TECH

TECH

Images by THE AUTHOR

Images by THE AUTHORhis is the opposite of putting lipstick on a pig (or whatever you want to call it).

We’re talking about taking one of the all-time-great engines—Chevrolet’s LS series—and dressing it to look like a classic, first-generation small-block. First off, when done right the LS engine is a great-looking powerplant all on its own. But sometimes you may want to disguise exactly what it is you’ve got powering your ride.

Sometimes you just don’t want your LS to look like an LS. This is particularly true when you are building a classic and you want to keep that old-school feel. If the outside of your Chevy car or truck looks all original, it can be a bit jarring to open the hood and find a modern powerplant sitting between the framerails. A first-generation small-block, or maybe even a 409 or rat motor, would look more at home in the engine bay. Or maybe you’re running a sleeper and want your potential victims to think you are running a workaday carbed small-block and not a big-inch LS with modern ignition controls and horsepower numbers a stock small-block 350 could only dream of.

If either one of these scenarios describes you, there are a few ways to dress up (or camouflage, depending on your point of view) a modern LS to look like a classic Chevrolet engine. Some kits are obviously more effective than others, and at All Chevy Performance we’ve recently covered mocking up a crate LS engine to look like an old-school big-block engine (inthegaragemedia.com/the-ls-classic-series-big-block-kit-installation-overview-with-detailed-images/) that turned out extremely well. This time around we’re taking a look at some tips for disguising your modern LS as a first-gen small-block—sort of taking a perfectly great engine and making it your own. The end result is modern power and dependability—and even the ability to find replacement parts easily—and giving it the look of a classic without all the hassles and drawbacks.

