TECH

TECH

By Ryan Manson  Photography by The Author

Photography by The Author

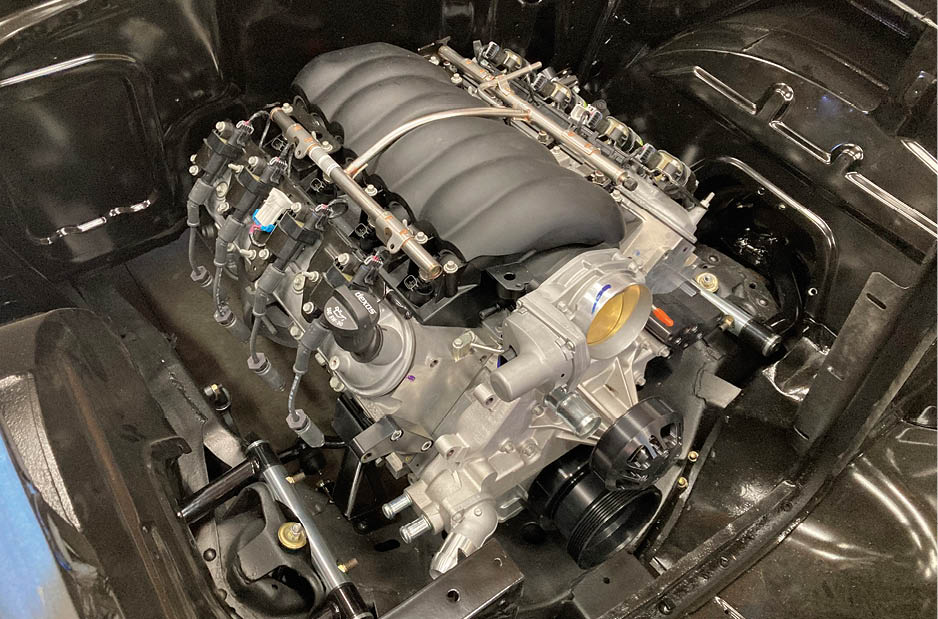

f you’re a regular reader of All Chevy Performance, you’ll probably recognize our ’57 Chevy 210 wagon that we’ve been building in the Clampdown Competition workshop for our buddy Bruce Valley. So far, we’ve replaced the front and rear suspension and added power steering, among other things. We also did a serpentine pulley system install on the LS3 Connect & Cruise engine kit in anticipation of its installation between the ’rails, which is where we’ve now found ourselves.

For a quick recap, Valley wanted to upgrade the old wagon with power steering, A/C, and an overdrive transmission. Quickly going over what was involved to make said upgrades to the existing 350ci small-block Chevy/Muncie four-speed combo, it was an easy decision to shift gears and proceed with an LS upgrade. Since all the components needed to be purchased, whether the 350 was used or we went the LS route, Valley was quickly convinced that what he really wanted was a more comfortable, reliable, user-friendly experience, with whatever that required—which meant we were going the LS route.

With that in mind, we recommended the Chevrolet Performance Connect & Cruise LS3 package. Rated at 430 hp, the 6.2L powerplant would be more than capable of hauling Bruce’s big wagon around town, and thanks to the 4L65-E transmission and its 0.70:1 final drive, it will be even more suited to efficiently cruise down the highway than with the old Muncie. Years of use and millions of miles traveled in nearly every marque made by GM make the LS and their relative electronic components dead reliable when compared to the electronics of yore.

