TECH

TECH

Images BY

Images BY he whole point of turning wrenches on your own car is to experience the satisfaction of getting behind the wheel of a car or truck you had a hand in building. Admittedly, sometimes we all do it because a buck must be stretched, and if we didn’t do it ourselves it wouldn’t get done at all. Sometimes we do it because there are no options in the marketplace that match what we’re trying to build. But even when both of those things are true, for most of us just getting into the shop and spending some time working with our hands is pure therapy.

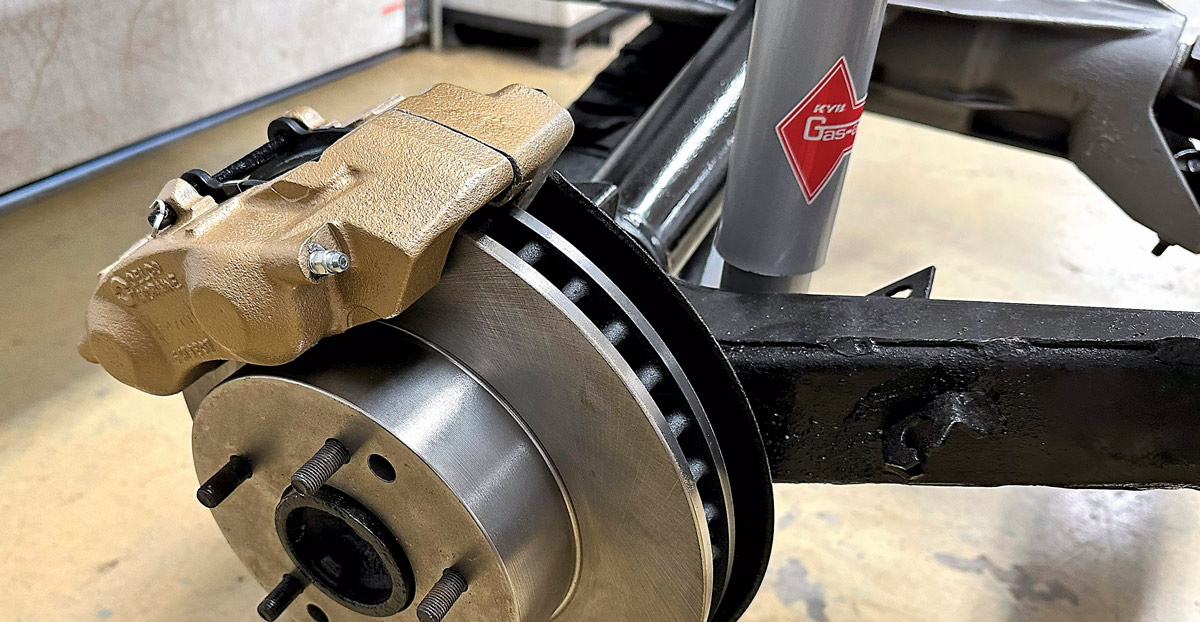

That’s why we’re taking you along on this little misadventure. The project at hand is a basket case ’80 Corvette that is going back together slowly. Eventually, we plan to bolt up a quality big-brake kit with stopping power like hitting a brick wall. But for now, we’re just trying to get the stupid thing back together and moving under its own power. Every nut and bolt has to be touched, so going top-shelf with every component as the car goes back together would cause the credit card to go nuclear. So, a little common sense had to be applied.