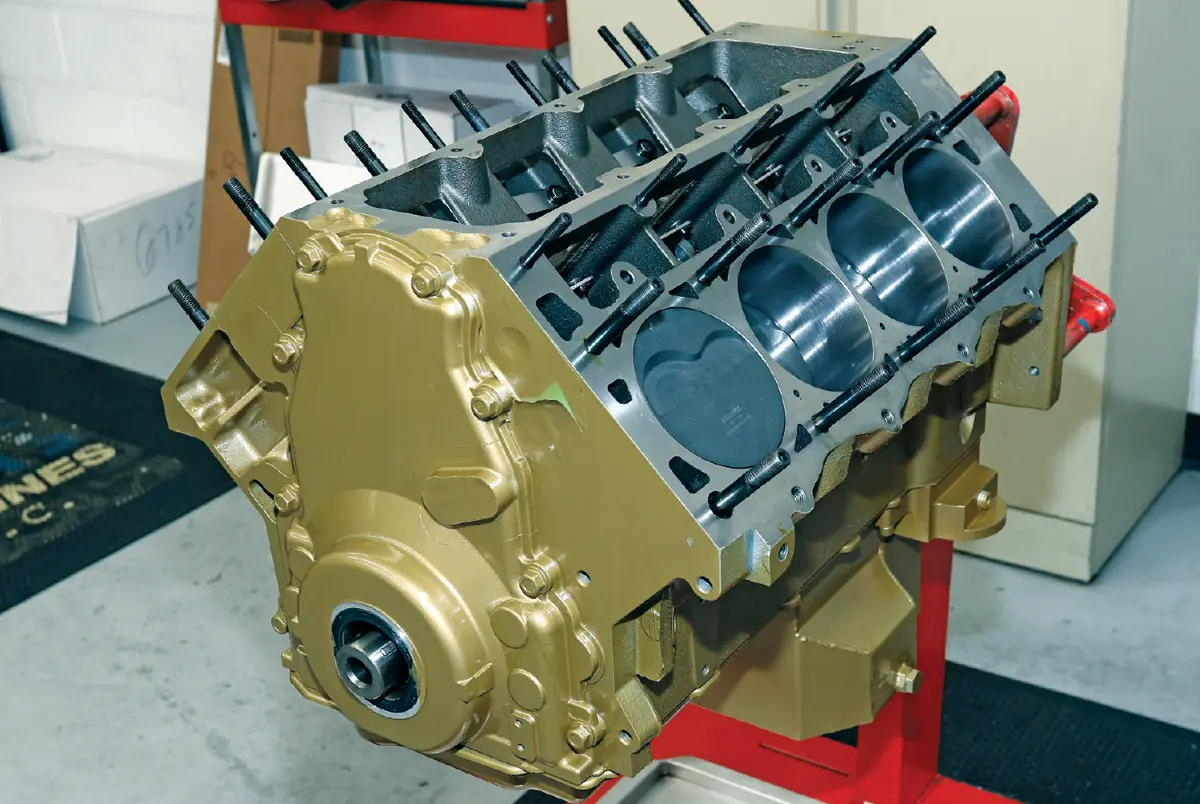

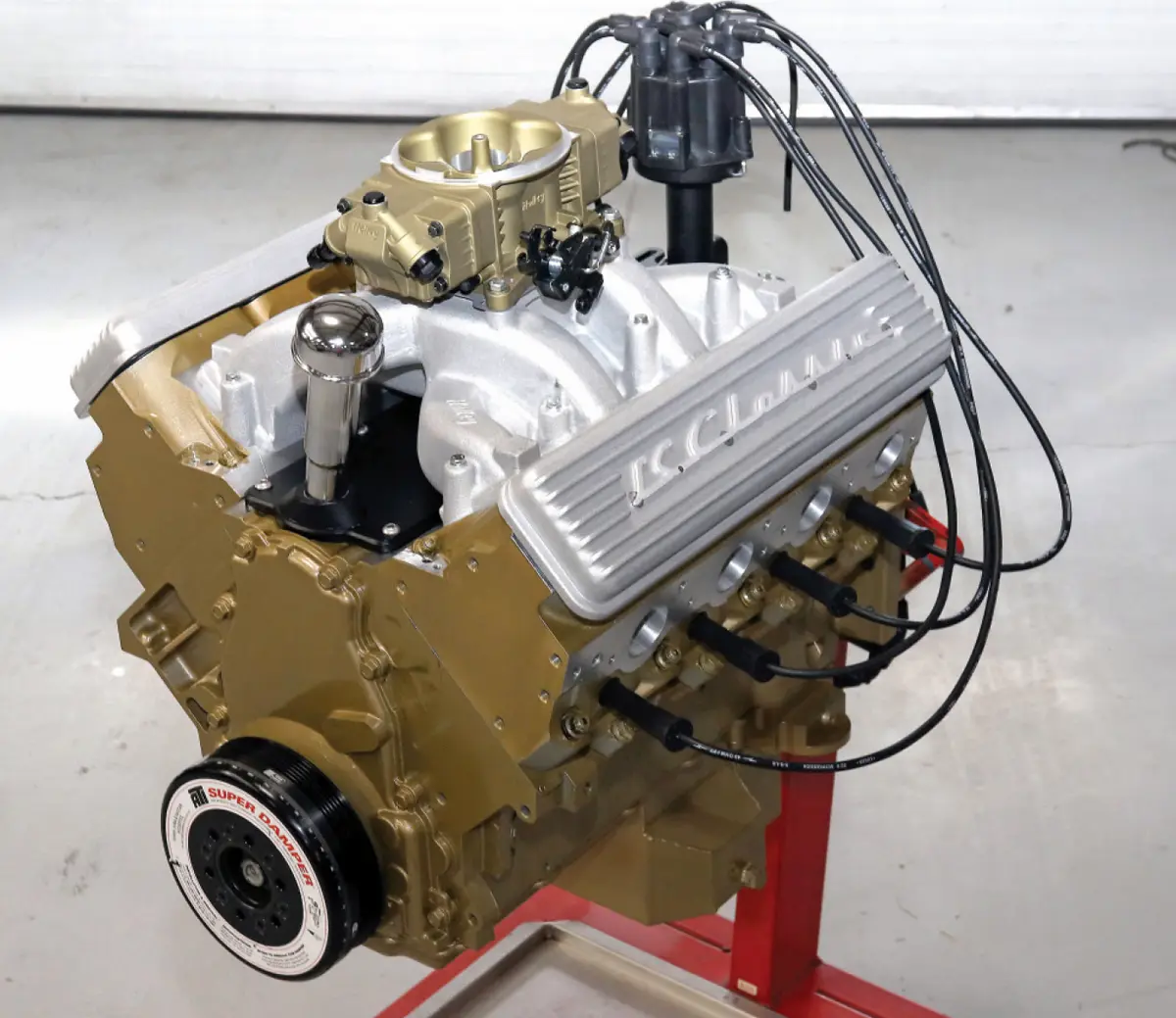

But first, a caveat: We aren’t starting with a crate engine, or even an LS that is anywhere close to stock. We caught up with father-son engine building duo Keith and Jeff Dorton at Automotive Specialists, who were building this custom engine for a car builder who is putting together a bucks-down ride for his customer. We can’t talk too much about the finished product quite yet, but we wanted to show you some of the tricks the folks at Automotive Specialists used during the course of this build. You will also notice that the engine isn’t completely dressed out. That’s because the car builder will be doing some things like potentially fabricating an air cleaner cover as well as changing up the accessory setup and front drive system.

Automotive Specialists also put on a first coat of paint, but as you will see there are still more touch-ups that will need to be made further down the line. But they didn’t want to do the final detail painting until everything was complete and the engine was off the dyno.

