the car when he was 15 years old from a neighbor who was a big Camaro guy, so Glenn was always over at his house admiring his car collection. It took about two years of begging before the owner would let it go. Knowing how much of a fan of the car Glenn was, he knew it would go to a good home. The factory 396 big-block and the Rally Sport hideaway headlights were what got Glenn’s attention. “My father loaned me $3,500 to purchase the car and I very slowly paid him back,” Glenn says. “It was 1986 and gas ran through that car quick, and even at 78 cents per gallon, most of my money went to fuel and tires.

“My fondest memories with this car were driving it every day to high school for three years, winning races on weekends to buy more fuel, and getting in trouble for running seven laps with it at the Charlotte Motor Speedway without permission,” Glenn laughingly recounts. “I continued to use the car as a daily driver all throughout my college years at UNCC and Clemson. Luckily, I never wrecked it.”

TECH

TECH

Images by THE AUTHOR

Images by THE AUTHORne of the most important areas of any high-performance ride always leads to the business office, which serves as the hub for monitoring the car’s vitals as well as maintaining its full operational control while also providing plenty of comfort for the occupants. Regardless of whether you’re taking on a full build or simply making updates, it’s a solid idea to think about upgrading your interior components, especially if you’re choosing to up the ante in the horsepower department of your classic Chevy. This can be as simple as opting to add a more-efficient gauge package or replacing a torn dashpad to more involved updates, like adding a new air conditioning system.

Many regular readers of All Chevy Performance will recognize the 1971 Camaro showcased across our pages, having followed its transformation from that of a stripped-out shell. As time has passed, we’ve focused on its suspension, brakes, LS driveline, cooling, exhaust, sheetmetal, wiring, and insulation. Looking deep into the bare interior, it’s time to focus on bringing it back to life with plenty of industry-leading technology to support the newly updated thunder of a 5.3L LC9 LS underhood. We recently followed up at Procision Industries in Taunton, Massachusetts, where shop owner, Pat O’Brien was preparing to move forward by taking on this very subject.

FEATURE

FEATURE

Images by Chadly Johnson

Images by Chadly Johnsonack in 2005 Domenic Ruffatto and his business partner came across a couple of barn-find Corvettes in Kentucky—one a ’67 and the other a ’59. Domenic mentions there were about 25 other Corvettes stored there, but he was interested in the ’59 over all the others, as he preferred collecting cars from the year he was born.

“When I bought the ’59, it was a mess, and not much to look at,” Domenic recalls. “The body was beat up, the interior was missing, the chassis was rusty, and the car barely rolled. The engine and transmission didn’t match, so they weren’t worth keeping. But the hard top was there, and that was something.”

TECH

TECH

Images Courtesy of Roadster Shop

Images Courtesy of Roadster Shopn this article, we’re looking at a 1968 Camaro being built at Roadster Shop. As is typical for a high-end build like this, they started with the best-quality donor vehicle that could be found. After fitting the Camaro body onto one of their Fast Track chassis, they did a complete scan of the body, and Mike O’Brien, the lead engineer at Roadster Shop, carefully designed a new floor to fit over the chassis, which kicks up in the rear to clear the independent rear suspension system.

Doing this work in CAD has many advantages. It was a straightforward process to determine the dimensions and shapes for all the panels, and to pinpoint the location of each reinforcing rib in the floor panels. All Roadster Shop chassis are CAD-designed, so that data was called into play to help design the floor, so it fits neatly to both the body and chassis in every critical area.

This digital information was also used to laser-cut guideplates to use on the Pullmax machine to precisely locate and form each rib. Some of the body mounts are located on the new floor, and these areas were heavily reinforced to provide the necessary strength.

FEATURE

FEATURE

Images by THE AUTHOR

Images by THE AUTHORhe time it takes to complete a world-class vehicle is rarely predictable. Goals evolve, technology advances, and costs rise. Mike House knows this well. A retired firefighter from Minnesota now living in Jacksonville, Florida, Mike has been a car enthusiast since his teenage years. His passion for Novas led to his latest build—a stunning 1968 Nova.

Purchased in New Mexico, every panel and body part is original except for the custom cowl induction hood. Once in his garage, the car was completely disassembled, marking the start of an ambitious Pro Touring build.