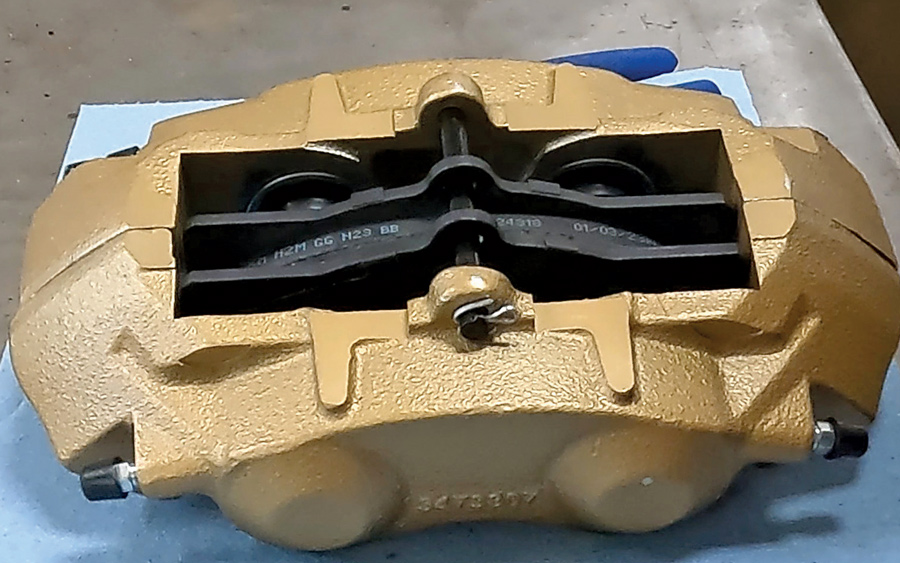

As many Chevrolet fans will note, there are plenty of faults when it comes to the C3 Corvette. Poor power levels, rattly interior components, vacuum lines out the wazoo—you name it. But one area where Chevrolet’s engineers got things right is the brakes. Granted, you won’t find them on any cars at Le Mans, but we’re talking pretty good for the time. Disc brakes all around, beefy rotors, and four-piston calipers at all four corners.