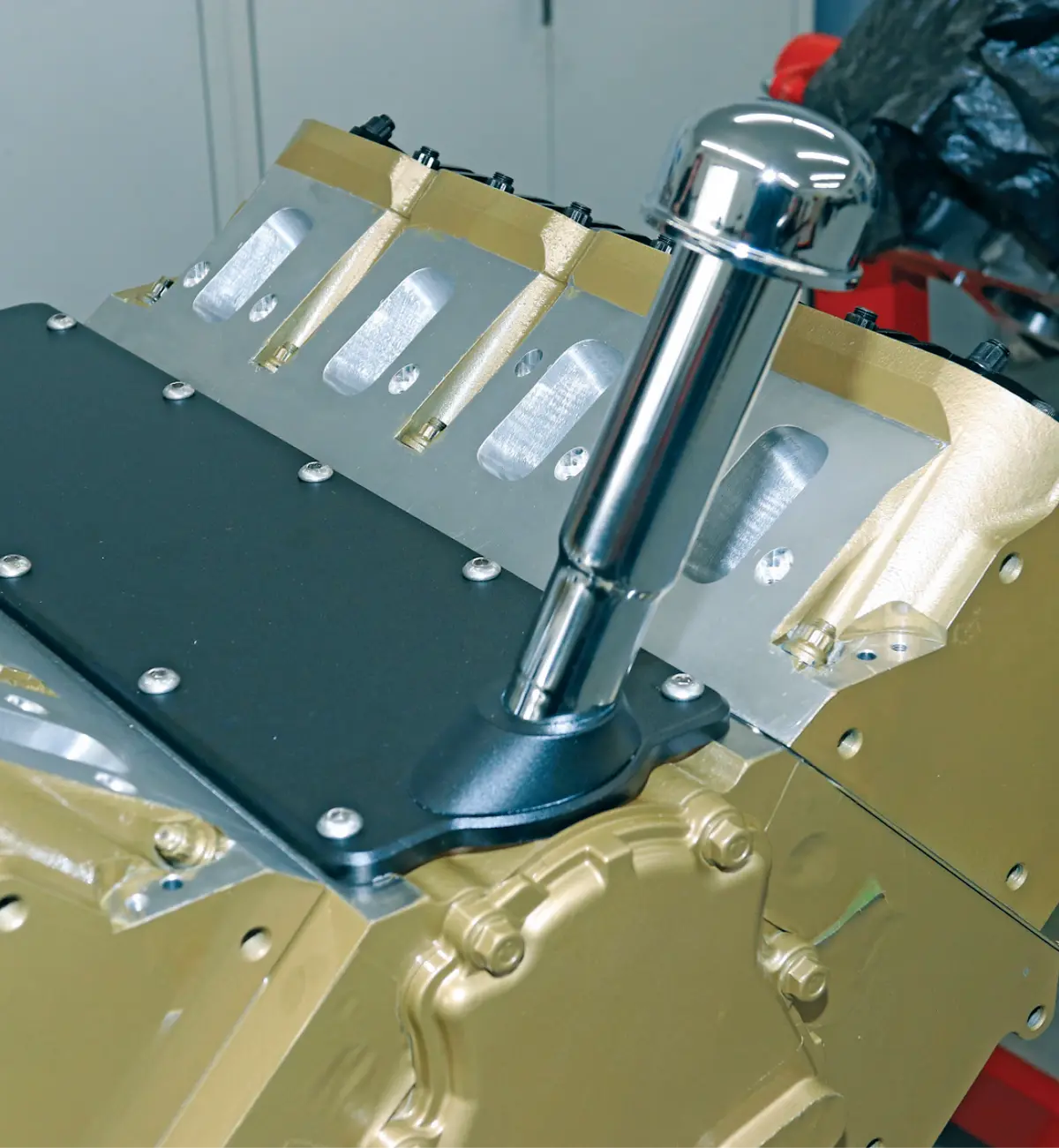

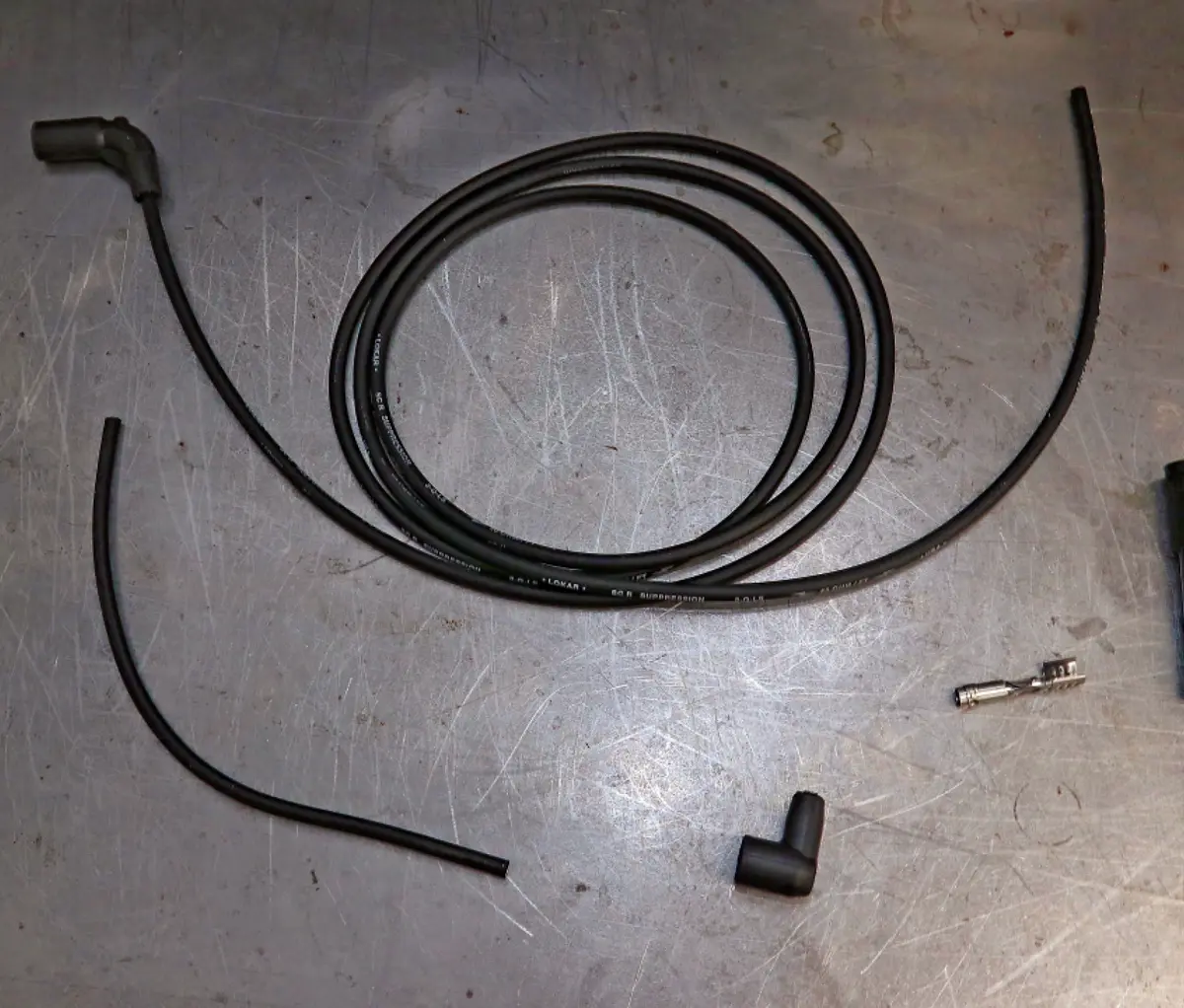

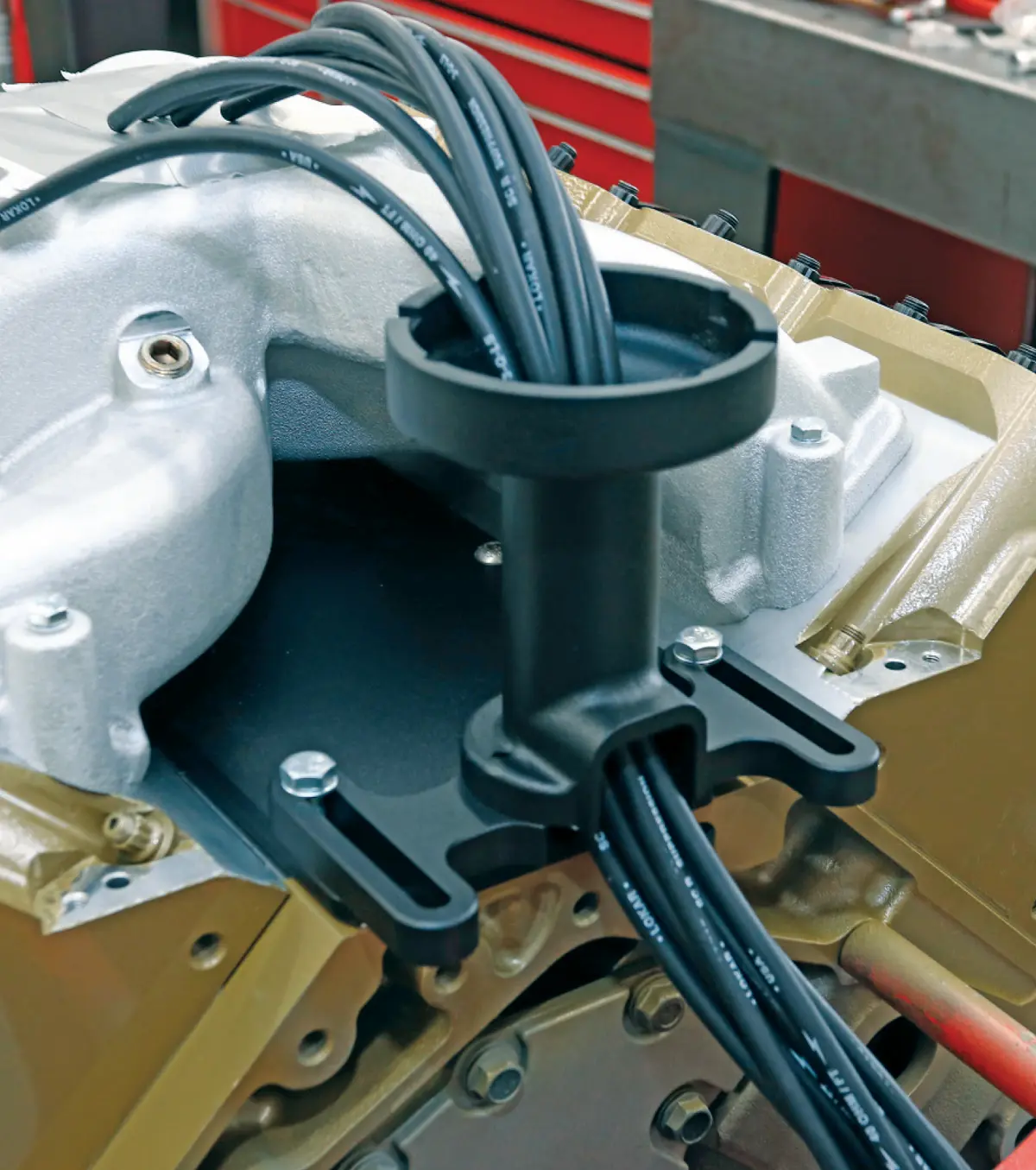

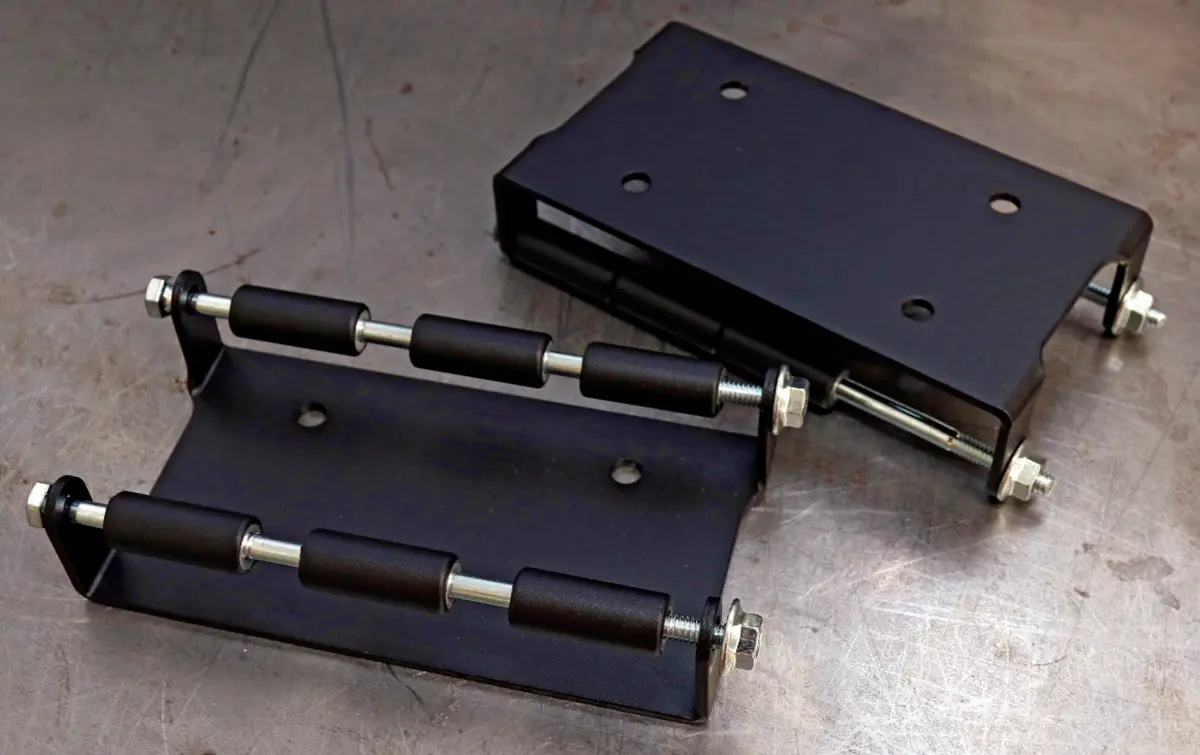

The good news here is that you can replicate everything you see here without any fabrication skills or special tools. Most of the heavy lifting was already done by Lokar and their LS Classic Series. They have developed a handful of packages that camouflage the LS engine with very different looks, from the famous “fuelie” to a big-block, which we’ve already mentioned.