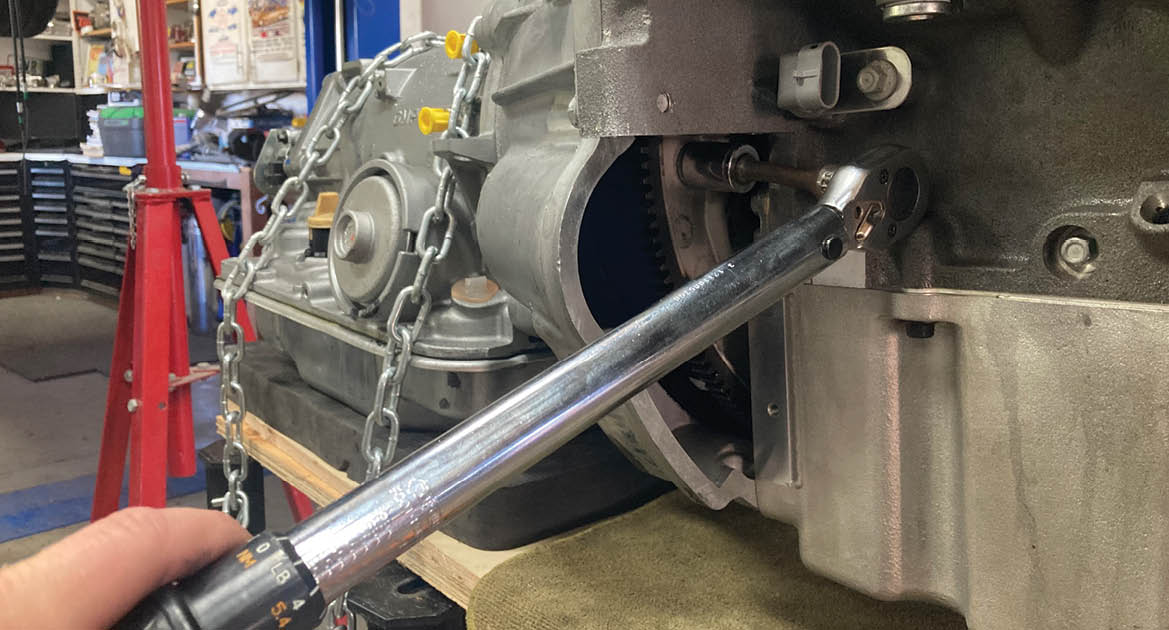

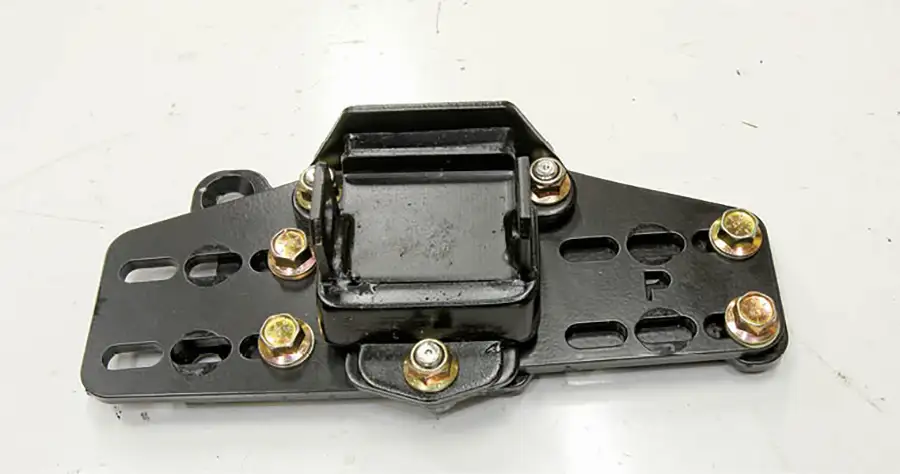

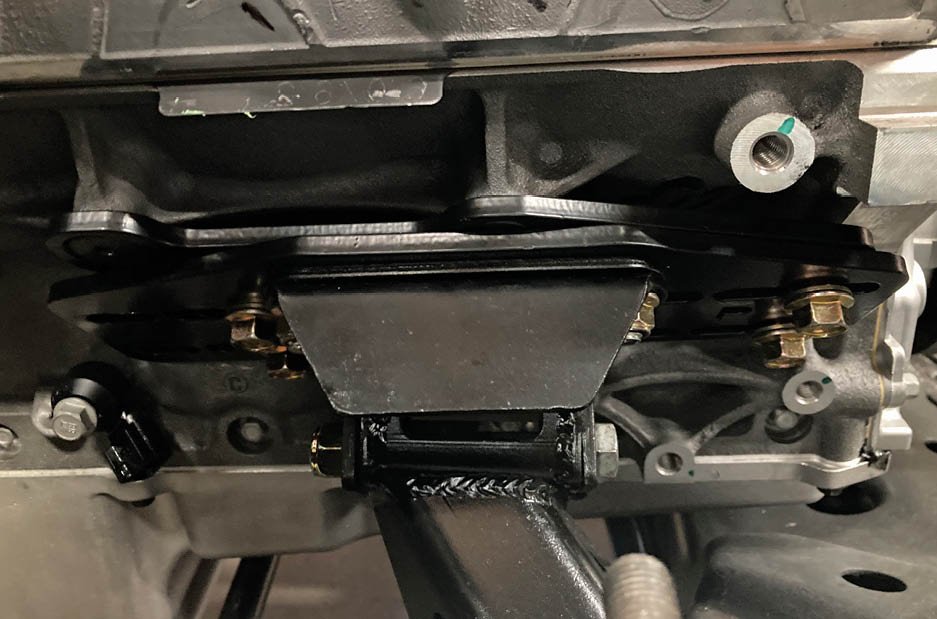

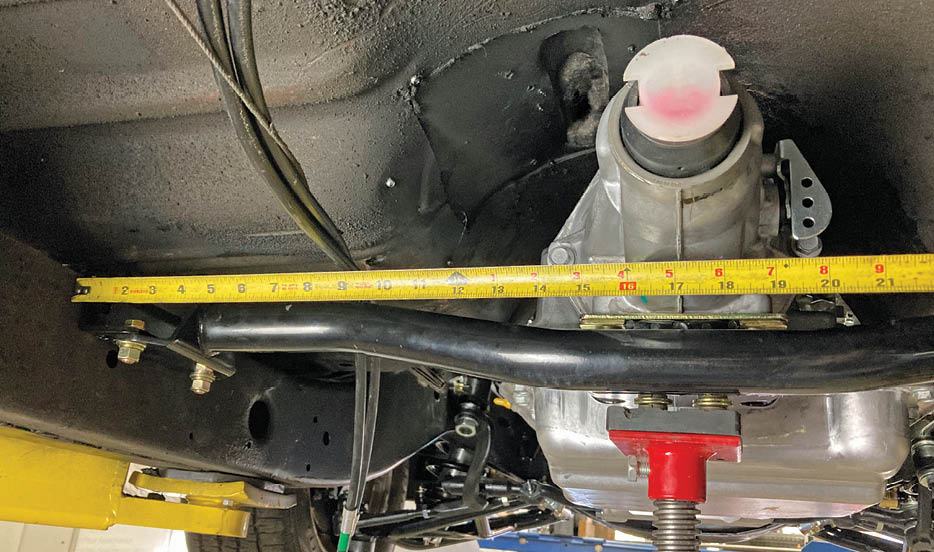

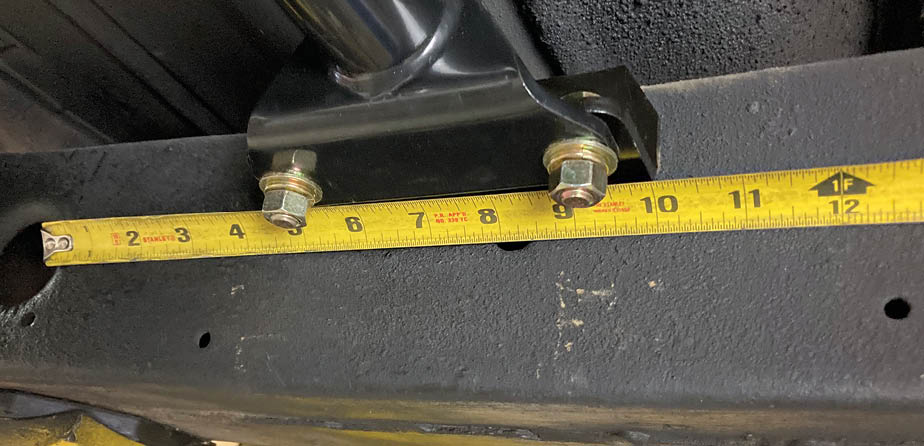

Convinced of the value of the LS swap, we still needed to figure out what it might take to put that modern powerplant between the ’rails of a nearly 70-year-old car. As luck would have it, we weren’t the first to attempt this swap (big surprise!) and companies like Classic Performance Products (CPP) and Summit Racing have everything one needs to achieve a fully bolt-in installation of a modern GM powerplant. By using a combination of stock engine mounting hardware and adjustable LS engine plates, not only is the installation a bolt-in, but it’s a fully adjustable bolt-in as well, making precise engine placement possible. These components make what would be a more advanced job saved for the mechanic with a fairly decent degree of fabrication possible by a guy with a little mechanical ability and a decent set of hand tools. It’s never been easier to swap a modern GM engine in a classic muscle car than it is today, and we’ll prove it!

SOURCES

SOURCES