Mike began the project in 2008 with a vision to create a unique car that departed from the typical Pro Touring mold. Knowing the Nova’s unibody lacked rigidity, his first task was reinforcing the structure. He welded 2×3 rectangular steel tubing into the rocker panels from wheelwell to wheelwell, then added crossmembers for strength. Additional 1.5-inch round tubing connected the new chassis to the Detroit Speed & Engineering front subframe. Mini-tubs, custom inner fenders, a new radiator core support, and a flat trunk floor solidified the foundation.

EVENT

EVENT

Images by The Author

Images by The Author

ome car shows simply can’t be contained by barriers, and the Pigeon Forge Rod Run is a prime example. This event occurs twice a year, with a Spring event in April and a Fall event in September, and it’s always packed with hot rods, muscle cars, and wild Pro Street combinations. The show itself is held at the LeConte Center, a beautiful convention center, nestled in the foothills of the Smoky Mountains. It features a great selection of customized cars and trucks, as well as a huge turnout of vendors and special attractions. It features indoor and outdoor areas and is always well attended.

Even though the show is popular, the real “wow” factor typically comes from the miles of cars lining the streets of Pigeon Forge. This town is set up nicely for cruising, but the traffic gets thick on Saturday, so most folks cruise earlier in the week. The show starts on Thursday, and many people arrive days in advance to get things started and enjoy the lowkey atmosphere before the masses roll into town. Thousands of cars fill every local parking lot, and all of the hotels are lined with cool cars, making it quite a spectacle as you work your way through town.