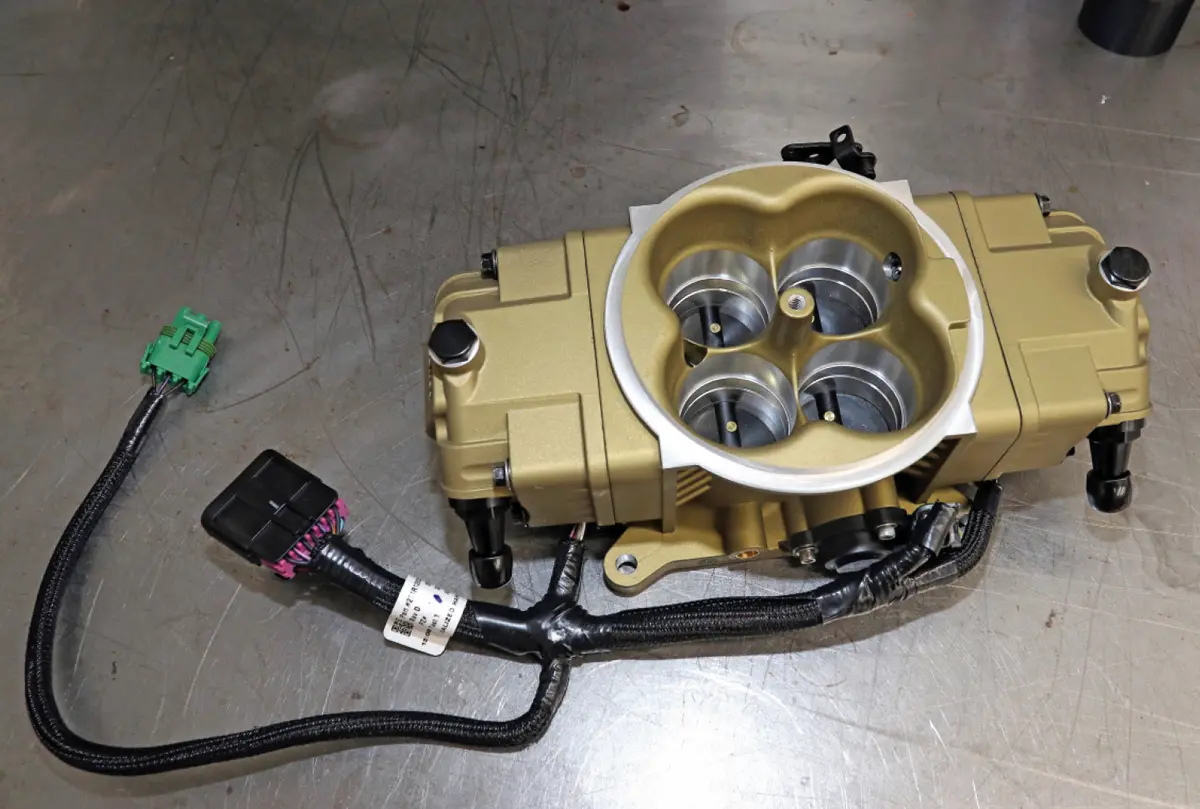

And while Lokar nailed most of the details for our camouflage LS, we did turn to Holley to square up one very important feature. Nothing gives away a modern engine dressed up as a classic faster than a pair of fuel rails mounted just above the intake manifold runners. A classic engine requires a carburetor, but we didn’t want to give up four-season reliability, excellent part-throttle response, and the improved fuel economy that comes with fuel injection. So, we dialed up one of Holley’s Sniper Stealth EFI units in gold that mimics a classic 4150-sized double-pumper. The Sniper Stealth does have some modern wiring that must be hidden, but it is much less than most EFI systems, and because it is throttle-body fuel injection it eliminates those giveaway fuel rails.

Check out the build for yourself and see if you can pick up some tips for your next project!

SOURCES

SOURCES