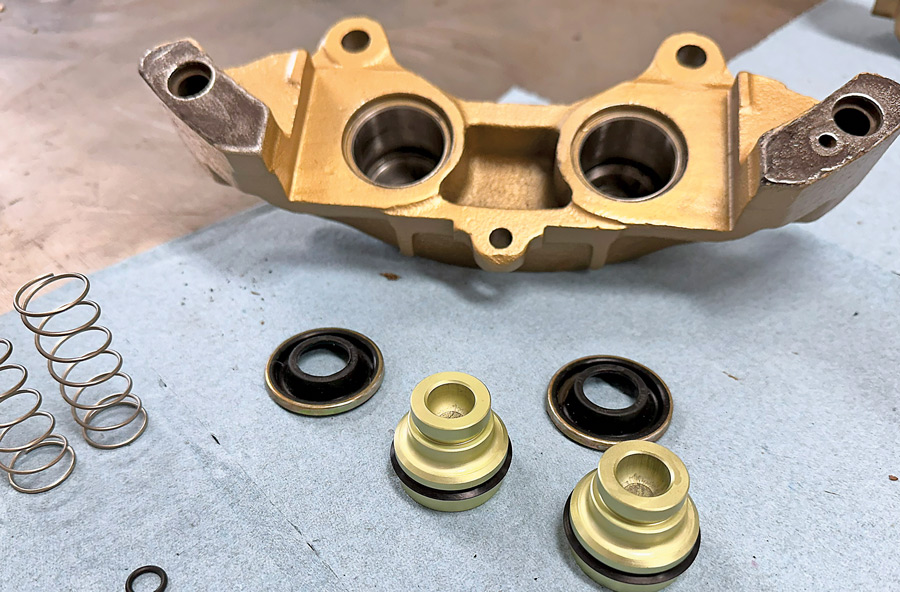

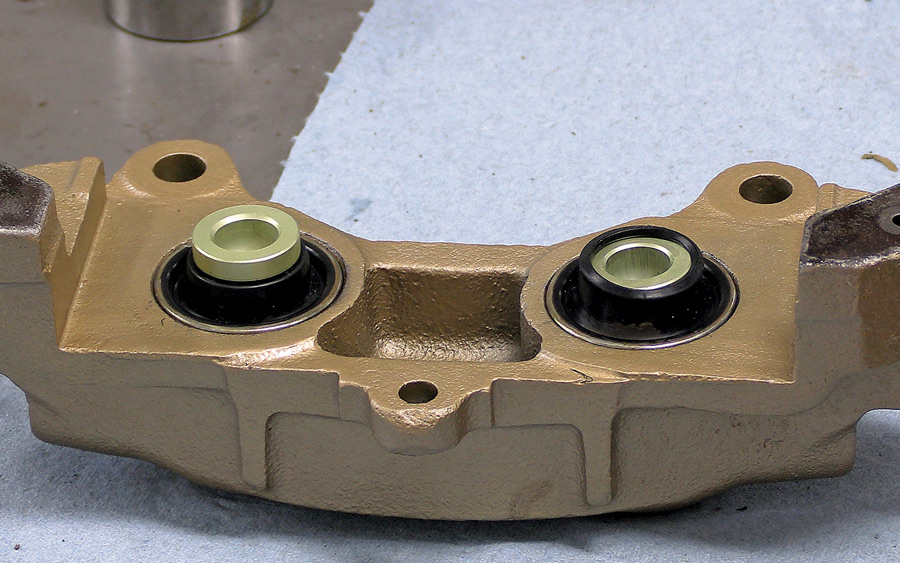

So, we decided to spend a weekend rehabbing the brake calipers on our Corvette to bring them back to their former glory. They looked pretty far gone, but fortunately the Corvette calipers have stainless steel liners. While the rust on the castings looked pretty severe, the critical liners in the piston bores were still in pretty good shape. The rotors, however, were too far gone and were added to the metal recycling pile.