Advertiser

- American Autowire31

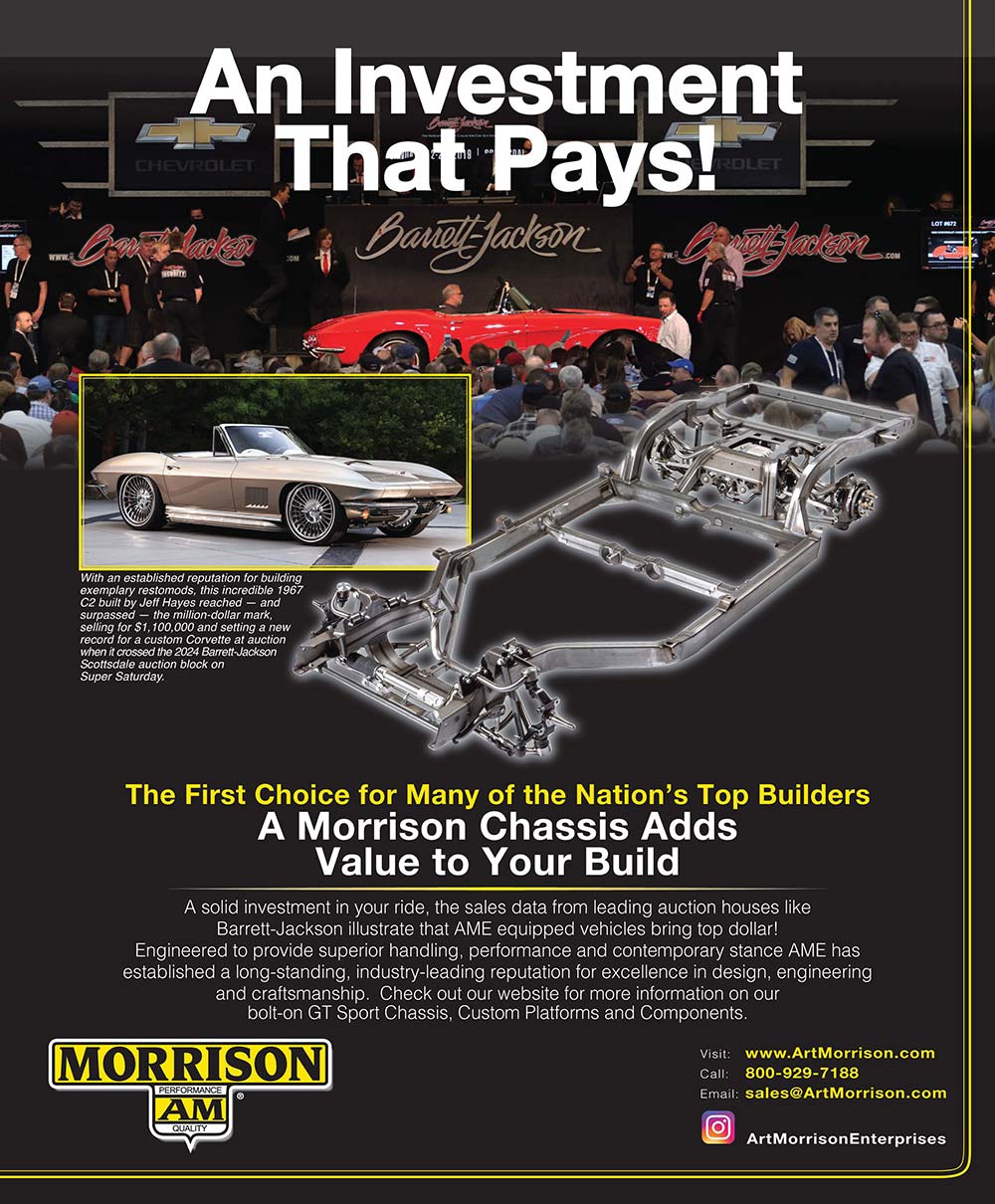

- Art Morrison Enterprises11

- Auto Metal Direct39

- Automotive Racing Products9

- Borgeson Universal Co.27

- Classic Industries13

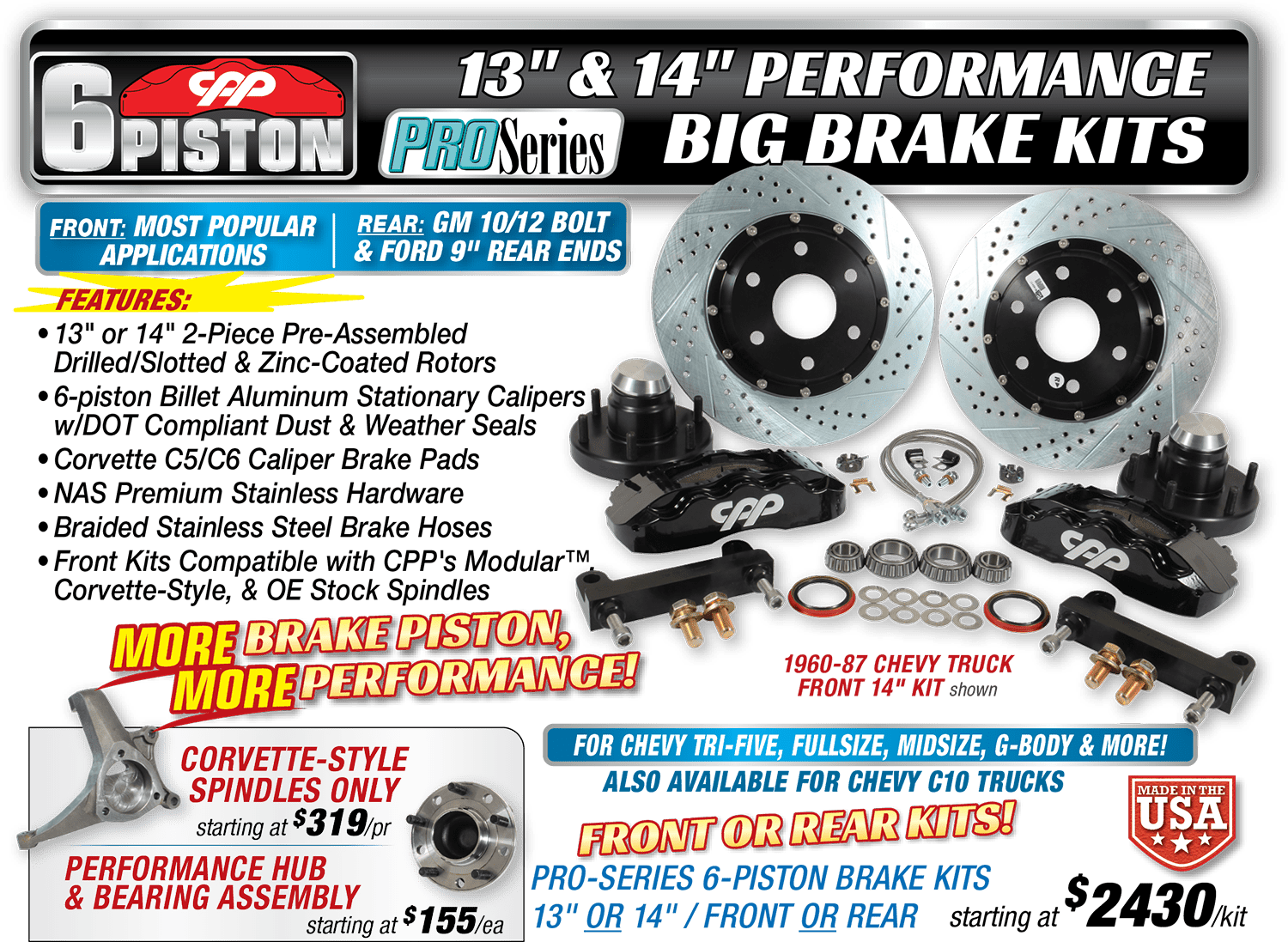

- Classic Performance Products4-5, 89, 92

- Dakota Digital91