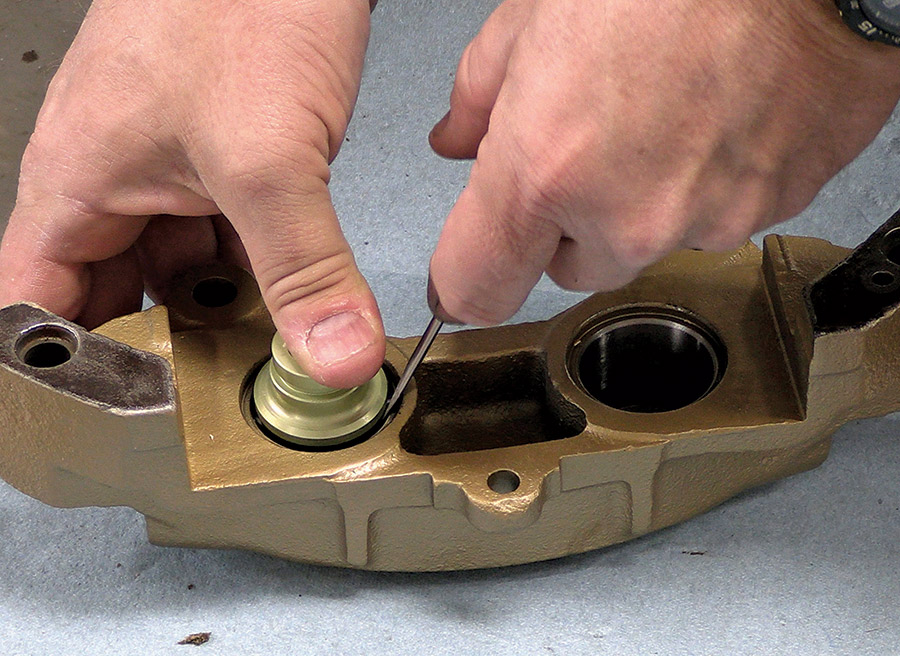

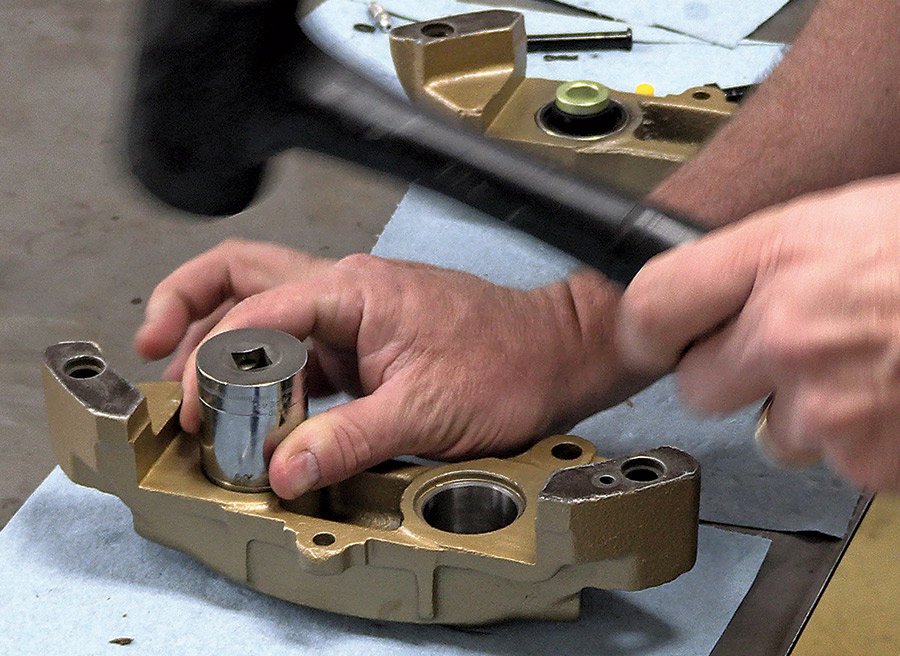

Tag along as we take you through the process of rehabbing these rotors. All the new components you see used here can be found either online at a company called Zip Corvette or any of the local auto parts chains. We also learned some tough lessons along the way, which we’ll be sharing. Even though Chevrolet never put too many four-piston calipers on their other cars and trucks, there is still plenty that can apply to the single-pot floating calipers that GM put on practically everything else.

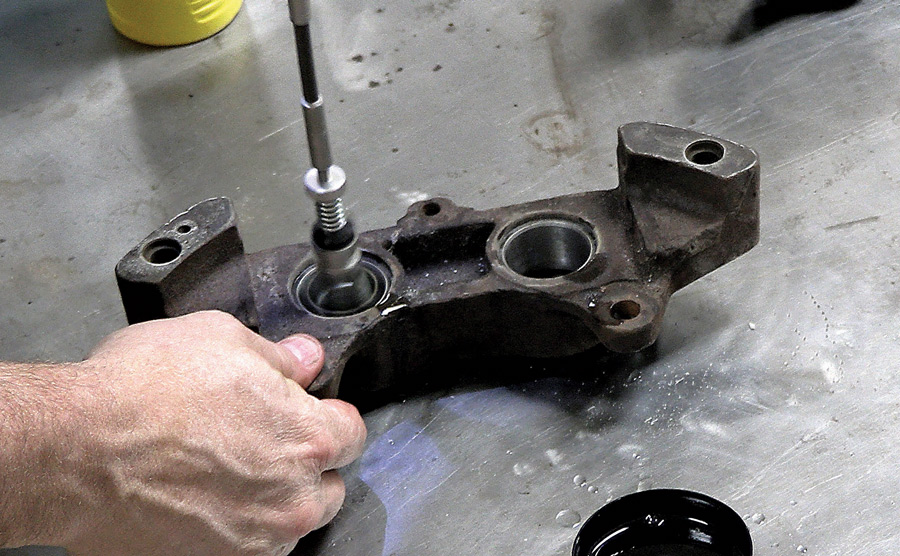

8. But it turns out trying to be careful with the pistons didn’t really matter. There was just too much corrosive buildup on the rear pistons (left). For comparison, you can see one of the larger front pistons as it came out of the caliper (center) and how one of the front pistons looked after applying a little elbow grease with brake cleaner and a Scotch-Brite pad. We tried a few different methods to get the rear pistons cleaned, but we just weren’t able to get all that ugly buildup off—especially in the grooves where the fit with the rubber seal must be perfect. It just wasn’t worth the risk to put the calipers back together only to have them leak, so we ordered new pistons and new backing springs for both rear calipers.

SOURCES

SOURCES