- FiTech EFI61

- Forgeline Motorsports59

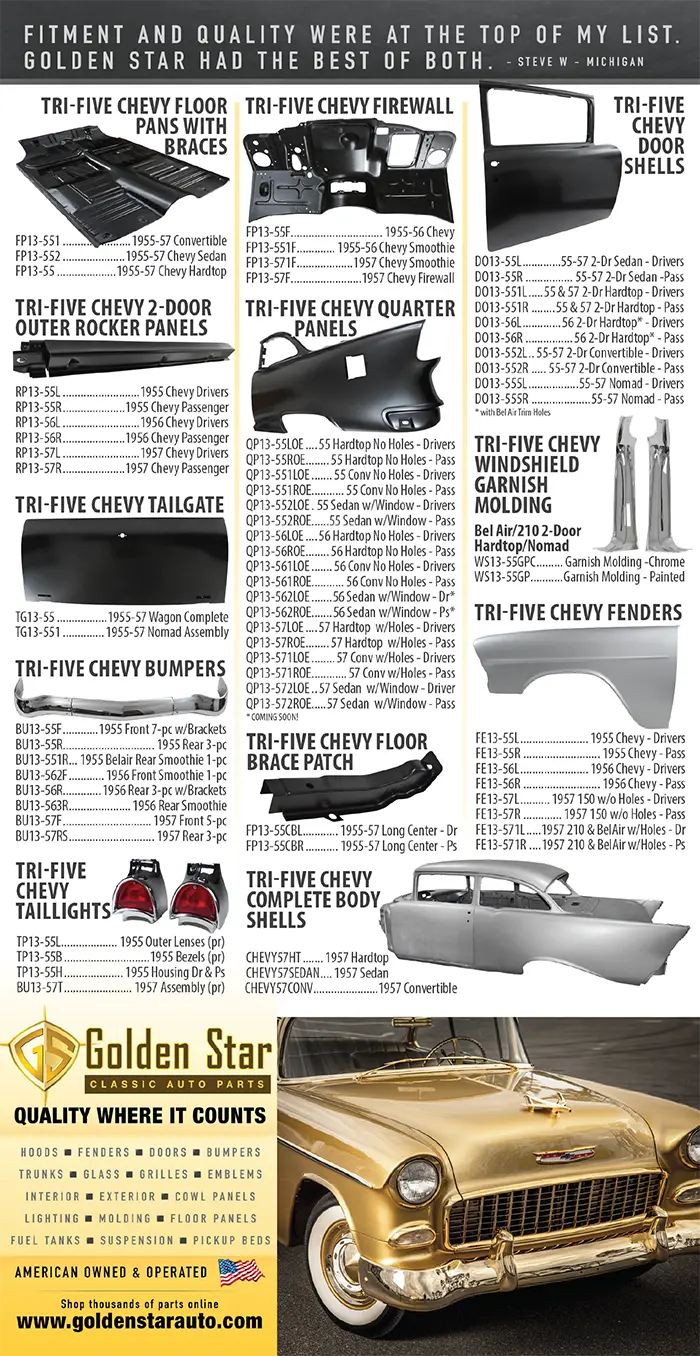

- Golden Star Classic Autoparts7

- Goodguys Rod & Custom Association57

- Granatelli Motor Sports, Inc.63

- Heidts Suspension Systems77

- Lokar2

- National Street Rod Association47

- Powermaster Performance69

- Scott’s Hotrods69

- Specialty Auto Parts USA, Inc.63

- Speedtech Performance USA61

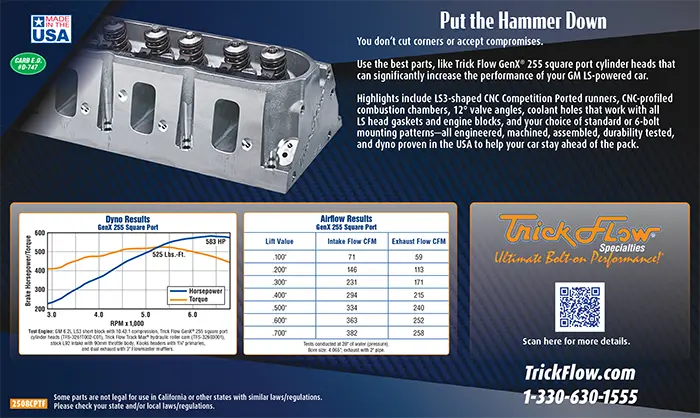

- Trick Flow Specialties59

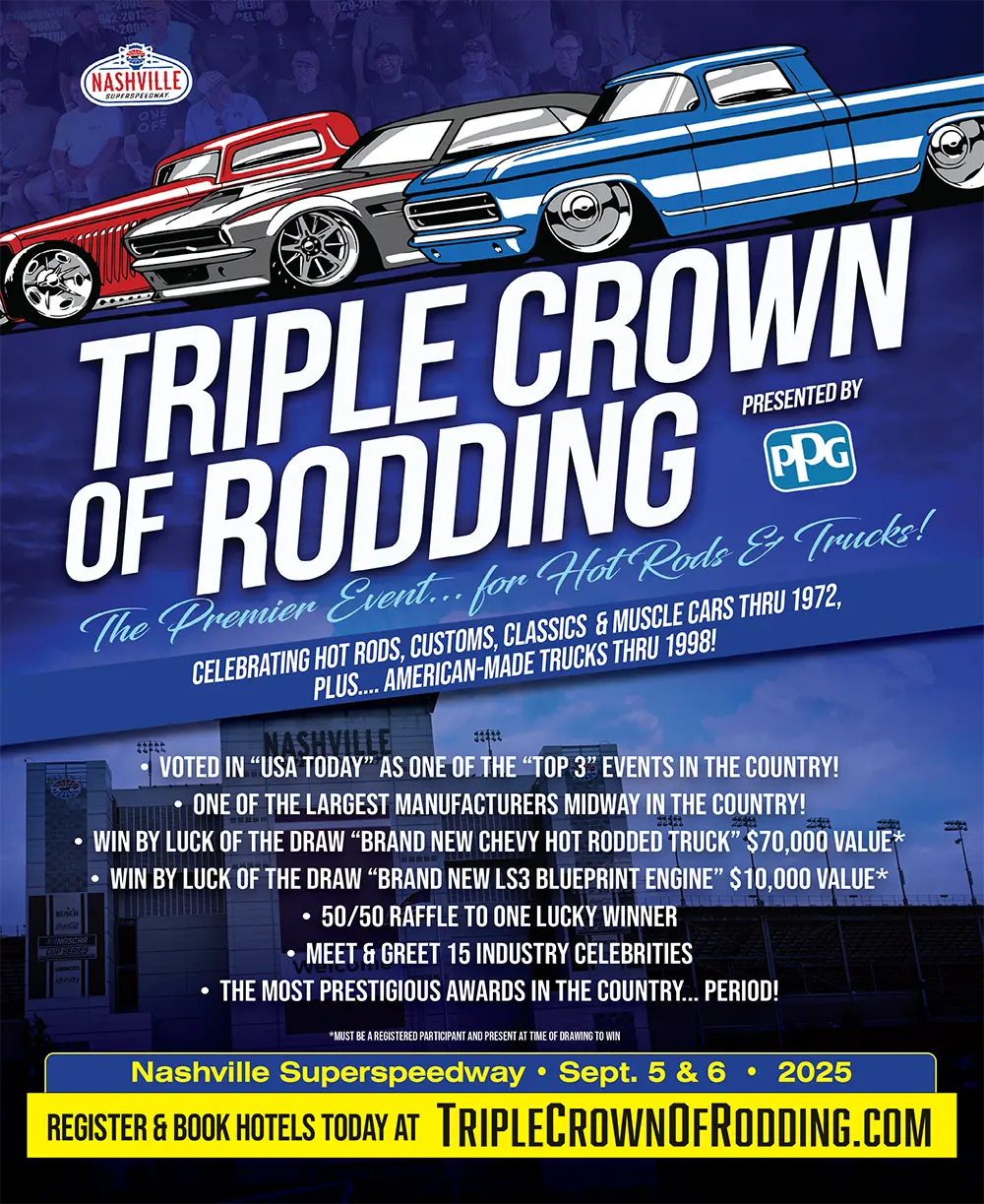

- Triple Crown of Rodding, LLC45

- Tuff Stuff Performance Accessories89

- Vintage Air6

- Wilwood Engineering29